Blog by Steve Laug

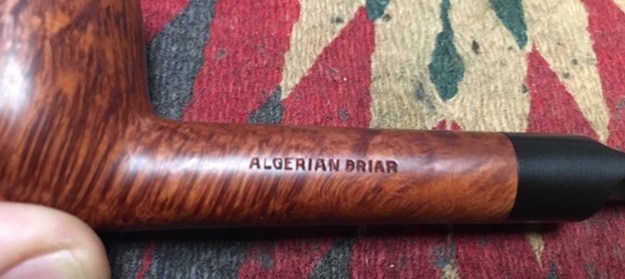

Jeff and I both have no idea where we picked up this pipe. We have no real memory of it but it is obvious that Jeff had cleaned it up sometime in its journey. It was stamped on the left side of the shank and read Peterson’s [over] System [over] Standard. On the right side it is stamped and reads Made in the Republic of Ireland (three lines) with the shape number 317 underneath. The pipe was a tired old workhorse with a worn finish. The bowl was also clean and there was no cake or damage on the bowl walls. The rim top was clean but there was some darkening on the top and on the inner and outer edge of the bowl. The nickel ferrule was tired and dull. It was stamped K&P [over] Peterson and there were no dents in the nickel ferrule. The stem was very clean with a light oxidation and light tooth marks and chatter on the top and underside. There was a faint “P” logo on the stem side. It had also straightened out over time and would need to be bent to fit the flow of the pipe. I took these photos before I started my clean up work to give an idea of the condition of the pipe.

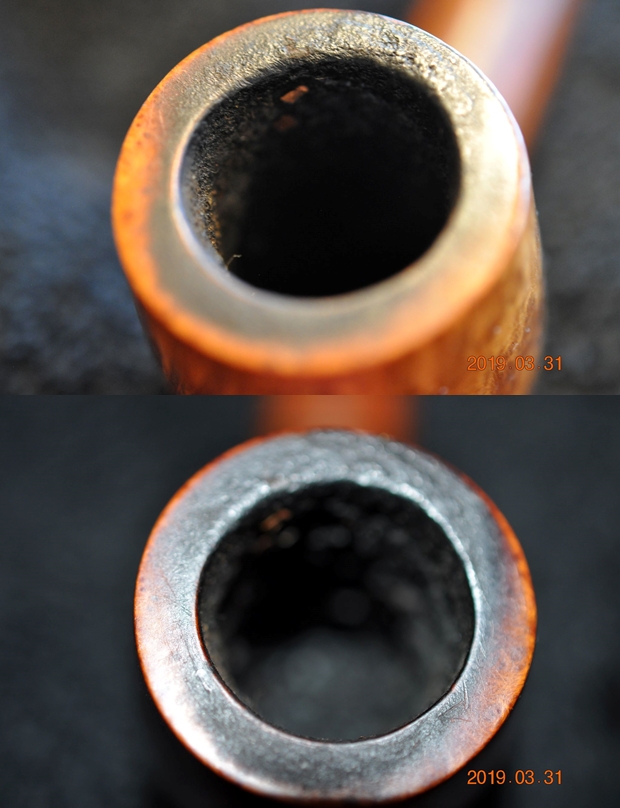

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top had some scratching on the top and damage to the inner edge and rim top. The stem cleaned up well and the tooth marks on the top and underside ahead of the button are light and should clean up easily.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top had some scratching on the top and damage to the inner edge and rim top. The stem cleaned up well and the tooth marks on the top and underside ahead of the button are light and should clean up easily. I took photos of the stamping on the sides of the shank and on the ferrule and stem. It is readable but faint in places. I took the stem out of the shank and took a photo of the overall look of the pipe.

I took photos of the stamping on the sides of the shank and on the ferrule and stem. It is readable but faint in places. I took the stem out of the shank and took a photo of the overall look of the pipe.

I remembered that Paresh had restored a Peterson’s System Standard (his was a 314) earlier this year and as usual had done good work on the research. I turned to his blog and read through his work on the pipe (https://rebornpipes.com/2021/07/24/helping-a-fellow-piper-with-his-dream-pipea-petersons-system-pipe/). I quote below from the section on his blog regarding the dating of the pipe.

I remembered that Paresh had restored a Peterson’s System Standard (his was a 314) earlier this year and as usual had done good work on the research. I turned to his blog and read through his work on the pipe (https://rebornpipes.com/2021/07/24/helping-a-fellow-piper-with-his-dream-pipea-petersons-system-pipe/). I quote below from the section on his blog regarding the dating of the pipe.

While dating a Peterson’s pipe, I always fall back to my under mentioned favorite site; http://thepetersonpipeproject.blogspot.com/2007/07/dating-peterons-pipes.html I quote from the above site.

Stamping of Bowl: During the years of Kapp and Peterson’s business operations, the country of Ireland has undergone several name changes and K&P’s stamping on their pipes reflects these changes. Knowing these changes, a Peterson pipe can be roughly dated and placed in “eras.”

- The Republic Era is from 1949 until the present. The Republic of Ireland was formed on 17 April 1949. From 1949 to present the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.

With that information at hand I turned to work on the pipe itself. I decided to start my work on the pipe by addressing the damage on the inside edge of the bowl and the rim top. I used a folded piece of 220 grit sandpaper to give the inner edge a slight bevel to remove the darkening and clean up the rim top. I wiped the top and edges down with a damp cloth and the rim top and edges looked much better.  I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I did not need to restain the rim top and edge because with polishing the match is very good. I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I did not need to restain the rim top and edge because with polishing the match is very good. I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned to work on the stem. I decided to start by rebending the stem. I heated it with the flame of a lighter to soften the vulcanite and when it was soft I bent it to the correct angle. It looked much better.

I set the bowl aside and turned to work on the stem. I decided to start by rebending the stem. I heated it with the flame of a lighter to soften the vulcanite and when it was soft I bent it to the correct angle. It looked much better. I repaired the tooth marks on the top of the stem with clear CA glue. There were two deeper marks that I could not lift. This took care of those on the top side. There were none on the underside. Once it cured I sanded the repairs smooth with 220 grit sandpaper and cleaned up the light marks on the underside at the same time. I started polishing the stem with 600 grit wet dry sandpaper.

I repaired the tooth marks on the top of the stem with clear CA glue. There were two deeper marks that I could not lift. This took care of those on the top side. There were none on the underside. Once it cured I sanded the repairs smooth with 220 grit sandpaper and cleaned up the light marks on the underside at the same time. I started polishing the stem with 600 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I continued polishing the stem using Before & After Pipe Polish – both Fine and Extra Fine to further it. I wiped it down with Obsidian Oil and set it aside to dry.

I continued polishing the stem using Before & After Pipe Polish – both Fine and Extra Fine to further it. I wiped it down with Obsidian Oil and set it aside to dry.  This Republic Era Peterson’s System Standard 317 Bent Billiard with a vulcanite stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. The dents in the rotated nickel ferrule really are a part of the story of the pipe and one that was unchangeable. It carries on to the next pipeman or woman who takes on the trust. As the pipe is smoked the patina should darken and look even better. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard 317 Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 33 grams/1.16 ounces. I will soon be adding it to the rebornpipe store in the Irish Pipe Makers Section. If you are interested in this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Republic Era Peterson’s System Standard 317 Bent Billiard with a vulcanite stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. The dents in the rotated nickel ferrule really are a part of the story of the pipe and one that was unchangeable. It carries on to the next pipeman or woman who takes on the trust. As the pipe is smoked the patina should darken and look even better. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard 317 Bent Billiard fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 33 grams/1.16 ounces. I will soon be adding it to the rebornpipe store in the Irish Pipe Makers Section. If you are interested in this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!