Year ago now, I was visiting a lawn mower repairman who worked out of a shop in his back yard. I have a 30+ year old Snapper gas powered mower that works great and have had parts and gears that have broken or seized up. Joe always is able to get things back in tip top shape. It always starts with one pull of the cord. On one of my first visits to Joe he looked at what I needed and took me into his workshop. He reached up to a shelf that held many small bins and took down one that had several of the parts that I needed. He selected the one he wanted and within short order fixed my lawn mower. I asked him about the part bins and he said that he scavenges parts from where ever he can. He buys broken mowers and strips them down and buys parts whenever he can. He stock piles old parts – some of them are no longer are made so his bins are truly a treasure trove. Over the years I continue to go back to Joe and he keeps my old lawn mower running like a watch. He never has to go and buy parts because his bins hold much.

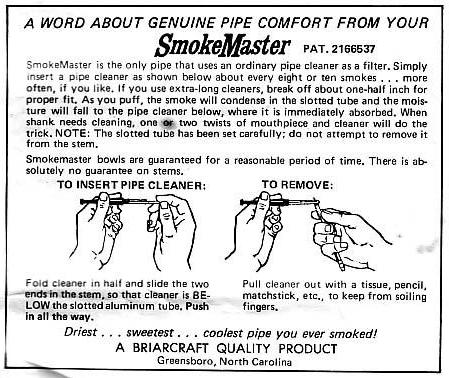

You might ask what that has to do with pipes and pipe refurbishing. Well in a very personal way it set the course of my pipe repair work. I have never forgotten Joe’s example with lawn mower parts. Since I don’t fix lawn mowers or motors I collect a totally different set of parts. I love refurbishing old pipes so I have started my own bins of pipe parts. I am looking forward to the day when I can set up a small shop of my own the yard where I can have the parts readily accessible when I am working on things. Until that time I collect the parts and store the bins in cupboards and drawers in the basement and laundry room. I have several bins of stems – old stock unused, scavenged used stems from broken pipes, new stem blanks in a variety of shapes and sizes. I buy stem blanks from Ebay and from Pipe Makers Emporium and new and used old stems where ever I find them. Currently I have them divided into a tin of round stems and a tin of different shaped stems. I also have bags of tenons, tins of stingers, a shelf of broken briar pieces and a box of bands of different sizes and shapes. I collect as many pipe parts as I can find from as many places as I find them.

If you were to follow me around on the hunt, you would see that I don’t just look for pipes that I can refurbish or collect. I also keep an eye out for pipes that can be cannibalized for parts. I find them in the pipe lots I buy on EBay (like the pictures below) – these often have extra stems, bands, broken pipes and parts that can be recycled and put to use again. (The photos below come from random EBay ads that are of the type that I usually bid on. There are a lot of redeemable parts in the lots below. I include them to give an idea of the things I look for.)

I email online estate pipe sellers and ask if they have old stock used stems that they want to sell. I literally look everywhere I can think of in the process of the hunt. I have stems and parts shipped from Denmark, Sweden, Germany, England, the US and Canada. I also scavenge for them. I pick up pipe parts at flea markets, antique shops, and thrift and rummage shops. Sometimes they are attached to beat up old pipes that are worthless and other times they are sitting in an old cigar box or tobacco tin. I bring them home and the stems and the old briar are kept for repurposing in my repairs.

When I find them in a shop of any kind I make an offer to the seller for the lot and have had success in picking up the parts at a good price. Both the seller and I are happy with the deal. But important to the process is to not just look for parts – any pipe can supply parts for you. I have bought chewed stems for the sole purpose of rescuing the logo from the stem. I have heated and removed metal tenons from stems, removed threaded parts from the tenons of broken pipes to use as replacements, removed stingers and labeled them for use in pipes that I come across that had stingers that were either broken or missing. I have also removed inserted logos from the shanks of broken pipes for reuse. I have also cut down broken stems, shortened them to fit and cut new buttons for them. I also pick up pipe bowls that can be cleaned up and restemmed. I have found some amazing old pipes that have been great smokers when repaired with a new stem. I rarely skip over bowls because I find that there are many uses for them. Worst case scenario – I have sold packages of bowls and stems for others to practice on.

There truly is no end to the parts you can strip off old pipes and very little that truly needs to be thrown away. I have found that most parts can be repurposed and used on other pipes in my repair work. Thus I always keep an eye on the minutiae of the pipes I am looking at – seeing them for the whole but also seeing the individual parts that can be reused. I never pass up buying parts and search regularly for them.

I am thankful to my lawn mower repairman Joe for giving me the vision to craft Rule #5. It has served me well and will be a part of the hunt for as long as I am hunting.