I was gifted a little Hardcastle Apple by a friend on Pipe Smokers Unlimited and a reader of the blog, Bill Tonge. It had the most unusual stem that I think I have ever seen on a pipe. In some ways it looked like a classic dental bit like those seen on other pipes. It had the higher curved upper edge of the button that worked to hang behind an upper plate and the grooves on the under and upper side of the stem for the plate to hook into. But that was all it had in common. The end of the stem, viewed from the button end had a single orific opening rather than a slot. It was a flat upright wall of vulcanite with a single hole in the middle. On the flat surface of the stem just ahead of the button was a large open area where it looked as if a piece of the vulcanite had broken or been removed. The airway was exposed. The gap between the dental end and the open end of the airway was a good ¼ inch. Both Bill and I were convinced it was a candidate for a stem replacement, cutback and reshaped button or as a guinea pig for me to practice on using Jacek’s stem splicing procedure.

I can’t tell you how many times I took it out of the repair box to have a look. I would turn it over in my hands and think about the three ways to repair what appeared to be damage. I even sketched out a splice on paper at work on my lunch hour. Then last evening I was looking it over thinking the time had come for the work. As I looked it over I noticed that everything was just too evenly cut. The grooves on the top and bottom did not line up. The top one made allowances for the open area. The open area was also very clean and regular. There were no jagged edges on the area. It was clearly cut that way on purpose. So before I started doing anything with the stem I decided to do a bit of digging.I have included some photos of the stem taken from two different Ebay sales of a Dental Briar Pipe. The first two are a top view of the stem and the last two are of the underside. These show the design of the stem and what I commented on above. The pipe on my table has exactly the same stem and stamping at the ones pictured below.

I looked it over and here is what I found. The pipe was stamped on the left side of the stem HARDCASTLE’S over DENTAL BRIAR over Reg. Design No.857327. On the right side it was stamped MADE IN LONDON ENGLAND. On the underside of the shank it is marked with the number 678, a shape number. Stamped on the vulcanite saddle stem is the Hardcastle’s H. The Reg. Design No. was a clue for me to start my hunt. (See the photo below of a pipe that is stamped identically to the one I have.)

I Googled for information on how to find out about a Registered Design Number. I figured that it would be like finding out patent information. One of the first links came up was to the National Archives. http://www.nationalarchives.gov.uk/records/research-guides/reg-design-trademark.htm I read through the various pages and put in the design number. I found that the designs having number beginning with 857,000 numbers come from 1949. This number was 857,327 so it was pretty clear to me that the design was registered in 1949. At least I had found that the pipe was a made during the time the Hardcastle family owned the brand. At first I thought the design was solely for the stem but when I removed the stem I found that it was far more than that. It included an inserted metal tube deep in the shank that rested against the airway in the bowl. It extended into the shank where it was met by a metal stinger like apparatus in the tenon. This apparatus was set in the tenon. It was a ball on the end of a short tube – the difference being that it was hollow. The end of the ball that rested against the tube in the shank was open thus connecting the airway in the bowl to the airway in the stem through a metal tube that gave a cool material to wick out the moisture in the smoke before it was delivered to the wide open end of the dental bit.

From there I went to the link for the British Intellectual Property Office. Now the problems arose for me. I could not find the Registered Design Number on that site. Nothing came back listed with that number on any British patent or registration sites. I was hoping to find at least a diagram of the pipe stem and internals as well as a patent/registration application. But there were none to be found on the sites. I wrote an email to the BIPO in hopes that they respond with some information. They wrote back saying that the design was too old and not in their records. They suggested the National Archives. I searched there again and could not access the files on this number. A dead end? Potentially but I would see if I could go at it from a different route.

I searched and read some of the history of the brand. One of the sites I turned to was Pipedia because I have found that they generally have good concise summaries of a particular brand or the lines in a brand. I found some helpful information on the different time periods of Hardcastle’s production. http://pipedia.org/index.php?title=hardcastle. I quote in part below:

“Hardcastle was founded in 1908 by Edmund Hardcastle and built itself a good reputation among the numerous British mid-graders. In 1935 Dunhill started to build a factory next door to Hardcastle in Forest Road, Walthamstow, London E17. The family owned Hardcastle Pipes Limited sold 49% of its equity to Dunhill in 1936.

Along with closing down its pipe factory in Notting Hill in 1946 Dunhill bought the remaining shares turning Hardcastle into a 100% Dunhill subsidiary. As members of the Hardcastle family continued as executives in the company’s management Hardcastle retained a certain independence.

This ended in 1967. Dunhill merged Hardcastle with Parker (100% Dunhill as well). The new Parker Hardcastle Limited also absorbed the former Masta Patent Pipe Company. Hardcastle’s Forest Road plant was immediately given up and the production of Hardcastle pipes was shifted to Parker’s nearby St. Andrews Road factory – now consequently called Parker-Hardcastle factory.

In fact this put a definite end to Hardcastle as an independent pipe brand and no one other than Edwin Hardcastle, the last of the family executives, spoke frankly and loudly of Hardcastle pipes being degenerated to an inferior Dunhill second. Today Hardcastle pipes use funneled down bowls that are not deemed suitable to bear the Dunhill or even the Parker name as well as obtaining briar from other sources.”

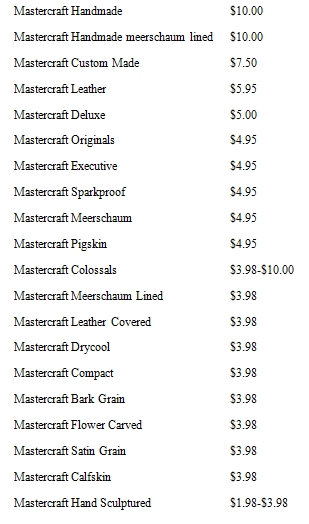

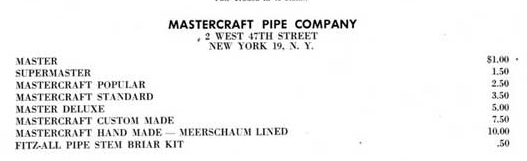

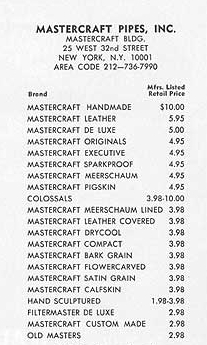

Now that I had a bit of a timeline for the brand it was time to see if I could find information on the various models & grades of Hardcastle pipes before the takeover by Dunhill – a time known as the Family Period. On the Pipedia site they listed that during that time the following models/lines were produced. Straight Grain, Supergrain, Leweard, Nut Bruyere, De Luxe, Royal Windsor Sandhewn, Royal Crown, The Crown, Phito Dental, Old Bruyere, Jack O’London, Dental Briar, Phito, Dental, Dryconomy, Drawel, Phithu, Telebirar, Camden, Lightweight, The Table, Dovetail, Dental, Crescent Extra, Lonsdale, Welard De Luxe . I have marked the Dental Briar in bold in the list above to make it stand out in the list. It was produced during this time. It appears that the Hardcastle was taken over by Dunhill in 1946. At that time, family still retained some control but the brand changed. In 1967 the brand was merged with Parker and became Parker/Hardcastle. With this merger Hardcastle as a distinct brand disappeared and the pipe became a line of seconds for Dunhill.

That information at least gives something of a timeline for my pipe. I know that it was made between the year that Registered Design Number gave of 1949 and the merger date of 1967. That is as close a date as I can ascertain at this time.

It seemed that I had found all I would find out about this pipe for the moment. It was time to work on the pipe itself and do the cleanup and restoration. I took the pipe to my worktable and quickly looked it over to see what I needed to address in this refurb. The bowl had an uneven cake in it – heavy in the middle and light at the top and the bottom of the bowl. The briar had several fills that had fallen out or somehow been dislodged along the way – one on the shank visible in the photo below next to the stem, one on the back side of the bowl and one on the bottom of the bowl. The rim was undamaged and quite clean other than a slight build up of tars and oils. The next series of three photos give a good picture of the state of the pipe when I began the work on it.

I removed the stem and cleaned out the shank and stem with pipe cleaners, cotton swabs and isopropyl alcohol. I scrubbed until they came out clean and unblemished. Then I reamed the bowl and wiped down the inside of the bowl with cotton swabs and alcohol and ran several more pipe cleaners through the shank to remove any carbon dust.

I cleaned out the damaged fills in the briar on the shank, back of the bowl and the bottom of the bowl with a dental pick. I wiped the bowl down with alcohol to clean off the dust and give the glue a clean surface to stick. I then packed briar dust into the crevices and dripped super glue onto the briar dust. I quickly put more briar dust on top of the glue before it dried. I have found that sandwiching the glue between briar dust enables the stain to have a better chance of taking on the patch.

I sanded the patches with 220 grit sandpaper, medium and fine grit sanding sponges and then with 1500-2400 grit micromesh sanding pads to smooth out the patches and blend them into the surface of the bowl.

When I had finished sanding the bowl I wiped it down with acetone to break down the finish and remove the waxes on the bowl to prepare it for restaining. When I do this kind of patches on a bowl I restain the entirety of the bowl rather than trying to match the stain in the spots to the whole.

I stained the bowl with a dark brown aniline stain. I heated the briar, applied the stain, flamed it and repeated the process to get a good solid, even coverage on the briar.

When it dried I wiped it down with a cotton pad and alcohol to lighten the stain and make the grain more visible.

At this point in the process I buffed the bowl and stem with red Tripoli and then White Diamond to even out the stain and make it flow better on the bowl. The briar dust and superglue patches blended in quite well on the bottom and back side of the bowl. The one on the shank was visible but at least it was smooth and dark. With some work on the finish I would be able to get it blend better.

I sanded the bowl with 1500-2400 grit micromesh pads to smooth out the finish and to lighten the stain on the bowl. I was aiming to bring it back as close as possible to the original finish which had red highlights. When I had finished sanding the bowl I gave it a second buff with White Diamond to see where I stood. At this point the work on the bowl was finished and I was pleased with the results. The grain showed clearly and the stain gave a pleasant contrast of dark and light. The patches looked much better and though visible blended in far better with the stain and the grain patterns. The rim and the inner bevel looked excellent.

Now it was time to address the stem. I scrubbed it down with Brebbia Pipe and Mouthpiece Polish. It has a fine grit in the paste and when it is rubbed into the stem works quite well to remove the surface oxidation and buildup. I worked it into the grooves and the dip on the end of the stem with a soft bristle tooth brush. I let it dry for a short time and then rubbed it down with cotton pads. The photos below show the stem after this initial polishing with the Brebbia Polish.

I scrubbed the stem with Meguiar’s Scratch X2.0 and when it dry buffed it off with a cotton pad. I repeated this process several times, scrubbing the grooves and dip on the end of the stem with the same tooth brush. I rubbed the stem down with Obsidian Oil and when dry took it the buffer for another buff with White Diamond. I gave it several coats of carnauba wax, buffing it with a soft flannel buff between coats. I found it very hard to remove some of the oxidation from the channels/grooves on the top and bottom of the stem. Under the flash it is clear that there is still some oxidation at that point. I rubbed it down with another coat of Obsidian Oil being careful to get deep into the edges of the grooves and the dip on the top of the stem.

The finished pipe is shown in the last series of photos below. I am happy with how this old timer turned out. I am so glad I did my research before cutting off the stem and recutting a new button or splicing in a new button. I would have ruined a unique piece of pipe history and lost the opportunity to learn yet another piece of the history of our fascinating hobby. Now instead it is a restored piece that shows the creativity of those seeking to create a more comfortable pipe. Now I have to load a bowl and give it a try.