by Steve Laug

The next pipe on the work table is a unique shape that looks a lot like a billiard banded with barrel iron and buttons. It is very unique looking. It is stamped on the top side of the shank and reads MANHATTAN in gold letter. The shank has a brass (nickel) decorative band with faux hallmarks on top. On the underside of the stem it reads SOLID RUBBER. There were no other identifying marks or stamps on the shank or the stem. It came to us form a seller in Austin, Texas, USA on 11/07/2020. It has a mix of grain around the sides and shank. The bowl had a heavy cake in the bowl and thick lava on the rim top. It was thick so it was hard to be certain what the inner edge looked like. The finish was very dirty so it was hard to know with certainty what lay underneath. The bowl is a classic Billiard shape. The solid rubber oval taper stem had an orific button and showed some age. It has oxidation, calcification, tooth chatter and tooth marks on both sides ahead of the button. Jeff took photos of the pipe before he started working on it.

Jeff took photos of the bowl, rim top and stem sides to show the condition of the both. It was a dirty bowl with debris and a heavy cake on the walls. The rim top had a thick lava covering the bowl and the edges. It was hard to know what the condition of the inner edge was underneath. I took photos of the top and underside of the stem showing condition and the tooth marks on both sides ahead of the button.

Jeff took photos of the bowl, rim top and stem sides to show the condition of the both. It was a dirty bowl with debris and a heavy cake on the walls. The rim top had a thick lava covering the bowl and the edges. It was hard to know what the condition of the inner edge was underneath. I took photos of the top and underside of the stem showing condition and the tooth marks on both sides ahead of the button.

Jeff took photos of the grain around the sides and the heel of the bowl to show the briar that was used to craft this unique pipe.

Jeff took photos of the grain around the sides and the heel of the bowl to show the briar that was used to craft this unique pipe.

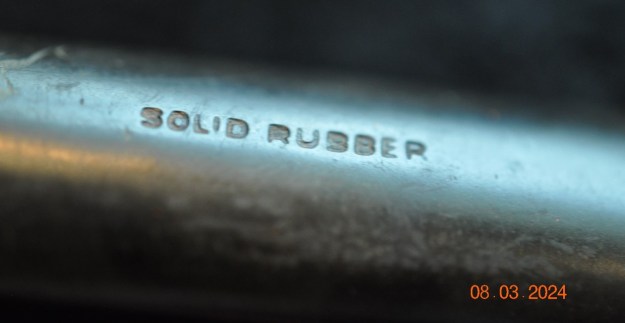

He took photos to capture the stamping on the top and underside of the shank, band and stem. It is clear and readable as noted above.

He took photos to capture the stamping on the top and underside of the shank, band and stem. It is clear and readable as noted above.

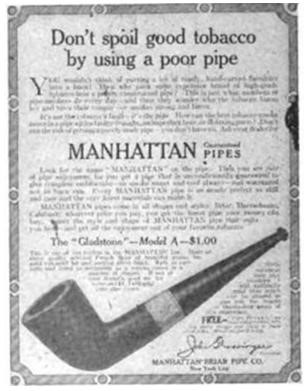

I turned to Pipedia and found a helpful article on the background. It was called The Manhattan Briar Pipe Company. It is an interesting read so I have included the article in its entirety as well as the advertisement from 1913 that showed a Manhattan pipe. The interesting thing for me is that the pipe is the same shape and style as the one I have in hand. The difference of course is that mine does not have a silver band and there is a horn stem rather than a vulcanite stem.

I turned to Pipedia and found a helpful article on the background. It was called The Manhattan Briar Pipe Company. It is an interesting read so I have included the article in its entirety as well as the advertisement from 1913 that showed a Manhattan pipe. The interesting thing for me is that the pipe is the same shape and style as the one I have in hand. The difference of course is that mine does not have a silver band and there is a horn stem rather than a vulcanite stem.

The Manhattan Briar Pipe Co. was organized in October, 1902 by the American Tobacco Company, under an agreement with the owners of the Brunswick Briar Pipe Company, as a New York corporation. Its initial address was 111 5th Avenue, New York City, and the value of its stock in 1902 was $350,000.00. American Tobacco Company had itself been founded in 1890 by J. B. Duke through a merger between a number of U.S. tobacco companies, and was one of the original twelve members of the Dow Jones Industrial Average in 1896. It was commonly called the “Tobacco Trust”.

The majority of the stock in Manhattan Briar Pipe Company was immediately acquired by the American Tobacco Company after the company was organized, but the prior owners retained a controlling minority interest for some years. In October, 1906, however, the American Tobacco Company acquired the remaining shares of stock, and from that point on Manhattan Briar was the pipe making branch of American Tobacco. By 1911, however, American Tobacco had been dissolved in anti-trust litigation, and Manhattan Briar Pipe Co. became a separate concern.

The majority of the stock in Manhattan Briar Pipe Company was immediately acquired by the American Tobacco Company after the company was organized, but the prior owners retained a controlling minority interest for some years. In October, 1906, however, the American Tobacco Company acquired the remaining shares of stock, and from that point on Manhattan Briar was the pipe making branch of American Tobacco. By 1911, however, American Tobacco had been dissolved in anti-trust litigation, and Manhattan Briar Pipe Co. became a separate concern.

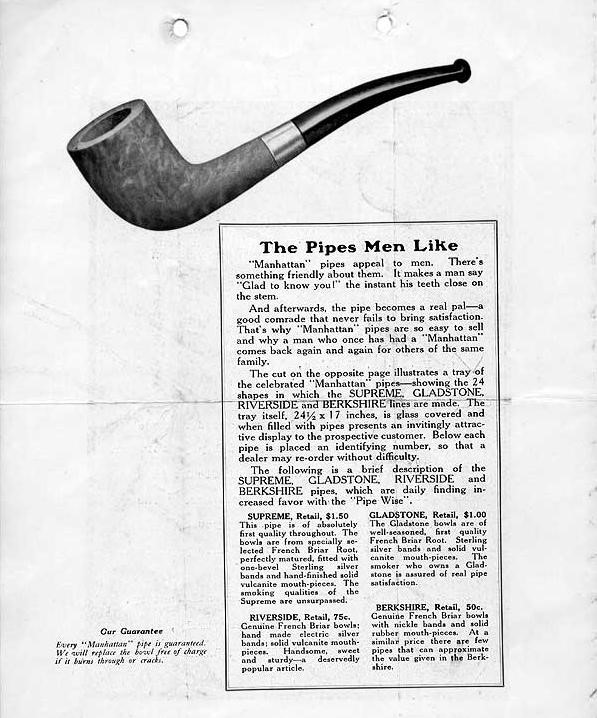

Manhattan Briar Pipe Co. had started operations in 1905 in Jersey City, New Jersey, having taken on a lease for a ten year period in 1905, and maintained a factory at Marion, New Jersey, where the pipes were made. By 1913, former American Tobacco pipe department chair John Glossinger was the president of Manhattan Briar Pipe Company, and began a significant advertising push for high grade pipes, using the slogan “Don’t spoil good tobacco by using a poor pipe”. It appears from cases having appeared on the estate market that Manhattan also sold meerschaum pipes, most likely rebranded articles originally made by European craftsmen.

After the expiration of the Jersey City lease the Manhattan Briar Pipe Company maintained offices and a factory at 415-425 Greenpoint Avenue, Brooklyn, New York beginning in 1915, evidently under the direction of W. C. Bastian, who had been granted a patent for a chambered pipe stem otherwise seemingly identical to a Peterson P-Lip in 1910. An employee of the company, one J. Gianninoto, was granted a patent for a device meant to permit the emptying of a cuspidor without the mess in early 1918, and the company continues to be listed in local directories through 1921. In 1922 Manhattan Briar was purchased by S.M. Frank and merged into that company. https://pipedia.org/wiki/Manhattan_Briar_Pipe_Co.

Further digging led me to a link on the S.M. Frank Co. & Inc. history page. Reading through the history of the company I found that S.M. Frank not only purchased the Manhattan Briar Pipe Company but also purchased WDC or William DeMuth & Company – two of the older brands that I enjoy working on. Here is the relevant section from the link: In the year 1900 Sam Frank Sr. started his own business, selling pipes and other tobacco items. His original office was located at 20 W. 17th Street, NYC. He was also closely associated with the sales staff of Wm. DeMuth & Co., selling their line of pipes. It was at this time that Mr. Frank first met Ferdinand Feuerbach and formed what would be a lifelong friendship. Mr. Feuerbach started working for the DeMuth Company in 1897 and by 1903 had become the production manager. In 1919, when Mr. Frank needed an experienced pipe man to run his pipe factory, located at 168 Southern Blvd., in the Bronx, he persuaded his old friend Ferdinand to join him. Mr. Feuerbach is credited with developing DeMuth’s popular Royal DeMuth and Hesson Guard Milano pipelines. In 1922, when S. M. Frank purchased the Manhattan Briar Pipe Co. the company incorporated. http://www.smfrankcoinc.com/home/?page_id=2

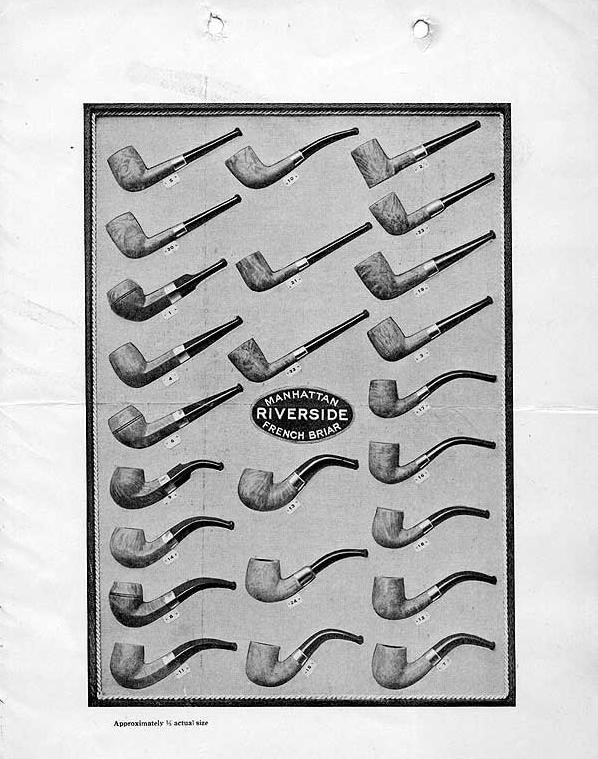

That link led me to me to some further information including an advertisement and a shape chart on Chris Keene’s Pipe Pages http://pipepages.com/mbpc2.htm. I have included them here with acknowledgement to Chris Keene. I always enjoy reading the old copy of these advertisements as they take me back to place where the pipe was an acceptable part of the life.

The pipe I have in hand is one that was made between the opening of the Manhattan Briar Pipe Company in 1905 in New Jersey and 1922 when SM Frank bought the company and it ceased to exist as a separate entity. That fit my experience of working on pipes with stems stamped Solid Rubber.

The pipe I have in hand is one that was made between the opening of the Manhattan Briar Pipe Company in 1905 in New Jersey and 1922 when SM Frank bought the company and it ceased to exist as a separate entity. That fit my experience of working on pipes with stems stamped Solid Rubber.

Armed with that information I turned to work on the pipe itself. Jeff had done a great job cleaning up the pipe as usual. He cleaned up the inside of the bowl with a PipNet reamer and a Savinelli Fitsall Pipe Knife. The bowl walls looked very good. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He worked on the rim top lava and darkening with the soap and tooth brush. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Briarville’s Pipe Stem Deoxidizer. He washed it off with warm water to remove the deoxidizer. The pipe looked far better. I took photos of the pipe when I received it before I started working on it.

I took photos of the bowl and rim top to show how clean it was. The top and the inner edge of the rim show some darkening, nicks and scratches. The stem looks clean of debris and grime. There are light tooth marks and chatter on both sides.

I took photos of the bowl and rim top to show how clean it was. The top and the inner edge of the rim show some darkening, nicks and scratches. The stem looks clean of debris and grime. There are light tooth marks and chatter on both sides.  I took a photo of the stamping on the top of the shank. The stamping is clear and readable and appears to have had gold stamp in the letters. The stem shows a Solid Rubber stamp clearly on the underside. I took a photo of the pipe with the stem removed to show the overall look of stem, tenon and profile of the pipe.

I took a photo of the stamping on the top of the shank. The stamping is clear and readable and appears to have had gold stamp in the letters. The stem shows a Solid Rubber stamp clearly on the underside. I took a photo of the pipe with the stem removed to show the overall look of stem, tenon and profile of the pipe.

I started my work on the pipe by addressing the issues on the top and the inner edge of the rim. I used a folded piece of 220 grit sandpaper to smooth out the roughness. It looked much better at this point in the process.

I started my work on the pipe by addressing the issues on the top and the inner edge of the rim. I used a folded piece of 220 grit sandpaper to smooth out the roughness. It looked much better at this point in the process. I sanded the briar rim top and the sides of the bowl with 320-3500 grit sanding pads. I wiped the bowl down with a damp cloth after each pad. By the time I finished with the 3500 grit pad the briar had taken on a rich glow.

I sanded the briar rim top and the sides of the bowl with 320-3500 grit sanding pads. I wiped the bowl down with a damp cloth after each pad. By the time I finished with the 3500 grit pad the briar had taken on a rich glow.

I touched up the gold stamp on the top of the shank with Rub’n Buff Antique Gold. I worked it into the stamping with a tooth pick and buffed it off with a soft cloth. It was very readable and looked good with the brass band and brass rings and studs on the bowl.

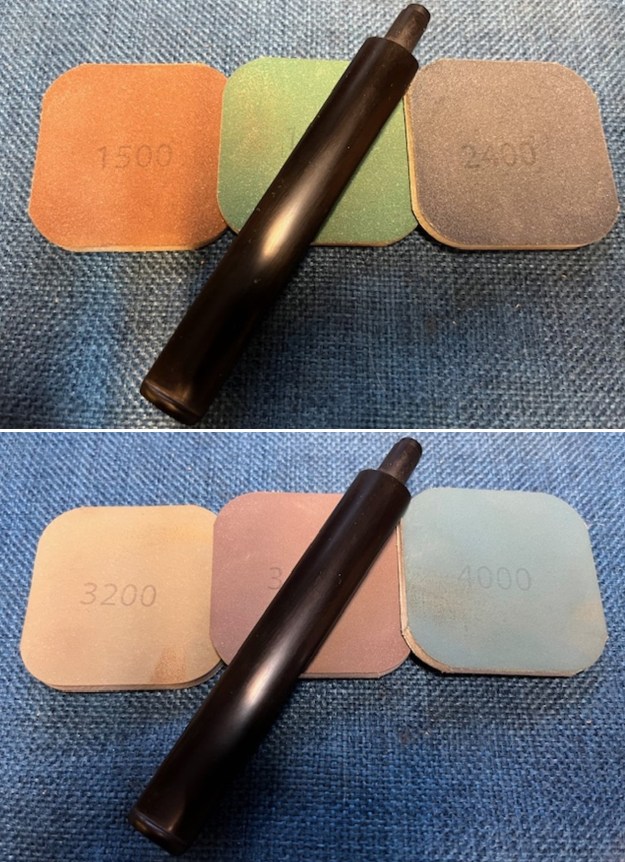

I touched up the gold stamp on the top of the shank with Rub’n Buff Antique Gold. I worked it into the stamping with a tooth pick and buffed it off with a soft cloth. It was very readable and looked good with the brass band and brass rings and studs on the bowl.  I polished the briar bowl and shank with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each pad to remove the debris. The bowl took on a rich glow.

I polished the briar bowl and shank with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each pad to remove the debris. The bowl took on a rich glow.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for 10 minutes and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for 10 minutes and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I set aside the bowl and turned my attention to the stem issues. I sanded it with a folded piece of 220 grit sandpaper to begin the process of blending the chatter and marks into the stem surface. On the underside I found a piece of metal embedded in the rubber confirming an early date as mentioned above.

I set aside the bowl and turned my attention to the stem issues. I sanded it with a folded piece of 220 grit sandpaper to begin the process of blending the chatter and marks into the stem surface. On the underside I found a piece of metal embedded in the rubber confirming an early date as mentioned above. I sanded it with 320-3500 grit sanding pads to further blend them in and smooth out the surface.

I sanded it with 320-3500 grit sanding pads to further blend them in and smooth out the surface. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I put the stem back on the Manhattan Barrel Like Oval Shank Billiard and took it to the buffer. I worked it over with Blue Diamond to polish out the remaining small scratches. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really well and the bevelled rim top looked good. I was happy with the look of the finished pipe. The photos below show what the pipe looks like after the restoration. This Oval Shank Manhattan Billiard is a beautiful and unique take on a classic shape. The polished solid rubber taper stem looks really good with the browns of the briar and the brass of the bands around the bowl and shank. The dimensions of the pipe are Length: 7 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 1.83 ounces/52 grams. This is another pipe that I will be putting it on the rebornpipes store in the American Pipe Makers Section shortly, if you are interested in adding it to your collection. The unique brass on the bowl gives it a great look and feel. This one should be a great smoker. Thanks for walking through the restoration with me on this beauty!