By Steve Laug

The next pipe on the table is a beautiful rusticated Billiard with a silver ferrule and silver spigot stem. We purchased it from an Antique Mall in Lincoln City, Oregon, USA on 08/24/2024. The pipe is stamped on a smooth panel on the underside of the shank and reads Ferndown [arched over] Bark followed by L&JS Briars [over] Hand Made In [over] England. There was a thin cake in the bowl and the rim top and inner edge had been scraped and was faded. There was grime ground into the rusticated finish around the bowl and shank. There was also some fading on the right side of the bowl toward the front running down from the rim edge to about midbowl. It was faded as if by sun or perhaps whatever had stripped the rim top. The pipe was someone’s obvious favourite and was well care. The inner edge looked to be in good condition. The oxidized ferrule and spigot end on the stem are both Sterling Silver. The ferrule bears the stamp L&JS followed by 925 on the left side. There is an LJS logo stamped in gold on the left side of the taper stem. The stem is heavily oxidized and calcified. There appears to be some light tooth chatter on the top and underside of the stem ahead of the button. I took photos of the pipe earlier this morning before I started my clean up work. I have included them below.

I took a photo of the rim top, bowl and the surfaces of the stem to give a sense of the condition of the pipe. The walls of the bowl had a thin cake with no lava on the rim edges or top. The stem is heavily oxidized, calcified and dirty. There are light tooth marks on both sides ahead of the button.

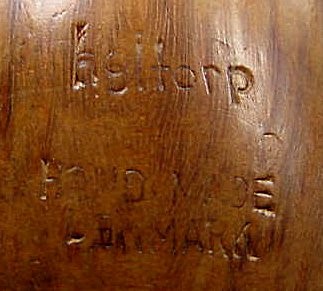

I took a photo of the rim top, bowl and the surfaces of the stem to give a sense of the condition of the pipe. The walls of the bowl had a thin cake with no lava on the rim edges or top. The stem is heavily oxidized, calcified and dirty. There are light tooth marks on both sides ahead of the button. I took a photo of the stamping on the smooth panel on the underside the heel and the shank. It is clear and readable and read as noted above. The silver ferrule and the left side of the taper both have clear stamping under the oxidation that reads as noted above.

I took a photo of the stamping on the smooth panel on the underside the heel and the shank. It is clear and readable and read as noted above. The silver ferrule and the left side of the taper both have clear stamping under the oxidation that reads as noted above. I took some photos of the fading on the front and the right side of the bowl extending half way down the rusticated surface. It is wash out and matches the washed out rim top on the bowl.

I took some photos of the fading on the front and the right side of the bowl extending half way down the rusticated surface. It is wash out and matches the washed out rim top on the bowl.  I took a photo of the pipe with the stem removed. It is definitely dirty and the silver and the stem both are oxidized.

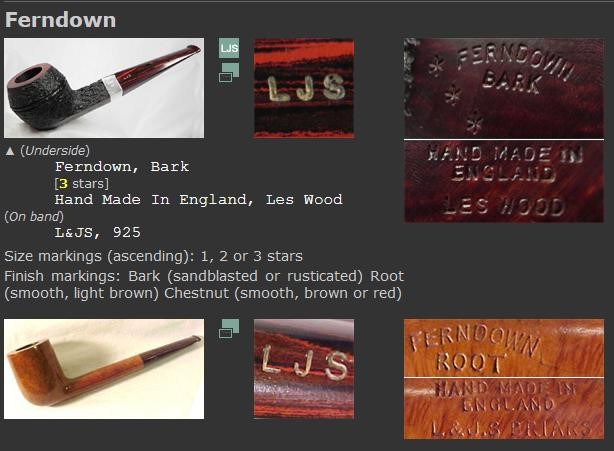

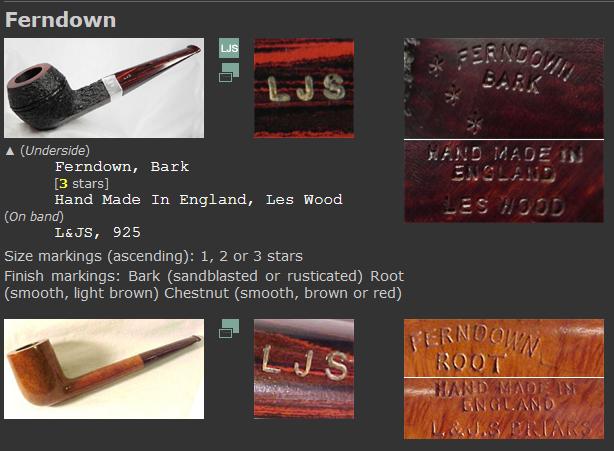

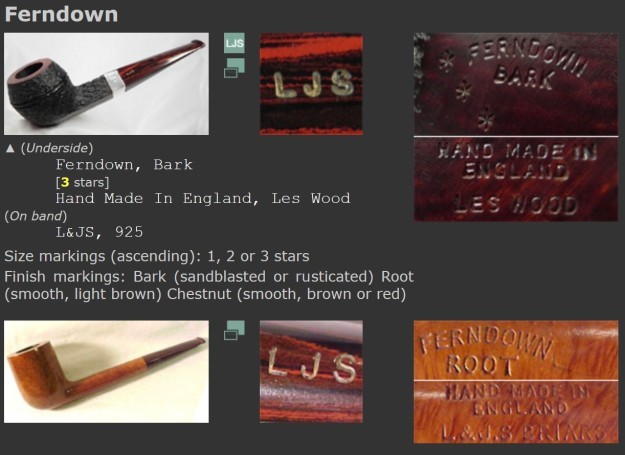

I took a photo of the pipe with the stem removed. It is definitely dirty and the silver and the stem both are oxidized.  To gather backgound on the brand I turned to Pipephil’s site to see what was included in the listing there (http://www.pipephil.eu/logos/en/logo-f1.html). I have included both the screen capture and also the side bar below the photo I have included.

To gather backgound on the brand I turned to Pipephil’s site to see what was included in the listing there (http://www.pipephil.eu/logos/en/logo-f1.html). I have included both the screen capture and also the side bar below the photo I have included. Artisan: Leslie (Les) Wood. He was the master silver smith at Alfred Dunhill Ltd. before starting L. & J.S. Briars. Pipes for the European market are stamped “L. Wood” while those for US are stamped “Ferndown”. Production: ~ 2000 pipes/year (Ferndown + L.Wood) See also Elwood

Artisan: Leslie (Les) Wood. He was the master silver smith at Alfred Dunhill Ltd. before starting L. & J.S. Briars. Pipes for the European market are stamped “L. Wood” while those for US are stamped “Ferndown”. Production: ~ 2000 pipes/year (Ferndown + L.Wood) See also Elwood

The first pipe pictured in the screen capture above is stamped similarly to mine. The pipe I had in hand did not have the stars on the heel so there was no size designation on the pipe. This is a large pipe. The Bark finish is a designation used for both sandblasted and rusticated. The stem on the pipe I am working on is also not Cumberland but rather black vulcanite with a silver spigot ending.

I turned to Pipedia next (https://pipedia.org/wiki/Ferndown). There is a great article there on the carver, the pipes and the workshop. It is worth the time to give it a read. I am quoting the section on the pipes below for the information included.

Due to the vagaries of international trademark law, he sold his earlier pipes as ”L.&J.S Briars”, “Ellwood”, “Les Wood” or “L. Wood”. Until recently, an average of 1500 – 2000 pipes a year were sold as “Ferndown” — named for the mansion he lives in — in the UK and US, but as “L. Wood” pipes in Germany…

…To many pipe smokers, Les Wood’s pipes embody the revival of great English pipe making initiated by Ashton in the early 1980s. The high-grade Italian and Spanish plateau he prefers is oil-cured in the tradition of both Dunhill and Ashton. The pipes are renowned for their pleasant, slightly nutty flavor and remarkable smoking characteristics. They feature impeccable craftsmanship extending to very good stem/bit work, though many pipes are often a bit heavier. The hallmark of his work, of course, is the excellent silver work. Almost all of his pipes feature rings or ferules for spigot stems. Grading is by finish: “Bark” (ca. 90%, rusticated, dark brown and black), “Antique Bark” (tan rusticated), “Reo” (brown and red, smooth), “Root” (orange, smooth), and “Tudor Root” (orange and brown smooth) and by size (one to four stars). He also designates straight grains with SG.

The pipe I am working on is as noted above a Ferndown which identifies it as a pipe named after his mansion and as a pipe made for the UK and the US. It is also as noted in red above stamped Bark which identifies it as a dark brown and black rusticated pipe.

Now it was time to work on the pipe. I started my work by reaming the pipe. I scraped out the light cake with a Savinelli Fitsall Pipe Knife. I took the cake back to bare briar. I sanded the walls smooth with 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good with no burn damage or checking on the walls.

I worked on the fading and damage to the rim top with 320-3500 grit sanding pads. It looked much better when I had finished with the last of the pads.

I worked on the fading and damage to the rim top with 320-3500 grit sanding pads. It looked much better when I had finished with the last of the pads. At this point I stained the rim top and the faded areas around the bowl with a Mahogany stain pen. It blended well with the surrounding briar on the bowl sides. The rim top looked better but I would need to polish it and clean up the finished look of the rim top.

At this point I stained the rim top and the faded areas around the bowl with a Mahogany stain pen. It blended well with the surrounding briar on the bowl sides. The rim top looked better but I would need to polish it and clean up the finished look of the rim top.

I cleaned out he internals of the shank, mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners.

I cleaned out he internals of the shank, mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I polished the smooth rim top with micromesh sanding pads. I dry sanded it with 1500-12000 grit sanding pads and wiped the bowl down after each pad with a damp cloth. By the final pads the briar really had a shine.

I polished the smooth rim top with micromesh sanding pads. I dry sanded it with 1500-12000 grit sanding pads and wiped the bowl down after each pad with a damp cloth. By the final pads the briar really had a shine.  I rubbed the briar down with Before & After Restoration Balm. I worked it into the smooth rim top surface with my fingertips and into the heavy rustication with a shoebrush. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the smooth rim top surface with my fingertips and into the heavy rustication with a shoebrush. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I polished the silver ferrule and the spigot end on the stem with a jeweller’s cloth to clean up and prevent further oxidation in the future. The contrast between the silver and the heavy rustication is very nice.

I polished the silver ferrule and the spigot end on the stem with a jeweller’s cloth to clean up and prevent further oxidation in the future. The contrast between the silver and the heavy rustication is very nice.

I set the bowl aside and turned my attention to the stem. I scrubbed the oxidation on the stem surface with Soft Scrub and cotton pads until it was much cleaner.

I set the bowl aside and turned my attention to the stem. I scrubbed the oxidation on the stem surface with Soft Scrub and cotton pads until it was much cleaner. I sanded the surface with 320-3500 grit sanding pads. I wiped the stem down after each pad with Obsidian Oil. I was able to remove the remnants of oxidation and the stem looked better.

I sanded the surface with 320-3500 grit sanding pads. I wiped the stem down after each pad with Obsidian Oil. I was able to remove the remnants of oxidation and the stem looked better. I touched up the LJS stamp on the left side of the taper stem with Rub’n Buff Antique Gold. I rubbed it on and worked it into the stamp with a tooth pick. I buffed it off with an Obsidian Oil cloth. It looks very good.

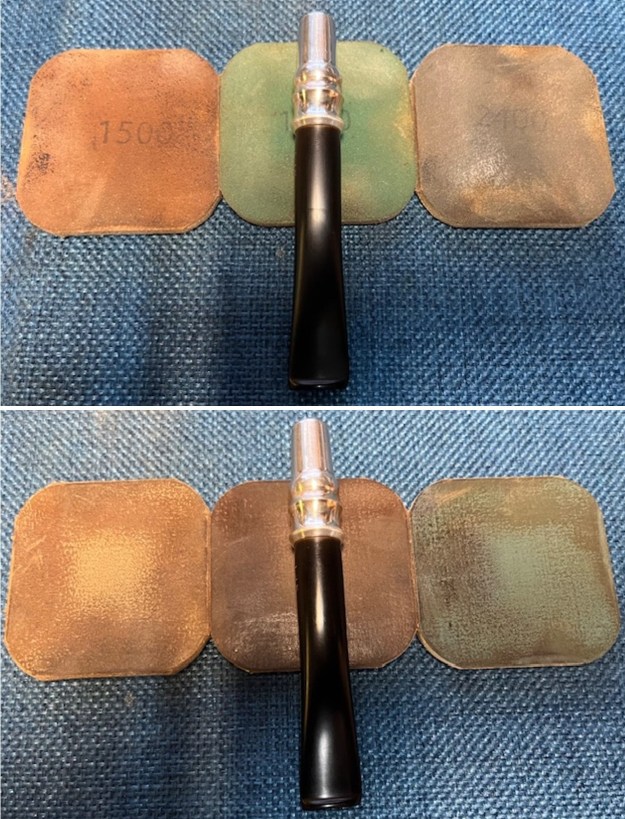

I touched up the LJS stamp on the left side of the taper stem with Rub’n Buff Antique Gold. I rubbed it on and worked it into the stamp with a tooth pick. I buffed it off with an Obsidian Oil cloth. It looks very good. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Stem Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Stem Polish – both Fine and Extra Fine to further polish the stem.

This beautiful Ferndown Bark Rusticated L&JS Briars Silver Spigot Billiard with a taper vulcanite stem looks amazing after the work on it. The briar is clean and the grain really came alive. The rich brown stains gave the finish a sense of depth with the polishing and waxing. The grain really popped. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ferndown Bark Silver Spigot Billiard really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 66 grams/2.33 ounces. This beautiful rusticated pipe will soon be on the rebornpipes store in the British Pipemakers Secton. It should make a great smoker for the next trustee. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.

This beautiful Ferndown Bark Rusticated L&JS Briars Silver Spigot Billiard with a taper vulcanite stem looks amazing after the work on it. The briar is clean and the grain really came alive. The rich brown stains gave the finish a sense of depth with the polishing and waxing. The grain really popped. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ferndown Bark Silver Spigot Billiard really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 66 grams/2.33 ounces. This beautiful rusticated pipe will soon be on the rebornpipes store in the British Pipemakers Secton. It should make a great smoker for the next trustee. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.