by Steve Laug

Last week I received a package of pipes to work on for a friend, Scott. I had no idea what was coming but when it arrived I was surprised with the interesting and amazing pieces he included for me to work on. These included a nice looking large Dunhill 841 ODA Lovat, a Campaign pipe with a Calabash style bowl and a start on the stem, a Sasieni 2 Dot London Made Canadian with a Lovat style saddle stem, and finally an older GBD MR&Co silver banded 5 Lovat. All of them are quite lovely and also interesting for me to be able to work on. I took a photo of the box when I unpacked the pipes. The final pipe I chose to work on from this lot was the Campaign style pipe with buffed out logos and stamping on the shank sides. The pipe has a smooth, rich brown finish. The stamping has been either buffed out or was absent. The bowl had a moderate cake in it and the rim top and inner edges had a heavy lava built up. When the bowl is unscrewed from the base the inside of the calabash is dirty and has a thick tar coat in it. The finish on the bowl and shank were worn and dirty with grime and darkening ground into the surface all around the bowl and shank. Under the tars the rim top and inner and outer edges of the bowl appeared to be in ok condition but cleaning would tell the story. The saddle stem was calcified and oxidized and there were tooth marks on the top and underside ahead of the button. There was also a bite through on the underside of the stem against the button. There is a inlaid white star on the topside of the saddle portion of the stem. I took a few photos of the pipe before I started working on the pipe and have included them below.

The final pipe I chose to work on from this lot was the Campaign style pipe with buffed out logos and stamping on the shank sides. The pipe has a smooth, rich brown finish. The stamping has been either buffed out or was absent. The bowl had a moderate cake in it and the rim top and inner edges had a heavy lava built up. When the bowl is unscrewed from the base the inside of the calabash is dirty and has a thick tar coat in it. The finish on the bowl and shank were worn and dirty with grime and darkening ground into the surface all around the bowl and shank. Under the tars the rim top and inner and outer edges of the bowl appeared to be in ok condition but cleaning would tell the story. The saddle stem was calcified and oxidized and there were tooth marks on the top and underside ahead of the button. There was also a bite through on the underside of the stem against the button. There is a inlaid white star on the topside of the saddle portion of the stem. I took a few photos of the pipe before I started working on the pipe and have included them below.

I took a photo of the rim top and bowl to show the condition of both of them. The briar calabash bowl itself had a thick cake on the walls and bowl bottom. The rim top showed a heavy coat of lava and the inner edge was heavily caked and its condition would be revealed with cleaning. The outer edge looks good. The photos of the stem show the oxidation, calcification and tooth marks/chatter on both sides ahead of the button. There is a large bite through on the underside of the stem ahead of the button.

I took a photo of the rim top and bowl to show the condition of both of them. The briar calabash bowl itself had a thick cake on the walls and bowl bottom. The rim top showed a heavy coat of lava and the inner edge was heavily caked and its condition would be revealed with cleaning. The outer edge looks good. The photos of the stem show the oxidation, calcification and tooth marks/chatter on both sides ahead of the button. There is a large bite through on the underside of the stem ahead of the button. I unscrewed the calabash bowl from the base and took photos of the parts. You can see from the photos that the inside of the base is very dirty with tars and oils. There is a lot of debris in the bottom of the base as well.

I unscrewed the calabash bowl from the base and took photos of the parts. You can see from the photos that the inside of the base is very dirty with tars and oils. There is a lot of debris in the bottom of the base as well.

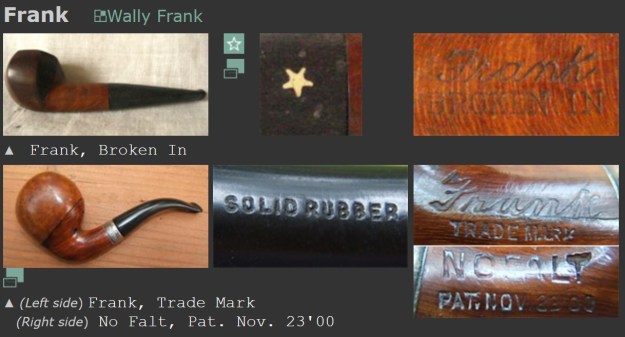

I checked on Pipephil (http://www.pipephil.eu/logos/en/logo-f4.html) to see if I could find something with a similar star on the stem. I found a pipe made by Frank that had the same five-point white star as the stem I am working on. It could very well have been made for Frank.

I checked on Pipephil (http://www.pipephil.eu/logos/en/logo-f4.html) to see if I could find something with a similar star on the stem. I found a pipe made by Frank that had the same five-point white star as the stem I am working on. It could very well have been made for Frank. I went back and read over the blogs I have written on previous Campaign pipes that I restored. I am attaching the link to one of the blogs and some of the information that I found in researching the brand at that time. (https://rebornpipes.com/tag/wdc-campaign-calabash-pipe/). The information is all on the WDC made Campaign pipe but the information is helpful.

I went back and read over the blogs I have written on previous Campaign pipes that I restored. I am attaching the link to one of the blogs and some of the information that I found in researching the brand at that time. (https://rebornpipes.com/tag/wdc-campaign-calabash-pipe/). The information is all on the WDC made Campaign pipe but the information is helpful.

In my online research I found a brief interchange on a Google group. I include the link if you would like to read it in context and its entirety. It gives some helpful information regarding this particular pipe. https://groups.google.com/forum/#!topic/alt.smokers.pipes/kpkpd3zXoiwExcerpt from pipedia.org

To a request for information regarding the WDC Campaign pipe on the Google Group there was quite a long string of answers. I am quoting two of those in full…

Respondent 1: While I can’t say anything about this pipe specifically, I have a hazy memory of that shape listed in a book about pipes; (I may be totally misremembering this, but here goes) the shape being called the “Dawes”, named after Harding’s Vice President? Anyone else remember this? Sounds like an interesting pipe, whatever it’s called…

Respondent 2: From Weber’s Guide to Pipes: “The Dawes Pipe (more correctly named the Lyons, after its inventor, Charles Herbert Lyons) happened to be the favorite pipe of General Charles G. Dawes, Vice-President of the USA from 1925 to 1929. General Dawes smoked the curious pipe incessantly and it became popularly known as the Dawes Underslung, because the shank joined the bowl near its rim.”

I looked on Pipedia, (https://pipedia.org/wiki/William_Demuth_Company) and I quote in part from the article on the William Demuth Company.

The Demuth Company is probably well known for the famous trademark, WDC in an inverted equilateral triangle. William commissioned the figurative meerschaum Presidential series, 29 precision-carved likenesses of John Adams, the second president of the United States (1797-1801) to Herbert Hoover, the 30th president (1929-1933), and “Columbus Landing in America,” a 32-inch-long centennial meerschaum masterpiece that took two years to complete and was exhibited at the World’s Columbian Exposition in Chicago in 1893.

The Presidential series was the result of Demuth’s friendship with President James A. Garfield, a connoisseur of meerschaum pipes. Demuth presented two pipes to Garfield at his inauguration in 1881, one in his likeness, the other in the likeness of the President’s wife. Later, Demuth arranged for another figurative matching the others to be added to the collection as each new president acceded to the White House, terminating with President Hoover.

From the above information I learned some significant details about the Campaign pipe. It was invented by Charles Herbert Lyons and was the favourite pipe of General Charles G. Dawes who was the Vice President of the USA under President Harding from 1925-1929. It fits nicely into that period when WDC was having Presidential Pipes commissioned ending in 1933. That places this old pipe in the time period between the late 1920s and early 1930s.

Now it was time to work on the pipe. I used a Savinelli Fitsall Pipe Knife to clean up the cake in the bowl. I used a dowel wrapped with 220 grit sandpaper to smooth out the walls of the bowl. I checked for damage on the bowl walls and it was in good condition. I also sanded the inside of the base with the dowel and sandpaper.

I scraped the rim top with a Savinelli Fitsall Pipe Knife. I cleaned up the inner edge of the bowl with a folded piece of 220 sandpaper.

I scraped the rim top with a Savinelli Fitsall Pipe Knife. I cleaned up the inner edge of the bowl with a folded piece of 220 sandpaper.  I scrubbed the exterior of the briar with a tooth brush and undiluted Murphy’s Oil Soap to remove the build up on the surface of the briar and clean off the lava on the rim top. I scrubbed it and then carefully rinsed the bowl with warm water. I dried it with a soft cotton cloth. It certainly looked significantly better and the patina remained in the wood.

I scrubbed the exterior of the briar with a tooth brush and undiluted Murphy’s Oil Soap to remove the build up on the surface of the briar and clean off the lava on the rim top. I scrubbed it and then carefully rinsed the bowl with warm water. I dried it with a soft cotton cloth. It certainly looked significantly better and the patina remained in the wood.

I scrubbed out the inside of the shank, mortise and the airway in both the stem and the bowl. I used pipe cleaners, cotton swabs and isopropyl alcohol. It cleaned up very well. I also wiped down the inside of the base with alcohol and paper towels.

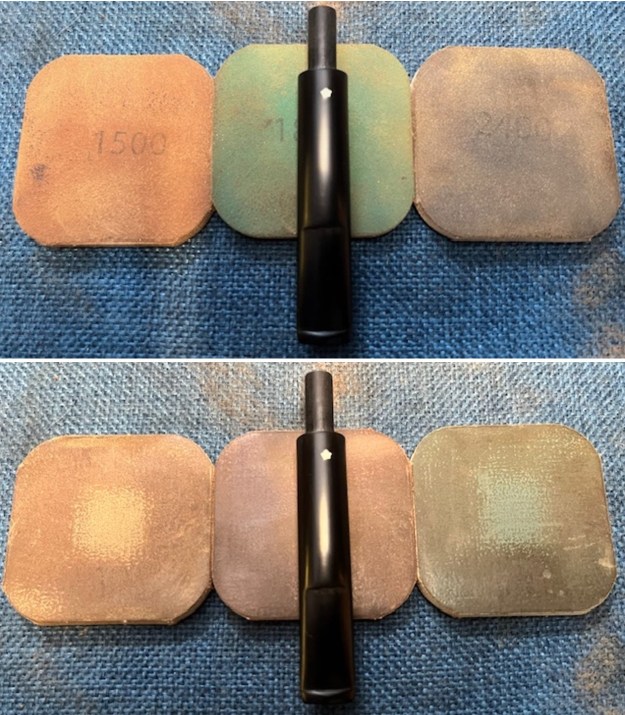

I scrubbed out the inside of the shank, mortise and the airway in both the stem and the bowl. I used pipe cleaners, cotton swabs and isopropyl alcohol. It cleaned up very well. I also wiped down the inside of the base with alcohol and paper towels. I polished the briar with micromesh sanding pads to minimise the scratches in the briar. I dry sanded with 1500-12000 grit pads and wiped the bowl down after each pad with a damp cloth to remove the sanding debris. By the end of the nine pads the briar took on a rich shine and the rim top looked very good.

I polished the briar with micromesh sanding pads to minimise the scratches in the briar. I dry sanded with 1500-12000 grit pads and wiped the bowl down after each pad with a damp cloth to remove the sanding debris. By the end of the nine pads the briar took on a rich shine and the rim top looked very good.

I paused the polishing to stain the rim top with a Cherry stain pen to match the rest of the bowl and shank. The stain is a bit spotty in the photo but once it is buffed out and further polished the blend is perfect.

I paused the polishing to stain the rim top with a Cherry stain pen to match the rest of the bowl and shank. The stain is a bit spotty in the photo but once it is buffed out and further polished the blend is perfect.  I went back to polishing the stem with the remaining sanding pads. I wiped it down with a damp cloth after each pad to remove the sanding debris and dust.

I went back to polishing the stem with the remaining sanding pads. I wiped it down with a damp cloth after each pad to remove the sanding debris and dust.

I rubbed the bowl down with Before & After Restoration Balm. It is a paste/balm that works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips to make sure that it covered every square inch of the pipe. I set it aside for 10 minutes to let it do its work. I buffed it with a cotton cloth. The briar really began to have a deep shine. The photos I took of the bowl at this point mark the progress in the restoration.

I rubbed the bowl down with Before & After Restoration Balm. It is a paste/balm that works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips to make sure that it covered every square inch of the pipe. I set it aside for 10 minutes to let it do its work. I buffed it with a cotton cloth. The briar really began to have a deep shine. The photos I took of the bowl at this point mark the progress in the restoration.

I set the bowl aside and turned my attention to the stem. The stem had a metal tube in the tenon to strengthen the connection. I needed to deal with was the bite through on the underside just ahead of the button before I did much else with the stem. I rubbed some Vaseline onto a folded pipe cleaner and pushed it into the airway underneath the hole. The Vaseline would keep the CA glue repair from sticking to the pipe cleaner. I filled in the hole with Black CA glue that was extra strength and had rubber in the mix. I sprayed it with an accelerator to harden the glue so I could pull the pipe cleaner out. Once the surface hardened I was able to remove the pipe cleaner. I set the stem aside for the repair to cure overnight.

I set the bowl aside and turned my attention to the stem. The stem had a metal tube in the tenon to strengthen the connection. I needed to deal with was the bite through on the underside just ahead of the button before I did much else with the stem. I rubbed some Vaseline onto a folded pipe cleaner and pushed it into the airway underneath the hole. The Vaseline would keep the CA glue repair from sticking to the pipe cleaner. I filled in the hole with Black CA glue that was extra strength and had rubber in the mix. I sprayed it with an accelerator to harden the glue so I could pull the pipe cleaner out. Once the surface hardened I was able to remove the pipe cleaner. I set the stem aside for the repair to cure overnight.

This morning I used a small file to flatten the repair and to remove the tooth marks on the topside of the stem.

This morning I used a small file to flatten the repair and to remove the tooth marks on the topside of the stem. I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation and smooth out the repair to the stem surface. I wiped it down after each sanding pad with an Obsidian Oil impregnated cloth. It began to look good.

I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation and smooth out the repair to the stem surface. I wiped it down after each sanding pad with an Obsidian Oil impregnated cloth. It began to look good. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

I put the Bowl and the Base of the Campaign Pipe bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The reddish/brown stains worked amazingly well with the polished vulcanite taper stem. The grain around the bowl and shank and looks quite remarkable. This is truly a beautiful Campaign Underslung Calabash Style Pipe. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.45 ounces/41 grams. With this one finished I can pack up Scott’s pipes and send them back to him in the week ahead. I am sure he will soon add them into his rotation and enjoy some great smokes. Thanks for walking through the restoration with me. Cheers.

I put the Bowl and the Base of the Campaign Pipe bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The reddish/brown stains worked amazingly well with the polished vulcanite taper stem. The grain around the bowl and shank and looks quite remarkable. This is truly a beautiful Campaign Underslung Calabash Style Pipe. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.45 ounces/41 grams. With this one finished I can pack up Scott’s pipes and send them back to him in the week ahead. I am sure he will soon add them into his rotation and enjoy some great smokes. Thanks for walking through the restoration with me. Cheers.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.