Blog by Dal Stanton

This pipe represents the 7th of 8 pipes that Jen rescued from my ‘Help Me!’ baskets. She’s leaving Bulgaria very soon returning to the US after working with us for a few years. She is not returning without gifts! She has chosen a trove of pipes that have garnered her attention to give as gifts to the men in her family. Each of these gifts has the added benefit of helping the Daughters of Bulgaria, our work here in Bulgaria with women and girls who have been sexually exploited and trafficked in Europe. My love of restoring pipes as The Pipe Steward is a way of shining a light on the tragedy of those caught in this modern-day slavery.

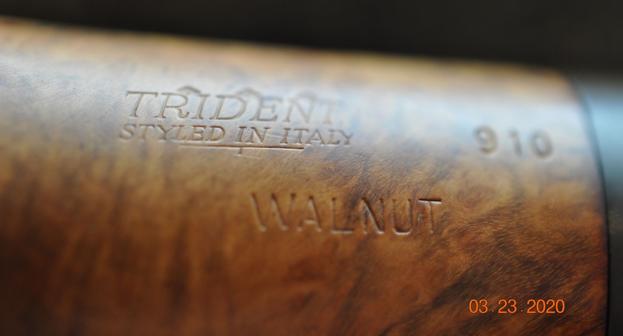

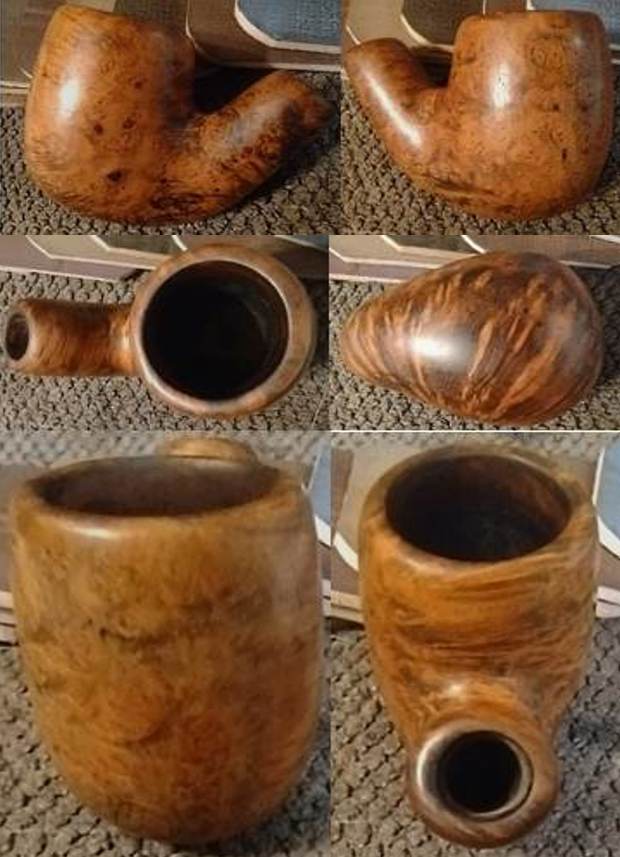

The ¾ Bent Billiard got Jen’s attention I believe, because of the blasted finish. The only stamping is under the shank and it is marked, “TRIDENT”. However, when I saw this pipe from an eBay seller in the UK, my attention was drawn also to the old-style P-Lip military stem and the old vintage feel of the pipe overall. Here’s what I saw on eBay UK: This seller had other offerings which I also placed bids to take advantage of combined shipping from UK to Bulgaria. With the Trident, I added a Hardcastle ‘Deluxe’ No. 12, and a Bewlay ‘The General’ to my basket for restoration. Now, on my work table on the 10th floor apartment of a formerly Communist apartment block, I look at the Trident with the question, ‘Is this pipe actually vintage old or does it just look old?’ I take more pictures to fill in the gap.

This seller had other offerings which I also placed bids to take advantage of combined shipping from UK to Bulgaria. With the Trident, I added a Hardcastle ‘Deluxe’ No. 12, and a Bewlay ‘The General’ to my basket for restoration. Now, on my work table on the 10th floor apartment of a formerly Communist apartment block, I look at the Trident with the question, ‘Is this pipe actually vintage old or does it just look old?’ I take more pictures to fill in the gap.

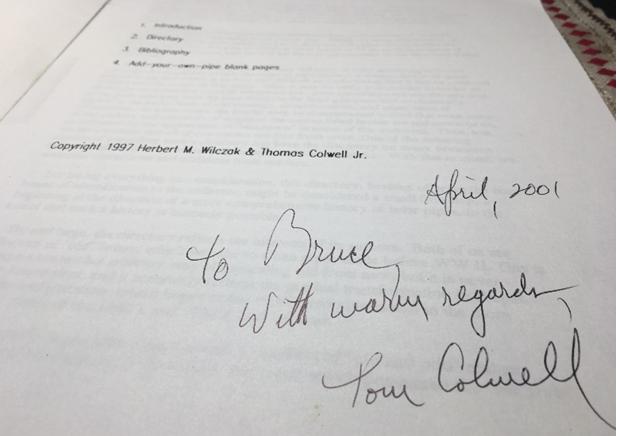

My first action was to look in my autographed copy of my eBay acquired copy of, ‘Who Made That Pipe?’ by Herb Wilczak & Tom Colwell. It’s not autographed to me, but still cool!

My first action was to look in my autographed copy of my eBay acquired copy of, ‘Who Made That Pipe?’ by Herb Wilczak & Tom Colwell. It’s not autographed to me, but still cool! In ‘WMTP?’ the name ‘TRIDENT’ was associated with two names, ‘E Deguingand & Son/ H. Comoy’. Country of origin, ENGL. First looking at Pipedia’s article on Comoy’s, I discover that ‘Trident’ is a second made by Comoy’s – one among many! Looking at PipePhil.eu, I found an example of this Comoy second which still displayed the ‘Comoy’s’ stamping and nomenclature. The Trident before me carries no other markings and for this reason, I’m dubious of it being from the Comoy’s line of seconds.

In ‘WMTP?’ the name ‘TRIDENT’ was associated with two names, ‘E Deguingand & Son/ H. Comoy’. Country of origin, ENGL. First looking at Pipedia’s article on Comoy’s, I discover that ‘Trident’ is a second made by Comoy’s – one among many! Looking at PipePhil.eu, I found an example of this Comoy second which still displayed the ‘Comoy’s’ stamping and nomenclature. The Trident before me carries no other markings and for this reason, I’m dubious of it being from the Comoy’s line of seconds. Then I turn to ‘E Deguingand & Son’ to see what I can find. Pipedia has a helpful article that collates information about the name.

Then I turn to ‘E Deguingand & Son’ to see what I can find. Pipedia has a helpful article that collates information about the name.

Deguingand & Son

Emile Deguingand & Son, Ltd. was a briar pipe maker in London at the end of the 19th and beginning of the 20th centuries. Originally they manufactured pipes in London, on Hamsell Street in Cripplegate, but that entire area was destroyed in the fire of 1897. Deguingand began selling at 5 Colonial Avenue, Minories, East London beginning in 1897. That same year Emile Deguingand purchased a pipe factory built by Charles Cayron in 1885 and 1886 at a place called Sur les Etapes in St. Claude, France. The factory in St. Claude was raised and enlarged in 1900 and 1902.

In 1906 Deguingand was granted a patent in France for a pipe consisting of a removable combustion chamber over a lower chamber filled with asbestos into which the airway ran.

In 1910, E. Deguingand & Son, known in France as E. Deguingand et Fils, became S.A. des anciens Etablissements Deguingand et Fils with Francis and Paul Deguingand’s entry into the business. While the plant doubled in size in approximately 1926, it was closed around 1930 and later converted to a commercial warehouse.

One pipe line known to have been sold by Deguingand was the Trident.

The last line is interesting in terms of the exclusivity it seems to imply. The article is helpful but leaves out much and creates more questions. When Deguingand opened operation in St. Claude, France, 1897, the same year opening another location in London after the fire of 1897, the assumption I believe, that is true, is that operations continued in both London and St. Claude under the Deguingand name. The indication is that the operation in France closed in 1930, but there is no indication that operation in London ceased as well. The challenge I am left with is that I can find precious little about production of Deguingand pipes or ‘Trident’ through the 1900s other than this early century reference by Pipedia. If theories can be developed from silence, the E. Deguingand & Son Company is NOT listed in the 1949 Tobacco Retailers’ Almanac found at Chris’ Pipe Pages. Can one deduce from this that pipes were no longer produced under the name?

The only other finding in my research that sheds some light on the E. Deguingand & Son name, comes from ‘Company Search Made Simple’ website. Here I find that E. Deguingand & Sons was incorporated, at least as an English entity, 3/12/1912, and was dissolved 7/30/1996. The address was listed as 20 VANGUARD WAY, SHOEBURYNESS, SOUTHEND ON SEA, ESSEX, SS3 9RA. The Director of the corporation was listed a John James Adler, from 8/1/1991 to 7/30/1996 – the same date as the dissolution of the corporation. Of interest to me, but probably not a surprise for others more informed (!), was when I was trolling around the corporate bones of the corporate umbrellas created to manage sales and acquisitions of pipe names in much of pipedom in England and France – I discovered, Cadogan. On this site, I compiled this list of well-known names in the pipe world that were started at different times, but all were, 1) dissolved on the same date (7/30/1996, with the exception of Kaywoodie, a few weeks later), 2) who shared the same address (Southend On The Sea) and, 3) had the same Director. Here’s the list I compiled. What this tells me is that E. Deguingand & Son, Limited, existed at least as a corporate entity in the Cadogan consortium until 1996, but I have no indication that pipes were produced under the corporate name from the 1930s to 1996. I’m growing in my understanding of the name, but is the Trident before me of a vintage that dates to the early 1900s? I’m not sure, but one thing about the Trident that creates question – Does the P-Lip Military style stem help place this pipe? It looks older to me, but my question lingers.

What this tells me is that E. Deguingand & Son, Limited, existed at least as a corporate entity in the Cadogan consortium until 1996, but I have no indication that pipes were produced under the corporate name from the 1930s to 1996. I’m growing in my understanding of the name, but is the Trident before me of a vintage that dates to the early 1900s? I’m not sure, but one thing about the Trident that creates question – Does the P-Lip Military style stem help place this pipe? It looks older to me, but my question lingers.

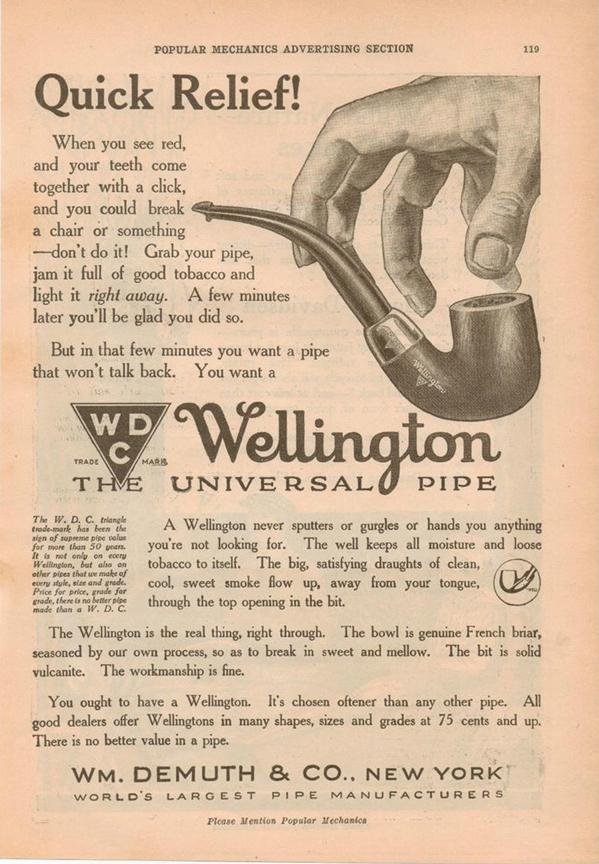

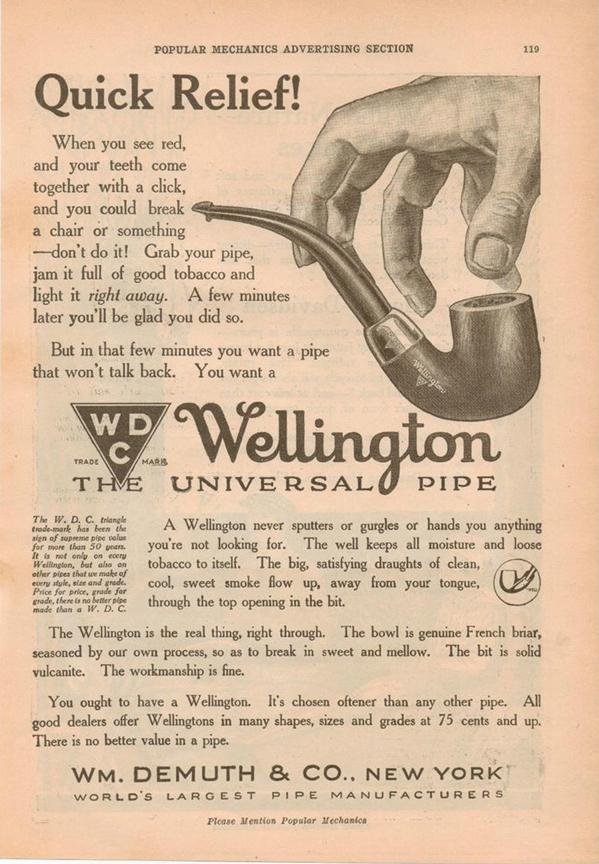

When the well runs dry in my research, I send questions to Steve to help prime the pump. I share with him some of the research related above and some pictures of the Trident, but my specific question is, “Can a P-Lip stem indicate the age of a pipe – or contribute to its age placement?” Steve’s first response was helpful in clueing me into the probability that the Trident before me could very well be of an early 1900s vintage. His response was: “It looks a lot like the Wellington that WDC made in the early 1910-1920s.” It was not difficult to find these artifacts in Pipedia’s article about the William Demuth Co. and the WDC Wellington – a WDC mainstay over the years.

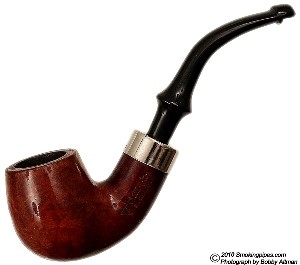

With the uncannily similar Wellington pictured above, courtesy of Doug Valitchka from Pipedia, the Trident lookalike before me could very well be of an early century vintage and a product of E. Deguingand & Son, Limited.

With the uncannily similar Wellington pictured above, courtesy of Doug Valitchka from Pipedia, the Trident lookalike before me could very well be of an early century vintage and a product of E. Deguingand & Son, Limited.

My second inquiry to Steve was how it all worked. Did WDC make pipes (Wellington styled) for E. Deguingand and E. Deguingand marked them with ‘Trident’ though made by WDC? Steve’s next response was even more to point questioning the accuracy of attributing the Trident to E. Deguingand. He said,

I wonder if the E. Deguingand is correct. I wonder if WDC in NYC did not make a Trident pipe. I would do some digging in old WDC catalogues and see if you can’t find it. It has the same style band, same style faux p-lip with the air hole in the end of the button rather than on top. WDC did that I think to avoid issues with Peterson.

I did as Steve recommended and looked at several old WDC catalogs I could find online. One forum was helpful in providing a WDC Master List. Unfortunately, no ‘Trident’ listing was evident there or anywhere else I looked indicating a William Demuth Company source. I come up empty finding a direct connection between WDC and the Trident. If anyone can help solve this mystery, I would be grateful!

I approach the restoration of this Trident as an early vintage 1900s vintage and will seek to maintain that. Not knowing at this point if this is an early E. Deguingand Trident or a WDC made Trident, I appreciate the fact that I do have an ‘Ole Timer’ and will handle him with care! The ‘faux’ P-Lip Military style stem is heavily oxidized and this will be addressed. The chamber has moderate cake and this will be removed to reveal fresh briar. The rim has some lava but is in good shape overall. The stummel needs cleaning of the grime and band polished. With an appreciation for the Trident before me, I begin the clean-up by putting the P-Lip stem into the OxiClean bath to start dealing with the heavy oxidation.  With the stummel in hand, the fire chamber has light carbon cake build up. I use the Savinelli Pipe Knife to ream the chamber. It does the job very quickly. I then wrap 240 grit sanding paper around a Sharpie Pen and sand the chamber wall to remove more residue carbon. I conclude the chamber clean up by wiping with a cotton pad wetted with alcohol to remove residue carbon dust. The pictures show the progress.

With the stummel in hand, the fire chamber has light carbon cake build up. I use the Savinelli Pipe Knife to ream the chamber. It does the job very quickly. I then wrap 240 grit sanding paper around a Sharpie Pen and sand the chamber wall to remove more residue carbon. I conclude the chamber clean up by wiping with a cotton pad wetted with alcohol to remove residue carbon dust. The pictures show the progress.

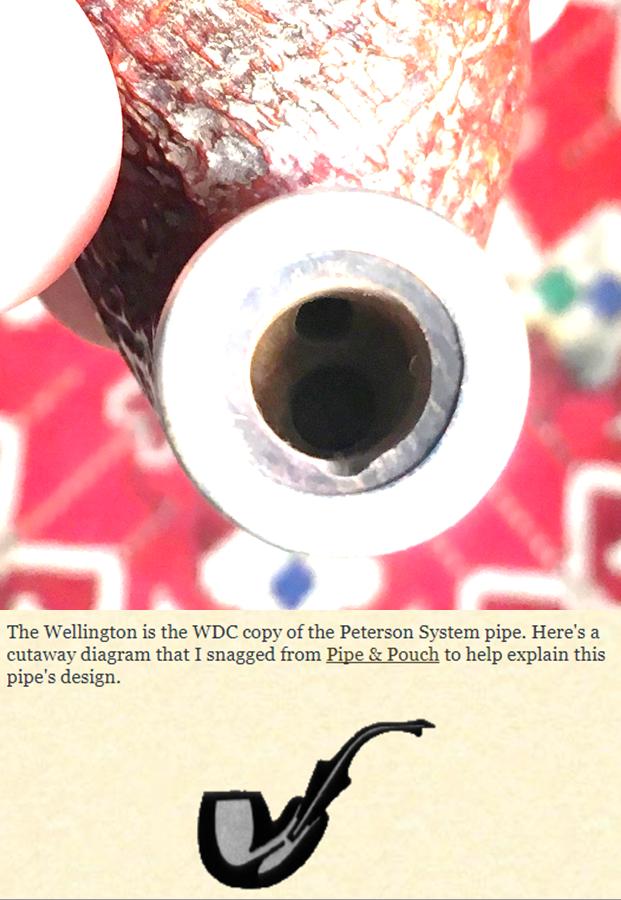

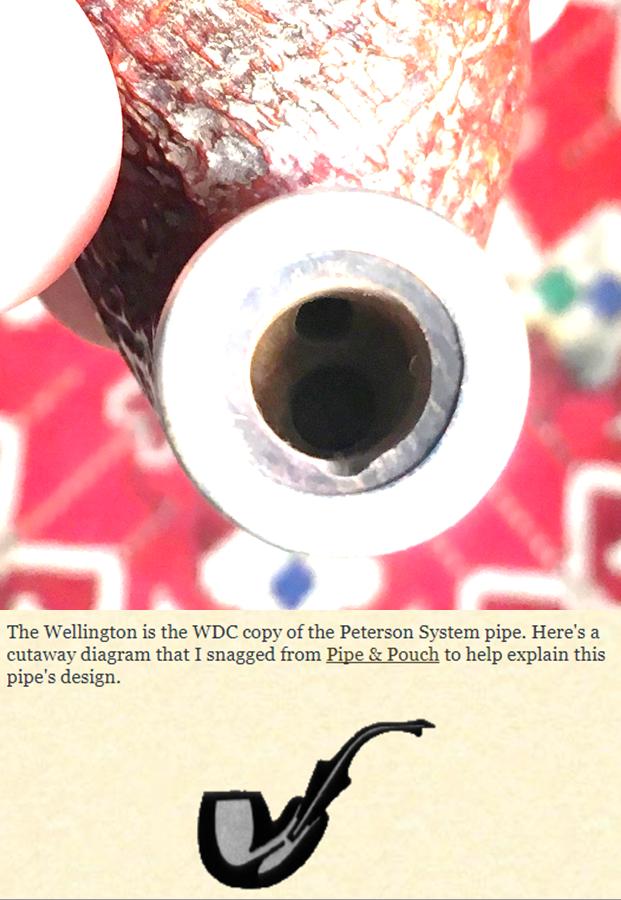

With the chamber reamed and cleaned I turn to the internals. Using cotton swabs, pipe cleaners dipped in alcohol and needle files to scrape the edge of the mortise, I work on cleaning the internals of the stummel. The internal architecture of the mortise has two internal holes drilled. The upper hole is the airway leading to the draft hole. Underneath this, a hole is drilled to create a reservoir for moisture to collect. I take a picture of this and include a cut-away of a WDC Wellington from The Briar Files discussion of WDC Wellingtons.

With the chamber reamed and cleaned I turn to the internals. Using cotton swabs, pipe cleaners dipped in alcohol and needle files to scrape the edge of the mortise, I work on cleaning the internals of the stummel. The internal architecture of the mortise has two internal holes drilled. The upper hole is the airway leading to the draft hole. Underneath this, a hole is drilled to create a reservoir for moisture to collect. I take a picture of this and include a cut-away of a WDC Wellington from The Briar Files discussion of WDC Wellingtons.

After some effort working on the gunk removal, and with the growing need to attend to other obligations not having to do with pipes or their restorations, I decide to continue the cleaning job using the kosher salt/alcohol soak. I fill the chamber with kosher salt that leaves no aftertaste, and twist and stretch a cotton ball to insert into the mortise, acting as a wick to draw out the oil and tar. I use a large eye dropper and fill the bowl with alcohol until is surfaces over the salt. I set it aside and let it do it work.

After some effort working on the gunk removal, and with the growing need to attend to other obligations not having to do with pipes or their restorations, I decide to continue the cleaning job using the kosher salt/alcohol soak. I fill the chamber with kosher salt that leaves no aftertaste, and twist and stretch a cotton ball to insert into the mortise, acting as a wick to draw out the oil and tar. I use a large eye dropper and fill the bowl with alcohol until is surfaces over the salt. I set it aside and let it do it work. Later, I remove the very oxidized P-Lip Military stem from the OxiClean bath and the bath did the job of raising the oxidation to the surface. The stem is now a light grey color not the usual dark olive green. I go to work removing the oxidation using a barrage of tools. I wet sand the stem in warm to hot water for about 30 minutes using 600 grit paper! Oxidation is very stubborn in the edges of the P-Lip orific button lips. I utilize hard edges to wedge the sand paper in the corners. I then use 0000 grade steel wool to work over the entire stem including the hard to reach corners and curves. Finally, I use Mr. Clean MagicEraser to put the oxidation to rest. This phase looks good – it didn’t come easily!

Later, I remove the very oxidized P-Lip Military stem from the OxiClean bath and the bath did the job of raising the oxidation to the surface. The stem is now a light grey color not the usual dark olive green. I go to work removing the oxidation using a barrage of tools. I wet sand the stem in warm to hot water for about 30 minutes using 600 grit paper! Oxidation is very stubborn in the edges of the P-Lip orific button lips. I utilize hard edges to wedge the sand paper in the corners. I then use 0000 grade steel wool to work over the entire stem including the hard to reach corners and curves. Finally, I use Mr. Clean MagicEraser to put the oxidation to rest. This phase looks good – it didn’t come easily! I go directly to cleaning the internals of the stem with pipe cleaners dipped in isopropyl 95%. It did the job quickly.

I go directly to cleaning the internals of the stem with pipe cleaners dipped in isopropyl 95%. It did the job quickly. After some time, I return to the stummel that is having a salt/alcohol soak. The salt has darkened showing that it has done its part. I remove the expended salt and cotton wick and clean the stummel with paper towel to remove residue salt. I return to cotton swabs and pipe cleaners, also using long bristled brushes to finish the job.

After some time, I return to the stummel that is having a salt/alcohol soak. The salt has darkened showing that it has done its part. I remove the expended salt and cotton wick and clean the stummel with paper towel to remove residue salt. I return to cotton swabs and pipe cleaners, also using long bristled brushes to finish the job.  With internals clean, I take another look at the stummel surface. I use undiluted Murphy’s Oil Soap to remove the grime in the crevices of the blast and on the rim top. I utilize cotton pads and a bristled tooth brush. The rim has mild cake and I use a mild kitchen scrub pad to gently clean it. I also clean and polish the band while I was at it.

With internals clean, I take another look at the stummel surface. I use undiluted Murphy’s Oil Soap to remove the grime in the crevices of the blast and on the rim top. I utilize cotton pads and a bristled tooth brush. The rim has mild cake and I use a mild kitchen scrub pad to gently clean it. I also clean and polish the band while I was at it.  Because there was normal wear around the rim, the cleaning leaves lightened areas devoid of finish, though the blasted architecture of the rim is intact. Using the lightest stain stick I have in the basket (Furniture Repair Marker – Oak), I color in the rim. I like the way it darkened and complimented the texture of the hues. I decide to use the stick on the stummel as well to highlight and deepen the peaks of the blasted surface. I like how it turns out overall – nice. I set the stummel aside to dry thoroughly.

Because there was normal wear around the rim, the cleaning leaves lightened areas devoid of finish, though the blasted architecture of the rim is intact. Using the lightest stain stick I have in the basket (Furniture Repair Marker – Oak), I color in the rim. I like the way it darkened and complimented the texture of the hues. I decide to use the stick on the stummel as well to highlight and deepen the peaks of the blasted surface. I like how it turns out overall – nice. I set the stummel aside to dry thoroughly.

I take the stem to begin the micromesh pad cycles and to my chagrin, I see that the oxidation is peeking through – mainly around the curves leading to the crest of the military stem (I’m not sure if there is a technical name for that part of the stem!). Ugh! It’s already late so I elect again to put the stem in the OxiClean bath to see if it will do the job. I heat the OxiClean solution in the microwave until it’s warm and plop the stem back in and turn out the lights!

I take the stem to begin the micromesh pad cycles and to my chagrin, I see that the oxidation is peeking through – mainly around the curves leading to the crest of the military stem (I’m not sure if there is a technical name for that part of the stem!). Ugh! It’s already late so I elect again to put the stem in the OxiClean bath to see if it will do the job. I heat the OxiClean solution in the microwave until it’s warm and plop the stem back in and turn out the lights! The next morning, I go straightaway to the stem in the bath, fish it out, wet sand the problem, oxidized areas with 600 grit paper then with 0000 steel wool. I’m hoping that the oxidation is now removed as much as it can be removed. I move on to wet sanding using micromesh pad 1500 to 2400, then dry sanding with pads 3200 to 4000 then 6000 to 12000. I follow each cycle with an application of Obsidian Oil to revitalize the once oxidized Military, Faux P-Lip style stem. I’m pleased with the pop of the vulcanite – it looks good. I put the stem aside to fully absorb the Obsidian Oil and to dry.

The next morning, I go straightaway to the stem in the bath, fish it out, wet sand the problem, oxidized areas with 600 grit paper then with 0000 steel wool. I’m hoping that the oxidation is now removed as much as it can be removed. I move on to wet sanding using micromesh pad 1500 to 2400, then dry sanding with pads 3200 to 4000 then 6000 to 12000. I follow each cycle with an application of Obsidian Oil to revitalize the once oxidized Military, Faux P-Lip style stem. I’m pleased with the pop of the vulcanite – it looks good. I put the stem aside to fully absorb the Obsidian Oil and to dry.

Next, I apply Museum Wax to the bowl with a small cotton cloth – working the wax in the blasted surface landscape. Then, I buff the bowl with a shoe brush to assimilate the Museum Wax into the surface and begin the shining process. Turning to the Dremel, I mount a clean cotton cloth buffing wheel and set at speed 2 (40% full power) and more fully buff the stummel. The buffing wheel does a good job working the wax in more thoroughly and bringing out a deep, resonate shine. The pictures show the progress.

Next, I apply Museum Wax to the bowl with a small cotton cloth – working the wax in the blasted surface landscape. Then, I buff the bowl with a shoe brush to assimilate the Museum Wax into the surface and begin the shining process. Turning to the Dremel, I mount a clean cotton cloth buffing wheel and set at speed 2 (40% full power) and more fully buff the stummel. The buffing wheel does a good job working the wax in more thoroughly and bringing out a deep, resonate shine. The pictures show the progress.

With the Dremel already in use, I load the cotton cloth wheel dedicated to applying Blue Diamond compound. Using the wheel, I apply the compound to the nickel-plated band to bring out the shine. As hoped, the buffing does the job well. The Trident is dressing up well!

With the Dremel already in use, I load the cotton cloth wheel dedicated to applying Blue Diamond compound. Using the wheel, I apply the compound to the nickel-plated band to bring out the shine. As hoped, the buffing does the job well. The Trident is dressing up well!

Taking the stem, I mount the cotton cloth buffing wheel dedicated to applying carnauba wax. I apply the wax to the stem to bring out the shine and protect it. After applying a few coats of carnauba wax, I then reunite the stummel with the Military style stem and give the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine of the Trident even more.

Taking the stem, I mount the cotton cloth buffing wheel dedicated to applying carnauba wax. I apply the wax to the stem to bring out the shine and protect it. After applying a few coats of carnauba wax, I then reunite the stummel with the Military style stem and give the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine of the Trident even more.

Only two things leave me a bit wanting with the restoration and recommissioning of this Trident Blasted 3/4 Bent Billiard – the distinguished Military stem still holds some small traces of oxidation around the concave curves of the stem’s crown or horn. Yet, my, my, it looks good mounted on the blasted stummel with its newly polished band! The other item was not being able to identify clearly the maker of this Trident – whether E. Deguingand according to Wilczak and Colwell or the Wm. Demuth Co. as Steve suspects because of the preponderance of similarities between the Trident and WDC’s mainstay of the same style pipe, the Wellington. In whatever way this question is ultimately settled, the Trident’s vintage status seems to place him in the 1910 to 1930 age range. Truly, an ole timer who is now ready for another lifetime serving a new steward – gifted to one of Jen’s family members as she soon returns to the US from Bulgaria. Her gifting helps to benefit the Daughters of Bulgaria, our work here in Bulgaria with those women and girls who have been sexually exploited and trafficked in Europe. For more information about this, and why I do what I do, check out my blog at The Pipe Steward. Thanks for joining me!

This time, after scouring cyberspace for hours, I lighted upon a Reborn Pipes blog by Dal Stanton, the Pipe Steward, about another fine Trident, a sandblasted bent billiard. Dal’s work on that pipe is remarkable for his skill in enhancing its original beauty and his tireless quest for the Trident’s provenance. An arduous course of leaps, hops and steps led Dal to the conclusion, with little doubt, that the brand was a second of the William Demuth Co. of New York, which lasted from 1835-1911 – making the Trident an antique. Here are before and afters of Dal’s Trident and an early 20th century WDC Wellington Dal compared it to, the latter courtesy of Doug Valitchka and Pipedia.

This time, after scouring cyberspace for hours, I lighted upon a Reborn Pipes blog by Dal Stanton, the Pipe Steward, about another fine Trident, a sandblasted bent billiard. Dal’s work on that pipe is remarkable for his skill in enhancing its original beauty and his tireless quest for the Trident’s provenance. An arduous course of leaps, hops and steps led Dal to the conclusion, with little doubt, that the brand was a second of the William Demuth Co. of New York, which lasted from 1835-1911 – making the Trident an antique. Here are before and afters of Dal’s Trident and an early 20th century WDC Wellington Dal compared it to, the latter courtesy of Doug Valitchka and Pipedia.  Now I offer one more photo I found, showing another Wellington with the same style of band Dal’s and mine had at our introductions. This one, from Worthpoint, ends any reservation I had regarding the Trident’s WDC connection.

Now I offer one more photo I found, showing another Wellington with the same style of band Dal’s and mine had at our introductions. This one, from Worthpoint, ends any reservation I had regarding the Trident’s WDC connection. RESTORATION

RESTORATION

The rounded end cap with which I replaced the original brass band was functional except for three hallmarks that were placed as a charade. I never cared for the marks, which I considered distracting, but in a misguided fit to make the previous dress version more Petersonian, I went with it. I have read other blogs discussing the meaning of EP in an oval on certain bands and understood it to stand for Electro Plated, a process of adding a thin layer of silver to the nickel. I found an online dictionary of silver band makers that claims the EP on the end cap stands for Edward Powers, who with his brother John began operation as the Powers Brothers tobacconist in Dublin in 1900. The end cap indeed could be called Petersonian (more or less, whatever the true meaning of EP!). At any rate, the end cap had to go, and I was happy it came off with the 12-hour Isopropyl soak, which removed little else. That’s the problem with a well-done black stain and shellac coat.

The rounded end cap with which I replaced the original brass band was functional except for three hallmarks that were placed as a charade. I never cared for the marks, which I considered distracting, but in a misguided fit to make the previous dress version more Petersonian, I went with it. I have read other blogs discussing the meaning of EP in an oval on certain bands and understood it to stand for Electro Plated, a process of adding a thin layer of silver to the nickel. I found an online dictionary of silver band makers that claims the EP on the end cap stands for Edward Powers, who with his brother John began operation as the Powers Brothers tobacconist in Dublin in 1900. The end cap indeed could be called Petersonian (more or less, whatever the true meaning of EP!). At any rate, the end cap had to go, and I was happy it came off with the 12-hour Isopropyl soak, which removed little else. That’s the problem with a well-done black stain and shellac coat. My 120/180-grit pad removed all remnants of the dress finish faster and far easier on my hand and arm than paper and revealed the total erosion of the one word of nomenclature. I had checked before using the pad to avoid not leaving even a ghost of the block Trident letters.

My 120/180-grit pad removed all remnants of the dress finish faster and far easier on my hand and arm than paper and revealed the total erosion of the one word of nomenclature. I had checked before using the pad to avoid not leaving even a ghost of the block Trident letters.

I did not yet grasp how flawed the wood was with almost bottomless scratches and some pits, so I continued with more of the sanding pad followed by 220-1000-grit paper progression. This turned out to be just the tip of the iceberg.

I did not yet grasp how flawed the wood was with almost bottomless scratches and some pits, so I continued with more of the sanding pad followed by 220-1000-grit paper progression. This turned out to be just the tip of the iceberg.  There were some black blotches left on the right shank below the opening that took 60-grit paper to eliminate. Nine micro mesh pads later, I accepted the fact that no amount of viable sanding magic would make the pits on both sides of the bowl disappear.

There were some black blotches left on the right shank below the opening that took 60-grit paper to eliminate. Nine micro mesh pads later, I accepted the fact that no amount of viable sanding magic would make the pits on both sides of the bowl disappear. I mixed some briar shavings with Super Glue, applied dabs (sort of) to the pits and let it dry.

I mixed some briar shavings with Super Glue, applied dabs (sort of) to the pits and let it dry.  I had missed tiny spots of the pits on the right side the first time, so I added fine drops of Super Glue alone.

I had missed tiny spots of the pits on the right side the first time, so I added fine drops of Super Glue alone. The 320 paper took off the dried glue, and I followed with 400-1000 before a full micro meshing.

The 320 paper took off the dried glue, and I followed with 400-1000 before a full micro meshing.

Next came an Everclear retort.

Next came an Everclear retort. My Fiebing’s Dark Brown leather dye was evaporated from long disuse, so I fell back on the Moccasin Brown for the stain. With a flick of my Bic, I achieved an excellent flambé effect. After a cool-off, I got rid of the char and gave the briar a shine with micro mesh from 6000-12000. As is apparent in the following shots, some areas were too light, although not all of the pics show just how light. I spot stained under the rim, the difficult to reach space on the back side of the bowl in the curve of the shank and most of the right and front sides. Okay-okay, I revise “some areas” to more or less all! Re-flambéeing the corrected places (I know that wasn’t a word until I added it to my MS Word dictionary), and another four-pad micro mesh were easy. I didn’t bother to memorialize with still more photos the steps that should have been unnecessary. I think 75 will be quite sufficient. Despite repeated staining of the small spot bordering the left side and right front views, I made it a tad better but not gone.

My Fiebing’s Dark Brown leather dye was evaporated from long disuse, so I fell back on the Moccasin Brown for the stain. With a flick of my Bic, I achieved an excellent flambé effect. After a cool-off, I got rid of the char and gave the briar a shine with micro mesh from 6000-12000. As is apparent in the following shots, some areas were too light, although not all of the pics show just how light. I spot stained under the rim, the difficult to reach space on the back side of the bowl in the curve of the shank and most of the right and front sides. Okay-okay, I revise “some areas” to more or less all! Re-flambéeing the corrected places (I know that wasn’t a word until I added it to my MS Word dictionary), and another four-pad micro mesh were easy. I didn’t bother to memorialize with still more photos the steps that should have been unnecessary. I think 75 will be quite sufficient. Despite repeated staining of the small spot bordering the left side and right front views, I made it a tad better but not gone. Finding the best match for a replacement, straight-edged endcap turned out to be the most challenging aspect of this third reincarnation of the Trident, again as far as I know about. I pawed through way too many candidates from a comprehensive collection I obtained from a friend on the Facebook smokers forums a while back, and after much more time than I had anticipated, I found a match that fit snugly on the shank and needed no Super Glue. The good news is that they are all organized in four baggies now.

Finding the best match for a replacement, straight-edged endcap turned out to be the most challenging aspect of this third reincarnation of the Trident, again as far as I know about. I pawed through way too many candidates from a comprehensive collection I obtained from a friend on the Facebook smokers forums a while back, and after much more time than I had anticipated, I found a match that fit snugly on the shank and needed no Super Glue. The good news is that they are all organized in four baggies now. I put off the stem because, for the first time in my pipe refurbishing life, it didn’t need any sanding – just an Oxi bath and micro mesh.

I put off the stem because, for the first time in my pipe refurbishing life, it didn’t need any sanding – just an Oxi bath and micro mesh. I buffed the stem and stummel with Brown Tripoli and carnauba.

I buffed the stem and stummel with Brown Tripoli and carnauba.

While I am unhappy with the tiny flaw on the bowl that remains un-darkened, I am pleased with the overall results. This Trident System, a WDC second made when Peterson’s System was still revolutionary, is a clear tribute to the folks in Dublin. Maybe it was the giant Irish maker that put an end to Trident because of the matter of a little patent infringement technicality! Who knows?

While I am unhappy with the tiny flaw on the bowl that remains un-darkened, I am pleased with the overall results. This Trident System, a WDC second made when Peterson’s System was still revolutionary, is a clear tribute to the folks in Dublin. Maybe it was the giant Irish maker that put an end to Trident because of the matter of a little patent infringement technicality! Who knows?