by Kenneth Lieblich

A fine gentleman (and regular customer) from Seattle recently sent a box of pipes for me to restore for him. Various and sundry reasons prevented me from photographing most of the pipe restorations, but I did snap some shots of this one and it is worth checking out. This is a nifty bent Dublin made primarily from Redmanol (more on that later). The stem and most of the stummel are made entirely from Redmanol and are two separate pieces. In this case, the mortise and tenon are reversed from most pipes: the screw tenon is in the shank and the mortise is in the stem. The bowl is made of briar and screws into the Redmanol bowl. Separating the briar from the Redmanol is a ring of brass. This restoration was quite a bit of work, but I could not be more pleased with how it turned out in the end. The pipe is really quite charming and reminiscent of a different era.

The pipe has no markings at all, so I cannot describe the maker to you with any authority. However, Steve has written up several blog posts on Redmanol pipes from makers such as MLC, WDC, and KB&B. Here is one of his articles on a pipe not too dissimilar from the one I’m restoring. So, what is Redmanol? It is an early 20th century type of plastic – a sort of Bakelite, if you will. On Pipedia, there is an excellent article on Redmanol (and gutta percha) written by the doyen of pipe literature, Ben Rapaport. I highly encourage you to read the whole article here, but here is an excerpt:

The pipe has no markings at all, so I cannot describe the maker to you with any authority. However, Steve has written up several blog posts on Redmanol pipes from makers such as MLC, WDC, and KB&B. Here is one of his articles on a pipe not too dissimilar from the one I’m restoring. So, what is Redmanol? It is an early 20th century type of plastic – a sort of Bakelite, if you will. On Pipedia, there is an excellent article on Redmanol (and gutta percha) written by the doyen of pipe literature, Ben Rapaport. I highly encourage you to read the whole article here, but here is an excerpt:

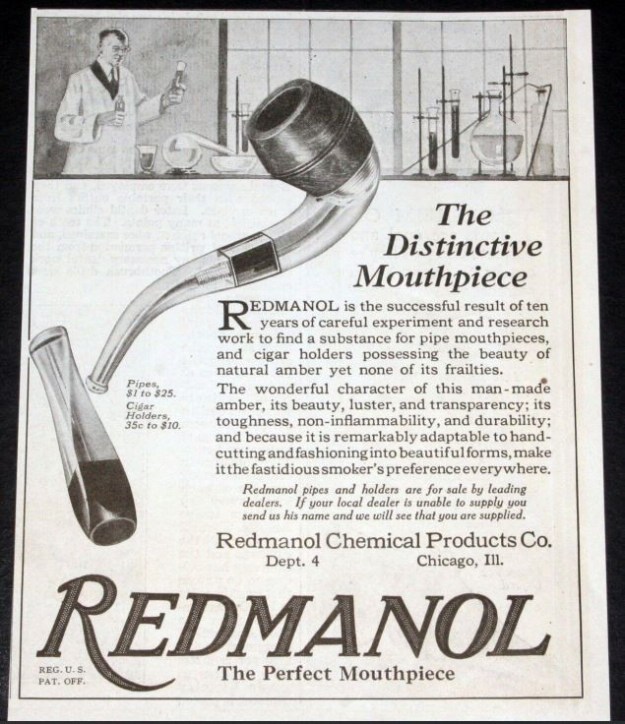

Then came Redmanol. In 1913, Lawrence V. Redman established the Redmanol Chemical Products Company in Chicago to produce a plastic, similar to Bakelite, made from the action of formin on carbolic acid. “Redmanol. Perfect molding material. Redmanol Chemical Products Co., 644 West 22nd Street, Chicago, was initially advertised as a molding compound to replace metal, rubber, fibre, wood, porcelain and other plastic materials. … suited to make pencils, buttons, pool triangles, acid containers” (Factory. The Magazine of Management, July 1923, 393). “’Redmanol,’” the new substitute for amber, a Chicago invention, seems to be making a hit from the start” (“Chicago Factories Await Readjustment,” United States Tobacco Journal, November 14, 1914, 13).

What is Redmanol? Here are a couple definitions, the first from the Redmanol company: “REDMANOL. The Material of a thousand uses. REDMANOL is sold as TRANSPARENT REDMANOL which has every physical property of Baltic amber, except that REDMANOL is more lustrous and has perfect transparency. The transparent REDMANOL is used for dental and surgical instruments and electrical insulation and is the material which has largely replaced amber in smokers’ supplies” (Directory. Chicago Section. American Chemical Society, 1911).

The second is from a tobacco industry leader. “Redmanol is a secret compound, the result of years of experiment and research work to find a substance for cigar and cigarette holders and stems which would possess the beauty of natural amber but none of the frailties. It is, in fact a man-made amber, being chemically known as synthetic amber, and has proved so admirable a substitute for natural amber that it is doubtful that the later [sic] will ever again be used to the extent it formerly was. …All in all Redmanol makes use of the most perfect and satisfactory mouth-pieces yet devised. Our customers are evidently aware of this fact as is amply demonstrated by the enormous increase in sales in our stores this year of Redmanol cigar and cigarette tubes” (“Pipe Points Worth Remembering. Redmanol,” The United Shield, November, 1919, 13).

And the third is from a journal article. “Redmanol, a similar substance [to Bakelite], is made using formin instead of formaldehyde, and on melting this with phenol it gives a clear, amber-colored, transparent substance that is plastic and can be bent and worked into shape. On further heating it becomes hard and insoluble and similar to bakelite except for its color and transparency. Redmanol, by virtue of its resemblance to real amber and its many desirable properties of insolubility, non-inflammability, the ability to mold easily before hardening, and its imperviousness to corrosive substances, is used for making hundreds of useful and ornamental objects, some of the most familiar being pipe stems, cigar and cigarette holders, and knife handles” (J. Maple Wilson, Jr., “The Relation of Chemistry to the Home,” Journal of Chemical Education, Vol. 3, No. 6, June, 1926, 670). Then later in the same article:

Then later in the same article:

According to Steve Laug who has studied this much more than I: “Original Bakelite, whatever the color, still looked like plastic, while deep red, translucent Redmanol was so close to amber of the same color that it often requires an expert to differentiate the two. Bakelite was produced in at least these colors: golden yellow, ruby, emerald, amethyst, and jet. Real amber comes in several colors: non-reflective deep-cherry red, golden, and yellow. Most often, Redmanol was a clear or translucent red. Deep-red Redmanol was so close to amber of the same color that it often required an expert to differentiate the two. It certainly didn’t help when ads for Redmanol products stated: “Odorless, taste-less, unbreakable, non-inflammable, and retains its amber color.”

It’s difficult to be accurate on the date of this pipe, but anywhere from the 1910s through the 1930s is a safe bet. Basically, this beauty is about a century old. Let’s take a closer look. The pipe is in terrific condition for its age! The Redmanol parts have a few minor scratches and dents, but no cracks or structural problems. The screw tenon is as dirty as anything, but that’s no big deal. The brass ring is similarly dirty, but not damaged at all. Finally, the briar bowl is also dirty and has a few minor nicks. It should clean up very nicely.

Let’s take a closer look. The pipe is in terrific condition for its age! The Redmanol parts have a few minor scratches and dents, but no cracks or structural problems. The screw tenon is as dirty as anything, but that’s no big deal. The brass ring is similarly dirty, but not damaged at all. Finally, the briar bowl is also dirty and has a few minor nicks. It should clean up very nicely.

I used oil soap on a few cotton rounds and wiped down the stem and stummel to provide an initial cleaning before moving on to the next steps. The primary cleaning came next. I disinfected the inside of both stem and stummel with pipe cleaners and cotton swabs dipped in 99% lemon-infused isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean. I paid particular attention to the tenon and cleaned it further with some 0000-grit steel wool. The next step of the cleaning process was to scour the inside of both stem and stummel with some soap and tube brushes. This was the culmination of a lot of hard work in getting the pipe clean.

The next step of the cleaning process was to scour the inside of both stem and stummel with some soap and tube brushes. This was the culmination of a lot of hard work in getting the pipe clean.

As the stem was now clean and dry, I set about fixing the tooth marks in the Redmanol. This was done by filling those divots with clear cyanoacrylate adhesive. I left this to cure and moved on.

The next step is sanding and I’m not going to sugar coat this: sanding Redmanol is pretty dreadful. First, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the Redmanol. I had to focus especially on a tricky area of the stummel where there were some deep scratches. I taped that area off, so it could be done properly. Following that, I used all nine grey sanding pads and all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the Redmanol, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, clear, amber-like glow to the stem and stummel when I was done.

The next step is sanding and I’m not going to sugar coat this: sanding Redmanol is pretty dreadful. First, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the Redmanol. I had to focus especially on a tricky area of the stummel where there were some deep scratches. I taped that area off, so it could be done properly. Following that, I used all nine grey sanding pads and all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the Redmanol, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, clear, amber-like glow to the stem and stummel when I was done.

I then grabbed the brass ring with both hands – sorry, couldn’t resist. This was quite straightforward. I tried cleaning it with some lemon-infused 99% isopropyl alcohol on cotton rounds. This didn’t really do anything, so I switched over to polishing with 0000-grit steel wool. This worked very well and the ring looked lovely again.

I then grabbed the brass ring with both hands – sorry, couldn’t resist. This was quite straightforward. I tried cleaning it with some lemon-infused 99% isopropyl alcohol on cotton rounds. This didn’t really do anything, so I switched over to polishing with 0000-grit steel wool. This worked very well and the ring looked lovely again.

Next on to the briar bowl. First, I reamed out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. As the bowl was fairly clean already, I used only a piece of sandpaper taped to a wooden dowel. This ensured that all the debris was removed. I also took a piece of machine steel and gently scraped the lava away from the rim. The metal’s edge is sharp enough to remove what I need, but not so sharp that it damages the rim.

Next on to the briar bowl. First, I reamed out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. As the bowl was fairly clean already, I used only a piece of sandpaper taped to a wooden dowel. This ensured that all the debris was removed. I also took a piece of machine steel and gently scraped the lava away from the rim. The metal’s edge is sharp enough to remove what I need, but not so sharp that it damages the rim. To tidy up the briar, I also wiped down the outside with some oil soap on cotton rounds and used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. Just like the stem and stummel, the last step of the cleaning process was to scour the inside of the bowl with some soap and tube brushes. I also scrubbed the aluminum bottom of the bowl with 0000-grit steel wool. Looked fantastic.

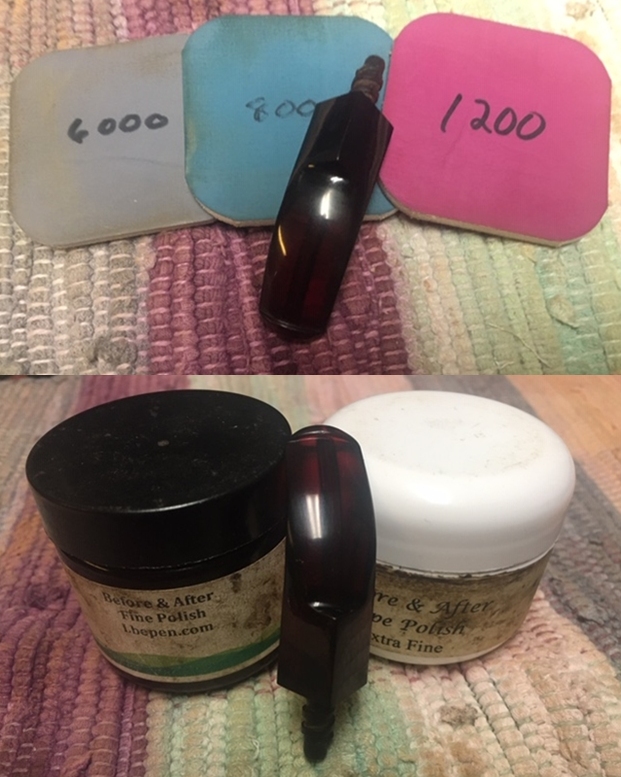

To tidy up the briar, I also wiped down the outside with some oil soap on cotton rounds and used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. Just like the stem and stummel, the last step of the cleaning process was to scour the inside of the bowl with some soap and tube brushes. I also scrubbed the aluminum bottom of the bowl with 0000-grit steel wool. Looked fantastic. I used all nine micromesh pads (1,500 through 12,000 grit) to sand the outside of the bowl and finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the bowl with a microfibre cloth. For the final step, I took the pipe to my bench buffer and carefully polished it – first with a blue diamond compound, then with three coats of carnauba wax. This procedure makes the pipe look its best.

I used all nine micromesh pads (1,500 through 12,000 grit) to sand the outside of the bowl and finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the bowl with a microfibre cloth. For the final step, I took the pipe to my bench buffer and carefully polished it – first with a blue diamond compound, then with three coats of carnauba wax. This procedure makes the pipe look its best.

All done! This no-name Redmanol bent Dublin pipe looks fantastic again and is ready to be enjoyed by my friend in Seattle. It was a pleasure to work on. It’s a gorgeous pipe. The approximate dimensions of the pipe are as follows: length 5¼ in. (134 mm); height 1⅞ in. (48 mm); bowl diameter 1⅜ in. (35 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1⅝ oz. (47 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

All done! This no-name Redmanol bent Dublin pipe looks fantastic again and is ready to be enjoyed by my friend in Seattle. It was a pleasure to work on. It’s a gorgeous pipe. The approximate dimensions of the pipe are as follows: length 5¼ in. (134 mm); height 1⅞ in. (48 mm); bowl diameter 1⅜ in. (35 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1⅝ oz. (47 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.