by Steve Laug

This mysterious pipe was purchased on 11/16/2024 from an auction in Mastic Beach, New York, USA. It is mysterious in terms of the maker. The only stamping on the pipe is on the right side of the shank and reads Imported Briar. The carving, or rustication is very similar to that of a recent Weber The Scoop that recently restored (https://rebornpipes.com/2025/04/16/restoring-a-unique-old-weber-the-scoop-squat-bulldog/). Like that one this pipe has three smooth spots on the sides and front of the bowl. The rustication leaves them as islands in a heavily rusticated bowl. The Weber Scoop I restored was the same. The rim cap was different from this one but there are many similarities that make we wonder if this mystery pipe is also a Weber made pipe. The bowl had a thick cake on the walls and an overflow of lava onto the rim top and edges. The rustication had a lot of dust and debris in the grooves and valleys. The vulcanite saddle stem was oxidized, calcified and has light tooth marks and chatter on both sides near the button. It was a unique and beautiful looking pipe in its own way. Jeff took photos of the pipe before he started cleaning it up. Have a look.

Jeff took close up photos of the bowl and rim top to show the condition of the bowl and the rim top. You can also see the lava on the rim top, inner edge and the cake in the bowl. He also took close up photos of the stem to show its condition as mentioned above. I also took photos of the tooth marks and chatter on both sides of the stem.

Jeff took close up photos of the bowl and rim top to show the condition of the bowl and the rim top. You can also see the lava on the rim top, inner edge and the cake in the bowl. He also took close up photos of the stem to show its condition as mentioned above. I also took photos of the tooth marks and chatter on both sides of the stem.

He took photos of the bowl sides and heel to show the rustication style around the bowl. The deep patterns around the smooth patches on the bowl front and sides. The rustication is swirled around the smooth patches and is doubly rusticated.

He took photos of the bowl sides and heel to show the rustication style around the bowl. The deep patterns around the smooth patches on the bowl front and sides. The rustication is swirled around the smooth patches and is doubly rusticated.

Jeff also took a photo of the stamping on the right side of the shank. It is clear and readable as noted above.

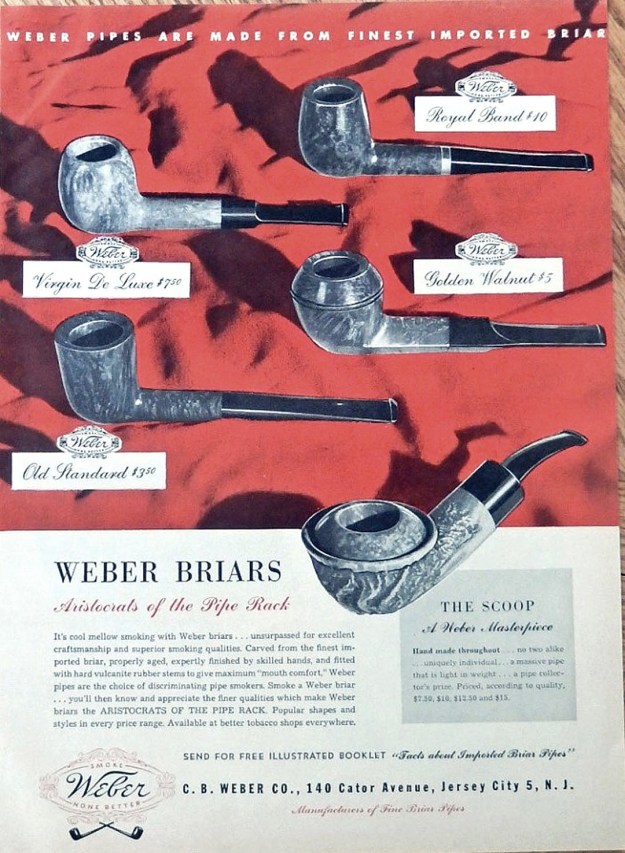

Jeff also took a photo of the stamping on the right side of the shank. It is clear and readable as noted above. Since I had a hunch about a connection to Weber pipes I decided to do a bit of reading on Weber pipes in general and also see if I could pick up specific information on this particular pipe. I turned to Pipedia and found the some interesting historical information (https://pipedia.org/wiki/Weber_Pipe_Co.).

Since I had a hunch about a connection to Weber pipes I decided to do a bit of reading on Weber pipes in general and also see if I could pick up specific information on this particular pipe. I turned to Pipedia and found the some interesting historical information (https://pipedia.org/wiki/Weber_Pipe_Co.).

Carl B. Weber was a German from Bavaria. Aged 21 he immigrated to the USA in 1911. In 1938 he established Weber Briars Inc. in Jersey City, New Jersey – later renamed the Weber Pipe Co. The firm grew to be one of the giants of American pipe industry focusing itself in the middle price and quality zone. Trademark: “Weber” in an oval. Beside that Weber – especially in the years after 1950 – was a most important supplier for private label pipes that went to an immense number of pipe shops. In New York alone for example, exactly the same pipes were found at Wilke’s, Barclay Rex, Trinity East, Joe Strano’s Northampton Tobacconist in Ridgewood, Queens, Don-Lou in Bensonhurst, Brooklyn. Nearly all pipes for Wilke were unstained and many models, for example the “Wilke Danish Bent”, could hardly deny originating of Weber. Among others well reputed pipemaker Anthony Passante worked for Weber.

Weber Pipe Co. owned and manufactured Jobey pipes – when mainly sold in the USA by The Tinderbox from 1970’s – 80’s. In addition Jobey / Weber bought Danish freehands from Karl Erik (Ottendahl). These pipes were offered as Jobey Dansk. Ottendahl discontinued exports to the United States in 1987 and in the very same year – obviously only as a ghost brand – Jobey was transferred to Saint-Claude, France to be manufactured by Butz-Choquin. Carl B. Weber is the author of the famous book “Weber’s Guide to Pipes and Pipe Smoking”.

Armed with just my suspicion I turned my attention to the pipe itself. Jeff had cleaned the pipe with his usual penchant for thoroughness that I really appreciate. He reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners, shank brushes and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks very good with good looking grain around the bowl and shank. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the rubber. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked very good. I took photos before I started my part of the work.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The cap on this pipe was smooth with a ring around the inner and out edge and a rim top that is slightly inset. It is unique among the Weber Pipes that I have worked on. The stem was clean and did not show either tooth marks or chatter.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The cap on this pipe was smooth with a ring around the inner and out edge and a rim top that is slightly inset. It is unique among the Weber Pipes that I have worked on. The stem was clean and did not show either tooth marks or chatter. I took photos of the stamping on the sides of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took photos of the stamping on the sides of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts. The exterior of the bowl was in excellent condition. I did not need to do any sanding or work on the rim or bowl edges. I started by working some Before & After Restoration Balm into the briar with my finger tips and a shoe brush to get into the nooks and crannies. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl was in excellent condition. I did not need to do any sanding or work on the rim or bowl edges. I started by working some Before & After Restoration Balm into the briar with my finger tips and a shoe brush to get into the nooks and crannies. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

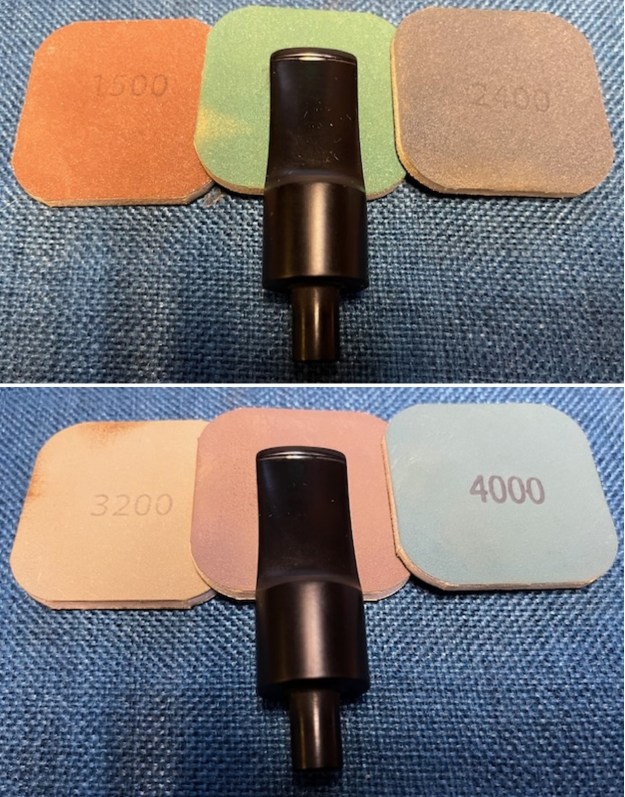

I set the bowl aside and sanded the stem with 320-3500 grit sanding pads. I wiped it down after each pad with Obsidian Oil and it began to look very good.

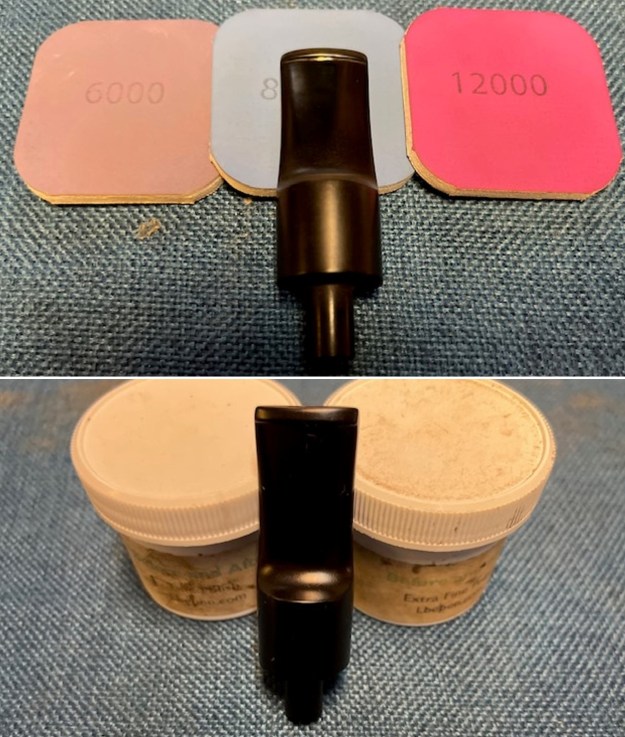

I set the bowl aside and sanded the stem with 320-3500 grit sanding pads. I wiped it down after each pad with Obsidian Oil and it began to look very good. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. Once again, I wiped it down between each pad with Obsidian Oil. I further polished it with Before and After Stem Polish – both Fine and Extra Fine. It looked very good.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. Once again, I wiped it down between each pad with Obsidian Oil. I further polished it with Before and After Stem Polish – both Fine and Extra Fine. It looked very good.

I am excited to be on the homestretch with beautiful Imported Briar Rhodesian. The mystery of the connection to Weber intrigues me. I look forward to when a pipe all comes back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond on the buffer to remove any scratches. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The unique rusticated finish looks really good with the interesting patterns standing out on the shape. The richly stained briar and the polished black vulcanite went really well together. This Weber Scoop has a recognizable shape and look that catches the eye. The brown stain really makes the rustication depths pop. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 39 grams/1.38 ounces. This one will soon be on the American Pipe Makers Section of the rebornpipes store. Let me know if you are interested in adding it to your rack. Thanks for reading this blog and my reflections on the pipe while I worked on it.

I am excited to be on the homestretch with beautiful Imported Briar Rhodesian. The mystery of the connection to Weber intrigues me. I look forward to when a pipe all comes back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond on the buffer to remove any scratches. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The unique rusticated finish looks really good with the interesting patterns standing out on the shape. The richly stained briar and the polished black vulcanite went really well together. This Weber Scoop has a recognizable shape and look that catches the eye. The brown stain really makes the rustication depths pop. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 39 grams/1.38 ounces. This one will soon be on the American Pipe Makers Section of the rebornpipes store. Let me know if you are interested in adding it to your rack. Thanks for reading this blog and my reflections on the pipe while I worked on it.