Andrew Selking posted a refurbishment of a Heritage Heirloom Canadian and posted a copy of this brochure in his article. I wanted to also post the brochure separately for those who might be hunting for information on this remarkable brand from Kaywoodie. Thanks Andrew for finding this copy of the Heritage brochure. (Courtesy Kaywoodiemyfreeforum)

Monthly Archives: December 2014

Refurbishing a Heritage Heirloom

Blog by Andrew Selking

I recently stumbled across the Heritage line of pipes. These pipes were made in the Kaywoodie factory, but on a completely separate line. Heritage pipes were Kaywoodie’s answer to Dunhill. According to one of their brochures, Heritage pipes were made from “briar burls seasoned and cured for up to 8 months,” with only “one briar bowl in over 300 selected to bear the Heritage name.” “Heritage stems are custom fitted with the finest hand finished Para Rubber stems. Mouthpieces are wafer thin and concave.”

The Heritage line began in the early 1960’s, with the trademark issued in 1964. The line was started at the request of Stephen Ogdon, (who worked for Kaywoodie in 1962). Mr. Ogdon had previous experience working for Dunhill, either running the New York store or working for Dunhill North America. Mr. Ogden was made President of Heritage Pi pes, Inc., Kaywoodie Tobacco Co.,Inc. and Kaywoodie Products Inc. as well as a Vice President of S.M. Frank & Co. Heritage Pipes were produced from 1964 until 1970 (Source Kaywoodie.myfreeforum.org).

Here is a copy of the Heritage brochure. (Courtesy Kaywoodiemyfreeforum)

The pipe I found was the number 72 Medium Canadian, oval shank. Interestingly, the one thing the Heritage line shared with Kaywoodie was the size and shape numbers. Unlike Kaywoodies, the Heritage pipes are normal push tenons.

The pipe I found was the number 72 Medium Canadian, oval shank. Interestingly, the one thing the Heritage line shared with Kaywoodie was the size and shape numbers. Unlike Kaywoodies, the Heritage pipes are normal push tenons.

When the pipe arrived, it had some tar build up on the rim and a thick layer of cake.

The stem had some oxidation, but minimal chatter.

The stem had some oxidation, but minimal chatter.

The finish was in nice condition, so I decided to forgo the alcohol bath and attempt to keep the original finish.

The finish was in nice condition, so I decided to forgo the alcohol bath and attempt to keep the original finish.

The first thing I did was ream the bowl. I used my Castleford reamer and was delighted to find that the cake was very loose, mostly old tobacco, and it easily cleaned back to the wood.

The first thing I did was ream the bowl. I used my Castleford reamer and was delighted to find that the cake was very loose, mostly old tobacco, and it easily cleaned back to the wood. Next I decided to find out how the bad the rim was under the tar build up.

Next I decided to find out how the bad the rim was under the tar build up. After a light buffing with 0000 steel wool, the tar was gone and I could see a pristine rim.

After a light buffing with 0000 steel wool, the tar was gone and I could see a pristine rim. Since I was on a roll, I decided to re-tort the shank.

Since I was on a roll, I decided to re-tort the shank. I normally show pictures of a brush loaded with gunk, but in this case the brush came clean on the first pass. I proceeded to use some q-tips and fuzzy sticks on the shank. Most of the tar came off with the first couple of q-tips, after that it was just a matter of a few more and the shank was clean.

I normally show pictures of a brush loaded with gunk, but in this case the brush came clean on the first pass. I proceeded to use some q-tips and fuzzy sticks on the shank. Most of the tar came off with the first couple of q-tips, after that it was just a matter of a few more and the shank was clean. Since I didn’t soak the bowl in alcohol, I decided to soak it with some alcohol soaked cotton balls.

Since I didn’t soak the bowl in alcohol, I decided to soak it with some alcohol soaked cotton balls. While the bowl soaked, I retorted the stem.

While the bowl soaked, I retorted the stem. It was just as clean as the shank (this was the first fuzzy stick I passed through after the retort).

It was just as clean as the shank (this was the first fuzzy stick I passed through after the retort). This was the cleanest “dirty” pipe I’ve ever had. Since the stem was so clean inside, I skipped the Oxyclean bath and tackled the oxidation. I used my normal progression of 400 grit wet/dry sandpaper with water, followed by 1500-2400 grit micro mesh pads with water.

This was the cleanest “dirty” pipe I’ve ever had. Since the stem was so clean inside, I skipped the Oxyclean bath and tackled the oxidation. I used my normal progression of 400 grit wet/dry sandpaper with water, followed by 1500-2400 grit micro mesh pads with water. The finish seemed really dark, probably the result of oil from the previous owner’s hands, so I used some 0000 steel wool and acetone to clean the outside of the bowl and shank.

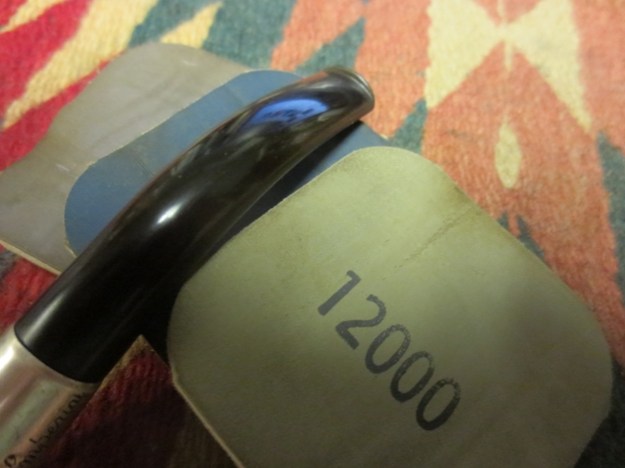

The finish seemed really dark, probably the result of oil from the previous owner’s hands, so I used some 0000 steel wool and acetone to clean the outside of the bowl and shank. The steel wool worked well on the bowl, so I skipped the 1500-2400 grit micro mesh and started at 3200. I used a progression of 3200-12,000 grit micro mesh for the bowl and stem in preparation for the buffing wheel.

The steel wool worked well on the bowl, so I skipped the 1500-2400 grit micro mesh and started at 3200. I used a progression of 3200-12,000 grit micro mesh for the bowl and stem in preparation for the buffing wheel. After an uneventful spin on the buffer, here is the finished pipe.

After an uneventful spin on the buffer, here is the finished pipe.

This line of pipes might be one of the best kept secrets out there. I find that the quality of the stem compares to Dunhills and the wood is spectacular. I highly recommend these pipes.

This line of pipes might be one of the best kept secrets out there. I find that the quality of the stem compares to Dunhills and the wood is spectacular. I highly recommend these pipes.

Cutting back a broken stem – rescuing a potential cast off

Blog by Steve Laug

When I recut the button on a recent Peterson Shamrock stem I thought I would use the opportunity to go into more detail on how I cut back the stem and shape a new button on the end of the cut off. The photo below shows the state of the stem when I received it. While I had other options in terms of repair of the stem I decided to cut it back. I have a Dremel that is my go to tool for cutting off a stem. Others use a saw – coping or hack saw, but I use the Dremel. The photo below shows the sanding drum that I use. It is pretty coarse sandpaper and makes short work of trimming back the vulcanite or Lucite of a stem. The trick is to hold the stem and the Dremel steady while you work the end of the stem against the sandpaper.

I have a Dremel that is my go to tool for cutting off a stem. Others use a saw – coping or hack saw, but I use the Dremel. The photo below shows the sanding drum that I use. It is pretty coarse sandpaper and makes short work of trimming back the vulcanite or Lucite of a stem. The trick is to hold the stem and the Dremel steady while you work the end of the stem against the sandpaper. Over time I have learned to hold it steady and work the cutting line straight. I take off all of the damaged material so that I have some thickness on the top and bottom of the stem that will accommodate a new button without making the stem too thin in the process. In this case I removed the funneled portion of the airway in the button and what remained was the round airway that would need to be reshaped. The line across the stem is pretty straight considering I do it by eyeballing it rather than using a straight edge.

Over time I have learned to hold it steady and work the cutting line straight. I take off all of the damaged material so that I have some thickness on the top and bottom of the stem that will accommodate a new button without making the stem too thin in the process. In this case I removed the funneled portion of the airway in the button and what remained was the round airway that would need to be reshaped. The line across the stem is pretty straight considering I do it by eyeballing it rather than using a straight edge.

The next step in the procedure is to cut a straight line equidistance on the top and the bottom of the stem that will be the sharp edge of the button. The outer edge is slightly rough in the photos but that does not matter as that edge will be bevelled toward the airway in the shaping process. I use a flat blade needle file with a square edge for this initial cut.

The next step in the procedure is to cut a straight line equidistance on the top and the bottom of the stem that will be the sharp edge of the button. The outer edge is slightly rough in the photos but that does not matter as that edge will be bevelled toward the airway in the shaping process. I use a flat blade needle file with a square edge for this initial cut.

Before I put the flat blade needle file away I use it to shave some of the material that is directly ahead of the sharp line of the button and begin the tapering process. I follow that up with an emery board to get a feel for the look of the stem and to assess how much material I will remove in the process.

Before I put the flat blade needle file away I use it to shave some of the material that is directly ahead of the sharp line of the button and begin the tapering process. I follow that up with an emery board to get a feel for the look of the stem and to assess how much material I will remove in the process.

The next step in the process is to shave more of the material away and adjust the angles of the stem to the button. I use a needle file with a knife shaped blade and draw it across the stem toward the button edge. As I draw the file toward the button it peels the material away. I work it from the point on the stem that I have picked as the place where the new taper will begin. I lightly draw it across the upper portion and deepen the cuts the further I go down the stem. I clean up the sharp edge with the straight file once again. I cut a groove in the material next to the button edge that sets the depth of the bottom of the taper. I work the stem angles until they taper directly into the button and the groove disappears. I used 220 grit sandpaper to clean up the file marks and smooth out the transition of the angles to the button. At this point the definition of the button is finished. All that remains is to shape the button and clean up the marks on the material.

The next step in the process is to shave more of the material away and adjust the angles of the stem to the button. I use a needle file with a knife shaped blade and draw it across the stem toward the button edge. As I draw the file toward the button it peels the material away. I work it from the point on the stem that I have picked as the place where the new taper will begin. I lightly draw it across the upper portion and deepen the cuts the further I go down the stem. I clean up the sharp edge with the straight file once again. I cut a groove in the material next to the button edge that sets the depth of the bottom of the taper. I work the stem angles until they taper directly into the button and the groove disappears. I used 220 grit sandpaper to clean up the file marks and smooth out the transition of the angles to the button. At this point the definition of the button is finished. All that remains is to shape the button and clean up the marks on the material.

I used the oval needle file to open and flare the edges of the airway to open the airways. Once I have the funnel cut I use a folded piece of sandpaper to clean up the file marks in the slot and smooth out the end of the button. I also use the sandpaper to shape the button and taper and round the edges to make the button oval and smooth.

I used the oval needle file to open and flare the edges of the airway to open the airways. Once I have the funnel cut I use a folded piece of sandpaper to clean up the file marks in the slot and smooth out the end of the button. I also use the sandpaper to shape the button and taper and round the edges to make the button oval and smooth.

I worked the curve of the underside of the stem to make a smooth and clean angle that matched the curve of the bottom of the bowl of the pipe. I used 220 grit sandpaper, medium and fine grit sanding sponges to reshape the curve. The next two photos show the curve and the shape of the button on the cut off stem.

I worked the curve of the underside of the stem to make a smooth and clean angle that matched the curve of the bottom of the bowl of the pipe. I used 220 grit sandpaper, medium and fine grit sanding sponges to reshape the curve. The next two photos show the curve and the shape of the button on the cut off stem.

Once the shaping was finished I sanded the stem with micromesh sanding pads. I sanded the blade and the button and slot area of the stem at the same time. I wet sanded with 1500-2400 grit sanding pads and dry sanded with 3200-12,000 grit pads. I polished the stem with red Tripoli and White Diamond on the wheel and then gave the stem multiple coats of carnauba to polish and raise the shine.

Once the shaping was finished I sanded the stem with micromesh sanding pads. I sanded the blade and the button and slot area of the stem at the same time. I wet sanded with 1500-2400 grit sanding pads and dry sanded with 3200-12,000 grit pads. I polished the stem with red Tripoli and White Diamond on the wheel and then gave the stem multiple coats of carnauba to polish and raise the shine.

The finished stem is shown below. The goal in the process is to return the stem as near as possible to its original shape and condition. The button shape is determined by photos or by the remnant of the stem prior to being cut off. The buffed and polished stem should look as close as possible to a factory cut stem. While I have done many of these I still feel like I am in the process of learning. The key to the whole thing is to move slowly, carefully and methodically until the stem is finished. Then sand some more and polish some more… I can’t tell you how many times I have gone back after several months of smoking the pipe and doing a bit more reworking until I am happy with the feel in the mouth.

The finished stem is shown below. The goal in the process is to return the stem as near as possible to its original shape and condition. The button shape is determined by photos or by the remnant of the stem prior to being cut off. The buffed and polished stem should look as close as possible to a factory cut stem. While I have done many of these I still feel like I am in the process of learning. The key to the whole thing is to move slowly, carefully and methodically until the stem is finished. Then sand some more and polish some more… I can’t tell you how many times I have gone back after several months of smoking the pipe and doing a bit more reworking until I am happy with the feel in the mouth.

Carrying on the story of a 1905 Imperial ITC Bent Billiard

Blog by Steve Laug

The seller had marked this little pipe an Imperial ITC Silver Mount Birmingham 1934. Something about the gentle bend of the stem and shank, the shape and wear on the bowl made me want to have this diminutive pipe as my own. I bid on it and was the only bidder picking it up for about $22 Canadian. I think the seller wet down the stem and bowl for the photos because it is far too shiny looking. When I see an old pipe like this I immediately begin to wonder about the gent who owned the pipe. What was he like? What did he smoke in it? When did he purchase it and what did he smoke in it? Many of those questions can of course be answered by the pipe itself. The date in this case was suspect and would be formalized once I had it here. The vulcanite stem appeared to have an older rounded button that let me to surmise that it has an orifice button – a single round hole in the end of the button rather than a flared airway. The bowl was obviously well smoked telling me that it was a good smoking pipe. The stem unchewed telling me that the owner had cared for it well. Other than that I was left wondering about the last owner, was he the purchaser? How had the seller come into possession of the pipe? Questions for which I will not have an answer. When the pipe arrived I opened the box and excitedly cut through the layers of tape that held the pipe captive in the bubble wrap that protected it. I was proven correct in my assumption regarding the state of the pipe. The finish was indeed wetted for the photos of the seller as the pipe did not glisten like the photos. The bowl was in decent shape, the finish worn and tired. The rim was shot with built up tars and damage from tapping the bowl out. The silver had multitudes of dents and pock marks in it that showed its carriage in a coat or vest pocket and was tarnished. The stem was clean a lightly oxidized but showed no tooth damage. The bowl was caked with a thick build up of carbons but did not have a sweet or smokey smell so it was likely a Virginia pipe. The curve of the stem matched the curve of the bowl. The stamping was clear and readable – Imperial in script at an angle with ITC underneath the underline of Imperial. There was no other stamping on the briar.

When the pipe arrived I opened the box and excitedly cut through the layers of tape that held the pipe captive in the bubble wrap that protected it. I was proven correct in my assumption regarding the state of the pipe. The finish was indeed wetted for the photos of the seller as the pipe did not glisten like the photos. The bowl was in decent shape, the finish worn and tired. The rim was shot with built up tars and damage from tapping the bowl out. The silver had multitudes of dents and pock marks in it that showed its carriage in a coat or vest pocket and was tarnished. The stem was clean a lightly oxidized but showed no tooth damage. The bowl was caked with a thick build up of carbons but did not have a sweet or smokey smell so it was likely a Virginia pipe. The curve of the stem matched the curve of the bowl. The stamping was clear and readable – Imperial in script at an angle with ITC underneath the underline of Imperial. There was no other stamping on the briar.

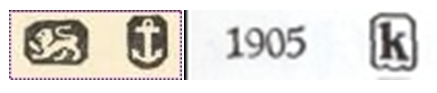

I wanted to check out the date given by the seller as I suspected it was somewhat earlier than the 1934 date given by the seller. The stem and button shape and the threaded bone tenon all pointed to an earlier date in my opinion. The hallmarks on the silver band would allow me to do that with some precision as they were not badly worn. I wiped down the band with a silver polishing cloth to remove the tarnish enough that I could read the stamping. To the naked eye it appeared to have a W.H. in an oval followed by an anchor, a lion and a lower case k.

I wanted to check out the date given by the seller as I suspected it was somewhat earlier than the 1934 date given by the seller. The stem and button shape and the threaded bone tenon all pointed to an earlier date in my opinion. The hallmarks on the silver band would allow me to do that with some precision as they were not badly worn. I wiped down the band with a silver polishing cloth to remove the tarnish enough that I could read the stamping. To the naked eye it appeared to have a W.H. in an oval followed by an anchor, a lion and a lower case k. I brought home a magnifying glass from work that had a built in light. I put the pipe under the lens and turned on the light. I lifted it to get the clearest magnification I could get on the silver hallmarks and what I had seen was indeed correct. It was a WH in two interlocking circles and the three hallmarks were correct.

I brought home a magnifying glass from work that had a built in light. I put the pipe under the lens and turned on the light. I lifted it to get the clearest magnification I could get on the silver hallmarks and what I had seen was indeed correct. It was a WH in two interlocking circles and the three hallmarks were correct.

I took this information to one of my favourite websites to process the information and gather what I could from the stamping http://www.silvercollection.it/englishsilverhallmarks.html. There I found the following data. The anchor stamp told me that the pipe or at least the silver band came from Birmingham, England. The lion told me I was dealing with sterling silver. And the k told me the date – 1905 not 1934. The pipe was significantly older than the seller had noted. That excited me as I love these older briar pipes.

I took this information to one of my favourite websites to process the information and gather what I could from the stamping http://www.silvercollection.it/englishsilverhallmarks.html. There I found the following data. The anchor stamp told me that the pipe or at least the silver band came from Birmingham, England. The lion told me I was dealing with sterling silver. And the k told me the date – 1905 not 1934. The pipe was significantly older than the seller had noted. That excited me as I love these older briar pipes. I also wanted to know what the W.H. in the oval could tell me about the pipe. I dug a little deeper on the English silver marks page and found more information.

I also wanted to know what the W.H. in the oval could tell me about the pipe. I dug a little deeper on the English silver marks page and found more information. The maker of the silver band was a William Harrison who was active in London. Various copies of Harrison’s marks in Chester Assay Office were registered by Imperial Tobacco Co between 1907 and 1916. The mark above shows a Birmingham 1908 hallmark. From that information I gathered that the W.H. was William Harrison and that the Birmingham Assay Office had stamped the band in 1905.

The maker of the silver band was a William Harrison who was active in London. Various copies of Harrison’s marks in Chester Assay Office were registered by Imperial Tobacco Co between 1907 and 1916. The mark above shows a Birmingham 1908 hallmark. From that information I gathered that the W.H. was William Harrison and that the Birmingham Assay Office had stamped the band in 1905.

I unscrewed the stem from the shank in order to work on the bowl. The cake was thick and crumbling in the bowl so I reamed it back to bare wood with a PipNet reamer.

The rim would take some serious work to get it back to workable condition. I set up a topping board and carefully worked the top of the bowl against the sandpaper. The surface of the rim was not even so this took some care so as not to angle the rim. I sanded the rim until the surface was flat and the damage was removed. There was still some darkening to the briar but I chose to leave that rather than to remove more of the briar from the rim.

The rim would take some serious work to get it back to workable condition. I set up a topping board and carefully worked the top of the bowl against the sandpaper. The surface of the rim was not even so this took some care so as not to angle the rim. I sanded the rim until the surface was flat and the damage was removed. There was still some darkening to the briar but I chose to leave that rather than to remove more of the briar from the rim.

To remove the spotty and damaged finish on the bowl I wiped it down with acetone on cotton pads and was able to take it back to the unfinished briar. The brown patina of the briar was not removed in the process and once finished would clean up well and still show some age.

To remove the spotty and damaged finish on the bowl I wiped it down with acetone on cotton pads and was able to take it back to the unfinished briar. The brown patina of the briar was not removed in the process and once finished would clean up well and still show some age. I wanted to take photos of the stem and tenon so that you could see the age and shape it was in. It was a bone tenon, threaded to match the threads in the shank. The end of the tenon has a funnel or tube that is part of the tenon to capture the smoke and bring it into the airway. The other end of the stem is the rounded orific button that I have come to expect on pipes from this time period.

I wanted to take photos of the stem and tenon so that you could see the age and shape it was in. It was a bone tenon, threaded to match the threads in the shank. The end of the tenon has a funnel or tube that is part of the tenon to capture the smoke and bring it into the airway. The other end of the stem is the rounded orific button that I have come to expect on pipes from this time period.

Once the exterior surfaces were clean it was time to work on the interior of the shank and stem. I put the pipe back together and set up a retort. I filled the test tube with 99% isopropyl alcohol and put the stopper and apparatus in place. I stuffed a cotton ball in the bowl to keep the alcohol that was boiled through the pipe in the pipe and not all over the desk top. I use a small tea light candle to heat the alcohol and boil it through the pipe. I repeat the process twice, changing the alcohol between procedures to remove the tars and oils from the shank and stem. Once I removed the retort I cleaned out the shank and stem with pipe cleaners, cotton swabs and isopropyl alcohol. It takes far less pipe cleaners once the retort has finished its work.

Once the exterior surfaces were clean it was time to work on the interior of the shank and stem. I put the pipe back together and set up a retort. I filled the test tube with 99% isopropyl alcohol and put the stopper and apparatus in place. I stuffed a cotton ball in the bowl to keep the alcohol that was boiled through the pipe in the pipe and not all over the desk top. I use a small tea light candle to heat the alcohol and boil it through the pipe. I repeat the process twice, changing the alcohol between procedures to remove the tars and oils from the shank and stem. Once I removed the retort I cleaned out the shank and stem with pipe cleaners, cotton swabs and isopropyl alcohol. It takes far less pipe cleaners once the retort has finished its work.

I decided to stain the briar using the stain pens instead of the usual aniline stains. I wiped down the surface of the bowl with alcohol and then used the stain the medium brown stain pen to stain the bowl. When applied the stain is streaked but that is easily taken care of with a quick buff with a cotton cloth. I also cleaned the silver with a silver polish and a jeweler’s polishing cloth to remove the tarnish and bring up the shine.

I decided to stain the briar using the stain pens instead of the usual aniline stains. I wiped down the surface of the bowl with alcohol and then used the stain the medium brown stain pen to stain the bowl. When applied the stain is streaked but that is easily taken care of with a quick buff with a cotton cloth. I also cleaned the silver with a silver polish and a jeweler’s polishing cloth to remove the tarnish and bring up the shine. I removed the stem and sanded it with a medium and a fine grit sanding sponge to address the light oxidation. I then sanded it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed down the stem between each set of three pads with Obsidian Oil. When I finished sanding with the 12000 grit pad I also gave it a final coat of Obsidian Oil and when dry took it to the buffer and buffed it with White Diamond and then carnauba wax to protect the stem.

I removed the stem and sanded it with a medium and a fine grit sanding sponge to address the light oxidation. I then sanded it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed down the stem between each set of three pads with Obsidian Oil. When I finished sanding with the 12000 grit pad I also gave it a final coat of Obsidian Oil and when dry took it to the buffer and buffed it with White Diamond and then carnauba wax to protect the stem.

I decided to rub down the bowl with a light coat of olive oil. I find that on these older pipes it brings out the patina nicely. I put some oil on a paper towel and then rub down the pipe, wipe off the excess and repeat the process until it shines.

I decided to rub down the bowl with a light coat of olive oil. I find that on these older pipes it brings out the patina nicely. I put some oil on a paper towel and then rub down the pipe, wipe off the excess and repeat the process until it shines.

When the olive oil was absorbed and the bowl was dry to touch I took the pipe to the buffer and lightly buffed it with White Diamond. I gave the entire pipe several coats of carnauba wax, buffing the silver with a very light touch so as not to damage the hallmarks and stamping. I finished by buffing it lightly with a soft flannel buffing pad to raise the shine. The finished pipe is shown below. It is ready to go back into service. I intend to enjoy it for many more years. I always enjoy smoking these old timers and only wish they could tell their stories. It is amazing to be able to load a bowl and smoke a pipe that is almost 110 years old. Speak to me, I am listening I want to hear your stories… and add my own to the saga you could tell.

When the olive oil was absorbed and the bowl was dry to touch I took the pipe to the buffer and lightly buffed it with White Diamond. I gave the entire pipe several coats of carnauba wax, buffing the silver with a very light touch so as not to damage the hallmarks and stamping. I finished by buffing it lightly with a soft flannel buffing pad to raise the shine. The finished pipe is shown below. It is ready to go back into service. I intend to enjoy it for many more years. I always enjoy smoking these old timers and only wish they could tell their stories. It is amazing to be able to load a bowl and smoke a pipe that is almost 110 years old. Speak to me, I am listening I want to hear your stories… and add my own to the saga you could tell.

Restoring a Republic Era Shamrock 999 Rhodesian

Blog by Steve Laug

When I saw this pipe on Ebay I immediately threw in a low bid. The seller included two photos the clear side view of the pipe shown below and the second photo below – an out of focus picture of the stem end. It was obvious there was damage to the stem and that it would take some work but it was still interesting to me. I was the only bidder so the pipe became mine.

When I saw this pipe on Ebay I immediately threw in a low bid. The seller included two photos the clear side view of the pipe shown below and the second photo below – an out of focus picture of the stem end. It was obvious there was damage to the stem and that it would take some work but it was still interesting to me. I was the only bidder so the pipe became mine.

It was stamped Shamrock on the left side of the shank in capital letters (once it arrived I saw that on the right side of the shank it bore the stamping “A Peterson Product” over Made in the Republic of Ireland with 999 stamped next to that). While the seller never revealed the data stamped on the right side of the shank or the shape number it was clearly a Peterson 999 – one of my favourite shapes. I am particularly fond of the thick shanked older versions of the shape but this one looked workable. While I waited for it I did some research on the brand. I have several Shamrock pipes and fortunately all of them are very nicely grained briar.

It was stamped Shamrock on the left side of the shank in capital letters (once it arrived I saw that on the right side of the shank it bore the stamping “A Peterson Product” over Made in the Republic of Ireland with 999 stamped next to that). While the seller never revealed the data stamped on the right side of the shank or the shape number it was clearly a Peterson 999 – one of my favourite shapes. I am particularly fond of the thick shanked older versions of the shape but this one looked workable. While I waited for it I did some research on the brand. I have several Shamrock pipes and fortunately all of them are very nicely grained briar.

I wrote to a favourite source of all things Peterson, Mark Irwin, to inquire about the mark. He responded with the following helpful information. “There were two Shamrock lines—the Rogers Import U.S.-only line with the nickel band, and the Peterson unmounted line with a white “S” stamped on the mouthpiece. This line—which is what your pipe is from—debuted in the 1945 catalog in the 30 classic shapes then being offered, in both smooth and sandblast, always with a fishtail mouthpiece, and continued with the same finish and “S” stamp until the 1975 catalog. It was a “Product” line, so look carefully for fills, as Peterson always strives to get the most mileage out of their briar. If it does indeed lack fills, someone messed up in the workshop, as it would normally have been released in a much higher line. The name was subsequently used on newer “Shamrock” lines with various finishes and stains until very recently, but always as an entry-grade line.”

I also was a bit more information on the stamping on the other side of the shank so I read more on dating Peterson Pipes in an article here on the blog by Mike Leverette. In it I found that pipes that bore the Republic of Ireland stamping came from the Republic Era which extended from 1949 until the present. “The Republic of Ireland was formed on 17 April 1949. From 1949 to present the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.”

Mike also addressed a further question on the stamping “A Peterson Product”. He wrote: “Also, we must address the stamp “A Peterson Product.” During the last few years of the Pre-Republic era and throughout the Republic era, Peterson began stamping their other lines, such as Shamrocks and Killarneys, with “A Peterson Product” over the COM stamp. So a pipe stamped thusly will have been made say from 1948 to the present with the COM stamp identifying it as a pre-Republic or a Republic pipe.”

That was helpful information. With Mark’s and Mike’s information I had learned a lot about my pipe even before it arrived. It came from the earlier Shamrock line which debuted in 1945 and continued until 1975. It certainly fit in the description of a classic shape and an unmounted line with a white S on the stem. It was a Republic Era pipe which put it after 1949 and bore the Peterson Product stamp which put it in the same time frame. That is as specific as I can get in dating this pipe.

When the pipe arrived I opened the box and took it out of the bubble wrap. The stem was frozen in the shank and did not fit against the shank. The grain was beautiful and the natural finish was dirty. The bowl had a thick cake and still had a half bowl of unsmoked tobacco. The rim had a build up of tar on it that was thick. The inner and outer edge of the rim was undamaged and the bowl was still round. The stem was oxidized and the button end had significant damage as can be seen in the third photo below.

I put the pipe in the freezer and left it overnight so that the temperature change would do its magic and loosen the stem in the shank. In the morning I took it out and was able to remove the stem with no problems. The photo below shows the damage to the button very clearly. There is also a sand pit visible in the side of the bowl. It is unfilled and from what I could see of the rest of the bowl there were not any fills.

I put the pipe in the freezer and left it overnight so that the temperature change would do its magic and loosen the stem in the shank. In the morning I took it out and was able to remove the stem with no problems. The photo below shows the damage to the button very clearly. There is also a sand pit visible in the side of the bowl. It is unfilled and from what I could see of the rest of the bowl there were not any fills. I left the tobacco in the bowl while I worked on the rim. I scrubbed it with saliva and cotton pads until I was able to remove all of the tarry build up. I also scrubbed down the rest of the exterior of the bowl and shank.

I left the tobacco in the bowl while I worked on the rim. I scrubbed it with saliva and cotton pads until I was able to remove all of the tarry build up. I also scrubbed down the rest of the exterior of the bowl and shank. I removed the tobacco with a dental pick and then reamed the pipe with a PipNet reamer and took the cake back to bare wood.

I removed the tobacco with a dental pick and then reamed the pipe with a PipNet reamer and took the cake back to bare wood. I used the dental pick to also clean out the twin rings around the bowl. These were packed with dust and wax from previous buffing.

I used the dental pick to also clean out the twin rings around the bowl. These were packed with dust and wax from previous buffing. I set up my retort and put the tube on the broken stem. I loosely stuff a cotton ball in the bowl and heated the alcohol over a tea light candle. I ran the alcohol through until it came out a rich brown. I emptied the test tube and refilled it with alcohol and repeated the process. The second time the alcohol came out clean. I removed the retort and cleaned out the shank and bowl with cotton swabs and pipe cleaners.

I set up my retort and put the tube on the broken stem. I loosely stuff a cotton ball in the bowl and heated the alcohol over a tea light candle. I ran the alcohol through until it came out a rich brown. I emptied the test tube and refilled it with alcohol and repeated the process. The second time the alcohol came out clean. I removed the retort and cleaned out the shank and bowl with cotton swabs and pipe cleaners.

I debated for a long time what to do with the damaged stem. I could try a stem splice or replace the stem. I could also cut off the stem and reshape the button. In looking over the stem I decided there was enough length and material to allow me to cut if off and reshape it. I used a Dremel with a sanding drum to remove the broken part of the stem. I squared it off on the topping board and I was ready to recut the button.

I debated for a long time what to do with the damaged stem. I could try a stem splice or replace the stem. I could also cut off the stem and reshape the button. In looking over the stem I decided there was enough length and material to allow me to cut if off and reshape it. I used a Dremel with a sanding drum to remove the broken part of the stem. I squared it off on the topping board and I was ready to recut the button.

I use needle files to cut the lines of the new button. They give me a good square edge and let me cut the basic shape of the button.

I use needle files to cut the lines of the new button. They give me a good square edge and let me cut the basic shape of the button.

Once the line is cut I use a variety of tools to trim back the taper from the line back toward the shank. I used an emery board to work on the shape of the stem. Often this is all I need but in this case it was not enough.

Once the line is cut I use a variety of tools to trim back the taper from the line back toward the shank. I used an emery board to work on the shape of the stem. Often this is all I need but in this case it was not enough.

I used a knife blade shaped needle file to shave the stem back to the button. With this blade I removed a lot of the excess material and the button began to take shape. I also used the file to begin to shape the oval of the button and to open up the slot in the end of the button. I continued to work on the taper of the stem and smoothed out the flow o the stem to the button using 220 grit sandpaper.

I used a knife blade shaped needle file to shave the stem back to the button. With this blade I removed a lot of the excess material and the button began to take shape. I also used the file to begin to shape the oval of the button and to open up the slot in the end of the button. I continued to work on the taper of the stem and smoothed out the flow o the stem to the button using 220 grit sandpaper.

Once I had the shape and the taper of the stem correct I put a washer on the tenon and inserted it in the shank so that I could work on the stem. I sanded the stem with 220 grit sandpaper to remove the oxidation and then sanded it with a medium and a fine grit sanding sponge. I carefully avoided damaging the logo stamp on the stem. I also rubbed the bowl down with a little olive oil on a cotton pad. It really enlivened the grain on the pipe. I buffed it lightly with White Diamond and then gave it several coats of carnauba wax.

Once I had the shape and the taper of the stem correct I put a washer on the tenon and inserted it in the shank so that I could work on the stem. I sanded the stem with 220 grit sandpaper to remove the oxidation and then sanded it with a medium and a fine grit sanding sponge. I carefully avoided damaging the logo stamp on the stem. I also rubbed the bowl down with a little olive oil on a cotton pad. It really enlivened the grain on the pipe. I buffed it lightly with White Diamond and then gave it several coats of carnauba wax.

Once the oxidation was taken care of I used some liquid paper to re-whiten the S on the stem. The photos below show the shape of the button and the stem at this point in the process. The new button works well and the shortening of the stem did not too seriously damage the appearance of the pipe.

Once the oxidation was taken care of I used some liquid paper to re-whiten the S on the stem. The photos below show the shape of the button and the stem at this point in the process. The new button works well and the shortening of the stem did not too seriously damage the appearance of the pipe.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12,000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three grits of micromesh sanding pads.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12,000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three grits of micromesh sanding pads.

I rubbed it down with a final coat of Obsidian Oil and once it had been absorbed into the vulcanite I hand buffed it with a soft cloth and took the next two photos to show the finished look of the stem.

I rubbed it down with a final coat of Obsidian Oil and once it had been absorbed into the vulcanite I hand buffed it with a soft cloth and took the next two photos to show the finished look of the stem.

The finished pipe is shown below. The two profile photos show the look of the new button and the revised taper of the stem. It feels great in the hand and in the mouth. The bend matches my other 999 pipes and the overall length actually is the same as the chunkier stemmed early 999s that I have in my collection. I buffed the pipe and stem with White Diamond and gave it several coats of carnauba wax. I buffed it with a soft flannel buff to raise the shine on the pipe. It looks and smells fresh and clean. It is ready to load with a bowl of Virginia and give an inaugural smoke. In closing look at the grain on this old Shamrock – for the life of me I can find no fills in the briar. It is clean – two or three smalls sandpits but they in no way effect the overall look of the pipe. Amazing, I think that it did indeed slip through during production. No problem for me, I will enjoy it.

The finished pipe is shown below. The two profile photos show the look of the new button and the revised taper of the stem. It feels great in the hand and in the mouth. The bend matches my other 999 pipes and the overall length actually is the same as the chunkier stemmed early 999s that I have in my collection. I buffed the pipe and stem with White Diamond and gave it several coats of carnauba wax. I buffed it with a soft flannel buff to raise the shine on the pipe. It looks and smells fresh and clean. It is ready to load with a bowl of Virginia and give an inaugural smoke. In closing look at the grain on this old Shamrock – for the life of me I can find no fills in the briar. It is clean – two or three smalls sandpits but they in no way effect the overall look of the pipe. Amazing, I think that it did indeed slip through during production. No problem for me, I will enjoy it.

A Review – a Jobert Olive Liverpool

Blog by Steve Laug

Many years ago while I was active on the Yahoo pipes page I had conversations with Johan via email and public posts regarding some of his pipes. I was intrigued with the varieties of African wood that he used for his pipes. Good friend John Offerdahl had several pipes made by Johan and I liked the look and feel of them. Over time I settled on an olive wood Liverpool shaped pipe. I contacted Johan and the deal was struck. My olive wood pipe was on its way to Canada.

Many years ago while I was active on the Yahoo pipes page I had conversations with Johan via email and public posts regarding some of his pipes. I was intrigued with the varieties of African wood that he used for his pipes. Good friend John Offerdahl had several pipes made by Johan and I liked the look and feel of them. Over time I settled on an olive wood Liverpool shaped pipe. I contacted Johan and the deal was struck. My olive wood pipe was on its way to Canada.

Recently I had the pipe out and was smoking it and wondered what had ever happened to Johan. I had heard that he had been ill and was no longer making pipes. I had emailed a few times and gotten no response. His website was down and unavailable so that did not bode well in my opinion. When I decided to write up a review of my wonderful pipe by Johan Slabbert the creator and crafter of Jobert pipes I went digging on the web to see if I could find more information regarding what had happened to him. I found a good write up on Pipedia.org http://pipedia.org/wiki/Jobert

The opening two sentences of the article gave me the information I was seeking. All of the posts and interactions I had read had spoken of a serious health issue for Johan. While that may be true it seems that his pipe making was cut short by “the untimely death of his friend and fellow pipe maker Leon du Preez…” Since that time Johan Slabbert no longer made pipes. The opening paragraph goes on to say that this information“was confirmed by his wife”.

The article also included the following for Johan himself. It reminds of what was originally on his website but I cannot confirm that at this point. I have copied the article here for ease of reference:

“I am Johan Slabbert from Goodwood, a suburb of the Cape Peninsula, South Africa.”

“I am a self trained pipe maker and a wood lover. Since my retirement in 1992, I kept myself busy with woodcarving, sculpturing, wood turning and restoring/renovating antique furniture. I also collect antique carpenters’ tools and other memorabilia.”

“During October 2000, while pondering what else I could do, I took one of my old collectors’ pipes and after 30 years I lit up a pipe again. While smoking, the idea came to me to try pipe making. Well, you are seeing the results now.”

“No Briar was available and I used our local obtainable wood like Wild Olive, Leadwood, Mopane, Black Hookthorn and African Black wood, which turned out to be very good smokers and popular among the local pipe smokers. I have since obtained some Briar, which I cherish.”

“My pipes are specially engraved with my logo “JOBERT”, an abbreviation of my first and last names.”

“Since I started creating pipes, I made a lot of pipe smoking friends on the Internet. I am also a member of the “Stuttgarter Pfeifen Freunde-79”, the “Buenos Aires Pipa Club” and the “Confraria Do Cachimbo” of Brazil.”

My own Jobert is a large Liverpool shaped pipe crafted of Wild Olive wood. It is a heavy piece of wood – far heavier than briar of the same size. It is 6 inches long and almost 2 inches tall. The tobacco chamber is 1 9/16 inches deep and 7/8 inches in diameter. The stem is handmade from vulcanite and its taper is smooth enough to make a comfortable stem. The shape execution is well done, though not quite ‘classic’. Johan takes a unique interpretation of traditional shapes. The craftsmanship, drilling and fit are all precise. This finish is natural, and no attempt has been made to mask or cover any imperfections in the graining of the wood. Wild Olive is visually stunning and unique in its pattern and flow. The look of the pipe, the natural wood and feel of it in my hand continues to keep me coming back to this pipe. I remember when the pipe arrived. I cut open the package, removed the bubble wrapped package on the inside and took the pipe out. I was immediately struck by the look and feel of this pipe. Johan had done a magnificent job on this one and it was beautiful. There is something about the smell and feel of a new pipe that is unique and special. In this case I could almost taste my favourite green olives in the aroma of the new pipe. The grain pattern swirls around the bowl and shank with a contrast between the dark lines and the warm light colour wood between the lines.Examining at it I can see Johan’s masterful plan in laying out the cutting pattern of the piece of wood he chose. It is a beautifully laid out pipe.

The look of the pipe, the natural wood and feel of it in my hand continues to keep me coming back to this pipe. I remember when the pipe arrived. I cut open the package, removed the bubble wrapped package on the inside and took the pipe out. I was immediately struck by the look and feel of this pipe. Johan had done a magnificent job on this one and it was beautiful. There is something about the smell and feel of a new pipe that is unique and special. In this case I could almost taste my favourite green olives in the aroma of the new pipe. The grain pattern swirls around the bowl and shank with a contrast between the dark lines and the warm light colour wood between the lines.Examining at it I can see Johan’s masterful plan in laying out the cutting pattern of the piece of wood he chose. It is a beautifully laid out pipe.

The stamping on the shank reads SOUTH AFRICA on the left side neat to the shank/stem union. On the other side it is stamped Jobert in script. The overall flow of the pipe from the bowl to the stem well executed. The natural colours of the olive wood bowl and shank are a stark contrast with the black of the tapered stem. The combination really sets off the pipe and gives it an air of distinction. The inner mechanics of the pipe are perfect. The drilling is straight and true from the shank and into the bowl – coming out exactly centre in the bottom of the bowl. The airway from the bowl into the mortise is centered. It is smooth in its entrance to the mortise and the mortise itself is also smooth with no rough spot left by drill bit. The end of the shank is sanded smooth and is finished. There is a bevel in the shank end to accommodate the tenon and provide a smooth fit against the shank. The bowl itself is U shaped and smooth from sides to bottom. The air way enters the bowl and is smooth and clean. The draught on the bowl is wide open and effortless. The bowl was bare – no bowl coating had been used to prepare the bowl.

The inner mechanics of the pipe are perfect. The drilling is straight and true from the shank and into the bowl – coming out exactly centre in the bottom of the bowl. The airway from the bowl into the mortise is centered. It is smooth in its entrance to the mortise and the mortise itself is also smooth with no rough spot left by drill bit. The end of the shank is sanded smooth and is finished. There is a bevel in the shank end to accommodate the tenon and provide a smooth fit against the shank. The bowl itself is U shaped and smooth from sides to bottom. The air way enters the bowl and is smooth and clean. The draught on the bowl is wide open and effortless. The bowl was bare – no bowl coating had been used to prepare the bowl. The stem is either hand cut vulcanite or a modified stem blank; it is very hard to tell. The shaping and flow are nicely done and descend gently to the button leaving a good thin bit for the mouth. The taper is even on both sides and the bottom with good even angles top and bottom progressing from the shank to the button. The bit end of the stem is thin and very comfortable. Johan did a great job shaping the stem and capturing a shape that really works with this pipe. The tenon is cut from the vulcanite stem and is quite short and compact. The airway is drilled wide open and lines up with the one in the mortise end. There is a gap between the end of the tenon and the base of the mortise that serves as a short condensation chamber.

The stem is either hand cut vulcanite or a modified stem blank; it is very hard to tell. The shaping and flow are nicely done and descend gently to the button leaving a good thin bit for the mouth. The taper is even on both sides and the bottom with good even angles top and bottom progressing from the shank to the button. The bit end of the stem is thin and very comfortable. Johan did a great job shaping the stem and capturing a shape that really works with this pipe. The tenon is cut from the vulcanite stem and is quite short and compact. The airway is drilled wide open and lines up with the one in the mortise end. There is a gap between the end of the tenon and the base of the mortise that serves as a short condensation chamber.

The draught of the stem is unrestricted and open. When the pipe is put together the draught is effortless. The fit of the stem to the shank is very well done. The button is cut with a good sharp inner edge and tapered to the tip. It is a thicker button compared to most of my pipes but still works for me. The edge provides a place for the button to fit behind the teeth. The slot is a straight rectangle and fanned out from the slot to the airway in the stem. The inside of the slot is sanded smooth and polished. The airway is absolutely smooth from slot to tenon. The overall construction of this pipe is very good. While not a work of art per se it is highly functional and delivers a flavourful and cool smoke. The finish is probably the biggest weakness in this pipe. It is rough with sanding scratch marks left behind. More time spent with higher grit sandpaper would have polished the wood to a glassy finish. Over time my hands have rubbed the finish smooth. One day I may well sand it down and refinish it myself but have not done that yet. The pipe is slightly heavier than a briar that is similar in size. It is well balanced and fits well in the hand. I have smoked the pipe a lot since I got it and have chosen to keep it as a designated English or Balkan pipe. Latakia smokes exceptionally well in it and seems to deliver a fuller range of flavours than some of my briar pipes. From the first bowl I smoked in it the pipe delivered a good smoke and continues to do so. It draws well; the lighting has never been a problem and continues to be an effortless smoke.

The overall construction of this pipe is very good. While not a work of art per se it is highly functional and delivers a flavourful and cool smoke. The finish is probably the biggest weakness in this pipe. It is rough with sanding scratch marks left behind. More time spent with higher grit sandpaper would have polished the wood to a glassy finish. Over time my hands have rubbed the finish smooth. One day I may well sand it down and refinish it myself but have not done that yet. The pipe is slightly heavier than a briar that is similar in size. It is well balanced and fits well in the hand. I have smoked the pipe a lot since I got it and have chosen to keep it as a designated English or Balkan pipe. Latakia smokes exceptionally well in it and seems to deliver a fuller range of flavours than some of my briar pipes. From the first bowl I smoked in it the pipe delivered a good smoke and continues to do so. It draws well; the lighting has never been a problem and continues to be an effortless smoke.

Thanks Johan for delivering a beautifully grained, well-made functional pipe that remains a very good smoking pipe to this day. Over the years the grain has darkened and both the lighter and darker portions of the bowl have acquired a grey brown hue that is quite nice.

If you can acquire a Jobert pipe, regardless of the type of wood, it will not disappoint you. It consistently delivers a great smoke. It may well become a favourite in your rack. For those who have never owned or smoked a Wild Olive pipe, try to find one you like and purchase one, you will not be sorry. Like others have said before me, Olive wood pipes initially impart a very nutty quality to a bowl of tobacco. Eventually as the cake develops in the bowl this property fades.

If you can acquire a Jobert pipe, regardless of the type of wood, it will not disappoint you. It consistently delivers a great smoke. It may well become a favourite in your rack. For those who have never owned or smoked a Wild Olive pipe, try to find one you like and purchase one, you will not be sorry. Like others have said before me, Olive wood pipes initially impart a very nutty quality to a bowl of tobacco. Eventually as the cake develops in the bowl this property fades.

I am sure that this will not be the last Jobert that own. I am on the prowl for one that fits the styles that I am now collecting. One day it will turn up and I will pounce on it. Until then I will continue to look and enjoy smoking this Liverpool. If anyone has heard on Johan is doing I would love to hear from you. If Johan, you happen to read this review of your pipe, I hope that you are well. Know that I continue to enjoy this beauty that was made for me.

I am sure that this will not be the last Jobert that own. I am on the prowl for one that fits the styles that I am now collecting. One day it will turn up and I will pounce on it. Until then I will continue to look and enjoy smoking this Liverpool. If anyone has heard on Johan is doing I would love to hear from you. If Johan, you happen to read this review of your pipe, I hope that you are well. Know that I continue to enjoy this beauty that was made for me.

A Unique Town and Country Squat Round Bottom Rhodesian – Robert M. Boughton

Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

The pipe with solemn interposing puff,

Makes half a sentence at a time enough;

The dozing sages drop the drowsy strain,

Then, pause and puff – and speak, and pause again. — William Cowper (1731-1800), English poet, in “Conversation,” 1782

INTRODUCTION

When this odd little pipe arrived in the mail a couple of months ago, as part of an estate lot, it stood out, to be sure. Amongst a beautiful Kaywoodie Standard mixed Sandblast/Smooth Grain Billiard, an elegant LHS Park Lane DeLuxe Dublin, a vintage WDC Full Bent Billiard with 14K ring, an Ehrlich Rusticated Billiard and two others – yes, it stood out. I will leave it to the reader to determine the nature of the deviation.

Still, it did force me to reconsider the true form and figure of a Rhodesian, and to imagine the turmoil I could incite if I threw this pipe as an example into the ongoing brouhaha that is the Bulldog versus Rhodesian debate. I do have a touch of Old Nick in me that way (and I don’t mean St. Nick).

Yet how else can I describe this weird pipe, at its basest, but as a Rhodesian, despite the squatness of its stature and the roundness of the bottom of the bowl? The fact is that this Town and Country (made by the Bradberry Briar Pipe Corp. of New York) has a rounded bowl with two slits carved into its upper end below the rim and a round shank.

RESTORATION

RESTORATION

Part of me did not want to mess with the original stain, but some impulse screamed at me, “Drown this thing in Everclear and see what lies beneath!” And so, that I did. As it turned out, the voice was right. All kinds of scratches and other flaws became apparent where they were obscured before.

Beginning the process of removing the various blemishes with a thorough sanding (except for the nomenclature)using 220-grit paper, I was careful to make smooth, even runs in the directions of the grain. After some time at this task, rubbing the fine briar dust away with a rag as I progressed, I was at last satisfied with the results.

Beginning the process of removing the various blemishes with a thorough sanding (except for the nomenclature)using 220-grit paper, I was careful to make smooth, even runs in the directions of the grain. After some time at this task, rubbing the fine briar dust away with a rag as I progressed, I was at last satisfied with the results.

To prep the wood for staining, I brushed the surface with super fine steel wool, which returned the natural color of the briar and created a light sheen. Then I commenced a thorough de-wrinkling treatment with micromesh pads, starting with 1500, then 1800, 2400, 3200 and 4000. Again, I rubbed the wood clear of any residue between each micromesh pad.

The obvious next step seemed to be a full cleaning of the pipe’s interior. Expecting to find the usual massive buildup of crud associated with the shanks of most estate pipes, I was in fact shocked to see the wire-handled, heavy-duty bristly cleaner, dipped in Everclear, emerge from the exercise almost un-befouled the first time and spotless the second.

The obvious next step seemed to be a full cleaning of the pipe’s interior. Expecting to find the usual massive buildup of crud associated with the shanks of most estate pipes, I was in fact shocked to see the wire-handled, heavy-duty bristly cleaner, dipped in Everclear, emerge from the exercise almost un-befouled the first time and spotless the second.

Still wary, I sanded the pinky-sized circumference of the chamber with a Lilliputian-sized scrap of 220-grit paper and succeeded in removing a fair amount of carbon. Then I inserted an alcohol-soaked square of gun cleaning cotton cloth and twirled it with the aforementioned pinky until most of the carbon residue was cleared from the chamber.

Despite the failure of the wire cleaner to dig up more than trace elements of old tobacco, and determined to assure the shank was truly ready to pass anyone’s test, I employed my newly acquired proficiency in retorting. To my utter dismay, despite my certainty that I had performed the retort without error, the remainder of the boiling alcohol – which had surged all the way into the chamber and left the cotton there somewhat dirtier than it started – returned to the Pyrex test tube clear enough to drink, if I were so inclined. Disbelieving the unheard of result, I re-boiled the alcohol in a second and sent it packing again whence it had returned once empty-handed, so to speak. The second try came back as clean as the first.

At last, my mind exploded in dizzying exultation, a clean shank at the outset!

I turned to the stem, which, other than being a uniform military green, was all but devoid of scratches or chatter. There was one small ding, but given the usual mauling of stems I encounter, this one was a gift from Heaven. As I have yet to come up with a formula for a solution in which to treat stems, I was compelled to do it the old fashioned way: by hand, using 320-grit paper to restore the stem from green to black. This step required several passes, more and more localized each time.

Next I turned to micromesh and gave the stem the same care I provided the wood: 1500, 1800, 2400, 3200 and 4000. I tend to enjoy re-staining the wood of a pipe when necessary, and my biggest question so far had been what shade of brown to use if not marine (burgundy) red. This pipe I wanted to do as a two-tone, with the beautiful natural color and grain of the rounded rim left unchanged and the rest of the bowl and shank dark enough to show the difference. And so the only question was whether to use medium brown, which is darker than it sounds, or marine? I admit to having a fluttery, nervous feeling in my stomach when I opted for the marine. Although the result was better than okay, I won’t be showing it here for reasons that will soon be apparent.

I tend to enjoy re-staining the wood of a pipe when necessary, and my biggest question so far had been what shade of brown to use if not marine (burgundy) red. This pipe I wanted to do as a two-tone, with the beautiful natural color and grain of the rounded rim left unchanged and the rest of the bowl and shank dark enough to show the difference. And so the only question was whether to use medium brown, which is darker than it sounds, or marine? I admit to having a fluttery, nervous feeling in my stomach when I opted for the marine. Although the result was better than okay, I won’t be showing it here for reasons that will soon be apparent.

Having stained the majority of the wood marine and left the round rim plain, I flamed out the alcohol from the boot stain, buffed the greater part of the wood with its resulting ash using 3200 micromesh and then waxed the wood and stem – from which I had removed the superfluous metal tenon extension by heating it with my Bic and yanking it out – and achieved a definite high contrast. The grain still showed through the stain, but I knew it wasn’t right.

Therefore, wishing to have a little fun and test my mentor, Chuck Richards, I took the “almost finished” product to him for his opinion. True to form, Chuck scrutinized every angle of the pipe through his glasses and handed it back to me. His critique was like the ultimate New Yorker bad book review: no comment. He still has no idea how good that made me feel!

Pleased with myself, I later returned home with the dark red body of the pipe topped by a blond head and with care again applied the super fine steel wool to remove the wax and stain on all of the wood but the rim. Ready for the correct approach, I re-stained most of the wood medium brown, went through all of the steps as before to prepare it for waxing on my two buffer machines, and applied white and red Tripoli, White Diamond and carnauba. The result was much more satisfying, and I felt no need to run it by Chuck again before submitting this blog, as I had already messed with him enough, albeit unbeknownst to my good friend.

CONCLUSION

CONCLUSION

All fun and pranks with my big-hearted but not coddling mentor aside, I ended this restoration with more work than was necessary. I should have learned by now not to disregard the advice of that little fluttery feeling of unease I had in my stomach when I chose marine over medium brown. In the end, the stomach almost always wins in all matters over the mind.

Narrowing Down a Date for Kaufman Brothers & Bondy’s KBB and KB&B Pipes

Blog by Steve Laug

Over the years I have refurbished many older KBB and KB&B pipes. I have kept many of them and others I have passed on to other pipemen and women. The KBB and KB&B stamping on these old timers are stamped in a cloverleaf on the side or top of the shank of the briar pipes. In more recent years the KBB and KB&B stamping is no longer present. Kaufmann Brothers and Bondy was the oldest pipe company in the USA, established in 1851. The Club Logo predated Kaywoodie with the “KB&B” lettering stamped within the Club, and a multitude of KB&B lines were in production long before “Kaywoodie” first appeared in 1919. I have several of these old timers including a Borlum that was made before Kaywoodie became the flagship name for pipes from Kaufman Brothers & Bondy (KB&B). It was made before the Kaywoodie invention of the “Stinger” was added, and even before shank logos, model stamps and other features invented by Kaywoodie came to be standards of the pipe making industry. It comes from the time when names like Ambassador, Heatherby, Melrose, Suez, Rivoli, Cadillac and Kamello dominated the pre-Kaywoodie scene. Borlum is one of those vintage names. That information helps date pre-1919 KB&B pipes. There is still a long history following that for which I wanted further information. I was left wondering about the variations in the stampings on the Kaufmann Brothers and Bondy pipes. I had seen a pattern in that the Yello-Bole pipes made by Kaufmann Brothers and Bondy that were stamped without the ampersand (KBB) and other pipes made by them that had the ampersand (KB&B) and wondered about whether I had stumbled upon something. I had no idea why there was a variation in stamping. I decided to do some digging online to see if I could get more information regarding this variation. The purpose of this article is to collate what I found in order to provide some guidelines on dating the older pipes and to differentiate between the two stampings.

I was left wondering about the variations in the stampings on the Kaufmann Brothers and Bondy pipes. I had seen a pattern in that the Yello-Bole pipes made by Kaufmann Brothers and Bondy that were stamped without the ampersand (KBB) and other pipes made by them that had the ampersand (KB&B) and wondered about whether I had stumbled upon something. I had no idea why there was a variation in stamping. I decided to do some digging online to see if I could get more information regarding this variation. The purpose of this article is to collate what I found in order to provide some guidelines on dating the older pipes and to differentiate between the two stampings.

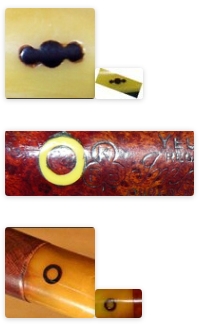

In the past when I had questions about KB&B pipes, Yello-Bole pipes and KW pipes I have found that the Kaywoodie Forum http://kaywoodie.myfreeforum.org/ftopic13-0-asc-0.php has been an invaluable source of information on the brand. The information found there on the KBB and KB&B pipes is very useful. Dave Whitney has an article on the topic of KBB pipes. I will summarize what I have found there to help with my search. I have several older Yello-Bole pipes with the shovel drinkless mechanism and the KBB-in-a-clover logo on the left side of the shank (not KB&B). These also have the yellow circle on the stem.

In the past when I had questions about KB&B pipes, Yello-Bole pipes and KW pipes I have found that the Kaywoodie Forum http://kaywoodie.myfreeforum.org/ftopic13-0-asc-0.php has been an invaluable source of information on the brand. The information found there on the KBB and KB&B pipes is very useful. Dave Whitney has an article on the topic of KBB pipes. I will summarize what I have found there to help with my search. I have several older Yello-Bole pipes with the shovel drinkless mechanism and the KBB-in-a-clover logo on the left side of the shank (not KB&B). These also have the yellow circle on the stem. From what I can ascertain from Dave’s information, pipes with this configuration seem to have been produced between the years of 1938-42. The lack of the aluminum stem ring and the drinkless mechanism that came out in the later period of KBB history 1945-50 (World War II) point to the earlier period. The shape/style of the drinkless mechanism helps to date the pipe. Let’s summarize what we know so far. The Kaywoodie stamp appeared in 1919 thus any pipes with the KB&B in a cloverleaf stamped on the shank pointed to a pre-1919 pipe. From 1919-1938 the combination of the KBB stamping and the shovel mechanism in the tenon help date those pipes. The metal drinkless attachment came out in 1945 and following. I have KB&B pipes and KBB Yello-Bole pipes from this early era.

From what I can ascertain from Dave’s information, pipes with this configuration seem to have been produced between the years of 1938-42. The lack of the aluminum stem ring and the drinkless mechanism that came out in the later period of KBB history 1945-50 (World War II) point to the earlier period. The shape/style of the drinkless mechanism helps to date the pipe. Let’s summarize what we know so far. The Kaywoodie stamp appeared in 1919 thus any pipes with the KB&B in a cloverleaf stamped on the shank pointed to a pre-1919 pipe. From 1919-1938 the combination of the KBB stamping and the shovel mechanism in the tenon help date those pipes. The metal drinkless attachment came out in 1945 and following. I have KB&B pipes and KBB Yello-Bole pipes from this early era.

Reading further led me to ascertain that the KBB in a cloverleaf stamp dates a pipe back to the ’30’s. I also learned that the 4 digit shape numbers stamped on the right side of the shank are older than 2 digit ones. The pipes with the logo inlaid on top of the stem are older than ones that have it on the side. I learned that in the past, Kaufman Brothers and Bondy would sort shipments of briar and send the culls to be used for Yello-Boles, meaning they got some quality briar. One fellow on the web believes that is why Yello-Bole pipes tend to be smaller over all, working around flaws. He also said that he thinks calling these pipes Kaywoodie seconds is a bit of a misnomer, being that Kaywoodie was one of the largest briar purchasers in the world at the time (’20’s-50’s) and got some fantastic wood.

Armed with this bit of information on the brand I did some more research and came across the SM Frank website http://www.smfrankcoinc.com/home/?page_id=2. There I found a wealth of historical information on Kaywoodies, Yello-Boles and the merger between KBB and SM Frank and later Demuth. It was a great read and I would encourage others to give the website a read. The information in the next paragraph was condensed from that site. I found confirmation for the statement above that the Yello-Bole line was an outlet for lower grade briar not used in Kaywoodie production. Yello-Bole’s were introduced in 1932 and manufactured by Penacook, New Hampshire subsidiary, The New England Briar Pipe Company. Advertising from the 1940′s, pictures the Yello-Bole “Honey Girl” and urges the pipe smoker to smoke the pipe with “a little honey in every bowl.” Honey was an ingredient of the material used to line the inside of the bowl. It was said to provide a faster, sweeter break-in of the pipe.

I went hunting further to see if I could find information on establishing dates for Yello-Bole pipes and found that there was not a lot of information other than what I had found above. Then I came across this link to the Kaywoodie Forum: http://kaywoodie.myfreeforum.org/archive/dating-yello-bole-pipes__o_t__t_86.html I quote the information I found there as it gives the only information that I found in my hunt to this point.

“OK so there isn’t a lot of dating information for Yello-Bole pipes but here is what I have learned so far.

– If it has the KBB stamped in the clover leaf it was made 1955 or earlier as they stopped the stamping after being acquired by S.M. Frank.

– From 1933-1936 they were stamped Honey Cured Briar.

– Pipes stems stamped with the propeller logo they were made in the 30s or 40s no propellers were used after the 40s.

– Yello-Bole also used a 4 digit code stamped on the pipe in the 30s.

– If the pipe had the Yello-Bole circle stamped on the shank it was made in the 30s this stopped after 1939.

– If the pipe was stamped BRUYERE rather than briar it was made in the 30s.

The pipes with propeller logos appear to be made in the 1930’s or 1940’s. The pipe with the yellow circle logo imprinted into the shank of the briar was made in the 1930’s. Those with the brass O seem also to have been made in the 1930’s.

The pipes with propeller logos appear to be made in the 1930’s or 1940’s. The pipe with the yellow circle logo imprinted into the shank of the briar was made in the 1930’s. Those with the brass O seem also to have been made in the 1930’s.

One further item was also found on that site. It was just a passing comment in the midst of some information on Kaywoodie pipes. I quote: “The pre-Kaywoodie KB&B pipes were marked on the shank with a cloverleaf around KB&B. Some early Kaywoodies had this same marking on the shank, but the practice was dropped sometime prior to 1936. Yello-Boles also had KBB in the leaf on the shanks, but did not have the ampersand found on Kaywoodies.” (Highlighting is mine)

That is all the information I have gathered to date. I don’t have anything on the multitude of stem stampings or any other age indicators. In summary, it seems that the stem logos, the stamping on the shanks of KBB and KB&B, the type of stinger apparatus in the tenon as well as aluminum decorative trim all are a part of dating the KBB and KB&B pipes. From the final paragraph above I have the answer to my question on the difference in the ampersand or lack of it – until 1936 the KBB and KB&B in a cloverleaf were stamped on the shanks of pipes made by Kaufman Brothers and Bondy. After 1936 that stamping disappeared and was replaced with the various Yello-Bole and Kaywoodie designation stampings. If anyone has more definitive information or other methods of determining date please feel free to post it in the comments below and I will add them to this piece.

If you would like to have a look at the KBB pipes that I have restored do a search on the blog for Kaufmann Brothers & Bondy, KBB, Yello-Bole and Kaywoodie pipes. The search will bring up quite a few of the pipes that I and other contributors to the blog have posted here.

ADDENDUM

I received two photos of the stinger apparatus that Andrew Selking removed from the KBB Doc Watson that he wrote about here. I am including them here. We both think that they predate the shovel like apparatus that I picture above.

Restoring a KB&B Doc Watson – Andrew Selking

Blog by Andrew Selking

My wife and I enjoy browsing antique shops and last weekend checked out a new shop. They didn’t have many pipes, most were worn out drug store pipes, but this one little pipe stood out. The first thing I notices was the fantail stem and interesting inlay on the stem. I picked it up and discovered that it was a rusticated panel billiard shape, unlike anything I’ve ever seen. I pulled the stem from the shank and saw a very unusual stinger/tube apparatus. The stem looked like it was hand cut, very thin and the button had nice clean angles. From what I found out about KB&B pipes, the clover leaf without the ampersand was from the 1930s. The best part was the price, $4.95! Here is what the pipe looked like, thick cake, but otherwise not too bad.