Blog by Steve Laug

This particular sandblasted Stanwell pipe was purchased in 2020 from a fellow in Los Angeles, California, USA. It really is nice looking shape that I would call a bent Dublin. The shape of the bowl is a bit oval and that is picked up by the oval shank and stem. The finish is a deep sandblast that has been stained with an undercoat of cordovan and a top coat of black or dark brown. It is stamped on a smooth panel on underside of the shank and reads 50 followed by Hand Made [over] In Denmark. That is followed by Stanwell [over] Regd. No. 969-48. The pipe is very dirty and there is some wear on the sharp edges. There is a thick cake in the bowl and a thick lava overflow on the rim top and inner edge of the bowl filling in the sandblast. There was grime ground into the sandblast finish and dust and debris in the valleys of the blast. The vulcanite saddle stem had the Stanwell Crown S logo on the left side of the saddle. It had light tooth marks and chatter on both sides near the button. The stem was oxidized and had some calcification on the end neat the button. The pipe must have been a great smoker judging from the condition it came it. Jeff took photos of the pipe before he started his work on it.

Jeff took photos of the rim top and the stem to show the condition of the pipe when we received it. You can see the thick cake in the bowl and the lava on the rim top and inner edge of the bowl. The bowl is oval (almost shaped like and eye) while the chamber is round. The oxidized vulcanite stem and has chatter and tooth marks on both sides near the button.

Jeff took photos of the rim top and the stem to show the condition of the pipe when we received it. You can see the thick cake in the bowl and the lava on the rim top and inner edge of the bowl. The bowl is oval (almost shaped like and eye) while the chamber is round. The oxidized vulcanite stem and has chatter and tooth marks on both sides near the button.

He took photos of the sides of the bowl and the heel to give an idea of the shape and the condition of the briar around the bowl. It really is a nicely shaped pipe with great sandblast finish.

He took photos of the sides of the bowl and the heel to give an idea of the shape and the condition of the briar around the bowl. It really is a nicely shaped pipe with great sandblast finish.

The next photo Jeff took shows the stamping on the underside of the shank. It is clear and readable as noted above. The stem logo is also clear.

The next photo Jeff took shows the stamping on the underside of the shank. It is clear and readable as noted above. The stem logo is also clear.

I turned to Pipephil (http://pipephil.eu/logos/en/logo-stanwell.html) to see what I could find. I found a side bar note on the stamping on the pipe. I found there that the company had begun in 1942 and that the “Regd. No.” stamping was discontinued in late 1960s to very early 1970s. So now I knew that the pipe was made after 1942 and before the late 1960s or early 1970s. I wanted to see if I could pin down the date a bit more.

I turned to Pipephil (http://pipephil.eu/logos/en/logo-stanwell.html) to see what I could find. I found a side bar note on the stamping on the pipe. I found there that the company had begun in 1942 and that the “Regd. No.” stamping was discontinued in late 1960s to very early 1970s. So now I knew that the pipe was made after 1942 and before the late 1960s or early 1970s. I wanted to see if I could pin down the date a bit more.

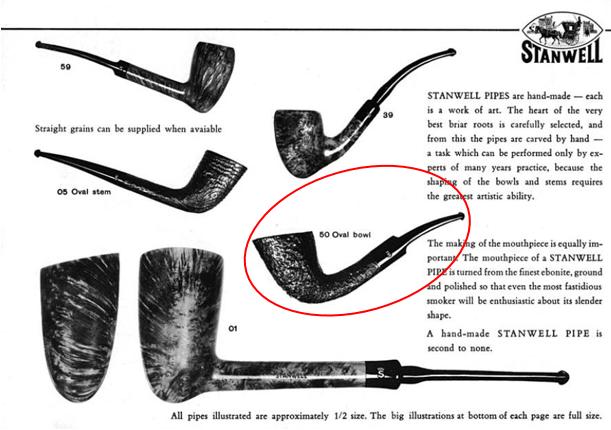

I turned to Pipedia to learn more about the pipe (https://pipedia.org/wiki/Stanwell). I read through the article by Smoking Pipes.com there and would recommend it as being a good read. In the material there I found no additional information. I scrolled through the photos and the included catalogue pages and there I found something helpful. There was a late 1950s catalogue shown there that had the description of the pipe I have and also the shape 50 shown in the pages. I have included a screen capture of the page below. I have circled the shape in the photo below. With that information I had learned that this pipe was available in the late 1950s in the shape that I had in hand. The Regd No. stamping ended in the late 1960s or early 1970s. My guess would place this pipe in the period between 1958-1965. It is a real beauty.

With that information I had learned that this pipe was available in the late 1950s in the shape that I had in hand. The Regd No. stamping ended in the late 1960s or early 1970s. My guess would place this pipe in the period between 1958-1965. It is a real beauty.

Jeff had cleaned up the pipe following his normal cleaning process. In short, he reamed the bowl with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed the sandblast bowl with undiluted Murphy’s Oil Soap with a tooth brush. He worked over the lava and debris on the rim top and was able to remove it. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the stem with Soft Scrub and cotton pads to remove the debris and oils on the stem. He soaked it in a bath of Briarville’s Pipe Stem Deoxidizer to remove the oxidation. He rinsed it with warm water and dried it off. I took photos of the pipe once I received it. It really looked good.

I took close up photos of the stem and the rim top to show both how clean they were and what needed to be addresses with both. The rim top and bowl look good. The stem looked better and the tooth marks and chatter though much lighter were still present.

I took close up photos of the stem and the rim top to show both how clean they were and what needed to be addresses with both. The rim top and bowl look good. The stem looked better and the tooth marks and chatter though much lighter were still present.  I took a photo of the stamping on the underside of the shank. You can see from the photo that it is readable.

I took a photo of the stamping on the underside of the shank. You can see from the photo that it is readable. I removed the stem from the bowl and took a photo of the parts to give a sense of the beauty of the pipe.

I removed the stem from the bowl and took a photo of the parts to give a sense of the beauty of the pipe. The bowl was in such good condition after the clean up that I worked some Before & After Restoration Balm into the surface of the briar with my finger tips and a horse hair shoe brush to get into the crevices of the sandblast. The product is incredible and the way it brings the grain to the fore is unique. It works to clean, protect and invigorate the wood.

The bowl was in such good condition after the clean up that I worked some Before & After Restoration Balm into the surface of the briar with my finger tips and a horse hair shoe brush to get into the crevices of the sandblast. The product is incredible and the way it brings the grain to the fore is unique. It works to clean, protect and invigorate the wood.

I set the bowl aside and turned my attention to the stem. I touched up the stamping on the left side of the saddle stem with PaperMate Liquid Paper. I painted it on and worked it into the stamp with a toothpick. Once it dried I polished off the excess. The stamp came out looking good.

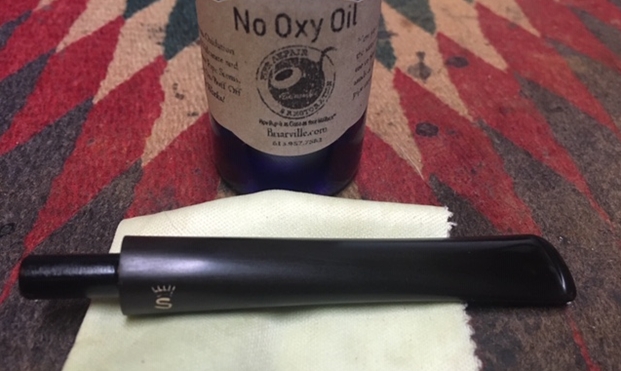

I set the bowl aside and turned my attention to the stem. I touched up the stamping on the left side of the saddle stem with PaperMate Liquid Paper. I painted it on and worked it into the stamp with a toothpick. Once it dried I polished off the excess. The stamp came out looking good.  I was able to polish out the tooth chatter and marks on the stem with micromesh sanding pads – wet sanding it 1500-12000 pads. I wiped it down with some Obsidian Oil each pad to remove the dust and polishing debris. I polished it with Before After Pipe Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I was able to polish out the tooth chatter and marks on the stem with micromesh sanding pads – wet sanding it 1500-12000 pads. I wiped it down with some Obsidian Oil each pad to remove the dust and polishing debris. I polished it with Before After Pipe Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

This is another pipe that I am really happy about the finished restoration. This Stanwell Oval Dublin turned out beautifully. It really is a great looking pipe with a great shape and rugged sandblast finish. The vulcanite saddle stem is really nice. The polished black of the stem works well with the briar. The briar really came alive with the buffing. The rich cordovan and black stains of the finish gave the pipe a sense of depth with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Stanwell Dublin really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¾ inches long x 1 ½ inches wide, Chamber diameter: ¾ of an inch. The weight of the pipe is 37 grams/1.31 oz. The pipe will be going on the rebornpipes store soon. It will be in the section on Danish Pipe Makers if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!

This is another pipe that I am really happy about the finished restoration. This Stanwell Oval Dublin turned out beautifully. It really is a great looking pipe with a great shape and rugged sandblast finish. The vulcanite saddle stem is really nice. The polished black of the stem works well with the briar. The briar really came alive with the buffing. The rich cordovan and black stains of the finish gave the pipe a sense of depth with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Stanwell Dublin really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¾ inches long x 1 ½ inches wide, Chamber diameter: ¾ of an inch. The weight of the pipe is 37 grams/1.31 oz. The pipe will be going on the rebornpipes store soon. It will be in the section on Danish Pipe Makers if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!