by Kenneth Lieblich

If you’re interested in acquiring a Peterson unlike any other, have I got the pipe for you! I unearthed this pipe a couple of years ago at an antique fair and I found it quite peculiar. The shape seemed perfectly normal, the components were in good (albeit, used) condition – but the finish was something I’d never seen before from an old Pete. I was definitely curious about what it might be. The pipe turned out very well, all things considered, and, like I said, if you want a pipe that no one else has – this is your pipe. I’m sure it’ll be a good smoker.

Neither Steve nor I were clear on how this pipe ended up the way it did. I initially wondered if this was an odd finish that Peterson tried years ago – but that didn’t seem likely. I had another theory, but Steve suggested that I contact Peterson expert, Mark Irwin, to ask him about it. Mark basically confirmed what I suspected: this Donegal has had its rustication (mostly) removed. In other words, it’s been sanded down. This is strange, but there’s no way of determining why this was done. Thanks for your help, Mark. Regardless, we’ve ended up with an interesting finish and a pipe that I need to make beautiful.

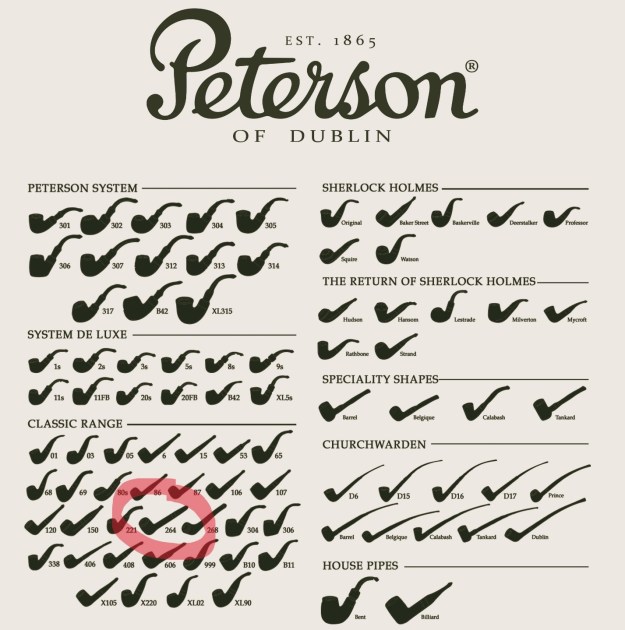

Neither Steve nor I were clear on how this pipe ended up the way it did. I initially wondered if this was an odd finish that Peterson tried years ago – but that didn’t seem likely. I had another theory, but Steve suggested that I contact Peterson expert, Mark Irwin, to ask him about it. Mark basically confirmed what I suspected: this Donegal has had its rustication (mostly) removed. In other words, it’s been sanded down. This is strange, but there’s no way of determining why this was done. Thanks for your help, Mark. Regardless, we’ve ended up with an interesting finish and a pipe that I need to make beautiful. The markings on this pipe were a problem, since they had suffered a bit during the sanding process. However, I did manage to figure them out. On the underside of the shank, we can see the word Peterson’s. There is something marked underneath that, but I’ll come back to that as it’s somewhat unreadable. Next to Peterson’s is the shape number, 264. And next to that are the words Made in the [over] Republic [over] of Ireland. It took me quite a while to determine what was marked underneath of Peterson’s, but, of course, it is the word Donegal. This is the Peterson line.

The markings on this pipe were a problem, since they had suffered a bit during the sanding process. However, I did manage to figure them out. On the underside of the shank, we can see the word Peterson’s. There is something marked underneath that, but I’ll come back to that as it’s somewhat unreadable. Next to Peterson’s is the shape number, 264. And next to that are the words Made in the [over] Republic [over] of Ireland. It took me quite a while to determine what was marked underneath of Peterson’s, but, of course, it is the word Donegal. This is the Peterson line.

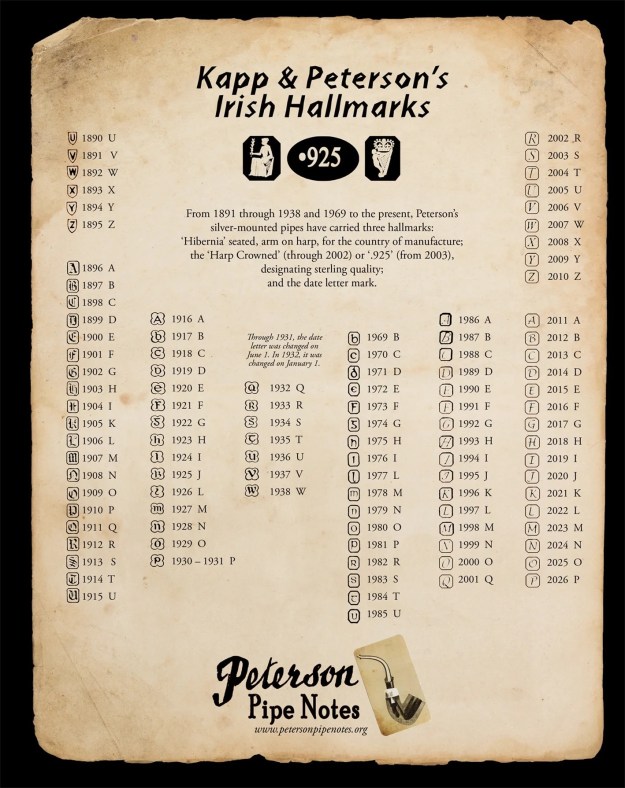

You will have noticed that the stem is the traditional Peterson P-lip, and it has the classic letter P. Most importantly, there is a sterling silver band on the end of the shank. On the sterling silver band is displayed three shields each containing the three marks K&P [over] Sterling [over] Silver. These are not silver hallmarks – they are simply Peterson’s marks. However, it does have a set of proper hallmarks (which are very difficult to see): Hibernia, which indicated that it was made in Dublin. Next is the Harp Crowned, which indicates sterling silver. Third is the date letter. In this case, it’s a stylized M. Checking the Irish hallmarks chart tells me that this pipe dates from 1978.

You will have noticed that the stem is the traditional Peterson P-lip, and it has the classic letter P. Most importantly, there is a sterling silver band on the end of the shank. On the sterling silver band is displayed three shields each containing the three marks K&P [over] Sterling [over] Silver. These are not silver hallmarks – they are simply Peterson’s marks. However, it does have a set of proper hallmarks (which are very difficult to see): Hibernia, which indicated that it was made in Dublin. Next is the Harp Crowned, which indicates sterling silver. Third is the date letter. In this case, it’s a stylized M. Checking the Irish hallmarks chart tells me that this pipe dates from 1978.

So, what is the state of the pipe? Well, it’s a mixed bag, as these things tend to be. The stem is in surprisingly good shape – not too dirty or oxidized. It does have a notable cut into the vulcanite, near the tenon end, but that’s not a problem to repair. The stummel is, for the most part, also quite nice. It has a few unsurprising scratches, but it’s fairly clean inside. The silver band is heavily tarnished and has a few bumps and knocks.

So, what is the state of the pipe? Well, it’s a mixed bag, as these things tend to be. The stem is in surprisingly good shape – not too dirty or oxidized. It does have a notable cut into the vulcanite, near the tenon end, but that’s not a problem to repair. The stummel is, for the most part, also quite nice. It has a few unsurprising scratches, but it’s fairly clean inside. The silver band is heavily tarnished and has a few bumps and knocks.

On with the restoration! This pipe had an inner tube, so I cleaned that first. I wiped it with some alcohol and ran a pipe cleaner or two through it. Much improved.

On with the restoration! This pipe had an inner tube, so I cleaned that first. I wiped it with some alcohol and ran a pipe cleaner or two through it. Much improved. The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean.

The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean. The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. This one wasn’t too bad at all.

The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. This one wasn’t too bad at all. Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush.

Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush. As the stem was now clean and dry, I set about fixing the nasty cut in the vulcanite. This was done by filling it with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on.

As the stem was now clean and dry, I set about fixing the nasty cut in the vulcanite. This was done by filling it with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on. After this, I painted the logo on the stem with some enamel nail polish. I restored the logo carefully and let it fully set before proceeding. Most of the logo has gone with the passage of time, but at least a bit of it still shows.

After this, I painted the logo on the stem with some enamel nail polish. I restored the logo carefully and let it fully set before proceeding. Most of the logo has gone with the passage of time, but at least a bit of it still shows. The penultimate step for the stem is sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done.

The penultimate step for the stem is sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done. As the stem was (nearly) complete, I moved on to the stummel. The first step was to clean out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. I didn’t need a reamer this time, so a pipe knife and a piece of sandpaper taped to a wooden dowel did the trick. Collectively, these ensured that all the debris was removed.

As the stem was (nearly) complete, I moved on to the stummel. The first step was to clean out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. I didn’t need a reamer this time, so a pipe knife and a piece of sandpaper taped to a wooden dowel did the trick. Collectively, these ensured that all the debris was removed. Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. Since the pipe wasn’t too dirty, it didn’t take long to clean it.

Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. Since the pipe wasn’t too dirty, it didn’t take long to clean it. I then decided to ‘de-ghost’ the pipe – that is to say, exorcize the remaining filth from the briar. I filled the bowl and the shank with cotton balls, then saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the remaining oils, tars and smells to leach out into the cotton.

I then decided to ‘de-ghost’ the pipe – that is to say, exorcize the remaining filth from the briar. I filled the bowl and the shank with cotton balls, then saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the remaining oils, tars and smells to leach out into the cotton. To tidy up the briar, I wiped down the outside, using a solution of a pH-neutral detergent and some distilled water, with cotton rounds. I also used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process was to scour the inside of the stummel with the same mild detergent and tube brushes.

To tidy up the briar, I wiped down the outside, using a solution of a pH-neutral detergent and some distilled water, with cotton rounds. I also used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process was to scour the inside of the stummel with the same mild detergent and tube brushes. I used all nine micromesh pads (1,500 through 12,000 grit) to sand the outside of the stummel and finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I had to be especially careful this time, to avoid losing any more of the markings on the underside of the shank.

I used all nine micromesh pads (1,500 through 12,000 grit) to sand the outside of the stummel and finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I had to be especially careful this time, to avoid losing any more of the markings on the underside of the shank.

To clean the silver band, I gently removed the tarnish with a soak in a bath of aluminum foil, baking soda, and hot water. Worked like a charm! I polished it up and glued it back in place. There are still some bumps and bashes, but it looks so much better.

To clean the silver band, I gently removed the tarnish with a soak in a bath of aluminum foil, baking soda, and hot water. Worked like a charm! I polished it up and glued it back in place. There are still some bumps and bashes, but it looks so much better.

I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth.

I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth.

For the final step, I took the pipe to my bench polisher and carefully buffed it – first with a blue diamond compound, then with three coats of conservator’s wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

For the final step, I took the pipe to my bench polisher and carefully buffed it – first with a blue diamond compound, then with three coats of conservator’s wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

This Peterson Donegal 264 Canadian looks fantastic again and is ready to be enjoyed by its next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5½ in. (138 mm); height 1¾ in. (45 mm); bowl diameter 1¼ in. (33 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1 oz. (32 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.