Blog by Steve Laug

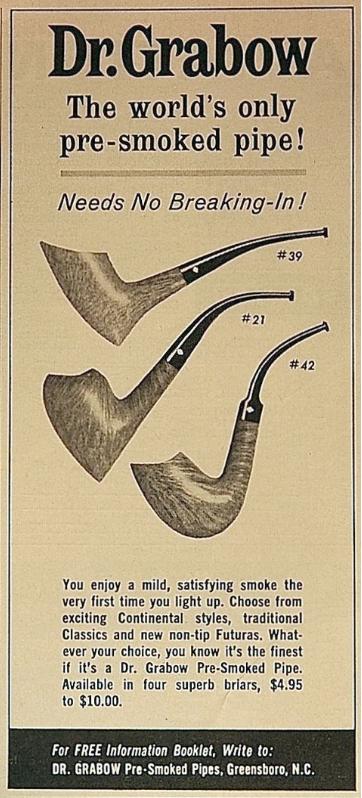

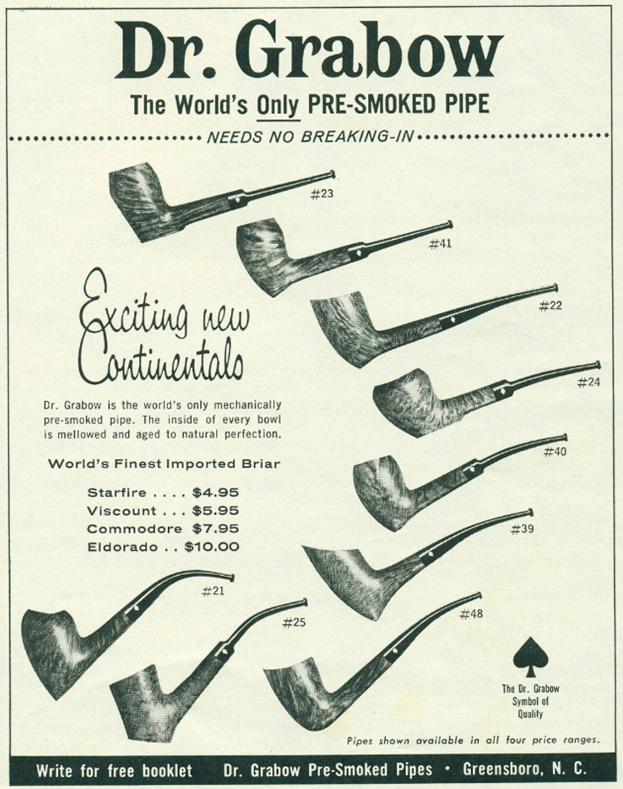

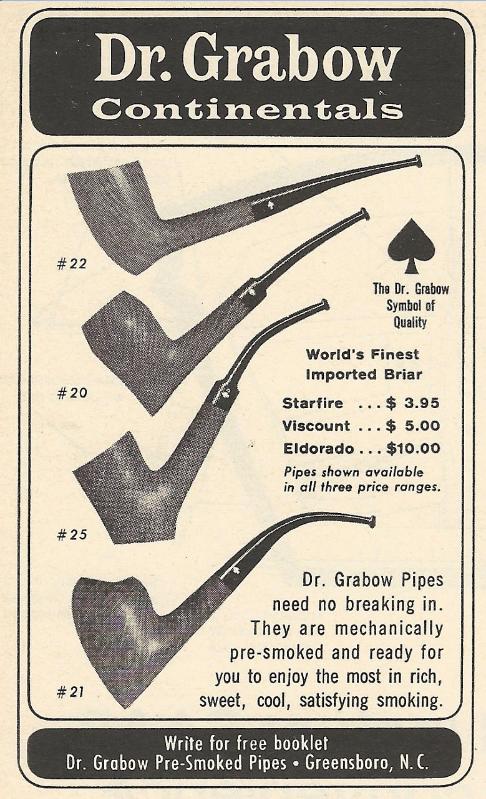

In a box of pipes I was gifted there was a pipe stamped WESTBROOK over Dr. Grabow on the left side of the shank. On the right side it is stamped Imported Briar over Adjustomatic over PAT. 2181833. I did some searching on the web and found that it was a shape number 42. I found plenty of photos of wire carved Westbrook 42s but only one of a smooth alongside of the wire carved. This pair was pictured on the Dr. Grabow Collectors Forum and belongs to Troy Wilburn. Mine is similar to the smooth one but the look of the stem is more of a true saddle like the wire carved one. The grain on it was beautiful under the peeling varnish finish. There was a lot of birdseye and swirls with some mixed flame and straight grain. There were small nicks on the left side near the rim and on the front edge of the rim. The stem was oxidized but otherwise clean. The internals were pretty clean. The bowl had some slight carbon build up. The stinger apparatus was missing but I have one thanks to Troy that will fit perfect.

The grain on it was beautiful under the peeling varnish finish. There was a lot of birdseye and swirls with some mixed flame and straight grain. There were small nicks on the left side near the rim and on the front edge of the rim. The stem was oxidized but otherwise clean. The internals were pretty clean. The bowl had some slight carbon build up. The stinger apparatus was missing but I have one thanks to Troy that will fit perfect.

I scrubbed the bowl with acetone on cotton pads to remove the bubbled and peeling varnish or lacquer coating. It took some elbow grease but it came out pretty well. With that coat gone you can begin to see the grain on the sides, top and bottom of the bowl.

I scrubbed the bowl with acetone on cotton pads to remove the bubbled and peeling varnish or lacquer coating. It took some elbow grease but it came out pretty well. With that coat gone you can begin to see the grain on the sides, top and bottom of the bowl.

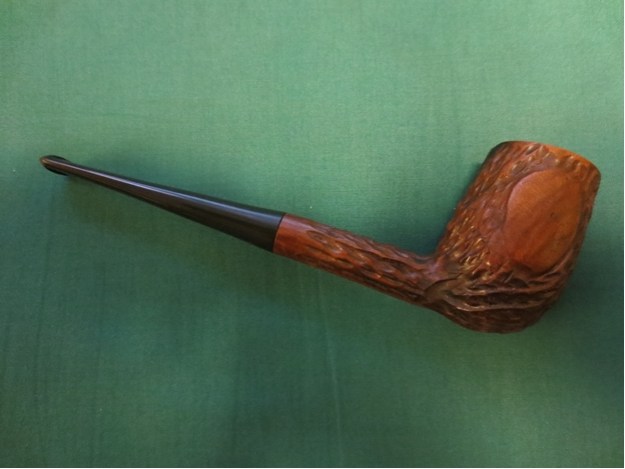

I wiped it down a final time with isopropyl alcohol and took the next photos to show the grain on this little beauty! It is a great piece of briar and what appeared to be fill were not but rather just chips of varnish that came off.

I wiped it down a final time with isopropyl alcohol and took the next photos to show the grain on this little beauty! It is a great piece of briar and what appeared to be fill were not but rather just chips of varnish that came off.

The front edge of the rim and the left side nicks would need to be sanded to smooth them out. The entire bowl would also need to be sanded with micromesh to remove the bits of varnish stuck on the briar and also smooth out some of the scratches in the briar.

The front edge of the rim and the left side nicks would need to be sanded to smooth them out. The entire bowl would also need to be sanded with micromesh to remove the bits of varnish stuck on the briar and also smooth out some of the scratches in the briar. I reamed the bowl with a PipNet reamer and took the cake back to just a thin coating. I left a little on the sides and bottom of the bowl to protect the bowl. I cleaned out the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the grime.

I reamed the bowl with a PipNet reamer and took the cake back to just a thin coating. I left a little on the sides and bottom of the bowl to protect the bowl. I cleaned out the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the grime.

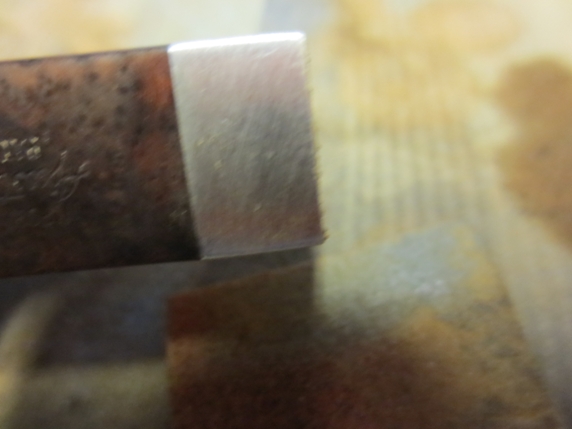

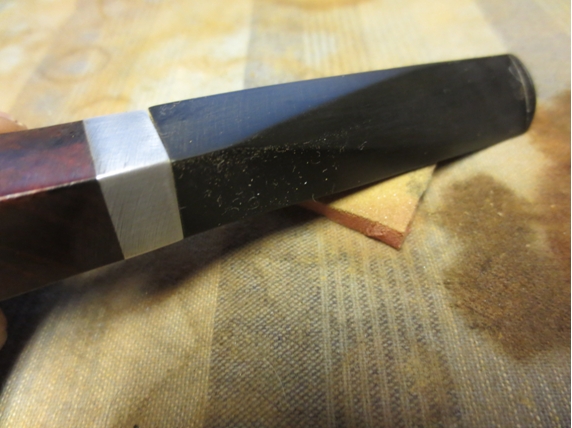

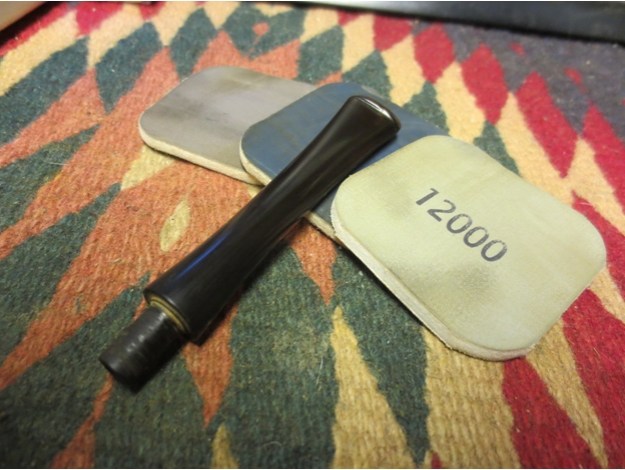

I sanded the rim of the bowl and bowl sides with micromesh sanding pads. I smoothed out the damage on the front of the bowl and on the side. I also worked on the stem. I wet sanded it with 1500-2400 grit pads and dry sanded with 3200-12000 grit pads. I rubbed it down with Obsidian Oil in between each set of three pads. I cleaned the metal threaded tenon with steel wool and then added the spoon stinger in the tenon to make the pipe complete.

I sanded the rim of the bowl and bowl sides with micromesh sanding pads. I smoothed out the damage on the front of the bowl and on the side. I also worked on the stem. I wet sanded it with 1500-2400 grit pads and dry sanded with 3200-12000 grit pads. I rubbed it down with Obsidian Oil in between each set of three pads. I cleaned the metal threaded tenon with steel wool and then added the spoon stinger in the tenon to make the pipe complete.

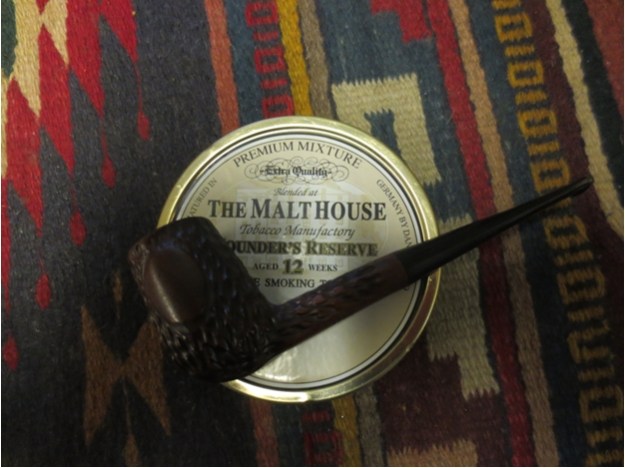

The oxidation on this one was tough to get off the stem. I took it to the buffer and use some Tripoli, White Diamond and then Blue Diamond and I finally beat it. I took it back to the work table and sanded it again with the last three grits of micromesh – 6000-12000 grit. I rubbed it down again with Obsidian Oil and then gave both the bowl and stem multiple coats of carnauba wax. I buffed it with a clean flannel buff and then hand buffed it with a microfibre cloth. The finished pipe is shown below.

The oxidation on this one was tough to get off the stem. I took it to the buffer and use some Tripoli, White Diamond and then Blue Diamond and I finally beat it. I took it back to the work table and sanded it again with the last three grits of micromesh – 6000-12000 grit. I rubbed it down again with Obsidian Oil and then gave both the bowl and stem multiple coats of carnauba wax. I buffed it with a clean flannel buff and then hand buffed it with a microfibre cloth. The finished pipe is shown below.