Blog by Steve Laug

You will see by the end of this blog why I say the pipe was reborn twice. Suffice it to say in this opening paragraph that a near pipe repair tragedy occurred when I had all but finished the first rebirth.When I picked up the pipe it was one of two that I found while on a pipe hunt in Bellingham, Washington with a friend. The other pipe was a Custom Bilt that I have already blogged about. The grain on this pipe attracted my attention and made me want to see what I could do with it. When I brought the pipe to the work table most of the issues were with the stem. The bowl had originally had a natural finish so it was dirty but not stained. There was no finish on it or varnish that needed to be removed so the clean up would be quite simple. The rim was caked with a thick tar and oil buildup that was shiny and hard. The bowl had a cake of the same material and had the sweet smell of an aromatic – lots of vanilla. The main issue with the stem was twofold. The top surface of the stem from the button up the stem about 1 inch there were many dents and bite marks. The underside of the stem had a large piece of vulcanite missing from the stem and the airway had been clamped down by biting. It also was oxidized and calcified. The fit against the shank was fairly decent with a slight gap on the left side, top and bottom at the shank.

When I brought the pipe to the work table most of the issues were with the stem. The bowl had originally had a natural finish so it was dirty but not stained. There was no finish on it or varnish that needed to be removed so the clean up would be quite simple. The rim was caked with a thick tar and oil buildup that was shiny and hard. The bowl had a cake of the same material and had the sweet smell of an aromatic – lots of vanilla. The main issue with the stem was twofold. The top surface of the stem from the button up the stem about 1 inch there were many dents and bite marks. The underside of the stem had a large piece of vulcanite missing from the stem and the airway had been clamped down by biting. It also was oxidized and calcified. The fit against the shank was fairly decent with a slight gap on the left side, top and bottom at the shank.

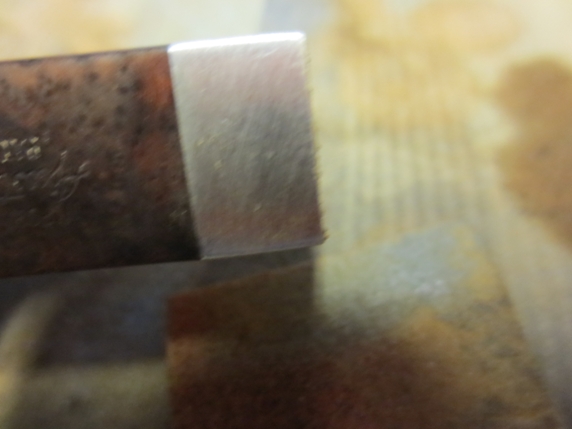

The next two close up photos of the stem show the damage to the top and bottom side of the surface next to the button. The underside is the most damaged with a huge chunk missing. The second photo shows the top of the stem with the many tooth marks and bumps that created a thin surface on the top of the stem.

The next two close up photos of the stem show the damage to the top and bottom side of the surface next to the button. The underside is the most damaged with a huge chunk missing. The second photo shows the top of the stem with the many tooth marks and bumps that created a thin surface on the top of the stem.

I took the next photo to show the rim. All edges are intact but the surface is coated with a thick, hard coat of oils and tar.

I took the next photo to show the rim. All edges are intact but the surface is coated with a thick, hard coat of oils and tar. The tenon had an inner tube insert in it. I have had several of these Savinellis but never had one with the tube. It would turn out to come in handy later.

The tenon had an inner tube insert in it. I have had several of these Savinellis but never had one with the tube. It would turn out to come in handy later. I weighed my options with the stem for several days before I decided to cut off the damaged portion of the stem. I used my Dremel with a sanding drum and took the stem back to solid material.

I weighed my options with the stem for several days before I decided to cut off the damaged portion of the stem. I used my Dremel with a sanding drum and took the stem back to solid material.

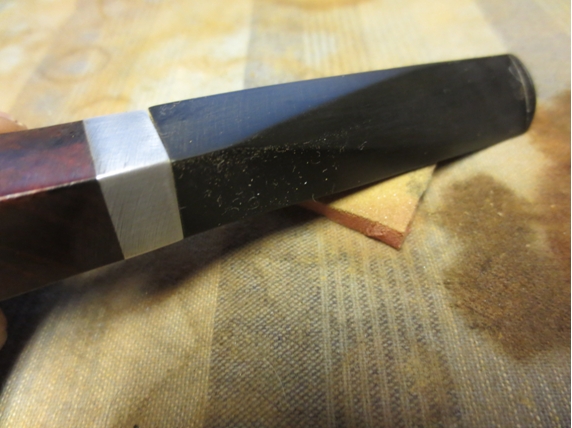

The next four photos show the look of the pipe with the shorter stem. Personally I like the more compact look of the stem as it seems to fit proportionally well with the pipe.

The next four photos show the look of the pipe with the shorter stem. Personally I like the more compact look of the stem as it seems to fit proportionally well with the pipe.

I decided to work on the button on the pipe before turning to the bowl. You can see from the photo below that the underside of the area where I would cut the button was quite thin. I did not want to cut back the stem any further so I built up that area with black super glue. I applied the glue and set the stem aside to cure. It would take several coats before the button was built up.

I decided to work on the button on the pipe before turning to the bowl. You can see from the photo below that the underside of the area where I would cut the button was quite thin. I did not want to cut back the stem any further so I built up that area with black super glue. I applied the glue and set the stem aside to cure. It would take several coats before the button was built up.

While the glue cured and hardened I worked on the bowl. I reamed it with a PipNet reamer starting with the smallest cutting head and working up to a head that would cut back the cake to bare briar.

While the glue cured and hardened I worked on the bowl. I reamed it with a PipNet reamer starting with the smallest cutting head and working up to a head that would cut back the cake to bare briar.

With the bowl reamed back I could tackle the top of the bowl. Even using the reamer did not chip or crack the buildup on the top of the rim. It was like rock. I scrubbed the rim with oil soap and a tooth brush. I picked at it with a dental pick and was not able to break through the rock. I decided to lightly top the bowl to remove the buildup. The idea was not to remove any briar but merely to take of the rock hard tars on the rim. I used my topping board and 220 grit sandpaper and worked the rim carefully to ensure that I only took the rim down to briar. Once I broke through the rock I took several more turns on the sandpaper to finish up the rim.

With the bowl reamed back I could tackle the top of the bowl. Even using the reamer did not chip or crack the buildup on the top of the rim. It was like rock. I scrubbed the rim with oil soap and a tooth brush. I picked at it with a dental pick and was not able to break through the rock. I decided to lightly top the bowl to remove the buildup. The idea was not to remove any briar but merely to take of the rock hard tars on the rim. I used my topping board and 220 grit sandpaper and worked the rim carefully to ensure that I only took the rim down to briar. Once I broke through the rock I took several more turns on the sandpaper to finish up the rim.

I scrubbed the bowl with acetone on cotton pads to remove the soiling and oils in the briar. It did not take much to bring the briar back to its natural state.

I scrubbed the bowl with acetone on cotton pads to remove the soiling and oils in the briar. It did not take much to bring the briar back to its natural state.

I decided to rub down the bowl with a light coat of olive oil to protect the briar and give it some life. I applied the oil with a paper towel and rubbed it in and rubbed it off. It also served to highlight the grain and make it stand out.

I decided to rub down the bowl with a light coat of olive oil to protect the briar and give it some life. I applied the oil with a paper towel and rubbed it in and rubbed it off. It also served to highlight the grain and make it stand out.

I cleaned out the shank with cotton swabs, pipe cleaners and isopropyl alcohol until they came out clean. For the amount of build up of tars and oils on the rim the shank was quite clean.

I cleaned out the shank with cotton swabs, pipe cleaners and isopropyl alcohol until they came out clean. For the amount of build up of tars and oils on the rim the shank was quite clean. I decided to use a cotton ball and alcohol soak on the bowl to remove the sweet smells of the aromatics that had been smoked in the bowl. It had a thick vanilla smell that needed to go in my opinion. I set the stuffed bowl in an ice cube tray and used an ear syringe to fill it with alcohol. I let the bowl soak overnight to leach out the oils in the wood.

I decided to use a cotton ball and alcohol soak on the bowl to remove the sweet smells of the aromatics that had been smoked in the bowl. It had a thick vanilla smell that needed to go in my opinion. I set the stuffed bowl in an ice cube tray and used an ear syringe to fill it with alcohol. I let the bowl soak overnight to leach out the oils in the wood.

By the time I had finished setting up the bowl I called it a night and went to bed. The next morning I worked on cutting and shaping the new button on the stem. I used my usual knife blade file to make the initial cuts and shave back the slope of the stem.

By the time I had finished setting up the bowl I called it a night and went to bed. The next morning I worked on cutting and shaping the new button on the stem. I used my usual knife blade file to make the initial cuts and shave back the slope of the stem.

When I had the slope and look right I sanded the newly shaped button and stem with 220 grit sandpaper. I then repaired some of the low spots with clear super glue. I recut the button with the needle files and sanded it with 220 grit sandpaper to clean up the edges.

When I had the slope and look right I sanded the newly shaped button and stem with 220 grit sandpaper. I then repaired some of the low spots with clear super glue. I recut the button with the needle files and sanded it with 220 grit sandpaper to clean up the edges.

With more sanding and shaping I had it where I wanted it and then sanded the stem with a medium and a fine grit sanding sponge to clean up the scratches in the vulcanite.

With more sanding and shaping I had it where I wanted it and then sanded the stem with a medium and a fine grit sanding sponge to clean up the scratches in the vulcanite.

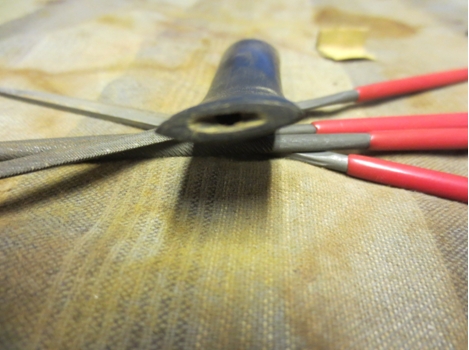

With the button shaped in I worked on the slot in the airway. I used my usual three needle files – a flat oval, an oval and a round file to work on the slot. I always start with the flat oval and work to the round file.

With the button shaped in I worked on the slot in the airway. I used my usual three needle files – a flat oval, an oval and a round file to work on the slot. I always start with the flat oval and work to the round file.

I used a folded piece of sandpaper to smooth out the inside of the slot.

I used a folded piece of sandpaper to smooth out the inside of the slot. At this point I worked some more on the surface of the button. It still was too rough to my liking. I sanded and filed it to reshape it. The next two photos show it before I worked it over with files and papers.

At this point I worked some more on the surface of the button. It still was too rough to my liking. I sanded and filed it to reshape it. The next two photos show it before I worked it over with files and papers.

Once I had the button shaped to my satisfaction I sanded it with micromesh sanding pads. I wet sanded with 1500-2400 grit pads, rubbed down with Obsidian Oil and then set it aside to dry. I was pleased with the overall effect of the new button and could not wait to finish polishing it. This is where I made the first mistake in this repair.

Once I had the button shaped to my satisfaction I sanded it with micromesh sanding pads. I wet sanded with 1500-2400 grit pads, rubbed down with Obsidian Oil and then set it aside to dry. I was pleased with the overall effect of the new button and could not wait to finish polishing it. This is where I made the first mistake in this repair.

Instead of leaving it on the work table and calling it a night I brought the pipe upstairs with me from the basement work area. I wanted to show the girls in my family the result of my work. I know that they are not that interested but they attempt to humour the old man. I stopped at the fridge to get some water and that is when the disaster struck. I could not believe it. The pipe simply slid through my fingers and hit the hardwood floor in our kitchen. I can’t tell you how many times that has happened with no issues. But this time there was going to be a major issue and it came with a vengeance. When it hit the floor, really only 2 feet as I was bending over, I heard the awful click and the stem and bowl separated. The tenon snapped at the shank.

Instead of leaving it on the work table and calling it a night I brought the pipe upstairs with me from the basement work area. I wanted to show the girls in my family the result of my work. I know that they are not that interested but they attempt to humour the old man. I stopped at the fridge to get some water and that is when the disaster struck. I could not believe it. The pipe simply slid through my fingers and hit the hardwood floor in our kitchen. I can’t tell you how many times that has happened with no issues. But this time there was going to be a major issue and it came with a vengeance. When it hit the floor, really only 2 feet as I was bending over, I heard the awful click and the stem and bowl separated. The tenon snapped at the shank. All that work done and now what to do? I was sick with the thought of starting over. I carried the broken pipe down the stairs to the work table and left it in the dark and went to bed – just a tad frustrated. If you are interested in seeing what I did to try and redeem this disaster make sure to read Part Two of the work on this pipe.

All that work done and now what to do? I was sick with the thought of starting over. I carried the broken pipe down the stairs to the work table and left it in the dark and went to bed – just a tad frustrated. If you are interested in seeing what I did to try and redeem this disaster make sure to read Part Two of the work on this pipe.