by Kenneth Lieblich

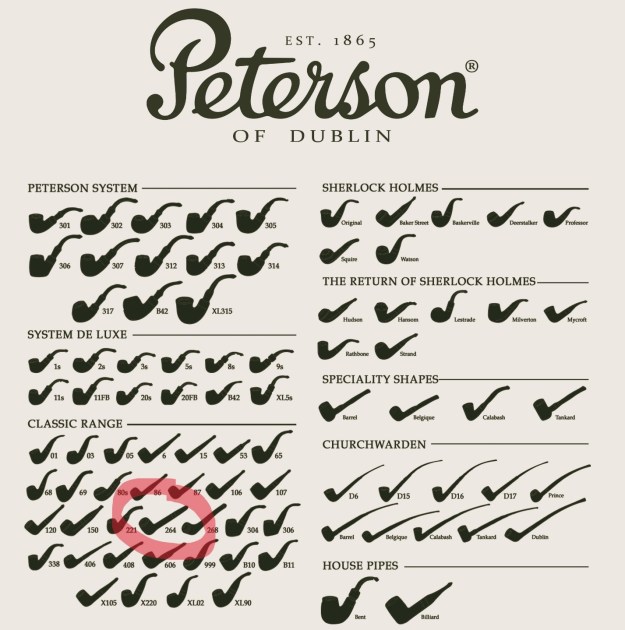

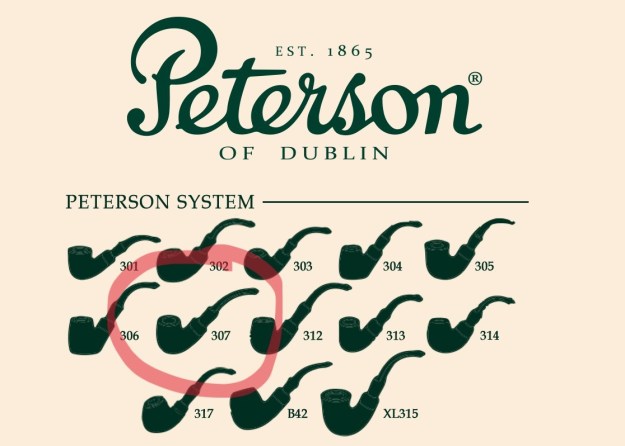

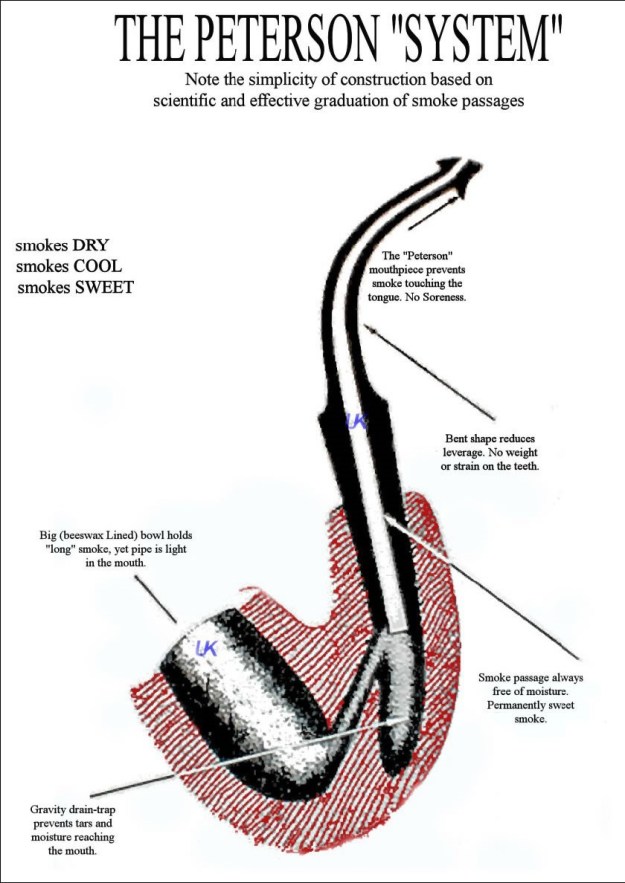

Perhaps this pipe has seen better days in its past, but I think its best days are still ahead. It’s a handsome, rugged Peterson 301 System Standard rusticated bent pot with a P-lip. This pipe came from an old gentleman, now deceased, who lived on Vancouver Island. I have no idea what he did with this pipe, but boy-oh-boy, it is pretty rough. No problem – it’s my job to sort things out.

The only markings to be found on this pipe are the 301 found on the underside of the stummel and the K&P [over] Peterson on the nickel ferrule.

The only markings to be found on this pipe are the 301 found on the underside of the stummel and the K&P [over] Peterson on the nickel ferrule. Mark Irwin of Peterson Pipe Notes has written a few good articles about the 301s on his blog and I recommend reading one here and another one here. Of course, Steve has also written restoration blogs about the 301, including this one and it contained an important tidbit of information that I quote here:

Mark Irwin of Peterson Pipe Notes has written a few good articles about the 301s on his blog and I recommend reading one here and another one here. Of course, Steve has also written restoration blogs about the 301, including this one and it contained an important tidbit of information that I quote here:

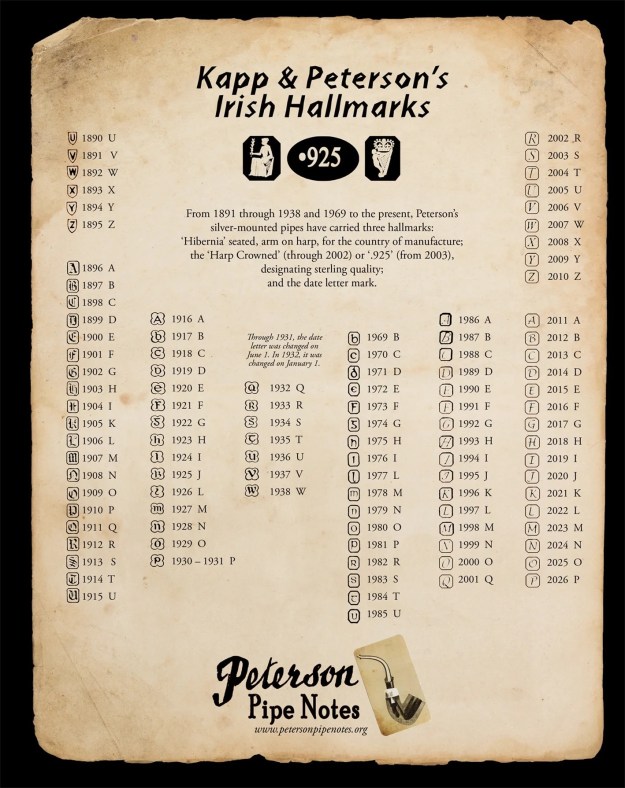

I learned previously that the shape 301 was not introduced until 1975. Considering the Republic stamp, this one would likely date between 1975 and 2000.

This was significant because, due to the markings being almost entirely worn on this pipe, there was nothing on the wood other than the number 301 – and I couldn’t tell an age from that. Charles Lemon from Dad’s Pipes also has a post about a 301, which he describes as coming from the “1970’s era”. Now, what’s interesting about Steve and Charles’ pipes is that the patch of briar which shows the marks is quite different from mine. Below are Steve’s, Charles’, and my pipes, respectively. The first two are sort of freeform oval-ish shapes. Third (mine) is a rectangle and I wonder if that indicates a different era. I don’t know, but if any of you reading this do, please let me know!

This pipe is filthy beyond description – but must have been smoked frequently and with great affection. The stem has dirt everywhere, severe toothmarks aplenty, and calcification as I have seldom seen. Meanwhile, the stummel looks as though dirt has been ground into the grooves of the rustication. The rim is coated in lava and the bowl is clogged with cake. The old fellow must have really loved his pipe.

This pipe is filthy beyond description – but must have been smoked frequently and with great affection. The stem has dirt everywhere, severe toothmarks aplenty, and calcification as I have seldom seen. Meanwhile, the stummel looks as though dirt has been ground into the grooves of the rustication. The rim is coated in lava and the bowl is clogged with cake. The old fellow must have really loved his pipe.

I began by cleaning some of the calcification on the outside of the stem. I took a blade (an old butter knife, actually) and began gently scraping at all that build-up. Obviously, I took it easy, as I did not want to damage the stem’s vulcanite any further. The butter knife worked quite well and I got a good amount loose. I followed that up with some oil soap on some cotton rounds to try and scrub the rest away.

I began by cleaning some of the calcification on the outside of the stem. I took a blade (an old butter knife, actually) and began gently scraping at all that build-up. Obviously, I took it easy, as I did not want to damage the stem’s vulcanite any further. The butter knife worked quite well and I got a good amount loose. I followed that up with some oil soap on some cotton rounds to try and scrub the rest away. I broke out the isopropyl alcohol and pipe cleaners, and got to work on the inside of the stem. Predictably, it was unbelievably dirty and I went through a good number of pipe cleaners in order to clean it up.

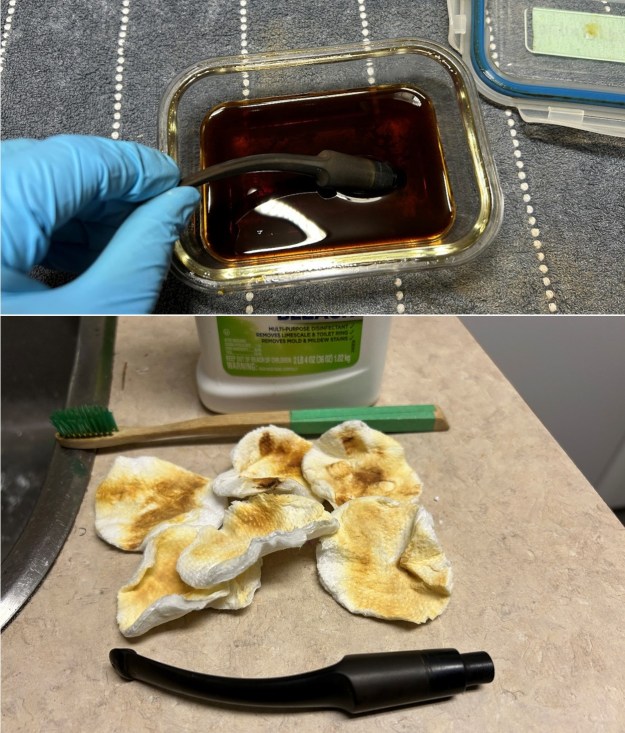

I broke out the isopropyl alcohol and pipe cleaners, and got to work on the inside of the stem. Predictably, it was unbelievably dirty and I went through a good number of pipe cleaners in order to clean it up. As I mentioned, there were quite a few dents in the stem. Some were obviously tooth marks, but other dents looked like blunt force trauma! Time to break out the BIC lighter to see if it could raise some of them. Quite frankly, it did not do much – this repair was going to require some considerable sanding etc. Before that, however, the stem went for an overnight soak in the deoxidizer. The following day, the oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed vigorously with some cream cleanser to remove the leftover oxidation.

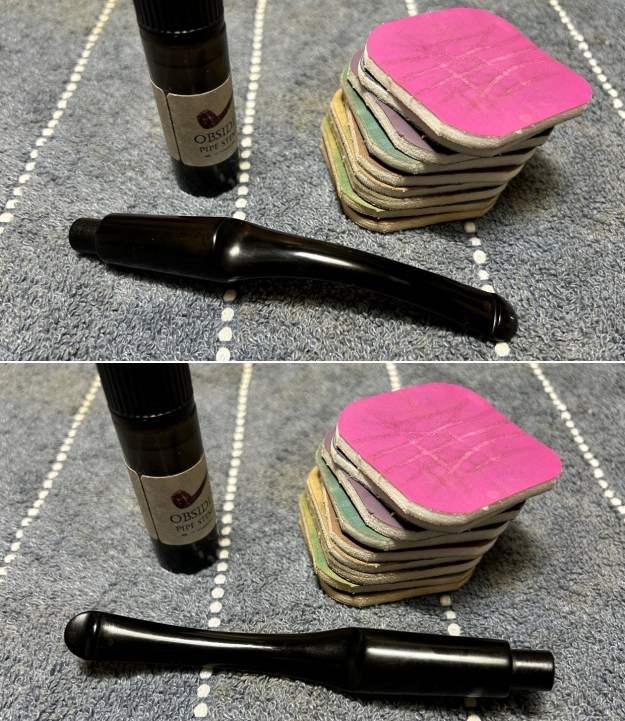

As I mentioned, there were quite a few dents in the stem. Some were obviously tooth marks, but other dents looked like blunt force trauma! Time to break out the BIC lighter to see if it could raise some of them. Quite frankly, it did not do much – this repair was going to require some considerable sanding etc. Before that, however, the stem went for an overnight soak in the deoxidizer. The following day, the oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed vigorously with some cream cleanser to remove the leftover oxidation. Once clean, I set about repairing the dents. Before I moved on to the Micromesh pads, I built up the dent damage on the stem with black cyanoacrylate adhesive and let it fully cure. I sanded the lumps down with my needle files and my grey pads, to make the stem look sort of normal. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each of the last five pads.

Once clean, I set about repairing the dents. Before I moved on to the Micromesh pads, I built up the dent damage on the stem with black cyanoacrylate adhesive and let it fully cure. I sanded the lumps down with my needle files and my grey pads, to make the stem look sort of normal. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each of the last five pads.

On to the stummel – this is where the lion’s share of the work was. The insides (both bowl and shank) were overwhelmed with cake and tar and anything else you’d care to mention. The bowl really needed to be reamed, so I used a reamer to scrape off as much built-up cake as possible. Generally, I prefer to sand the chamber down to bare briar. When restoring, it is important to ensure that there is no damage to the briar under the cake. There are a few situations when I might leave some cake in the bowl, but not today. There were definitely some craze lines in the interior walls of the briar. I’ll come back to that later.

On to the stummel – this is where the lion’s share of the work was. The insides (both bowl and shank) were overwhelmed with cake and tar and anything else you’d care to mention. The bowl really needed to be reamed, so I used a reamer to scrape off as much built-up cake as possible. Generally, I prefer to sand the chamber down to bare briar. When restoring, it is important to ensure that there is no damage to the briar under the cake. There are a few situations when I might leave some cake in the bowl, but not today. There were definitely some craze lines in the interior walls of the briar. I’ll come back to that later. Just like the bowl, the shank was absolutely disgusting. It had never been cleaned – or, not for many decades. I started cleaning the inside with isopropyl alcohol, cotton swabs, and pipe cleaners. This took a while. The inside was very dirty and required an extraordinary number of cotton swabs and pipe cleaners. Eventually some cleanliness came to it.

Just like the bowl, the shank was absolutely disgusting. It had never been cleaned – or, not for many decades. I started cleaning the inside with isopropyl alcohol, cotton swabs, and pipe cleaners. This took a while. The inside was very dirty and required an extraordinary number of cotton swabs and pipe cleaners. Eventually some cleanliness came to it. I decided to de-ghost the pipe. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused even more oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this.

I decided to de-ghost the pipe. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused even more oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this. I scrubbed the stummel with some pH-neutral soap and a toothbrush. This made things much better, but it’s a case of two steps forward and one step back: sure, it’s clean, but a bit of colour has faded. No problem – I can bring that back with wood balm.

I scrubbed the stummel with some pH-neutral soap and a toothbrush. This made things much better, but it’s a case of two steps forward and one step back: sure, it’s clean, but a bit of colour has faded. No problem – I can bring that back with wood balm. On to the ferrule – which was bashed and discoloured from years of mistreatment. Somewhat to my surprise, the ferrule came off very easily and required no special effort. I began by cleaning the metal with some cleanser on cotton rounds. This was quite good at removing the unsightly bits. I used my finer MicroMesh pads to eliminate some of the minor scratches on the metal. It also gave a nice shine which clearly hadn’t been seen for decades. I used a jewelry cloth to give the final polish to the nickel. This ferrule will always retain some small dents etc. from its hard life, but it looks much improved.

On to the ferrule – which was bashed and discoloured from years of mistreatment. Somewhat to my surprise, the ferrule came off very easily and required no special effort. I began by cleaning the metal with some cleanser on cotton rounds. This was quite good at removing the unsightly bits. I used my finer MicroMesh pads to eliminate some of the minor scratches on the metal. It also gave a nice shine which clearly hadn’t been seen for decades. I used a jewelry cloth to give the final polish to the nickel. This ferrule will always retain some small dents etc. from its hard life, but it looks much improved. I now wanted to address the heat crazes inside the bowl. I prepared some heat-resistant epoxy and filled the cracks and gouges, ensuring that the epoxy was thinly and evenly spread throughout the bowl. Of course, I did plug the draught hole with a folded pipe cleaner (coated in petroleum jelly) to make sure none of the epoxy made its way up there. Once done, a good 24 hours was needed to ensure that the epoxy was properly cured. The next day, I roughened up the epoxy’s surface with 220-grit sandpaper for the next step. I thinly coated the inside of the bowl with a mixture of my wife’s homemade yogurt and activated charcoal. Once hardened, this provided a good, faintly rough surface for a new cake to build.

I now wanted to address the heat crazes inside the bowl. I prepared some heat-resistant epoxy and filled the cracks and gouges, ensuring that the epoxy was thinly and evenly spread throughout the bowl. Of course, I did plug the draught hole with a folded pipe cleaner (coated in petroleum jelly) to make sure none of the epoxy made its way up there. Once done, a good 24 hours was needed to ensure that the epoxy was properly cured. The next day, I roughened up the epoxy’s surface with 220-grit sandpaper for the next step. I thinly coated the inside of the bowl with a mixture of my wife’s homemade yogurt and activated charcoal. Once hardened, this provided a good, faintly rough surface for a new cake to build.

I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth.

I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth.

It was at this point that something funny happened. The P-lip stem, which fit when this project began, no longer fit! All of the filth and goo was holding it in place. Now that the yuckiness was gone, I realized that the stem was actually not right – it had been replaced at some point in the past. Annoyingly, it was clearly not the right size. Fortunately, Steve had another Peterson factory stem (a fishtail, this time) and donated it to make this pipe look wonderful again. Unfortunately, I don’t have photos of the old stem looking loose, but the new stem is a Peterson original and looks so good in place.

It was at this point that something funny happened. The P-lip stem, which fit when this project began, no longer fit! All of the filth and goo was holding it in place. Now that the yuckiness was gone, I realized that the stem was actually not right – it had been replaced at some point in the past. Annoyingly, it was clearly not the right size. Fortunately, Steve had another Peterson factory stem (a fishtail, this time) and donated it to make this pipe look wonderful again. Unfortunately, I don’t have photos of the old stem looking loose, but the new stem is a Peterson original and looks so good in place.

At long last, I was off to my bench buffer to put the final touches on this pipe. Several coats of conservator’s wax created a beautiful, glossy seal on the pipe and moved closer to closure for this long and involved repair. At this point, I glued the ferrule back in place. All done! This handsome Peterson System Standard 301 rusticated bent pot looks fantastic again and is ready to be enjoyed by its next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5⅓ in. (136 mm); height 1⅞ in. (46 mm); bowl diameter 1½ in. (37 mm); chamber diameter ⅞ in. (22 mm). The weight of the pipe is 1½ oz. (46 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

All done! This handsome Peterson System Standard 301 rusticated bent pot looks fantastic again and is ready to be enjoyed by its next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5⅓ in. (136 mm); height 1⅞ in. (46 mm); bowl diameter 1½ in. (37 mm); chamber diameter ⅞ in. (22 mm). The weight of the pipe is 1½ oz. (46 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.