by Steve Laug

I picked some older pipes to work on next. The next of these is a GBD Bent Billiard. We purchased this one on 03/21/2024 from a seller in Oregon City, Oregon, USA. Jeff regularly visits shops along the coast hunting for pipes and though there are less of them there are still a lot available. The is a Bent Billiard that is stamped on the left side of the shank and reads GBD in an oval [over] Prestige and on the right side it is stamped London, England over the shape number 508. The pipe was well used. The finish was dirty with dust and debris ground into the finish. There were some dark marks on the sides of the bowl that looked to be on the surface. The bowl had a thick cake in it and some lava on the inwardly bevelled rim top and the inner edge. There was also some roughening to the inner edge and darkening on the top of the bowl. The vulcanite stem was oxidized, calcified and had some tooth marks on the surface ahead of the button. Jeff took photos of the pipe before he started his cleanup work.

He took some closer photos of the rim top and bowl to show the condition. You can see the thick cake in the bowl and the lava on the rim top and inner edge. It is hard to know for certain but it looks like there is some roughening on the back inner edge. He also took photos of the stem to show its condition. You can see the oxidation, calcification and tooth marks and chatter on the stem at the button.

He took some closer photos of the rim top and bowl to show the condition. You can see the thick cake in the bowl and the lava on the rim top and inner edge. It is hard to know for certain but it looks like there is some roughening on the back inner edge. He also took photos of the stem to show its condition. You can see the oxidation, calcification and tooth marks and chatter on the stem at the button.

Jeff took some photos of the sides and heel of the bowl to show the smooth finish and the grain around the bowl and shank.

Jeff took some photos of the sides and heel of the bowl to show the smooth finish and the grain around the bowl and shank.

He captured the stamping on the left and right sides of the shank. It is clear and faint in spots and reads a noted above. The brass inset GBD oval logo on the left side of the saddle stem is clear and undamaged.

He captured the stamping on the left and right sides of the shank. It is clear and faint in spots and reads a noted above. The brass inset GBD oval logo on the left side of the saddle stem is clear and undamaged.

I looked on the Pipephil logos site for information on the Prestige line and found nothing there. I turned to Pipedia’s general article on the GBD brand looking for any information on the Prestige line and once again found nothing. The history article is a great read. Be sure to have a look at it.

I looked on the Pipephil logos site for information on the Prestige line and found nothing there. I turned to Pipedia’s general article on the GBD brand looking for any information on the Prestige line and once again found nothing. The history article is a great read. Be sure to have a look at it.

The article included link to other articles on Pipedia and one of those was to an article on the GBD Model Information (https://pipedia.org/wiki/GBD_Model_Information). I turned there and found what I was looking for. There was a short description of the line and I have included it below:

Prestige — England, unknown if also made in France: Matt natural finish, Perspex mouthpiece.

That was helpful in terms of the finish which matches the pipe in my hand other than it has a vulcanite mouthpiece. I read further and in a short note from GL Pease I found the information below. I quote:

…In a circa 1973 chart which I have, here are the descriptions of the higher grades:

- Virgin — “Only the finest of closely grained briar is utilized for this exceptional pipe. Natural finish”

- Century — “A golden finish created to celebrate over a century of manufacturing the finest briar pipes.”

- New Era — “The beauty of this pipe’s perfect briar is accentuated by the richness of the ‘take-off’ dual finish.”

- Prestige — “This pipe features a black handcut perspex mouthpiece which precludes discoloration and ‘bad taste’ after continual smoking. Only the finest of the fine-grained bowls are selected for this handsome matt virgin finished briar.”

- Prehistoric Perspex — “The deep sandblasting silhouettes the grain in bold relief. The crystal clear mouthpiece creates an attractive contrast to the deep dark finish.”

From that I now knew that the pipe was a higher grade GBD that is described as having a black handcut Perspex mouthpiece and a matte finished, fine grained virgin briar. The pipe I have on the table has a bent vulcanite stem rather than the Perspex otherwise the description is perfect.

I turned to another link on the site to look at shape numbers and see if I could identify further information regarding the shape (https://pipedia.org/wiki/GBD_Shapes/Numbers). I quote what I found below:![]() Now it was time to work on the pipe.

Now it was time to work on the pipe.

Jeff had cleaned up the pipe and it looked very good. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs, shank brushes and pipe cleaners. He soaked the stem in Briarville’s Stem Deoxidizer and rinsed it off with warm water. While it does nothing for the finish on the stem as it is Perspex it is worth the effort in that it removes the grime on the stem. I took photos of the pipe before I started my part of the restoration work.

The inwardly bevelled rim top cleaned up really well. The rim top and outer edge of the bowl look very good. The inner edge and spots on the top have some darkening and light damage. The stem surface was still lightly oxidized and there were tooth marks and chatter on both sides near the button.

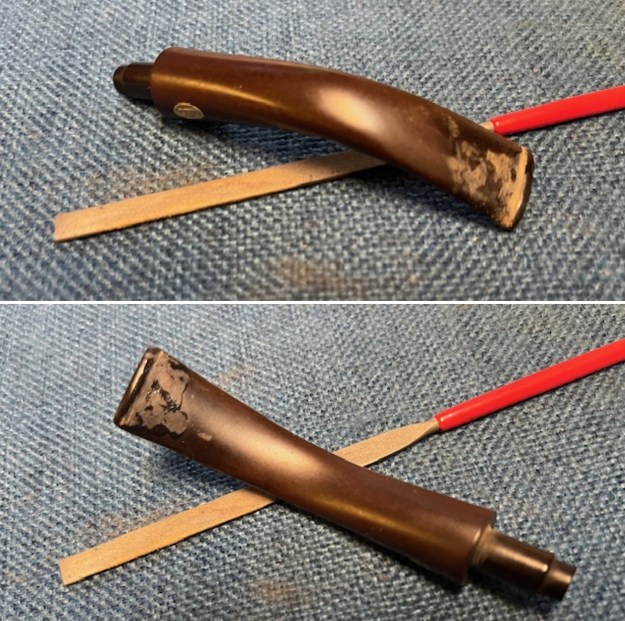

The inwardly bevelled rim top cleaned up really well. The rim top and outer edge of the bowl look very good. The inner edge and spots on the top have some darkening and light damage. The stem surface was still lightly oxidized and there were tooth marks and chatter on both sides near the button. The stamping on sides of the shank is faint but readable. It is stamped as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole. The thin taper stem is nice and the photo shows the step down tenon.

The stamping on sides of the shank is faint but readable. It is stamped as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole. The thin taper stem is nice and the photo shows the step down tenon.

I cleaned up the top and the inner edge of the bowl with a folded piece of 220 grit sandpaper to smooth out the damage to the edge and the darkening on the rim top.

I cleaned up the top and the inner edge of the bowl with a folded piece of 220 grit sandpaper to smooth out the damage to the edge and the darkening on the rim top.  I sanded the bowl with 320-3500 grit sanding pads to smooth out the nicks and marks in the briar around the sides of the bowl. I wiped it down with a damp cloth after each sanding pad. It was looking pretty good once I finished.

I sanded the bowl with 320-3500 grit sanding pads to smooth out the nicks and marks in the briar around the sides of the bowl. I wiped it down with a damp cloth after each sanding pad. It was looking pretty good once I finished.

I polished the bowl and the rim top with micromesh sanding pads. I dry sanded it with 1500-12000 grit pads and wiped the bowl down with a damp cloth to remove the sanding dust. By the final pad it was starting to real take on a great shine.

I polished the bowl and the rim top with micromesh sanding pads. I dry sanded it with 1500-12000 grit pads and wiped the bowl down with a damp cloth to remove the sanding dust. By the final pad it was starting to real take on a great shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. It works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and buffed with a cotton cloth to raise the shine. The grain came alive.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. It works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and buffed with a cotton cloth to raise the shine. The grain came alive.

I set the bowl aside and turned my attention to the stem. I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a lighter to lift them. The heat did a great job lifting most of them. The marks and chatter that remained I filled in with black CA glue strengthened with carbon and rubber. Once cured I flattened them and redefined the button edge with a file and blended them into the surface by sanding with 220 grit sandpaper.

I set the bowl aside and turned my attention to the stem. I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a lighter to lift them. The heat did a great job lifting most of them. The marks and chatter that remained I filled in with black CA glue strengthened with carbon and rubber. Once cured I flattened them and redefined the button edge with a file and blended them into the surface by sanding with 220 grit sandpaper.

I polished the sanding and scratch marks and smoothed the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil impregnated cloth. It removes the dust and also gives the sanding pads some bite. By the final pad it was looking quite good.

I polished the sanding and scratch marks and smoothed the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil impregnated cloth. It removes the dust and also gives the sanding pads some bite. By the final pad it was looking quite good. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I rubbed it down with a final coat of Obsidian Oil and let it dry.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I rubbed it down with a final coat of Obsidian Oil and let it dry.

This GBD Prestige 508 Bent Billiard is a real beauty. I buffed the bowl and the Perspex saddle stem with Blue Diamond on the wheel and was amazed at how the grain popped and the stem began to shine. I gave the bowl and stem multiple coats of carnauba wax and buffed them with a clean buffing pad. I finished by hand buffing the pipe with a microfibre cloth. The finished pipe is shown in the photos below. While there are some small brown stains in the button area it is clean. I think you will agree that it is a stunning example of a GBD Prestige. The grain and the stem work really well together. The finished GBD Prestige 508 Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 3/4 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 3/4 of an inch. The weight of the pipe is 39 grams/1.38 ounces. I will be putting it on the rebornpipes store in the British Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. I appreciate your support and time!

This GBD Prestige 508 Bent Billiard is a real beauty. I buffed the bowl and the Perspex saddle stem with Blue Diamond on the wheel and was amazed at how the grain popped and the stem began to shine. I gave the bowl and stem multiple coats of carnauba wax and buffed them with a clean buffing pad. I finished by hand buffing the pipe with a microfibre cloth. The finished pipe is shown in the photos below. While there are some small brown stains in the button area it is clean. I think you will agree that it is a stunning example of a GBD Prestige. The grain and the stem work really well together. The finished GBD Prestige 508 Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 3/4 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 3/4 of an inch. The weight of the pipe is 39 grams/1.38 ounces. I will be putting it on the rebornpipes store in the British Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. I appreciate your support and time!