Blog by Steve Laug

Though I am not currently not taking on new work but trying to catch up on my backlog of pipes I have a commitment to doing repairs for customers of our local pipe shop. I have worked on several pipes for the pipeman who dropped this pipe and two others off at my house on Tuesday morning. All three had the tenons snapped off in the shank and two with broken or damaged stems. All three were heavily smoked with cakes almost completely filling in the bowls. It always make me wonder how one can fill a bowl when cake is so thick my finger would not fit in the bowl. The exterior of all three bowls were heavily caked with tars, oils and grime ground into the finish. The pipes reeked of the aromatic tobaccos that had been smoked in them. My wife bagged the three pipes and sealed them until I could get to them.

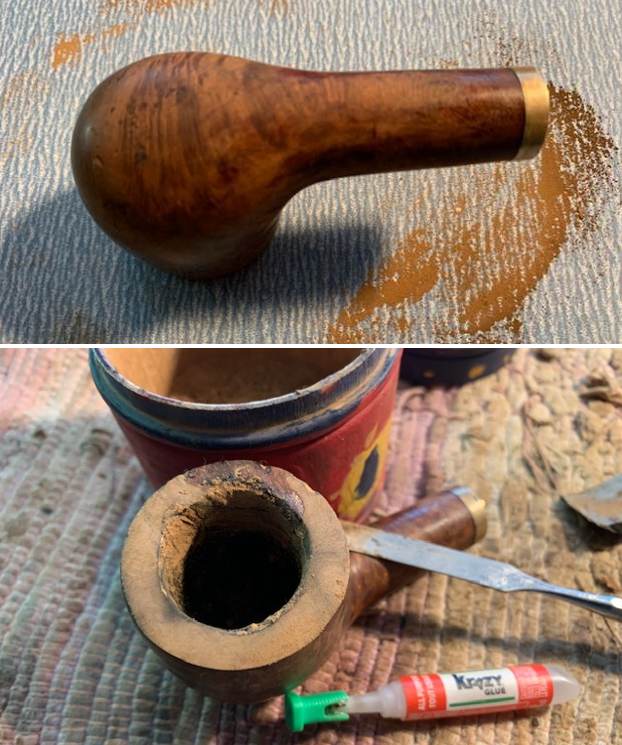

I decided to work on this billiard first. I opened the bag and removed both the bowl and the stem. It was a real mess. I took photos of the bowl to show its condition before I started on it. I took my normal foursome of photos and then added a few extra to show the heavy grime on the bowl sides, the cake in the bowl and the snapped tenon in the shank. Somewhere along its journey the pipe had been banded. Something about it makes me think it may well have been that I had banded and restemmed for the fellow quite a few ago. I did a bit of searching on rebornpipes for the blog but could not find it. In the big picture is did not matter but I am always very curious.

I tried to pull the broken tenon and was not surprised that it was stuck in the shank. I put the bowl in the freezer and let it sit for 30 minutes. Once I removed it I used a screw turned into the airway to wiggle the tenon out of the shank. It actually came out quite easily.

I tried to pull the broken tenon and was not surprised that it was stuck in the shank. I put the bowl in the freezer and let it sit for 30 minutes. Once I removed it I used a screw turned into the airway to wiggle the tenon out of the shank. It actually came out quite easily.  I went through my stems and found one that matched the broken one that had been included in the bag. I took a photo. I would need to reduce both the length and the diameter of the tenon to get a snug fit in the shank. It had a lot of potential but would take work to lift the dents in the stem and fit it to the pipe. Here is a photo of the bowl with the broken stem and the new one.

I went through my stems and found one that matched the broken one that had been included in the bag. I took a photo. I would need to reduce both the length and the diameter of the tenon to get a snug fit in the shank. It had a lot of potential but would take work to lift the dents in the stem and fit it to the pipe. Here is a photo of the bowl with the broken stem and the new one. Now it was time to clean it up so I could work on it. I like restoring clean pipes so that was going to be a lot of work but worth it to me to get rid of the grime. I reamed the bowl with a PipNet reamer using the largest cutting head. I cleaned up the reamer with a Savinelli Fitsall PipeKnife. I sanded the walls of the bowl with 220 grit sandpaper wrapped around a piece of dowel. There was a small mountain of carbon.

Now it was time to clean it up so I could work on it. I like restoring clean pipes so that was going to be a lot of work but worth it to me to get rid of the grime. I reamed the bowl with a PipNet reamer using the largest cutting head. I cleaned up the reamer with a Savinelli Fitsall PipeKnife. I sanded the walls of the bowl with 220 grit sandpaper wrapped around a piece of dowel. There was a small mountain of carbon.

I scrubbed the externals of the pipe to remove the heavy oils and tar build up on the bowl. It took a lot of elbow grease using a tooth brush and Murphy’s Oil Soap. I worked on it until the grime washed away with running water. It looks much better at this point.

I scrubbed the externals of the pipe to remove the heavy oils and tar build up on the bowl. It took a lot of elbow grease using a tooth brush and Murphy’s Oil Soap. I worked on it until the grime washed away with running water. It looks much better at this point.

With the externals cleaned I turned my attention to the internals. I scrubbed the shank and the airway in the bowl and stem with pipe cleaners, cotton swabs and isopropyl alcohol until it was clean. It was a mess.

With the externals cleaned I turned my attention to the internals. I scrubbed the shank and the airway in the bowl and stem with pipe cleaners, cotton swabs and isopropyl alcohol until it was clean. It was a mess. I topped the bowl to prepare it for reworking the damage to the inner edge of the bowl. I used briar dust and super glue to build up the heavily damaged areas around the edge. I layered it in place in the damaged area with a dental spatula. The second photo below shows the repair.

I topped the bowl to prepare it for reworking the damage to the inner edge of the bowl. I used briar dust and super glue to build up the heavily damaged areas around the edge. I layered it in place in the damaged area with a dental spatula. The second photo below shows the repair. I cleaned up the rough edge of the inner edge with a folded piece of 220 grit sandpaper. I wanted to smooth it out before working on the inner bevel of the bowl. I used a wooden ball and 220 grit sandpaper to give the bowl a bevel. The final photo of the four below shows the repaired and reshaped rim edge.

I cleaned up the rough edge of the inner edge with a folded piece of 220 grit sandpaper. I wanted to smooth it out before working on the inner bevel of the bowl. I used a wooden ball and 220 grit sandpaper to give the bowl a bevel. The final photo of the four below shows the repaired and reshaped rim edge.

I stained the rim top and edges with an oak stain pen to match the colour of the bowl. With the micromesh polishing it would be a good match.

I stained the rim top and edges with an oak stain pen to match the colour of the bowl. With the micromesh polishing it would be a good match. I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. It looks far better than it did before even with the many fills in the briar around the bowl.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. It looks far better than it did before even with the many fills in the briar around the bowl.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips. The balm works to clean, enliven and preserve the briar. I let it sit for 10 minutes then buffed it off with a soft cloth. It is a beautiful pipe.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips. The balm works to clean, enliven and preserve the briar. I let it sit for 10 minutes then buffed it off with a soft cloth. It is a beautiful pipe.

The bowl looks surprisingly good when you consider what it looked like when I started. I set the bowl aside and turned my attention to the stem. I sanded the surface of the stem and then “painted” the surface of the stem with the flame of a Bic lighter to lift the tooth marks and scratches. I was able to lift many of them. I used clear super glue to fill in those that remained. I sanded the surface of the stem with 220 grit sandpaper to smooth out the repairs and started the polishing with 400 grit wet dry sandpaper. I also sanded the tenon with 220 grit sandpaper to reduce the diameter of the tenon and get a snug fit.

The bowl looks surprisingly good when you consider what it looked like when I started. I set the bowl aside and turned my attention to the stem. I sanded the surface of the stem and then “painted” the surface of the stem with the flame of a Bic lighter to lift the tooth marks and scratches. I was able to lift many of them. I used clear super glue to fill in those that remained. I sanded the surface of the stem with 220 grit sandpaper to smooth out the repairs and started the polishing with 400 grit wet dry sandpaper. I also sanded the tenon with 220 grit sandpaper to reduce the diameter of the tenon and get a snug fit.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with some Obsidian Oil. I finished hand polishing it with Before & After Pipe Stem Polish – Fine and Extra Fine. I rubbed it down with another coat of Obsidian Oil and let it dry. The stem really was beginning to look very good.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with some Obsidian Oil. I finished hand polishing it with Before & After Pipe Stem Polish – Fine and Extra Fine. I rubbed it down with another coat of Obsidian Oil and let it dry. The stem really was beginning to look very good.

This was a very beat up No Name Straight Billiard and now with its newly fit tapered black vulcanite stem it looks far better than when I started. The reworked rim top works very will with the rest of the bowl. I polished the bowl and the stem with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The brown stain makes the grain just sing and it works well with the polished vulcanite stem. Have a look at the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 60 grams/ 2.12 ounces. Once I finish restemming the other two pipes the three will be going home with the fellow who dropped them off. Thanks for walking through the restoration with me as I worked over this pipe.

This was a very beat up No Name Straight Billiard and now with its newly fit tapered black vulcanite stem it looks far better than when I started. The reworked rim top works very will with the rest of the bowl. I polished the bowl and the stem with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The brown stain makes the grain just sing and it works well with the polished vulcanite stem. Have a look at the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 60 grams/ 2.12 ounces. Once I finish restemming the other two pipes the three will be going home with the fellow who dropped them off. Thanks for walking through the restoration with me as I worked over this pipe.