by Steve Laug

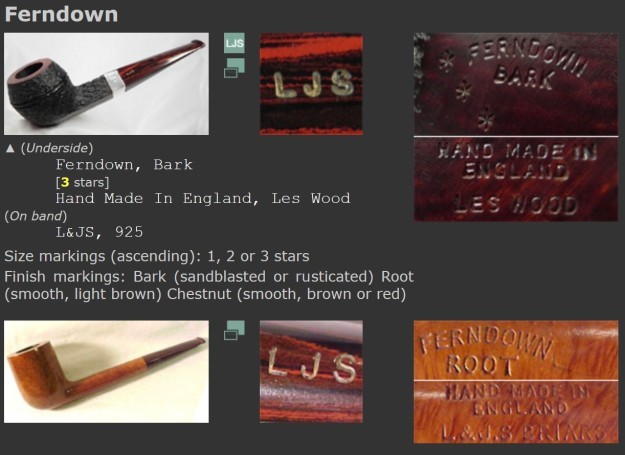

Last weekend Kenneth and I went to an antique show in New Westminster, BC. It is our third year going but still we have no idea what we are going to fine each time we go. It is always a part of the fun to wander through the various stalls and see what the vendors are offering on their tables. There are always surprising things – items that I grew up with that are now called antiques or at least collectibles. If only my foresight had been as good as my memory is now I could have sold many of the things I played with and ate from! But I digress. Back to the pipe hunting. We saw the usual offerings of things Grabow and Medico that were in very rough shape. I think we both have become much more selective over time and we passed on spending time with them. I did a few items that I picked up to restore. I took a picture of the group of fout pipes. In the left column from top to bottom there was a Peterson’s System Standard 1307 (Canadian number on a 307 shape), a Bulldog that was stamped Fraser Valley Made in Canada with a white dot stem and at the bottom was another Peterson – a K&P Dublin Made in Ireland Canadian with a Sterling Silver Band. The one on the right side is an older GBD Nosewarmer with an orific button on the short stem. Not a bad group of pipes to bring to the work table. The first of them I chose to bring to the table was the K&P Canadian at the bottom of the above photo. It is a pretty pipe and bears the stamping on the top of the shank that reads K&P [over] Dublin. On the underside the COM stamp is Made in Ireland in a circle. That format for the stamp made the pipe one that was made between 1945-1972. On the worn and oxidized Silver band it is stamped K & P in three shields [over] Sterling [over] Silver. The bowl has a light cake but the rim top and edges are very clean. The shank looks to be clean also. The stem is heavily oxidized and will take some work to bring it back to black. There does not appear to be any stamping or logo on the stem. It is an original P-lip style stem and it is in surprisingly good condition under the oxidation. I took photos of the pipe before I started my clean up work on it.

The first of them I chose to bring to the table was the K&P Canadian at the bottom of the above photo. It is a pretty pipe and bears the stamping on the top of the shank that reads K&P [over] Dublin. On the underside the COM stamp is Made in Ireland in a circle. That format for the stamp made the pipe one that was made between 1945-1972. On the worn and oxidized Silver band it is stamped K & P in three shields [over] Sterling [over] Silver. The bowl has a light cake but the rim top and edges are very clean. The shank looks to be clean also. The stem is heavily oxidized and will take some work to bring it back to black. There does not appear to be any stamping or logo on the stem. It is an original P-lip style stem and it is in surprisingly good condition under the oxidation. I took photos of the pipe before I started my clean up work on it.

I took a close-up photo of the rim top to show the condition of the bowl and inner edge of the bowl and the stem. You can clearly see the cake in the bowl and the darkening and lava on the rim top. The stem photos show the deep oxidation on the stem and the silver band.

I took a close-up photo of the rim top to show the condition of the bowl and inner edge of the bowl and the stem. You can clearly see the cake in the bowl and the darkening and lava on the rim top. The stem photos show the deep oxidation on the stem and the silver band. I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above. I removed the stem and took a photo of the parts of the pipe. It is a pretty little pipe.

I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above. I removed the stem and took a photo of the parts of the pipe. It is a pretty little pipe. Now it was time to work on the pipe. I cleaned up the silver band with a jeweller’s cloth so that I could read the stamping clearly. It read as noted above and the characters were slightly worn under the oxidation. But it is a great addition to the pipe.

Now it was time to work on the pipe. I cleaned up the silver band with a jeweller’s cloth so that I could read the stamping clearly. It read as noted above and the characters were slightly worn under the oxidation. But it is a great addition to the pipe.

I reamed the pipe with a Savinelli Fitsall Pipe Knife to remove the thin cake in the bowl and check the bowl walls. I sanded the bowl with a piece of dowel wrapped with 220 grit sandpaper. It looked much better at this point.

I reamed the pipe with a Savinelli Fitsall Pipe Knife to remove the thin cake in the bowl and check the bowl walls. I sanded the bowl with a piece of dowel wrapped with 220 grit sandpaper. It looked much better at this point. I moved on to clean up the internals. I cleaned out the airway and mortise with pipe cleaners, cotton swabs and alcohol. I cleaned out the airway in the stem at the same time. I was surprised at how clean the internals were.

I moved on to clean up the internals. I cleaned out the airway and mortise with pipe cleaners, cotton swabs and alcohol. I cleaned out the airway in the stem at the same time. I was surprised at how clean the internals were.  I scrubbed the externals of the pipe with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime in the finish and on the rim top. I worked on it until it looked much better and then rinsed it off with warm water. I dried it off with a soft cloth.

I scrubbed the externals of the pipe with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime in the finish and on the rim top. I worked on it until it looked much better and then rinsed it off with warm water. I dried it off with a soft cloth.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down between pads with a damp cloth. It really began to take on a deep shine. There is a dark spot on the right side of the bowl. It is solid so it is not a fill. My guess is that it is where a root or such came out of the briar.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down between pads with a damp cloth. It really began to take on a deep shine. There is a dark spot on the right side of the bowl. It is solid so it is not a fill. My guess is that it is where a root or such came out of the briar.

The exterior of the bowl looks better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl looks better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

I set the bowl aside and turned my attention to the stem. I scrubbed the stem with Soft Scrub and cotton pads to remove the oxidation. I was able to rid the surface of the majority of the brown and what was left would be able to be sanded off.

I set the bowl aside and turned my attention to the stem. I scrubbed the stem with Soft Scrub and cotton pads to remove the oxidation. I was able to rid the surface of the majority of the brown and what was left would be able to be sanded off. There were no deep marks or chatter so I sanded the stem with 320-3500 grit sanding pads and wiped it down with Obsidian Oil to remove the sanding dust.

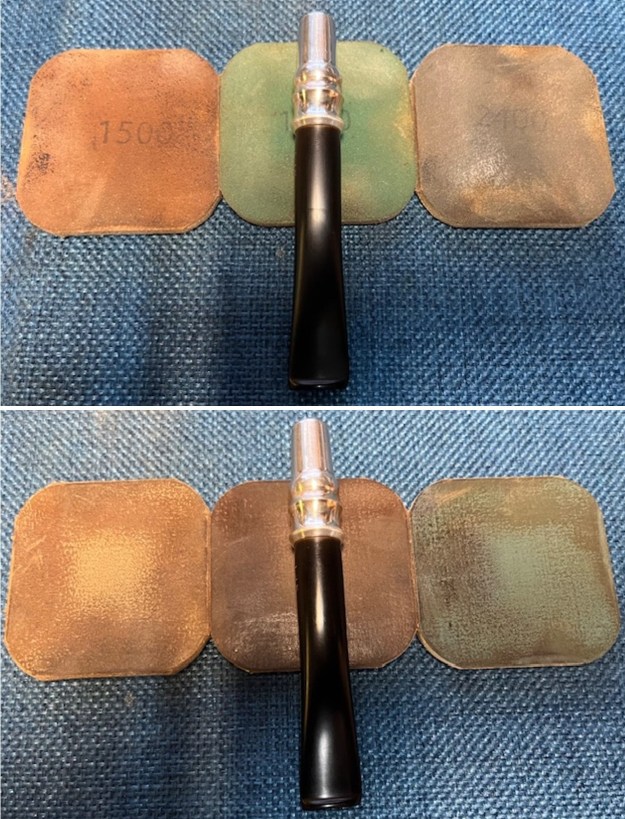

There were no deep marks or chatter so I sanded the stem with 320-3500 grit sanding pads and wiped it down with Obsidian Oil to remove the sanding dust. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil to further protect the vulcanite surface. I finished the polishing with Before & After Pipe Stem Polish – Fine and Extra Fine. I wiped the stem down a final time with Obsidian Oil and a cloth. It really looks very good.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil to further protect the vulcanite surface. I finished the polishing with Before & After Pipe Stem Polish – Fine and Extra Fine. I wiped the stem down a final time with Obsidian Oil and a cloth. It really looks very good.

I am always excited to finish working on a pipe. This K&P Dublin Made in Ireland Canadian made between 1945-1972 is no exception. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with a microfibre cloth to deepen the shine. It is fun to see what the polished bowl looks like with polished silver and the black vulcanite taper stem. This Classic looking Peterson’s K&P Dublin Canadian feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 31 grams/1.09 ounces. I will be putting it on the rebornpipes store shortly in the Irish Pipe Makers Section if you are interested in it. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am always excited to finish working on a pipe. This K&P Dublin Made in Ireland Canadian made between 1945-1972 is no exception. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and hand buffed it with a microfibre cloth to deepen the shine. It is fun to see what the polished bowl looks like with polished silver and the black vulcanite taper stem. This Classic looking Peterson’s K&P Dublin Canadian feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 31 grams/1.09 ounces. I will be putting it on the rebornpipes store shortly in the Irish Pipe Makers Section if you are interested in it. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.