Blog by Steve Laug

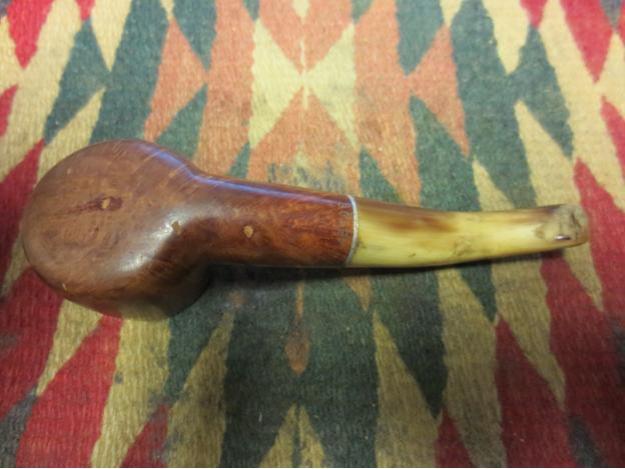

I was going through boxes of old pipes here, sorting and getting them ready to sell as grab bags. In the process I came across this pipe. It is stamped Gitana in an oval with an L on the left of the oval and G on the right side of the oval. Underneath the oval stamp is the word Depose. There is a polished aluminum band on the end of the shank. The briar is quite nice with birdseye around the bowl. The stem is horn and has a lot of tooth damage next to the button on both sides. There are deep troughs carved by the teeth in the horn material on both sides. The rim had a lot of damage from burn marks and the inner edge had been damaged by reaming with a knife. There was a white waxy substance on the inside of the bowl from the edge down about a ½ inch. There was a light cake in the bowl and some light lava on the bowl top.

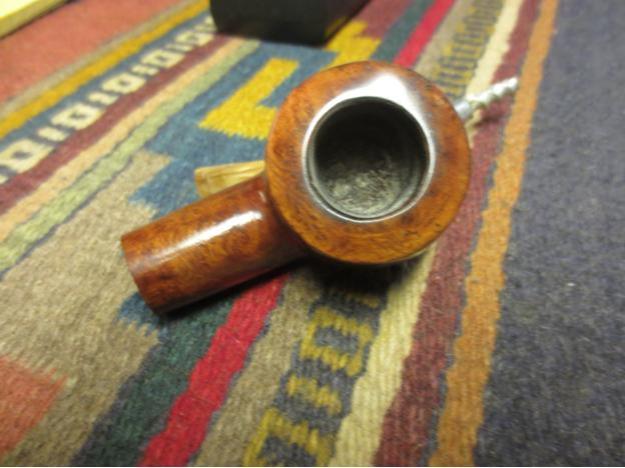

I took a close up photo of the rim top to show the damage to the inner edge of the bowl from the reaming job. The cake on the bowl sides and the tarry oil on the rim top are also visible. The briar at the top is quite damaged and will take some work to remove the knife cuts and deep gouges in the briar. The stem is also shown with the chewed damage on both sides.

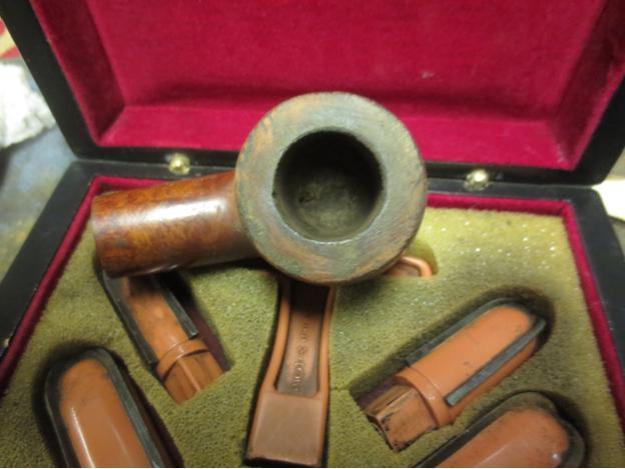

I took a close up photo of the rim top to show the damage to the inner edge of the bowl from the reaming job. The cake on the bowl sides and the tarry oil on the rim top are also visible. The briar at the top is quite damaged and will take some work to remove the knife cuts and deep gouges in the briar. The stem is also shown with the chewed damage on both sides.  I removed the stem from the shank and was a bit surprised by the aluminum system that was inside. The tenon was aluminum and had a bullet shaped cap on the end of it. The cap had a hole in the top that allowed the smoke to be drawn through the airway in the stem. The previous own had wrapped the aluminum portion of the tenon with what looked like aluminum foil to build it up to fit tightly in the shank. The photos below show the tenon and the system.

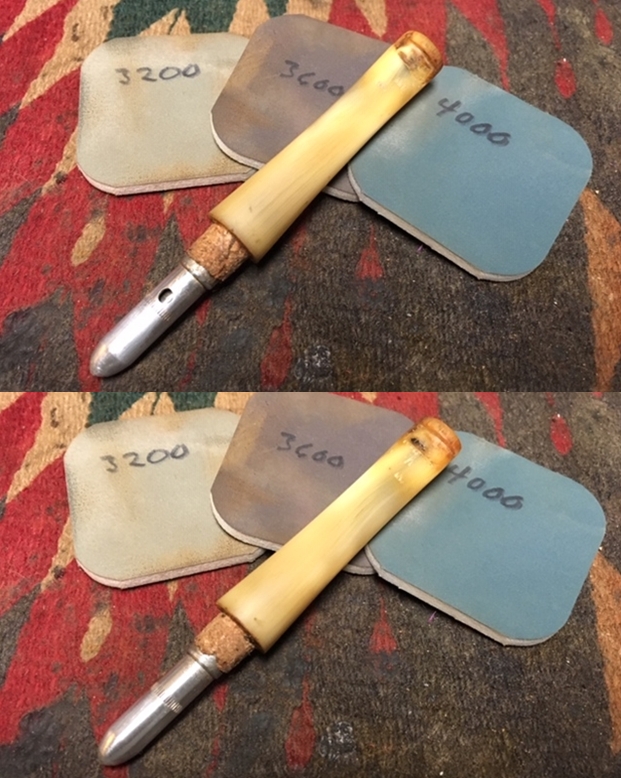

I removed the stem from the shank and was a bit surprised by the aluminum system that was inside. The tenon was aluminum and had a bullet shaped cap on the end of it. The cap had a hole in the top that allowed the smoke to be drawn through the airway in the stem. The previous own had wrapped the aluminum portion of the tenon with what looked like aluminum foil to build it up to fit tightly in the shank. The photos below show the tenon and the system.

I was unfamiliar with the brand and was surprised by the tenon system. I did some searching online and could find nothing on the Gitana brand or the Gitana Depose brand. I did happen across a similar pipe on Smokingpipes.com. The writer who described the pipe for the site wrote the following which contained some really helpful information. I quote:

I was unfamiliar with the brand and was surprised by the tenon system. I did some searching online and could find nothing on the Gitana brand or the Gitana Depose brand. I did happen across a similar pipe on Smokingpipes.com. The writer who described the pipe for the site wrote the following which contained some really helpful information. I quote:

We were able to ascertain a little information about La Gitana, which was a French brand created by Chapel Frés…but this relic from the early 20th century still sports its original horn stem, coupled with a novel aluminum tenon arrangement that we can only assume is meant to trap moisture. Although we aren’t sure how well it achieves this, it does do quite well at looking like an old-school James Bond accessory. It fits securely within a cork-lined mortise, which many briars of this period tended to have. https://www.smokingpipes.com/pipes/estate/france/moreinfo.cfm?product_id=196840

From that I learned that the brand was called La Gitana. It was a French made pipe from a company called Chapel Frés. It was made in the early 20th century and the author had described the tenon system like the one I had. I also learned that the mortise had originally been cork lined to facilitate holding the tenon snuggly in the shank. This was what was missing in the pipe I had and it had been replaced with the foil mess that is seen in the above photos.

Armed with the name Chapel Frés I looked on Pipedia under French Pipe Companies and found the brand there. It stated that it came from that factory and the brand had been founded in 1904 in Saint-Claude, France. Here is the link https://pipedia.org/wiki/Chapel_Fr%C3%A9s.

Armed with that information I started my cleanup of the stem. I scraped away the foil that was wrapped around the tenon. I examined the bullet shaped cap on the tenon and figured out that it unscrewed from the tenon. I cleaned the metal underneath alcohol, cotton swabs, pipe cleaners and steel wool. I cleaned out the airway in the shank at the same time. The tube in the end of the tenon looked clean. I used alcohol, cotton swabs and pipe cleaners to clean out the inside of the bullet cap. I cleaned out the walls in the shank with pipe cleaners, cotton swabs and alcohol. It was a very dirty pipe that once it was clean had an interesting look to it.

I cleaned up the inside of the bowl with a Savinelli Fitsall Pipe Knife. I scraped the walls clean of the carbon build up. I sanded the walls of the bowl with a piece of dowel wrapped with 220 grit sandpaper.

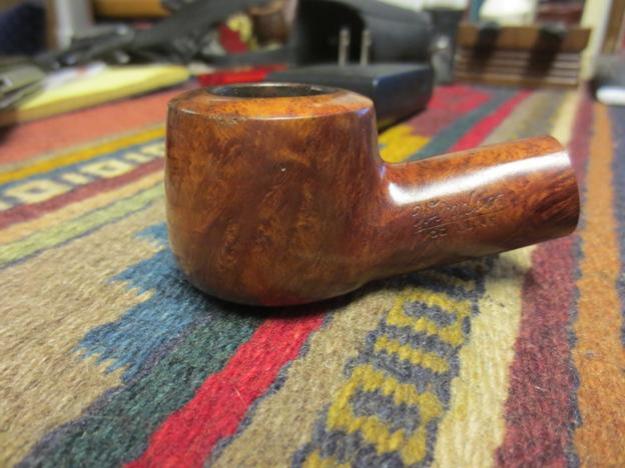

I cleaned up the inside of the bowl with a Savinelli Fitsall Pipe Knife. I scraped the walls clean of the carbon build up. I sanded the walls of the bowl with a piece of dowel wrapped with 220 grit sandpaper. To remove the damage on the rim top I topped the bowl until the damaged areas were removed and the rim top was clean. I used a folded piece of sandpaper to smooth out the inner edge of the rim and bring it back to round as much as I could.

To remove the damage on the rim top I topped the bowl until the damaged areas were removed and the rim top was clean. I used a folded piece of sandpaper to smooth out the inner edge of the rim and bring it back to round as much as I could.

I washed down the exterior of the bowl with acetone on a cotton pad to remove the finish and the grim on the briar. The pipe looked really good at this point. I needed to round down the outer edges to bring it back to the shape it was when I started but for now it was clean.

I washed down the exterior of the bowl with acetone on a cotton pad to remove the finish and the grim on the briar. The pipe looked really good at this point. I needed to round down the outer edges to bring it back to the shape it was when I started but for now it was clean.

I took a photo of the stamping on the left side of the shank. The stamping is quite readable and clear.

I took a photo of the stamping on the left side of the shank. The stamping is quite readable and clear. The tenon had some sticky substance for the glue on the foil on the tenon end. The tenon and threads still needed more cleaning to remove the oils.

The tenon had some sticky substance for the glue on the foil on the tenon end. The tenon and threads still needed more cleaning to remove the oils. I filled in the tooth marks and troughs in the surface of the horn with clear super glue. I set the stem aside to dry.

I filled in the tooth marks and troughs in the surface of the horn with clear super glue. I set the stem aside to dry. I decided to try to fit a cork in the shank to line it as suggested above. I cut away some of the excess cork from a wine cork I had. I trimmed it down with a Dremel and sanding drum until the diameter was close to the inside of the shank. I drilled it out with a series of drill bits starting small and working my way up to one that was close to the size of the tenon. I sanded down the cork exterior until it was a fit in the shank. I pressed it in place in the shank.

I decided to try to fit a cork in the shank to line it as suggested above. I cut away some of the excess cork from a wine cork I had. I trimmed it down with a Dremel and sanding drum until the diameter was close to the inside of the shank. I drilled it out with a series of drill bits starting small and working my way up to one that was close to the size of the tenon. I sanded down the cork exterior until it was a fit in the shank. I pressed it in place in the shank. I used a needle file to thin down the inner walls of the cork lining. It needed to be very thin to allow the tenon to fit in the shank. I tried to put the tenon in the shank. The fit was still not right. The cork was too thick to allow a fit. I pulled it out of the shank and slid it over the tenon. I sanded it down with sandpaper and files until it was a good fit. I glued the cork on the tenon and let it dry. When it cured I rubbed the cork down with Vaseline to soften it and allow it to slide into the shank. The fit was very good. I took some photos to show what the pipe looked like at this point in the restoration (I had also started the shaping on the bowl top).

I used a needle file to thin down the inner walls of the cork lining. It needed to be very thin to allow the tenon to fit in the shank. I tried to put the tenon in the shank. The fit was still not right. The cork was too thick to allow a fit. I pulled it out of the shank and slid it over the tenon. I sanded it down with sandpaper and files until it was a good fit. I glued the cork on the tenon and let it dry. When it cured I rubbed the cork down with Vaseline to soften it and allow it to slide into the shank. The fit was very good. I took some photos to show what the pipe looked like at this point in the restoration (I had also started the shaping on the bowl top).

I polished the briar with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped it down with a clean cloth after each pad. The grain began to pop and really stand out.

I polished the briar with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped it down with a clean cloth after each pad. The grain began to pop and really stand out.

Once the glue repairs cured I sanded them with 220 grit sandpaper to smooth out the repairs. I sanded them to blend them into the surface of the horn. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 and dry sanding them with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I gave it a final coat and let it dry. The following photos show both sides of the stem.

Once the glue repairs cured I sanded them with 220 grit sandpaper to smooth out the repairs. I sanded them to blend them into the surface of the horn. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 and dry sanding them with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I gave it a final coat and let it dry. The following photos show both sides of the stem.

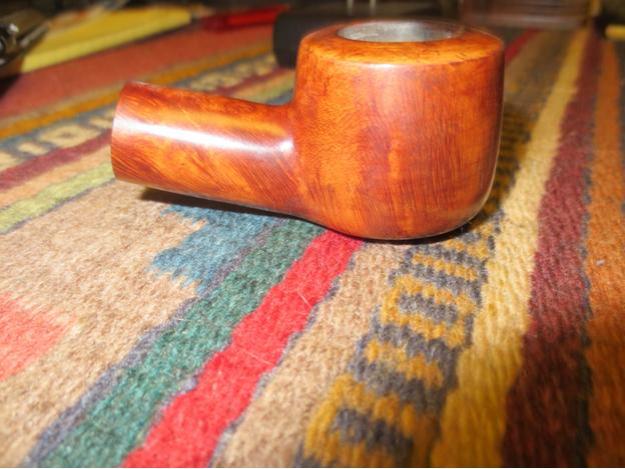

I worked Before & After Restoration Balm into the briar and the horn stem with my fingertips to clean, enliven and protect the wood and the horn. I let the balm sit for about 20 minutes and buffed it off with a soft cotton cloth. I took photos of the pipe at this point in the process to show what the bowl and stem looked like. I am happy with the look of the pipe.

I worked Before & After Restoration Balm into the briar and the horn stem with my fingertips to clean, enliven and protect the wood and the horn. I let the balm sit for about 20 minutes and buffed it off with a soft cotton cloth. I took photos of the pipe at this point in the process to show what the bowl and stem looked like. I am happy with the look of the pipe.

I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and horn. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The original patina on the bowl came alive with the buffing and worked well with the polished striated horn stem. The pipe has a rich look. The finished pipe is shown in the photos below. The shape, finish and flow of the pipe and stem work give the pipe a very classic look. The dimensions of the pipe are Length: 5 1/2 inches, Height: 1 1/2 inches, Outside diameter of the bowl: 1 1/2 inches, Chamber diameter: 3/4 of an inch. Thanks for reading this while I worked on it. It was interesting and unusual piece to restore and I really enjoyed the work.

I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and horn. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The original patina on the bowl came alive with the buffing and worked well with the polished striated horn stem. The pipe has a rich look. The finished pipe is shown in the photos below. The shape, finish and flow of the pipe and stem work give the pipe a very classic look. The dimensions of the pipe are Length: 5 1/2 inches, Height: 1 1/2 inches, Outside diameter of the bowl: 1 1/2 inches, Chamber diameter: 3/4 of an inch. Thanks for reading this while I worked on it. It was interesting and unusual piece to restore and I really enjoyed the work.