Blog by Paresh Deshpande

I had randomly selected four pipes to work on since I prefer to put a few pipe stems together in the “Before And After” Deoxidizer solution that has been developed by Mark Hoover. I have completed the restoration of one of these pipes, a Wally Frank “BLACKTHORNE” sandblast billiard.

The moment I had picked up this pipe, as had happened with the BLACKTHORNE, I thought this pipe to be a Family era Sasieni what with the two dots that peered back at me and the classic Bulldog shape. However, when I saw the stampings, again for the second time on the trot it turned out to be a US brand. The smooth briar, shape and quality of the stem all oozed high quality.

The pipe is a Bulldog with a diamond shank and a straight diamond saddle stem. It is a medium sized pipe with a nice hand feel and the light weight makes it easy for clenching. This pipe is stamped on the upper left smooth surface of the shank as “WALLY FRANK” over “LTD” and on the upper right shank surface as “NATURAL UNVARNISHED” over “IMPORTED BRIAR”, all in block capital letters. The stampings appear faint due to accumulation of dirt and grime over the surface. The high quality vulcanite diamond saddle stem has two Blue Dots.  I had read about Wally Frank, while researching a Wally Frank Blackthorne, as being an old Tobacconist from around New York City in US who also sold English made pipes under his name since 1930s. The NATURAL UNVARNISHED was one of the lines/styles of pipes that was offered by Wally Frank. For the readers who wish to acquaint themselves with the Tobacconist and the brand, given below is the link to the write up on pipedia.org.

I had read about Wally Frank, while researching a Wally Frank Blackthorne, as being an old Tobacconist from around New York City in US who also sold English made pipes under his name since 1930s. The NATURAL UNVARNISHED was one of the lines/styles of pipes that was offered by Wally Frank. For the readers who wish to acquaint themselves with the Tobacconist and the brand, given below is the link to the write up on pipedia.org.

https://pipedia.org/wiki/Wally_Frank

To unravel the mystery of the two dots, I searched the internet and came across a forum Pipe Smokers Dens where there was thread on Wally Frank. Here is the link to the discussion;

https://pipesmokersdens.com/threads/show-us-your-wally-franks.3139/page-2

I reproduce the relevant part of the discussion which references the TWO DOTs seen on my pipe that makes for an interesting read.

No, it’s just a standard push tenon. It’s a “Wally Frank Limited” & “Made in England”. I never delved too deep into who in England made pipes for them, but if I recall correctly, Sasieni and Charatan supplied them with pipes over the years. Regardless, this was a good buy. Some beautiful grain without a single fill. It’s a nice, classically shaped pipe.

Piffyr Replied

Comoy was their primary British supplier. If the pipe has a shape number, it likely matches the Comoy chart. They also bought pipes from Charatan and (maybe/likely) GBD. Also, a few smaller manufacturers in England that are mostly forgotten today. I think the Sasieni thing started because of the pale blue dots used on the Natural Unvarnished stems coupled with some wishful thinking, but it doesn’t hold up. The pipes aren’t COM stamped and the shapes don’t match. Sometimes, a pale blue dot is just a pale blue dot.

I have not been able to accurately pinpoint the period that this pipe was made in, so any assistance in this regard is welcome and highly appreciated.

Initial Visual Inspection

This pipe has the classic Bulldog shape with the rim cap separated from the rest of the stummel by two rings. The stummel boasts of some beautiful flame and cross grains all over the bowl and shank and is covered in dirt and grime of the overflowed lava. There is not a single fill in the briar which speaks of high quality selection of the briar. There is a decent layer of cake in the chamber. The stem is heavily oxidized with a few deep bite marks in the bite zone. Here is how the pipe appears as it sits on my work table.

Detailed Inspection Of The Pipe And Observations

Detailed Inspection Of The Pipe And Observations

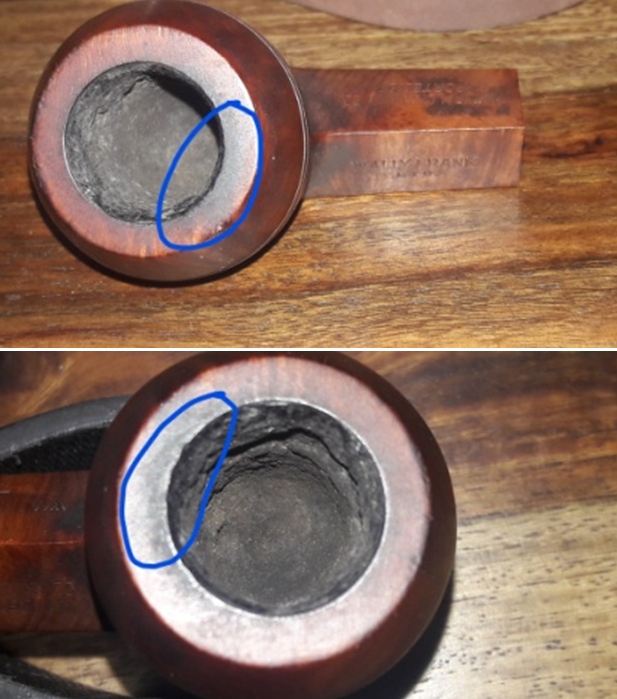

The bowl is in perfect round with a decently wide rim and a depth of about 1 7/8 inches. The chamber has an uneven layer of thick cake. The smooth rim top surface is covered in lava overflow and dirt and grime from previous usage and subsequent storage. The maximum deposition of lava is seen in the 6 o’clock direction (enclosed in blue circle). The inner rim appears to be in pristine condition and the outer rim has suffered a few blows on a hard surface resulting in a few minor chipped edge surfaces. The condition of the inner walls of the chamber can be commented upon after the cake has been taken down to the bare briar. The draught hole is dead center and at the bottom of the chamber and that makes me believe that it should great smoke and the thick cake in the chamber lends credence to this observation. The stummel appears solid to the touch all around and hence I do not foresee any serious damage to the walls in the form of burnout/ deep heat fissures/ lines or pits. The darkened inner rim edge may present a surprise in the form of charred rim edge making the chamber out of round.

The smooth stummel surface has taken on a layer of aged patina, through which one can make out the beautiful flame grains all around interspersed with tightly packed cross grains. There are a few minor dents and dings on the lower edge of the diamond shank, probably due to likely falls and or rubbing against other pipes while being stored for more than 40 years. However, there is not a single fill in the entire stummel, signifying very high quality of briar used in carving this pipe. The two rings demarcating the rim cap is intact and the grooves are filled with grime and dust. The briar is looking lifeless and bone dry and has taken on dirty grey hues. I need to be careful while cleaning the paneled shank surfaces to preserve the stampings on this pipe. Thorough cleaning and rising under warm water of the stummel surface should highlight the grain patterns while preserving the patina. In all probability, I shall let these minor dents and dings to the lower edge of the shank remain and avoid the process of sanding the stummel with sand paper in order to preserve the beautiful patina. Maybe, micromesh polishing will address a few of these dents and scratches to some extent.

The smooth stummel surface has taken on a layer of aged patina, through which one can make out the beautiful flame grains all around interspersed with tightly packed cross grains. There are a few minor dents and dings on the lower edge of the diamond shank, probably due to likely falls and or rubbing against other pipes while being stored for more than 40 years. However, there is not a single fill in the entire stummel, signifying very high quality of briar used in carving this pipe. The two rings demarcating the rim cap is intact and the grooves are filled with grime and dust. The briar is looking lifeless and bone dry and has taken on dirty grey hues. I need to be careful while cleaning the paneled shank surfaces to preserve the stampings on this pipe. Thorough cleaning and rising under warm water of the stummel surface should highlight the grain patterns while preserving the patina. In all probability, I shall let these minor dents and dings to the lower edge of the shank remain and avoid the process of sanding the stummel with sand paper in order to preserve the beautiful patina. Maybe, micromesh polishing will address a few of these dents and scratches to some extent.

The mortise shows accumulation of oils, tars and gunk and the air flow is not full and smooth.

The mortise shows accumulation of oils, tars and gunk and the air flow is not full and smooth.  The high quality vulcanite diamond saddle stem is so heavily oxidized that it appears brownish green in color! It is evident that the pipe was used with a softie rubber bite as can be seen from the difference between the area covered by the rubber bite and rest of the stem surface. Some minor tooth chatter and one deep gouge mark is seen on the lower surface of the stem. There are a couple of not very deep bite marks on the upper stem surface. This issue should not be a major headache to address. The lip edge on both sides is in good shape requiring nothing more than minor reshaping. The tenon has accumulated ash and oils/ tars that have dried out on the inside as well as on the outside. The horizontal slot has grime deposits which will have to be cleaned. The tooth chatter and the bite marks will be raised to the surface by heating and the deeper tooth indentations will be filled using charcoal and CA superglue mix.

The high quality vulcanite diamond saddle stem is so heavily oxidized that it appears brownish green in color! It is evident that the pipe was used with a softie rubber bite as can be seen from the difference between the area covered by the rubber bite and rest of the stem surface. Some minor tooth chatter and one deep gouge mark is seen on the lower surface of the stem. There are a couple of not very deep bite marks on the upper stem surface. This issue should not be a major headache to address. The lip edge on both sides is in good shape requiring nothing more than minor reshaping. The tenon has accumulated ash and oils/ tars that have dried out on the inside as well as on the outside. The horizontal slot has grime deposits which will have to be cleaned. The tooth chatter and the bite marks will be raised to the surface by heating and the deeper tooth indentations will be filled using charcoal and CA superglue mix.

The Process

The Process

I started the restoration of this pipe by first cleaning the internals of the stem with bristled pipe cleaners and 99.9% pure isopropyl alcohol. I scraped out the dried oils and tars from the tenon end with my fabricated knife and also removed the dried oils and tars from the slot end. I followed it up by sanding the entire stem with a folded piece of 220 grit sand paper to remove the surface oxidation. It has been our (Abha, my wife and self) experience that sanding a stem before dunking it in to the deoxidizer solution helps in bringing the deep seated oxidation to the surface which in turn make further cleaning a breeze with fantastic result.  I dropped the stem in to “Before and After Deoxidizer” solution developed by my friend Mark Hoover. The solution helps to draw out heavy oxidation to the surface, making its further removal a breeze, while the minor oxidation is eliminated to a very great extent. The initial sanding helps to draw out the complete oxidation as the sanding opens up the stem surface that has been initially covered with oxidation. I usually dunk stems of 4-5 pipes that are in-line for restoration and this pipe is marked in yellow arrow. I generally allow the stems to soak in this solution overnight to do its work.

I dropped the stem in to “Before and After Deoxidizer” solution developed by my friend Mark Hoover. The solution helps to draw out heavy oxidation to the surface, making its further removal a breeze, while the minor oxidation is eliminated to a very great extent. The initial sanding helps to draw out the complete oxidation as the sanding opens up the stem surface that has been initially covered with oxidation. I usually dunk stems of 4-5 pipes that are in-line for restoration and this pipe is marked in yellow arrow. I generally allow the stems to soak in this solution overnight to do its work. While the stem was soaking in the deoxidizer solution, I worked on the stummel by first reaming the chamber with size 1 and 2 Castleford reamer heads. I further scraped the chamber walls with my fabricated knife to remove the remaining carbon deposits. I scraped out the lava overflow from the rim top surface, especially from the area in the 6 o’clock direction. Once the cake was reamed back to the bare briar, I used a 150 grit sand paper followed by 220 grit sand paper to remove all the traces of remaining cake and also to smooth out the inner walls of the chamber surface. Finally, to remove the residual carbon dust, I wiped the chamber with a cotton pad wetted with 99.9% pure isopropyl alcohol. The chamber walls are sans any damage. There are a couple of minor chips to the inner edge of the inner rim which revealed themselves after the lava overflow was removed from the rim top in 7 o’clock direction. Thankfully the inner rim was not charred under the lava overflow. The ghost smells are negligible and may further reduce after the shank/ mortise are thoroughly cleaned.

While the stem was soaking in the deoxidizer solution, I worked on the stummel by first reaming the chamber with size 1 and 2 Castleford reamer heads. I further scraped the chamber walls with my fabricated knife to remove the remaining carbon deposits. I scraped out the lava overflow from the rim top surface, especially from the area in the 6 o’clock direction. Once the cake was reamed back to the bare briar, I used a 150 grit sand paper followed by 220 grit sand paper to remove all the traces of remaining cake and also to smooth out the inner walls of the chamber surface. Finally, to remove the residual carbon dust, I wiped the chamber with a cotton pad wetted with 99.9% pure isopropyl alcohol. The chamber walls are sans any damage. There are a couple of minor chips to the inner edge of the inner rim which revealed themselves after the lava overflow was removed from the rim top in 7 o’clock direction. Thankfully the inner rim was not charred under the lava overflow. The ghost smells are negligible and may further reduce after the shank/ mortise are thoroughly cleaned.

This was followed by cleaning the mortise with q-tips, pipe cleaners and shank brush dipped in isopropyl alcohol. I scraped the walls of the mortise with my fabricated knife to remove the dried oils and tars. I was surprised to find the shank a bit cleaner than I had anticipated from my detailed inspection. The ghost smells are history and the chamber now smells clean.

This was followed by cleaning the mortise with q-tips, pipe cleaners and shank brush dipped in isopropyl alcohol. I scraped the walls of the mortise with my fabricated knife to remove the dried oils and tars. I was surprised to find the shank a bit cleaner than I had anticipated from my detailed inspection. The ghost smells are history and the chamber now smells clean. With the bowl internals clean, I move to clean the exterior of the stummel. I used a hard bristled tooth brush and Murphy’s Oil soap to scrub the stummel and rim top. For this stummel cleaning, l I used Murphy’s Oil soap as I wanted to preserve the old patina that had developed on the stummel and was not sure how the Briar cleaner product would affect it. After the scrub with oil soap, I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth. I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. The stummel surface has cleaned up nicely with the beautiful grain patterns on full display.

With the bowl internals clean, I move to clean the exterior of the stummel. I used a hard bristled tooth brush and Murphy’s Oil soap to scrub the stummel and rim top. For this stummel cleaning, l I used Murphy’s Oil soap as I wanted to preserve the old patina that had developed on the stummel and was not sure how the Briar cleaner product would affect it. After the scrub with oil soap, I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth. I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. The stummel surface has cleaned up nicely with the beautiful grain patterns on full display.

While the stummel was drying, the next morning, Abha removed the stems (stem indicated with yellow arrow is the one being worked on) that had been soaking in the deoxidizer solution overnight. She cleaned the stem and the stem airway under running warm water and scrubbed the raised oxidation from the stem surface using a Scotch Brite pad and the airway with a thin shank brush. She further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little EVO to rehydrate the stem. This now gives a clearer picture of the extent of depth of the bite marks as can be seen in the pictures below. These will definitely require a fill. The oxidation is deep and stubborn and can be seen over the stem surface and in the concave of the diamond shape, as dirty green coloration. I need to further sand the stem to completely remove the oxidation.

While the stummel was drying, the next morning, Abha removed the stems (stem indicated with yellow arrow is the one being worked on) that had been soaking in the deoxidizer solution overnight. She cleaned the stem and the stem airway under running warm water and scrubbed the raised oxidation from the stem surface using a Scotch Brite pad and the airway with a thin shank brush. She further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little EVO to rehydrate the stem. This now gives a clearer picture of the extent of depth of the bite marks as can be seen in the pictures below. These will definitely require a fill. The oxidation is deep and stubborn and can be seen over the stem surface and in the concave of the diamond shape, as dirty green coloration. I need to further sand the stem to completely remove the oxidation. I used a 220 grit sand paper to sand the stem and remove all the oxidation that was raised to the surface. This step further reduced the tooth chatter and bite marks present on the stem. I wiped the stem with Murphy’s Oil soap on a cotton swab. This helps in cleaning the stem surface while removing the loosened oxidation. Using a lighter, I flamed the surface of the stem. This helped in raising some of the tooth chatter and bite marks to the surface as vulcanite has a property to regain its original shape on heating. The remaining tooth chatter and bite marks would be addressed subsequently.

I used a 220 grit sand paper to sand the stem and remove all the oxidation that was raised to the surface. This step further reduced the tooth chatter and bite marks present on the stem. I wiped the stem with Murphy’s Oil soap on a cotton swab. This helps in cleaning the stem surface while removing the loosened oxidation. Using a lighter, I flamed the surface of the stem. This helped in raising some of the tooth chatter and bite marks to the surface as vulcanite has a property to regain its original shape on heating. The remaining tooth chatter and bite marks would be addressed subsequently. I addressed the deeper tooth chatter and bite marks by filling them up with a mix of activated charcoal and CA superglue. Once I had applied the mix, I set it aside to cure overnight. Once the fill has hardened, I shall file and sand the fills to match the surface of the stem and sharpen the button edges on either surface.

I addressed the deeper tooth chatter and bite marks by filling them up with a mix of activated charcoal and CA superglue. Once I had applied the mix, I set it aside to cure overnight. Once the fill has hardened, I shall file and sand the fills to match the surface of the stem and sharpen the button edges on either surface. With the fills in the stem set aside to cure, I turned my attention back to the stummel. The minor dents to the lower edge of the diamond shank was bothering me as I wanted it to be as pristine as was possible. I decided to sand it down with a higher grade sandpaper. With a folded piece of 600 grit sandpaper I sand dents along the either sides of the shank edge till the dents are not easily discernible. I followed it by wet sanding the stummel with 1500 to 12000 grit micromesh pads, wiping frequently with a moist cloth to check the progress. I really like the looks of the stummel at this point in restoration. The grains and the clean lines of this piece of briar is really appreciable.

With the fills in the stem set aside to cure, I turned my attention back to the stummel. The minor dents to the lower edge of the diamond shank was bothering me as I wanted it to be as pristine as was possible. I decided to sand it down with a higher grade sandpaper. With a folded piece of 600 grit sandpaper I sand dents along the either sides of the shank edge till the dents are not easily discernible. I followed it by wet sanding the stummel with 1500 to 12000 grit micromesh pads, wiping frequently with a moist cloth to check the progress. I really like the looks of the stummel at this point in restoration. The grains and the clean lines of this piece of briar is really appreciable.

Next, I rubbed a small quantity of “Before and After Restoration Balm” deep in to the briar with my finger tips and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful grain patterns displayed in their complete splendor. I further buffed it with a horse hair brush. The contrast of the dark browns of the flame and cross grains with the natural unvarnished finish of the rest of the stummel adds an interesting dimension to the appearance of the stummel which may be insufficiently described in words and be rather seen in person.

Next, I rubbed a small quantity of “Before and After Restoration Balm” deep in to the briar with my finger tips and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful grain patterns displayed in their complete splendor. I further buffed it with a horse hair brush. The contrast of the dark browns of the flame and cross grains with the natural unvarnished finish of the rest of the stummel adds an interesting dimension to the appearance of the stummel which may be insufficiently described in words and be rather seen in person.

With the stummel rejuvenation almost complete, save for the final wax polish, I worked the stem. The fill had cured and with a flat head needle file, I worked on the filling till I had achieved a rough match with the surrounding surface and had sufficiently sharpened the button edges. For a better blending, I further sand the entire stem with 220 followed by 400, 600 and 800 grit sand paper. This helps to reduce the scratch marks left behind by the more abrasive 220 grit paper. To bring a deep shine to the vulcanite stem, I went through the complete set of micromesh pads, wet sanding with 1500 to 2000 grit sandpapers followed by further wet sanding with 3200 to 12000 grit pads. I wiped the stem with moist cloth after each pad and rubbed it down with Extra Virgin Olive oil to rejuvenate the vulcanite. The finished stem is shown below.

With the stummel rejuvenation almost complete, save for the final wax polish, I worked the stem. The fill had cured and with a flat head needle file, I worked on the filling till I had achieved a rough match with the surrounding surface and had sufficiently sharpened the button edges. For a better blending, I further sand the entire stem with 220 followed by 400, 600 and 800 grit sand paper. This helps to reduce the scratch marks left behind by the more abrasive 220 grit paper. To bring a deep shine to the vulcanite stem, I went through the complete set of micromesh pads, wet sanding with 1500 to 2000 grit sandpapers followed by further wet sanding with 3200 to 12000 grit pads. I wiped the stem with moist cloth after each pad and rubbed it down with Extra Virgin Olive oil to rejuvenate the vulcanite. The finished stem is shown below.

I have now reached the homestretch in this restoration project. To complete the restoration, I mount a cotton cloth buffing wheel on to my hand held rotary tool and polished the stummel and stem with Blue Diamond compound. This compound helps to remove the minor scratch marks that remain from the sanding. I mounted another cotton buffing wheel that I have earmarked for carnauba wax and applied several coats of the wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks amazingly beautiful and is ready to join my collection. I only wish it could share with me its life story of the past years while I enjoy smoking my favorite Virginia blend in it or maybe an English blend or maybe just keep admiring it!! The finished pipe is as shown below.

I have now reached the homestretch in this restoration project. To complete the restoration, I mount a cotton cloth buffing wheel on to my hand held rotary tool and polished the stummel and stem with Blue Diamond compound. This compound helps to remove the minor scratch marks that remain from the sanding. I mounted another cotton buffing wheel that I have earmarked for carnauba wax and applied several coats of the wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks amazingly beautiful and is ready to join my collection. I only wish it could share with me its life story of the past years while I enjoy smoking my favorite Virginia blend in it or maybe an English blend or maybe just keep admiring it!! The finished pipe is as shown below.

P.S. As I was working this pipe, a fleeting question “Why do I enjoy bringing these old battered and discarded pipes back to life?” crossed my mind…

P.S. As I was working this pipe, a fleeting question “Why do I enjoy bringing these old battered and discarded pipes back to life?” crossed my mind…

I wish to thank each one for sparing their valuable time to read through this write up and each one is my prayers. Stay home…stay safe!!