Blog by Steve Laug

The next pipe on the table is another Dunhill Group 4 Shell Briar Billiard with a taper stem that is proportionally well done. It has a two digit the shape number that I will define below. This is another pipe from the group which Jeff and I purchased on 04/26/2022 from a woman who contacted us from Cleveland, Ohio, USA. They had belonged to her husband’s father. We spent time chatting with her and arrived at a price and she sent the pipes to Jeff. It included 28+ pipes along with this one.

This Dunhill Billiard is stamped on the underside and reads 60F/T on the heel of the bowl followed by Dunhill over Shell Briar followed by Made in England9 (two lines with the 9 the same size as the letter D). A circle 4 followed by S is stamped next to that. The numbers and stamping tell me that the pipe is a Shell Briar and the size is a Group 4. The F/T refers to the Fish Tail style stem. The finish was very dirty with spots of grime and debris stuck on it. The bowl had a thick cake in the bowl and heavy lava overflowing onto the rim top. The rim top appeared to have burn on inner edge. It was hard to know what was under the lava at this point. The stem had calcification, oxidation and tooth marks and chatter on both sides ahead of the button. The button itself appeared to be in good condition. Jeff took photos of the pipe before he started his clean up work on it.

He took photos of the bowl and rim top to show the condition. You can see the thick cake in the bowl and rim top and edges. The lava is so thick that is hard to know what the edges and top look like underneath. The sandblast on the rim top is also completely filled in with tar and lava. The stem was heavily oxidized, calcified and has tooth marks and chatter on both sides ahead of the button. Overall the pipe is a real mess.

He took photos of the bowl and rim top to show the condition. You can see the thick cake in the bowl and rim top and edges. The lava is so thick that is hard to know what the edges and top look like underneath. The sandblast on the rim top is also completely filled in with tar and lava. The stem was heavily oxidized, calcified and has tooth marks and chatter on both sides ahead of the button. Overall the pipe is a real mess.

Jeff took a photo of the sandblast finish around the bowl side and heel. It was nice looking if you can see through the grime ground into the blast.

Jeff took a photo of the sandblast finish around the bowl side and heel. It was nice looking if you can see through the grime ground into the blast.  He took photos of the stamping on the underside of the bowl, shank and stem. The stamping is readable but filthy. It reads as noted above.

He took photos of the stamping on the underside of the bowl, shank and stem. The stamping is readable but filthy. It reads as noted above. Now it was time to begin to work on the stamping on the pipe. Because I had just finished working on another Shell Briar I used the information that I had dug up on that one. I quote below.

Now it was time to begin to work on the stamping on the pipe. Because I had just finished working on another Shell Briar I used the information that I had dug up on that one. I quote below.

Pipedia had some great information on the Root Briar finish and dates and how the finish was made (https://pipedia.org/wiki/Dunhill#Bruyere). The first quote below give the short version of the finish. I quote from both below.

Shell – A deep craggy sandblast with a black stain finish (usually made using Algerian briar) – the color of the stain used has varied over the years. Although there is some doubt as to them being the first to sandblast pipes, Dunhill’s Shell pipes, and the sandblasting techniques developed to create them are considered one of Dunhill’s greatest and most lasting contributions to the art of pipe making.

The documented history of Dunhill’s inception of the Shell is largely limited to patent applications — there are no catalog pages or advertisements promoting blasted pipes at the time. The preliminary work on the English patent (No. 1484/17) was submitted on October 13, 1917. The patent submission was completed half a year later, on April 12, 1918, followed by the granting of the English patent on October 14, 1918. This was less than a month before the end of The Great War on November 11th.

In 1986 Dunhill released a line of premium Shell finish pipes – “RING GRAIN”. These are high-quality straight grain pipes which are sandblasted. Initially only Ring Grain, but now in two different finishes. In 1995 the “Shilling” was introduced with Cumberland finish – it is an extremely rare series. These pipes exhibit a deeper blast characteristic of that of the 1930’s – mid-1960’s (and the limited ‘deep blast’ pipes of the early 1980s) and show a fine graining pattern. These are considered the best new Dunhills by many enthusiasts today and are very rare. The finish is sometimes described as tasting like vanilla at first, with the taste becoming more normal or good as the pipe breaks in.

- See more examples here: Dunhill Shell

- See more about this incredible pipe here: The History of Dunhill’s Shell

- See more about the patents applied here: Shellbriar & Tanshell, Patents 1917-1954

With that information clear for me I wanted to identify the shape number and try to pin that down (https://pipedia.org/wiki/Dunhill_Shape_Chart). I turned to the section on the older 3 digit Shape Numbers and read it. I quote it below.

Early Days – 2 digits/letters – The original skus/model numbers from the 1920’s until the early 1970’s stood for very specific shapes and bowls. For example, the codes 31, 34, 59, 111, 113, 117, 196, LB, LBS… were all different types of Billiard shaped pipes and there were about 50(!), such codes for the Billiard shape alone. On top of those are a large variety of other shapes.

With the information on the 2 digit stamp not making clear enough the meaning of the number I turned to another link on Pipedia (https://pipedia.org/wiki/Dunhill_Shapes_List) to a shape list that Eric Boehm put together for Dunhills. It is amazing to see the sheer number of variations on the Billiard shape. I copied the four of the two digit numbers in the list as it includes the shape 60 Billiard.

I knew that the pipe shape number locked in a time period between 1920-1970 – a large time span that I needed to narrow down more clearly. I turned to another link on Pipedia (https://pipedia.org/wiki/Dunhill_Shapes_List) to a shape list that Eric Boehm put together for Dunhills. I copied the two 2 digit numbers on Billiards from the list. The shape 60 was in the list.

59 Billiard, tapered bit 4 5¾” 1928, 50, 69 3

60 Billiard, tapered bit 4 5½” 1928, 50, 60, 69 3 (This is the pipe I am working on. It is a tapered bit Billiard with an F/T or Fish Tail bit.)

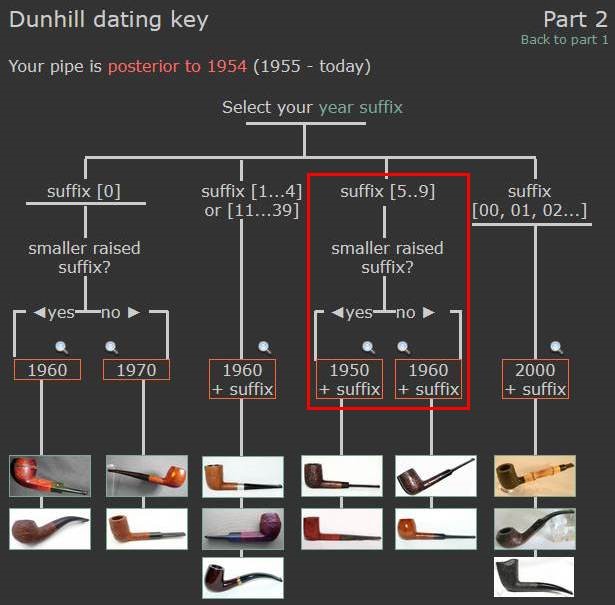

I turned next to dating the pipe. There is a 9 following the D in ENGLAND on the underside of the shank. The 9 is the same size as the D in England. I turned to the dating chart on Pipephil to pin down the date on this twin (http://pipephil.eu/logos/en/dunhill/cledat-en1a.html). I did a screen capture of Part 2 of the Dunhill Dating Key and included it below. I drew a red box around the section dating this pipe. It is clear that the pipe was made after 1954 so that is why I went to Part 2. Once again, because the year suffix is a 9 that is the same size and on line with D in England that tells me that the pipe was made in 1960+9 for a date of 1969. Armed with that information I turned to work on the pipe itself. Before he sent it to me, Jeff had done an amazing job cleaning the pipe. It almost looked like a different pipe after his work. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with isopropyl alcohol, cotton swabs and pipe cleaners. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and then rinsed it off with warm water. He scrubbed the stem with Soft Scrub and a tooth brush and rinsed it off with warm water. It looked amazing when I took it out of the package of pipes he shipped me. I took photos of the pipe before I started my part of the restoration work.

Armed with that information I turned to work on the pipe itself. Before he sent it to me, Jeff had done an amazing job cleaning the pipe. It almost looked like a different pipe after his work. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with isopropyl alcohol, cotton swabs and pipe cleaners. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and then rinsed it off with warm water. He scrubbed the stem with Soft Scrub and a tooth brush and rinsed it off with warm water. It looked amazing when I took it out of the package of pipes he shipped me. I took photos of the pipe before I started my part of the restoration work.

The rim top was cleaner and the inner and outer edge of the bowl showed some damage. The rim top had smooth spots that would need to be worked on and the sandblast surface had been worn off. The stem surface looked good with the oxidation gone and light but visible tooth chatter on either side of the stem.

The rim top was cleaner and the inner and outer edge of the bowl showed some damage. The rim top had smooth spots that would need to be worked on and the sandblast surface had been worn off. The stem surface looked good with the oxidation gone and light but visible tooth chatter on either side of the stem. I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above.

I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I took the stem off the shank and took a photo of the parts of the pipe. It is another great looking Dunhill Shell Briar.

I took the stem off the shank and took a photo of the parts of the pipe. It is another great looking Dunhill Shell Briar. I started my portion of the work on this pipe by addressing the damage to the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the edge and give it a slight bevel to deal with the chipping and cutting on the inner edge. I used a brass bristle wire brush to knock off any residual grime on the rim top. With the bevel and wire brush it looked better but there were still flat spots on the rim top where the blast had worn away.

I started my portion of the work on this pipe by addressing the damage to the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the edge and give it a slight bevel to deal with the chipping and cutting on the inner edge. I used a brass bristle wire brush to knock off any residual grime on the rim top. With the bevel and wire brush it looked better but there were still flat spots on the rim top where the blast had worn away.

I used a series of burrs on my Dremel to copy the finish that was on the good spots on the rim and sides. I took a photo of the burrs and the rim top once I had finished the rustication process. It looked better and once stained to match the bowl it would look very good.

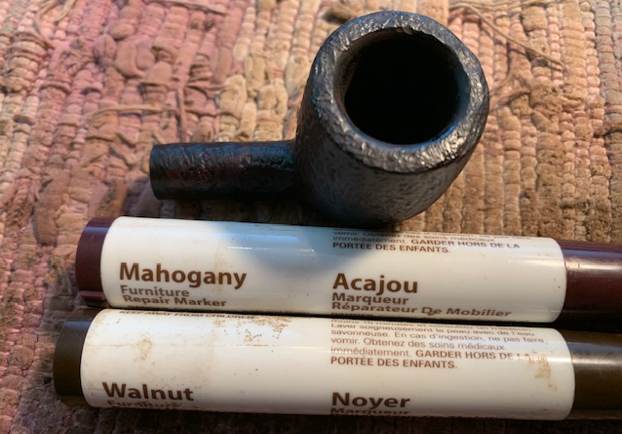

I used a series of burrs on my Dremel to copy the finish that was on the good spots on the rim and sides. I took a photo of the burrs and the rim top once I had finished the rustication process. It looked better and once stained to match the bowl it would look very good. I used a Mahogany and a Walnut Stain Pen to restain the rim top and the inner bevel of the rim edge. Once it dried I buffed it with a cotton cloth and the match was very good. It looked much better with the work on the rim edge.

I used a Mahogany and a Walnut Stain Pen to restain the rim top and the inner bevel of the rim edge. Once it dried I buffed it with a cotton cloth and the match was very good. It looked much better with the work on the rim edge. The bowl looked good at this point so I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl and shank with my fingertips and a horse hair shoe brush to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine.

The bowl looked good at this point so I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl and shank with my fingertips and a horse hair shoe brush to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned my attention to the stem. I polished the vulcanite stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem and gave it a final coat of Obsidian Oil to finish it.

I set the bowl aside and turned my attention to the stem. I polished the vulcanite stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem and gave it a final coat of Obsidian Oil to finish it.

This Sandblasted 1969 Dunhill Shell Briar 60F/T Taper Stem 4S is a great looking pipe now that it has been restored. The rich Shell Briar sandblast finish that highlights the grain and works well with the polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Dunhill Shell Briar 60F/T Billiard is a Group 4 size pipe that will be a great smoker. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 32 grams/1.13 ounces. I will be adding the pipe to the British Pipemakers Section of the rebornpipes store shortly. If you are interested in adding it to your collection be sure to let me know. I take a moment to remind myself and each of us that we are trustees of pipes that will outlive us and the lives of many other pipe men and women who carry on the trust of their care and use. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This Sandblasted 1969 Dunhill Shell Briar 60F/T Taper Stem 4S is a great looking pipe now that it has been restored. The rich Shell Briar sandblast finish that highlights the grain and works well with the polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Dunhill Shell Briar 60F/T Billiard is a Group 4 size pipe that will be a great smoker. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 32 grams/1.13 ounces. I will be adding the pipe to the British Pipemakers Section of the rebornpipes store shortly. If you are interested in adding it to your collection be sure to let me know. I take a moment to remind myself and each of us that we are trustees of pipes that will outlive us and the lives of many other pipe men and women who carry on the trust of their care and use. Thanks for reading this blog and my reflections on the pipe while I worked on it.