This is yet another of the pipes from the lot of Vancouver Pipe Club pipes that I have been working on. This is not a brand that I have ever heard of and I cannot find any information on the web regarding it. If anyone reading this has any information on the brand please leave a comment and give us a few clues. The pipe is stamped on the left side of the shank Evident in script over Super in block print. On the right side of the shank it is stamped Old Briar. On the underside of the shank next to the stem it is stamped 760. The finish was covered with the standard varnish and the bowl coated with the black rubberized bowl coating. The rim was in very rough shape – the inner bevel was in good shape with minor nicks to it but the outer edge of the bowl had been hammered all around the top. There was also spillage from the bowl coating on the side of the bowl on the back and right side. The stem was clean other than some very minimal tooth chatter near the button. It seems to have a light stamp on the left side – the letters J.T.

I took some close up photos of the rim and edges of the bowl before and during the time I was topping it to give a clear picture of the damage that had been done to this pipe. The first photo below is a close up of the rim. It was an absolute mess and the edges of the bowl was hammered and broken.

I set up my topping board and sandpaper and began the process of topping the bowl. I took some photos after I first started to show clearly the edge damage.

I topped the bowl until the majority of the rim damage was gone. I then used a folded piece of sandpaper to re-bevel the inner edge of the rim. I used a sanding block to smooth out the rough edges that remained after topping the bowl. I decided that if I were to top the bowl to totally remove all of the damage it would change the profile too dramatically so I took the majority of the damage down and then lightly rounded the outer edge of the bowl with the sanding block.

I wiped the bowl down with acetone on cotton pads to remove the varnish, bowl coating spillage and old stain. I reamed the pipe with the PipNet reamer to remove the black bowl coating and cleaned up the inside of the bowl with some Everclear.

As mentioned before I have been using a MinWax Medium Walnut stain as it is quick and easy to use on these pipes that I am working through for the club. It does a great job, the colour matches the old original stain quite well and it is a simple application – rub on and off. Each successive coat adds depth and richness to the final colour.

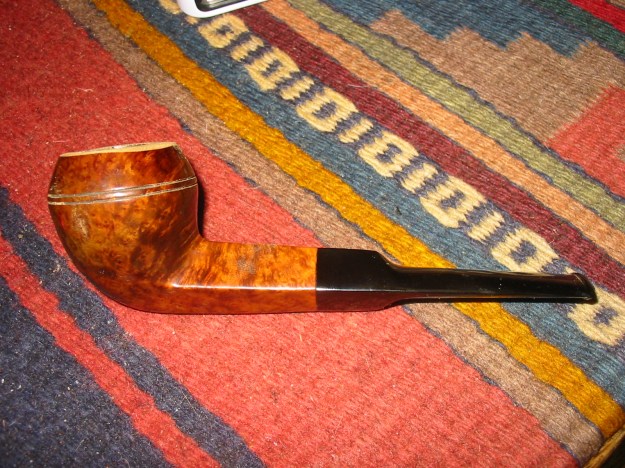

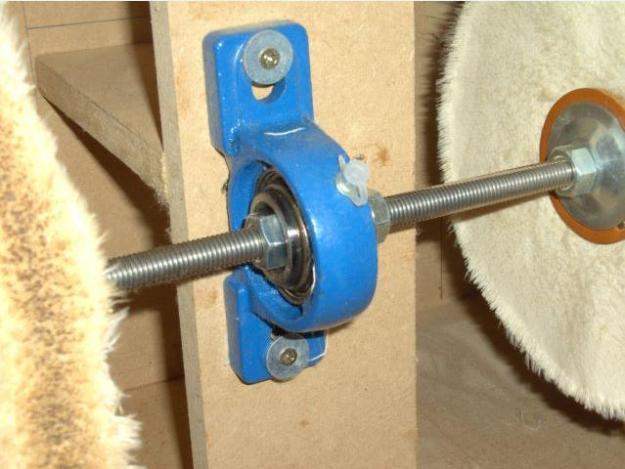

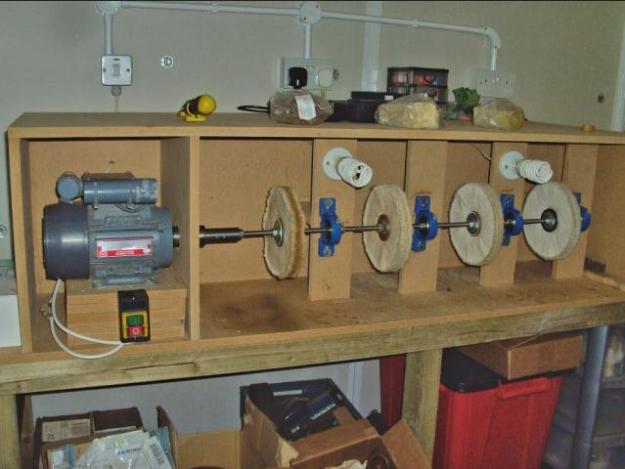

I sanded the tooth chatter on the stem to remove it and sanded it with micromesh sanding pads to polish the stem. I took the pipe to the buffer and buffed the bowl and stem with red Tripoli and then White Diamond. Once I had finished I rubbed the stem down with Obsidian Oil and rubbed it into the vulcanite. I buffed the stem and bowl one last time with White Diamond and then gave it multiple coats of carnauba wax. I finished with a soft flannel buff on the wheel. The finished pipe is shown in the photos below. It is ready to join the other finished pipes in the box of pipes for the Pipe Club. I look forward to seeing what they do with the lot.