Blog by Neill Archer Roan

This piece originally was posted on Neill’s Blog – A Passion for Pipes (http://www.apassionforpipes.com/neills-blog/2012/6/24/reborn-pipes.html) not long after I had started rebornpipes. I had no idea that he was going to write this or what he would say. I was quietly starting the blog and the readership was really low. I did not know what I was doing I only knew that I wanted an online presence to put the pieces that I had written on refurbishing pipes and the extra ones that would come. I also wanted it to be a place that others could contribute to and share their work. I wanted a virtual community of amateur and otherwise pipe refurbishers. Now looking back three years or more after rebornpipes began I want to take time to thank Neill for his jump-start for rebornpipes. It was his publication of this piece on A Passion for Pipes that opened up a broader readership very quickly. I have read Neill’s blog for a long time now and when I read this piece he wrote it actually brought tears to my eyes. He got the point of rebornpipes. I can honestly say that it was his encouragement then and now that keeps me going. I want to take this venue to publicly thank you once again Neill. Your encouragement has meant the world to me. Thank you very much

As of my last researching the number, there are over 150 million blogs out there on the internet. By the time I finish typing this sentence there will probably be 160 million. It’s amazing how many people blog these days.

As of my last researching the number, there are over 150 million blogs out there on the internet. By the time I finish typing this sentence there will probably be 160 million. It’s amazing how many people blog these days.

Steve Laug at breakfast at the Chicago Pipe Show

There is one new pipe blog out there that deserves your attention: Reborn Pipes, written by the Vancouver, BC pipe man Steve Laug. It is better than good. It is wonderful. Truly wonderful.

I became acquainted with Steve Laug through the popular Smokers Forums, an online pipes and tobacco forum. Steve serves as a moderator on that forum. Subsequent to my online introduction, I met Steve in real time at the Chicago Pipe Show quite a few years ago. I had already intuited Steve’s kindness and generosity; these things can be experienced in an online environment, but they are amplified in real time.

In real life, Steve is a member of the clergy. He is the sort of man whose flock I would immediately join if he lived within driving distance of my home. Thoughtful, quiet, and warm, Steve is, to my mind, an old-fashioned ministerial type in that his ministry emerges from serving others. I once learned of him bringing a homeless stranger back to his home and table for Thanksgiving dinner, an event inside his life that is probably so routine as to seem unremarkable. I’m sure he will be embarrassed to read these words, assuming he ever does. In other words, he actually lives the example of Jesus Christ as opposed to preaching the example.

I bring this up because that spirit of service comes across authentically in his writing.

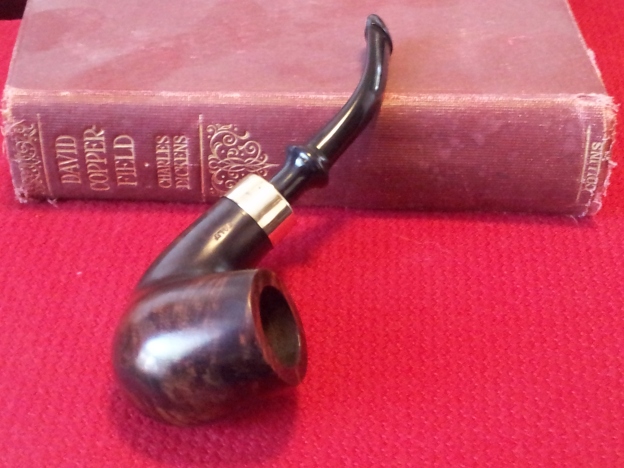

In his pipe life, Steve brings homeless pipes to his workbench – pipes that have seen better days. In most cases, these are unremarkable pipes in brand or collectible terms. The one thing they seem to share is that they were once loved by someone. Most of them have had the tarnation smoked out them. As we would say of this kind of horse in Wyoming where I grew up, they were “rode hard and put away wet.”

Taking a gander at these pipes in Steve’s “before” pictures, most people would muse, “Why bother?” Why indeed?

It only takes looking at the “after” pictures to answer the question. When Steve applies his considerable refurbishment skills to these pipes, they are, in fact, reborn. Steve’s blog is aptly named because these pipes leave Steve’s bench more than refurbished. They are reborn to their purpose, ready to be smoked. Ready to be treasured.

In Reborn Pipes, Steve shares more than his refurbishment process, he shares his patience and his insights.

In practical terms, by reading Steve’s blog, you can learn how to restore your own pipes to their former glory. If you are new to the pipe world, or trying to build your rotation without draining your bank account, you can acquire skills that make it possible for you to buy estate pipes, spiff them up, and then enjoy them. By so doing, you’ll learn that you can buy and smoke much better pipes than you could otherwise afford. Plus, they will be yours – truly yours – in terms that you could never understand if you haven’t gone through this process.

I’ve bought many a fine pipe in my nearly 60 years, many of them high-grade, artisanal pipes. They have come to me in exquisite and pristine condition. It has surprised and perplexed me that a pipe’s beauty is not only an attribute that conjures desire, it can also be a barrier to my enjoyment of the pipe. All that newness, all that perfection defies defilement by putting match to tobacco within its little chamber of perfection. I have pipes in my collection that have remained unsmoked and unenjoyed for over a decade. I own these pipes, but they certainly do not feel like they are mine.

I’ve never felt this way when buying an estate. As I have assembled my Comoy Blue Riband collection, I have wound up with more than few pipes in need of refurbishment. When I’ve finished restoring the pipe, the work has created a bond of affection for that pipe that only time and labor can endow. I appreciate its qualities in deeper, more meaningful ways than I have ever felt for any of my brand-spanking-new treasures because I have had a hand in revealing its better qualities.

If you haven’t sussed out my point by now, let me state it outright: Steve’s blog addresses in metaphorical terms more than the refurbishment of pipes. He reveals that all things under heaven may be reborn through love, and not through love as it is so popularly and shallowly understood, but rather love as it is expressed by the farmer or the gardener.

The farmer and gardener express their love of the land by working it. They endow their land with purpose through the dignity of stewardship. There is not only affection here, but economy, thrift, and satisfaction that comes from the husbandry of more than oneself.

There aren’t many blogs out there that improve oneself by reading them. Reborn Pipes is special in this way. It deserves an audience. I invite you to join me as part of it. Navigate to Reborn Pipes by clickin here.

Article originally appeared on Pipe Blog (http://www.apassionforpipes.com/). Used by permission from the author. See website for complete article licensing information.

Van Roy pipes started around 1944-1945 .They were headquartered out of the Empire State building. They were the first pipe to use the Adjustamatic stem. HL&T (Dr.Grabow ) purchased the company around 1949 and used the Adjustamatic exclusively on the Dr. Grabow pipes. All Van Roy’s after that used a push stem ,so Van Roy Adjustamatics were only made for around 4- 5 years. I could not find out if Van Roy had their own pipe manufacturing facility . Most likely they had production of the pipes made by different pipe makers like Mastercraft did.

Van Roy pipes started around 1944-1945 .They were headquartered out of the Empire State building. They were the first pipe to use the Adjustamatic stem. HL&T (Dr.Grabow ) purchased the company around 1949 and used the Adjustamatic exclusively on the Dr. Grabow pipes. All Van Roy’s after that used a push stem ,so Van Roy Adjustamatics were only made for around 4- 5 years. I could not find out if Van Roy had their own pipe manufacturing facility . Most likely they had production of the pipes made by different pipe makers like Mastercraft did.