Blog by Steve Laug

One of the great packages I brought back from my trip to Idaho was a small bag of C.P.F. pipes smoked and unsmoked. Some have horn stems; some have gutta percha bases and stems. I went through the bag and chose the next pipe I wanted to work on. It was an unsmoked C.P.F. French Briar Straight Rhodesian with a decorative bead between the twin rings separating the bowl from the cap. The finish had a coat of varnish or possibly shellac over it so it had a spotty shiny look to it. The top of the shank is stamped with gold leaf and reads C.P.F. in the oval logo with French arched over the top of the logo and Briar arched underneath. The bowl was unsmoked but still had a lot of dust and debris inside. It had a brass/silver band that had the typical C.P.F. faux hallmarks as well as the oval logo. The glue that held it in place had long since dried out and the band was loose. The horn stem had a few nicks in the top side but was undamaged. The threaded bone tenon was flawless and clean. I took photos of the pipe to show its condition at the start of the process.

I took a close up photo of the rim top and bowl to show the condition of the unsmoked briar. It was clean but dusty and grimy. The rim top showed some wear in the shellac coat that was on the rest of the bowl. The photos of the horn stem show its general condition. It was dull but unused so it should clean up well.

I took a close up photo of the rim top and bowl to show the condition of the unsmoked briar. It was clean but dusty and grimy. The rim top showed some wear in the shellac coat that was on the rest of the bowl. The photos of the horn stem show its general condition. It was dull but unused so it should clean up well. The next photo shows the stamping on the shank and the band. It is clear and readable. The stamping reads as noted above. The hallmarks are the now familiar faux hallmarks that I have found on all banded C.P.F. pipes.

The next photo shows the stamping on the shank and the band. It is clear and readable. The stamping reads as noted above. The hallmarks are the now familiar faux hallmarks that I have found on all banded C.P.F. pipes. I went back and read a previous blog that I had written on the brand to reacquaint myself. The link to the blog follows (https://rebornpipes.com/2013/04/14/some-reflection-on-the-historical-background-on-cpf-pipes/). I quote a pertinent part of the blog below:

I went back and read a previous blog that I had written on the brand to reacquaint myself. The link to the blog follows (https://rebornpipes.com/2013/04/14/some-reflection-on-the-historical-background-on-cpf-pipes/). I quote a pertinent part of the blog below:

From my reading and research it seems to me that C.P.F. brand was discontinued sometime in the 1910-1920 range. Again, turning to Bill Feuerbach I found that he notes the following, which pins down the time frame of the discontinuation of the brand more specifically, “I have a C.P.F. Chesterfield in our office display that has a nametag from way before my time that says 1900 C.P.F. Chesterfield. It looks like most other Chesterfields you’ve seen, including the military type push stem, except this stem is horn and not vulcanite. As far as I have gathered the C.P.F. brand was phased out sometime around 1915.” Interestingly, he noted that the Chesterfield name and style was later introduced in the KB&B, Kaywoodie and Yello-Bole lines. He says that the 1924 KB&B catalog shows KB&B Chesterfields…

… From my research I believe that we can definitively assert that the C.P.F. logo stands for Colossus Pipe Factory. The brand was purchased by KB&B sometime between 1884 and 1898 and that it continued until 1915. That time frame gives help in dating some of the older C.P.F. pipes you or I might find. It can be said that prior to the dual stamping it is fairly certain that the pipe is pre-1884 to 1898. After the dual stamping it can be placed post 1898 until the closure of the brand line in 1915. C.P.F. made beautiful pipes.

From that information I can definitely date the pipe to the period prior to 1884-1898 because of the single C.P.F. stamp on the shank. The horn stem, bone tenon and decorative bead on the bowl also push for that earlier date. At any rate it is an old pipe to remain unsmoked for this long. The story of its journey to Jeff and me this long after the date it was made is another mystery. This is one of those times that I wish an old pipe could speak and share the story of its journey. The most I can say is that it came from New York to Idaho Falls in journey that began in the 1880s and ended in 2019. Now it is has further traveled by air to Vancouver Canada as far west as it can go and remain on the same continent… What a well-traveled pipe and one that I will never really know the story about the nature of the journey. Armed with that information it was not time to work on the pipe.

I decided to begin with the bowl. I took the stem off the bowl and the band on the shank came off very easily. I turned it to align it and then decided to take it off to clean up the shank end before I reglued it. I wiped down the bowl with acetone on a cotton pad to break down the remaining shellac coat and remove the dried glue remnants left on the briar from the loose band. I am still experimenting with Mark Hoover’s Briar Cleaner to see what I think of it as a possible replacement for my usual Murphy’s Oil Soap scrub. I rubbed it onto the bowl and worked it into the grain of the briar. I wiped it off with a clean cloth. There was still a coat of grime and grit from the cleaner left behind so I rinsed it with warm water to remove that and dried it with a microfiber cloth. I am really not sure if this is any better than the Murphy’s but I am committed to working with it. I took photos of the pipe at this point in the process.

I am still experimenting with Mark Hoover’s Briar Cleaner to see what I think of it as a possible replacement for my usual Murphy’s Oil Soap scrub. I rubbed it onto the bowl and worked it into the grain of the briar. I wiped it off with a clean cloth. There was still a coat of grime and grit from the cleaner left behind so I rinsed it with warm water to remove that and dried it with a microfiber cloth. I am really not sure if this is any better than the Murphy’s but I am committed to working with it. I took photos of the pipe at this point in the process.

Once the shank and bowl were cleaned it was time to reglue the band. I coated the end of the shank with Weldbond white glue. I spread it on the shank with a tooth pick. I spread it around and make it even. I pressed the band into place on the shank and wiped away the excess glue that squeezed out from under the band. I wiped it down with a cotton pad and alcohol to make sure it was clean. I set it aside to let the glue cure.

Once the shank and bowl were cleaned it was time to reglue the band. I coated the end of the shank with Weldbond white glue. I spread it on the shank with a tooth pick. I spread it around and make it even. I pressed the band into place on the shank and wiped away the excess glue that squeezed out from under the band. I wiped it down with a cotton pad and alcohol to make sure it was clean. I set it aside to let the glue cure. One of the nice features of working on a NOS pipe is that the internals are very clean. I ran a pipe cleaner through the airway in the stem and shank just to remove dust. I did the same in the mortise with a cotton swab and the internals were finished. I directed my attention to polishing the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the dust.

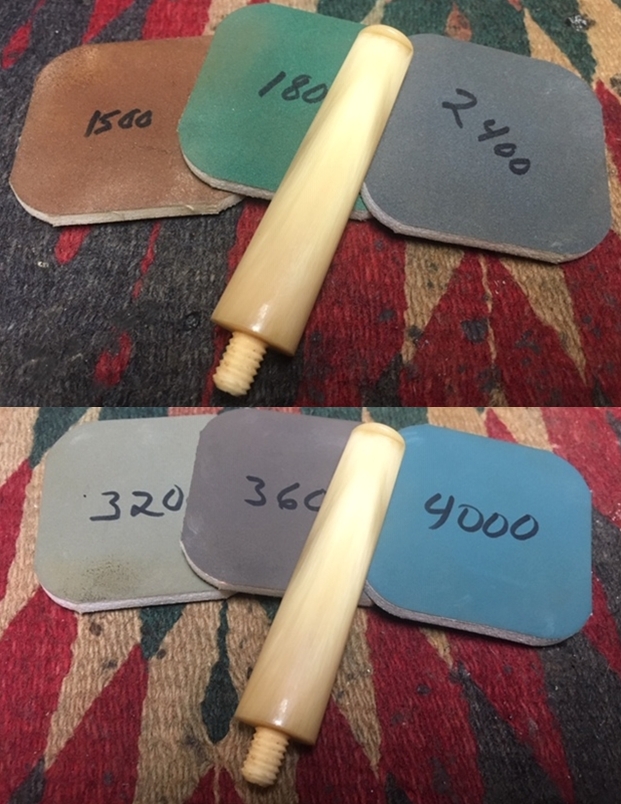

One of the nice features of working on a NOS pipe is that the internals are very clean. I ran a pipe cleaner through the airway in the stem and shank just to remove dust. I did the same in the mortise with a cotton swab and the internals were finished. I directed my attention to polishing the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the dust.

I rubbed the bowl and shank down with a coat of Before & After Restoration Balm. I worked it into the surface of the briar – using a pipe cleaner to work it into the twin rings and the bead work. The product works to clean, enliven and protect the briar. The old briar was dry and it drank up the balm. I buffed the bowl with a soft cloth to raise a shine. I like how the pipe looks as this point in the process.

I rubbed the bowl and shank down with a coat of Before & After Restoration Balm. I worked it into the surface of the briar – using a pipe cleaner to work it into the twin rings and the bead work. The product works to clean, enliven and protect the briar. The old briar was dry and it drank up the balm. I buffed the bowl with a soft cloth to raise a shine. I like how the pipe looks as this point in the process.

I set the bowl aside and started working on the stem. There was a small hole at the top of the stem on the face behind the bone tenon. I filled in the hole with clear super glue and set it aside.

I set the bowl aside and started working on the stem. There was a small hole at the top of the stem on the face behind the bone tenon. I filled in the hole with clear super glue and set it aside.  I sanded the stem with a folded piece of 220 grit sandpaper to remove the scratches in the surface of the horn. I polished out the scratches with 400 grit wet dry sandpaper and wiped the stem down with Obsidian Oil.

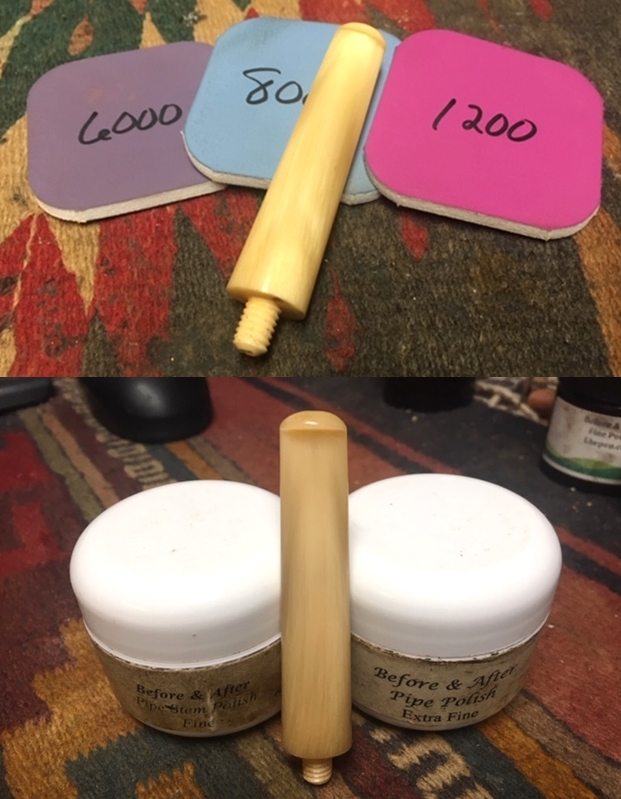

I sanded the stem with a folded piece of 220 grit sandpaper to remove the scratches in the surface of the horn. I polished out the scratches with 400 grit wet dry sandpaper and wiped the stem down with Obsidian Oil. I polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I finished the polishing with Before & After Pipe Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I finished the polishing with Before & After Pipe Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I love these old C.P.F. pipes. There is some serious thought that they were carved by European trained craftsman who were skilled pipemakers. These pipemakers were brought to the US by the C.P.F. Company to make pipes. Many of the shapes, bands and stems have such high quality workmanship involved that I really think there is truth to this story. This is little straight shank, horn stem Rhodesian is a real beauty. There may be one small fill on the bowl cap just above the decorative bead on the right side of the bowl. I polished stem and the bowl with Blue Diamond polish on the buffing wheel carefully avoiding the stamping on the shank. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The contrasting grain really began to stand out; it seemed to take on life with the buffing. The rich contrasting brown colour works well with the polished striated horn stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 5 ¼ inches, Height: 1 7/8 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: 3/4 of an inch. This one will be joining my collection as it fits in the C.P.F. niche group that I have been building. The shape and feel in the hand is perfect. Now I have to make a hard decision – do I leave it unsmoked or do I load it up with some aged Virginia and break it in. Thanks for walking through the restoration with me as I restored and reworked this old Rhodesian from 1884-1898. It is always a treat for me to work on a piece of pipe history especially when I have learned a bit of the story behind it.

I love these old C.P.F. pipes. There is some serious thought that they were carved by European trained craftsman who were skilled pipemakers. These pipemakers were brought to the US by the C.P.F. Company to make pipes. Many of the shapes, bands and stems have such high quality workmanship involved that I really think there is truth to this story. This is little straight shank, horn stem Rhodesian is a real beauty. There may be one small fill on the bowl cap just above the decorative bead on the right side of the bowl. I polished stem and the bowl with Blue Diamond polish on the buffing wheel carefully avoiding the stamping on the shank. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The contrasting grain really began to stand out; it seemed to take on life with the buffing. The rich contrasting brown colour works well with the polished striated horn stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 5 ¼ inches, Height: 1 7/8 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: 3/4 of an inch. This one will be joining my collection as it fits in the C.P.F. niche group that I have been building. The shape and feel in the hand is perfect. Now I have to make a hard decision – do I leave it unsmoked or do I load it up with some aged Virginia and break it in. Thanks for walking through the restoration with me as I restored and reworked this old Rhodesian from 1884-1898. It is always a treat for me to work on a piece of pipe history especially when I have learned a bit of the story behind it.