by Steve Laug

I received an email from a fellow pipeman, Larry about a pipe he had that had been knocked off the stand and the tenon had snapped. I have included his email below.

I have a Pipe stem that broke on a Velani Caprice, and I was wondering how much you would charge to replace the stem. The pipe was knocked off my stand and broke the stem from the pipe; I was able to get the part that broke out from the pipe. I would like your opinion and what you would charge. I could send you pictures as well. Thank you. – Larry

I wrote back with my normal questions about what had broken and if he was able to send me photos of the pipe so I could more thoroughly assess what had happened to the pipe. He sent me the following photos that clearly showed the damage.

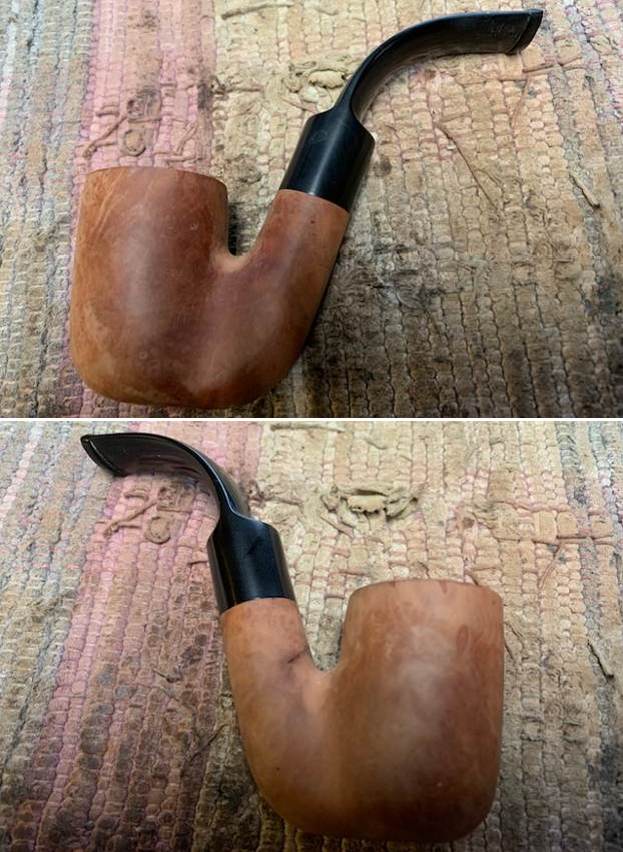

When the box arrived from Larry yesterday I opened it to see what I was dealing with. The pipe was stamped on the left side of the shank and read Velani [over] Caprice and AV 75 on the underside. It was also stamped Italy against the acrylic spacer in the shank end. The stamping was clear and readable. The heavily coral like rusticated finish was quite clean and the bowl inside was smooth and appeared to have been recently reamed. The rim top was smooth and it was quite clean. It was dusty but otherwise clean. The stem was wrapped along with the broken tenon in the box. The saddle portion of the stem had cracked off and Larry had glued it back together with epoxy. He had done a great job and the crack was solid. There were still some light crevices where the repair had been done that would need to be filled in. I set the pipe aside so that I could think about the repair. I took photos of the broken parts of the pipe and have included them below.

When the box arrived from Larry yesterday I opened it to see what I was dealing with. The pipe was stamped on the left side of the shank and read Velani [over] Caprice and AV 75 on the underside. It was also stamped Italy against the acrylic spacer in the shank end. The stamping was clear and readable. The heavily coral like rusticated finish was quite clean and the bowl inside was smooth and appeared to have been recently reamed. The rim top was smooth and it was quite clean. It was dusty but otherwise clean. The stem was wrapped along with the broken tenon in the box. The saddle portion of the stem had cracked off and Larry had glued it back together with epoxy. He had done a great job and the crack was solid. There were still some light crevices where the repair had been done that would need to be filled in. I set the pipe aside so that I could think about the repair. I took photos of the broken parts of the pipe and have included them below.

I took photos of the stamping on the shank. It was clear and readable as noted above.

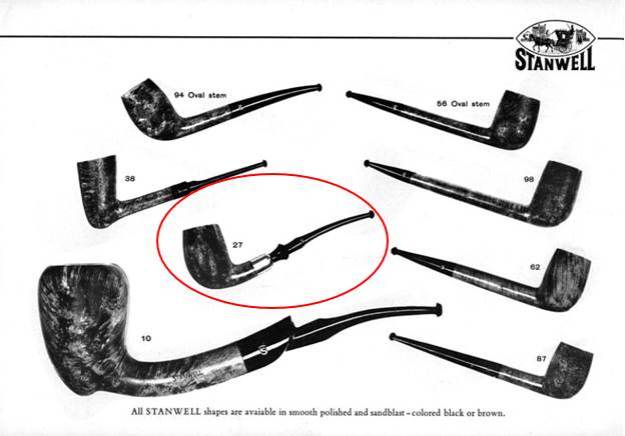

I took photos of the stamping on the shank. It was clear and readable as noted above.  I turned to Pipephil to refresh my memory of the brand understand a bit more about it before I started working on the stem (http://www.pipephil.eu/logos/en/logo-a3.html#aldovelani). I am including a screen capture below.

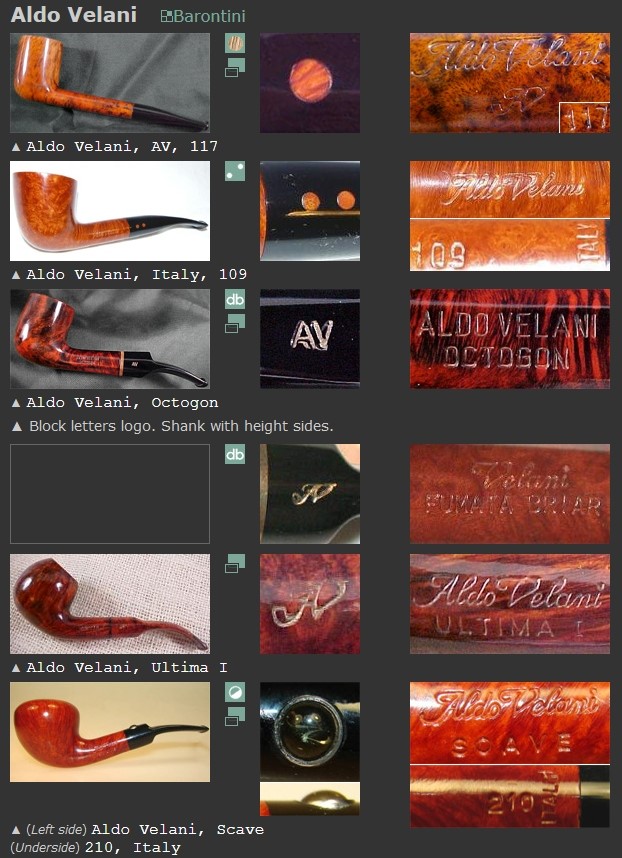

I turned to Pipephil to refresh my memory of the brand understand a bit more about it before I started working on the stem (http://www.pipephil.eu/logos/en/logo-a3.html#aldovelani). I am including a screen capture below.  From the side bar on Pipephil I was reminded that Aldo Velani is the fictional name for a sub-brand of Barontini that was mainly intended for export.

From the side bar on Pipephil I was reminded that Aldo Velani is the fictional name for a sub-brand of Barontini that was mainly intended for export.

I turned to Pipedia to see if I could learn a bit more about the brand and the link took me to Cesare Barontini’s page (https://pipedia.org/wiki/Aldo_Velani). It also confirmed the information from the side bar above. Now it was time to work on the pipe.

I began my work on the pipe by addressing the cracked portion of the saddle stem. I cleaned out the surface of the repairs that Larry had done and filled in the shallow grooves with black CA glue.  I sanded the repairs with 220 grit sandpaper to smooth them out. I sanded the end of the saddle and fitted it with a thin brass band. I thinned the depth of the band with a topping board to reduce the profile so that it would not cover the briar dot on the top of the saddle. It would function as an external band to hold the repairs tight while I drilled the airway for the new tenon. I coated the inside of the band with white glue and pressed it on the stem.

I sanded the repairs with 220 grit sandpaper to smooth them out. I sanded the end of the saddle and fitted it with a thin brass band. I thinned the depth of the band with a topping board to reduce the profile so that it would not cover the briar dot on the top of the saddle. It would function as an external band to hold the repairs tight while I drilled the airway for the new tenon. I coated the inside of the band with white glue and pressed it on the stem.

Once the band was solid on the stem I drilled the airway open with two progressively larger drill bits on the cordless drill. I needed it open enough to hold the new tenon in place. It would also provide an internal tube that the stem was bound to. The repair that Larry had done, the band on the outside and the new tenon would provide a solid repair for the crack in the saddle portion of the stem.

Once the band was solid on the stem I drilled the airway open with two progressively larger drill bits on the cordless drill. I needed it open enough to hold the new tenon in place. It would also provide an internal tube that the stem was bound to. The repair that Larry had done, the band on the outside and the new tenon would provide a solid repair for the crack in the saddle portion of the stem.

I went through my bag of tenons and found one that was the right fit for the shank. I used a tenon that was made for the Jobey link system. I removed the ridge around the tenon that was made for the Jobey stem and would inset. I used my Dremel to remove that ridge as it was not necessary for a regular tenon.

I went through my bag of tenons and found one that was the right fit for the shank. I used a tenon that was made for the Jobey link system. I removed the ridge around the tenon that was made for the Jobey stem and would inset. I used my Dremel to remove that ridge as it was not necessary for a regular tenon. I reworked a second tenon and once it was done I painted the threads on the tenon with black CA glue and inserted it in the opened airway on the stem. I set it aside to cure.

I reworked a second tenon and once it was done I painted the threads on the tenon with black CA glue and inserted it in the opened airway on the stem. I set it aside to cure. I took a photo of the finished tenon and then once cured I inserted it in the shank and took more photos of the finished repair. I still need to polish the pipe to be finished but the fit was correct.

I took a photo of the finished tenon and then once cured I inserted it in the shank and took more photos of the finished repair. I still need to polish the pipe to be finished but the fit was correct.

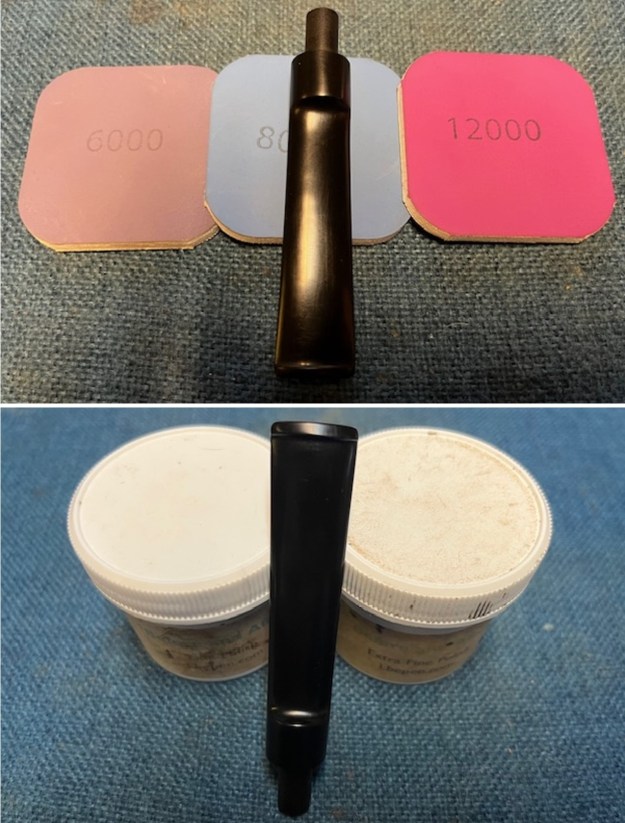

I finished working on the stem by sanding it with 32-3500 grit 2×2 inch sanding pads to smooth out the repair and to remove the tooth chatter. The pipe stem was looking very good.

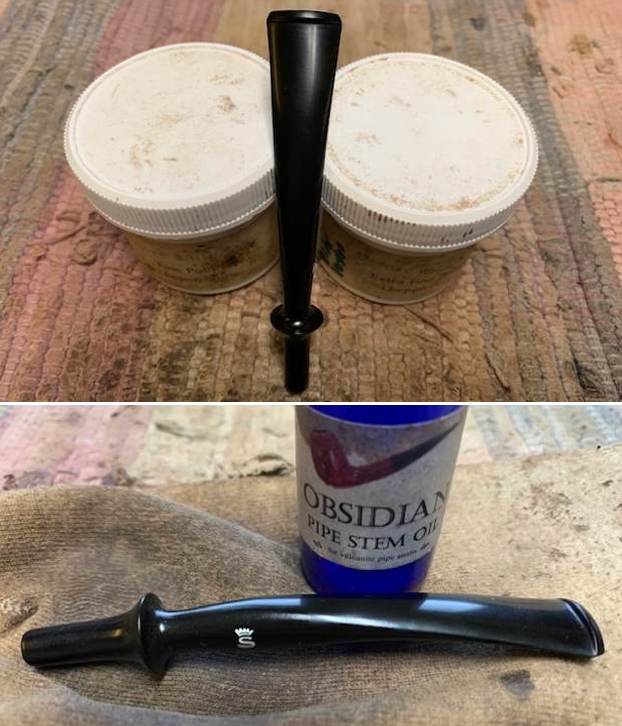

I finished working on the stem by sanding it with 32-3500 grit 2×2 inch sanding pads to smooth out the repair and to remove the tooth chatter. The pipe stem was looking very good.  I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiped down the stem with some Obsidian Oil after each sanding pad. I finished the polishing with some Before & After Stem Polish – both fine and extra fine. I gave it a final coat of Obsidian Oil and set the stem aside.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiped down the stem with some Obsidian Oil after each sanding pad. I finished the polishing with some Before & After Stem Polish – both fine and extra fine. I gave it a final coat of Obsidian Oil and set the stem aside.

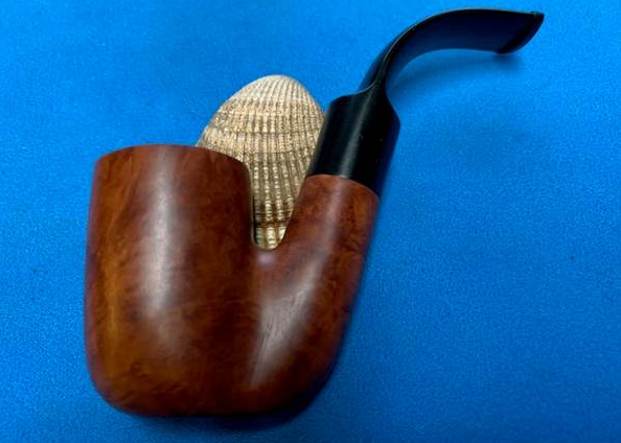

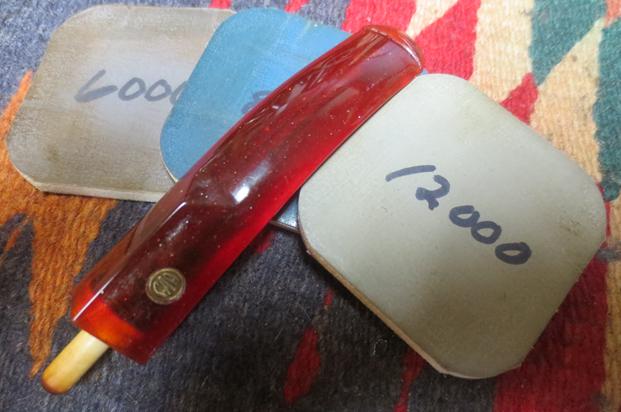

I polished the smooth rim top and portions of the shank with 1500-12000 grit micromesh sanding pads. I wiped it down with a damp cloth after each pad to remove the debris. I worked over the inner edge of the rim at the same time. The smooth portions began to look very good.

I polished the smooth rim top and portions of the shank with 1500-12000 grit micromesh sanding pads. I wiped it down with a damp cloth after each pad to remove the debris. I worked over the inner edge of the rim at the same time. The smooth portions began to look very good.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

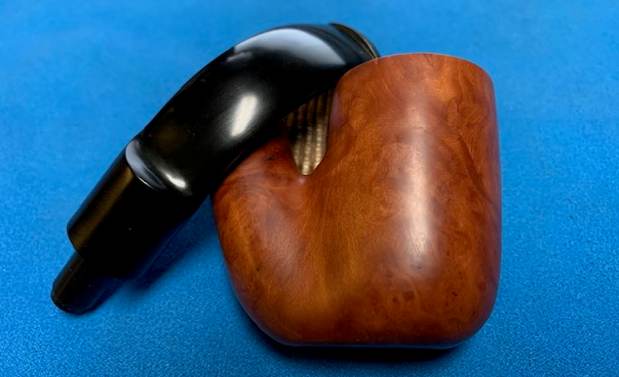

This rusticated Velani Caprice 75 Bent Billiard with a fancy saddle stem is a great looking pipe now that it has been restored and the tenon and stem repaired. The briar around the bowl is clean and the rustication really came alive. The rich brown stains of the rustication took on a sense of depth with the polishing and waxing. The grain really popped. I put the acrylic stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Velani Caprice Rusticated Bent Billiard is a beauty and feels in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.76 ounces/49 grams. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This rusticated Velani Caprice 75 Bent Billiard with a fancy saddle stem is a great looking pipe now that it has been restored and the tenon and stem repaired. The briar around the bowl is clean and the rustication really came alive. The rich brown stains of the rustication took on a sense of depth with the polishing and waxing. The grain really popped. I put the acrylic stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Velani Caprice Rusticated Bent Billiard is a beauty and feels in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.76 ounces/49 grams. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!