Blog by Steve Laug

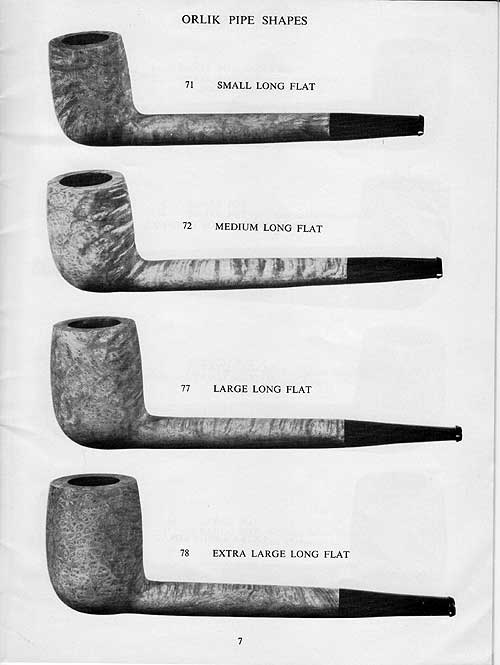

The pipe is stamped The in script over Guildhall over London Pipe on the left side of the shank and number 345 near the bowl on the right side of the shank and Made in London in a circle over England. This is the third of the pipes from the box my daughters found for me. The first two were the Orlik’s that I wrote about earlier. This one was in better condition than the other two. The top was beat up with outer and inner rim damage and also the same varnish coat over the uncleaned rim and the bowl and shank. The stem was original and has the three silver bars on the left side as expected in the Guildhall series. There were tooth dents that had been buffed out and left the stem with waves around the remaining marks. The grain was quite nice on this one – lots of cross grain and birdseye but it was obscured by the finish coat. The interior was filthy as were the others. In the side photos below the finish looks pretty good but the grain could stand out more clearly.

I took the next photo to show the damage on the rim. The inner edge was rough and the outer edge was also rough. There was tar build up under the varnish coat that had not been cleaned off before varnishing. The bowl was also coated with a black bowl coating.

I sanded the top and bottom side of the stem with 20 grit sandpaper to smooth out the ripples in the vulcanite and remove the remainder of the tooth marks. Once I had them removed I worked on the bowl.

I topped the bowl on the sandpaper and flat board as is my usual method. I took off enough briar to make the top smooth and the outer edge sharp as well. I sanded the inner edge with a folded piece of sandpaper to smooth out the damage there as well. The next two photos show the topping process and the sanding of the inner edge.

The interior of the shank and stem were filthy and needed a lot of work with Everclear, pipe cleaners and cotton swabs. The photo below shows the first lot that was used but by the time I was finished cleaning the shank I had used about twice that number.

I wiped down the surface of the bowl with acetone on cotton pads to remove the varnish coat and the finish. I wanted to remove as much of it as possible so that when I restained the rim it would be easier to match.

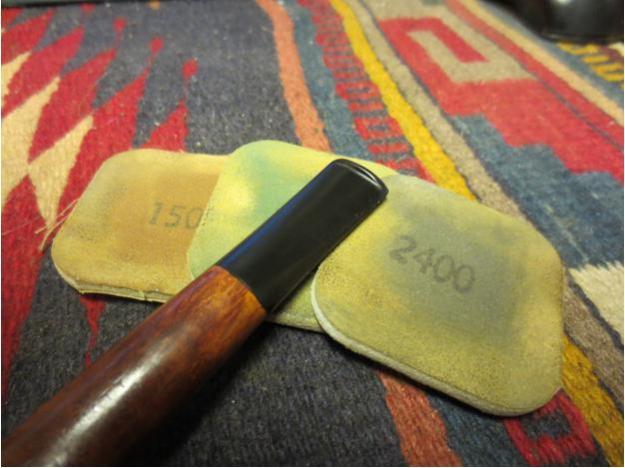

I sanded the stem with a medium grit sanding sponge and then with my usual array of micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12,000 grit pads. I buffed the stem in between the wet sanding and the dry sanding with red Tripoli because I wanted to see what I had to work with and if I had removed the rippling on the vulcanite. I had so I went on to the dry sanding. When I had finished I buffed the stem with White Diamond and then rubbed it down with Obsidian Oil and put it aside to dry.

I stained the bowl with MinWax Medium Walnut stain. I applied it with a cotton pad and rubbed it off with a cotton cloth. I repeated the process until I had the coverage that I wanted and the rim and bowl matched.

I reinserted the stem in the shank and took the pipe to the buffing wheel for a buff with White Diamond. I gave both the bowl and the stem multiple coats of carnauba wax and polished it with a soft flannel buff. The reworked Comoy’s Guildhall Stack is shown in the photos below ready and clean for its inaugural smoke.