by Kenneth Lieblich

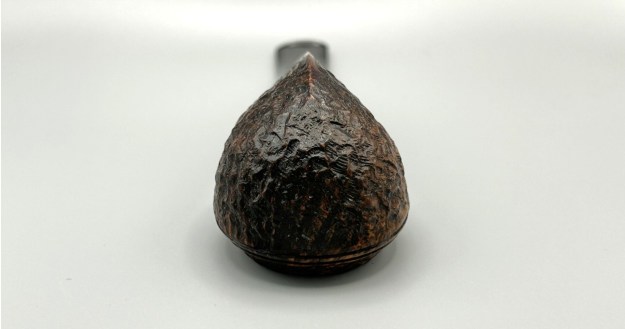

Last Sunday, a gentleman at my church approached me about restoring some pipes that he recently found at the local Sally Ann. He found some nice things and I happily restored three of his pipes – one of which ended up as this blog post! This is a very handsome Brigham 2-dot bulldog and, from first viewing, I could tell that this one was a bit older than the usual Brighams I see. This Brigham had the patented ‘Rock Maple Distillator’ filter system in it. Even though this one had been through the ringer, I was keen to get this it shining and bright again.

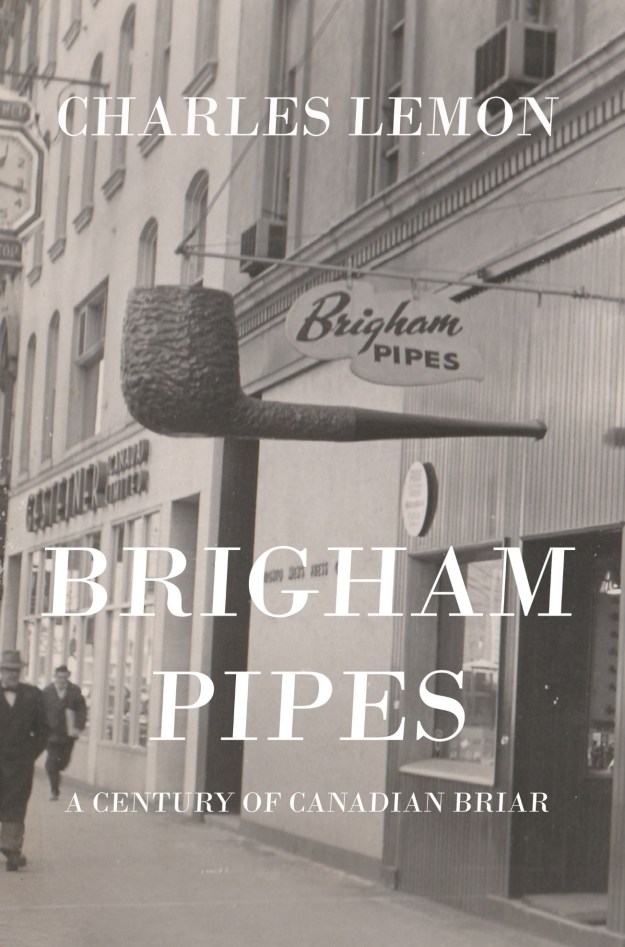

A quick look at the markings told me a lot of information. First of all, the stem showed two dots (or, to be more precise, two brass pins). This is typical of Brigham’s marking system and, in this case and in this era, two dots means the ‘Select’ level of briar. As Charles Lemon wrote in his book, Brigham Pipes: A Century of Canadian Briar,

A quick look at the markings told me a lot of information. First of all, the stem showed two dots (or, to be more precise, two brass pins). This is typical of Brigham’s marking system and, in this case and in this era, two dots means the ‘Select’ level of briar. As Charles Lemon wrote in his book, Brigham Pipes: A Century of Canadian Briar,

A single brass pin inserted in the left flank of the stem near the shank was originally used as a physical anchor to hold the press-fit aluminum tenon/filter holder securely in the stem. Brigham built on this manufacturing necessity by setting additional pins or Dots as they came to be known to denote the quality level of his pipes. On the underside of the shank, we can see the word Brigham [over] Can Pat 372982. To the left of that is the shape number 226,

On the underside of the shank, we can see the word Brigham [over] Can Pat 372982. To the left of that is the shape number 226,

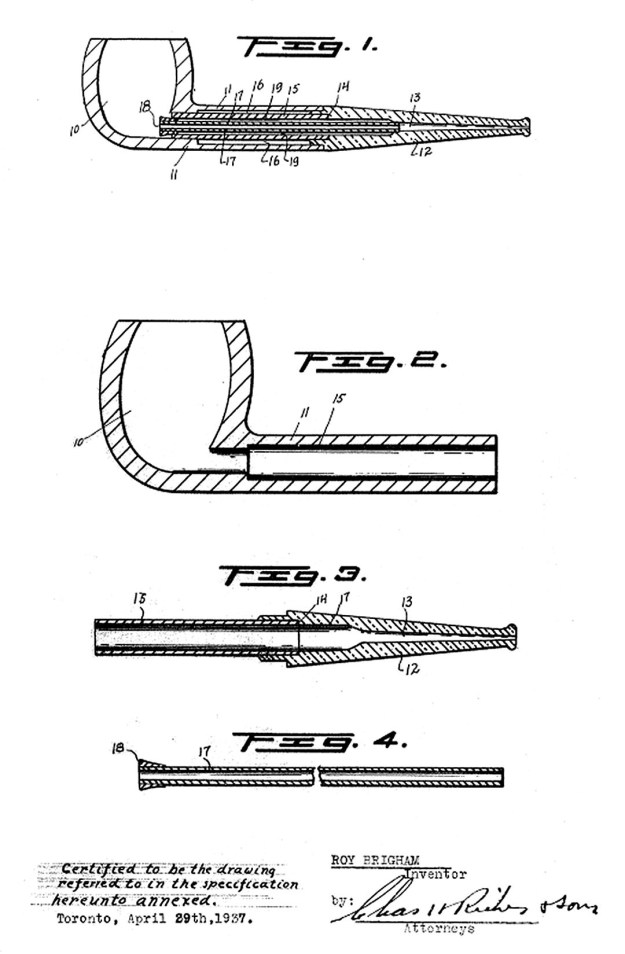

where the first digit refers to the pipe’s grade and the second and third digits to the pipe shape itself. The markings have been somewhat worn over time, but they are still readable. Crucially, they told me that this pipe was made during the patent era of Brigham pipes – that is to say, between 1938 and 1955. The Brigham logo is the variety that Lemon describes as the thin-script logo with a long tail on the “m” wrapping back under the name. The patent in question is the Canadian patent number for the filter system. Finally, the initial 2 in the three-digit shape number obviously connects to the two brass dots. Referring back to Lemon’s book, I found that shape 26 was called the ‘Bent Squatty’, with the description: Medium, ¼ Bent Bulldog, Diamond Taper Stem. Yep, that describes this pipe, alright. Anyway, for a more thorough view of Brigham’s history, please visit Pipedia’s article here. Meanwhile, here is a view of Brigham’s patented filter system:

The markings have been somewhat worn over time, but they are still readable. Crucially, they told me that this pipe was made during the patent era of Brigham pipes – that is to say, between 1938 and 1955. The Brigham logo is the variety that Lemon describes as the thin-script logo with a long tail on the “m” wrapping back under the name. The patent in question is the Canadian patent number for the filter system. Finally, the initial 2 in the three-digit shape number obviously connects to the two brass dots. Referring back to Lemon’s book, I found that shape 26 was called the ‘Bent Squatty’, with the description: Medium, ¼ Bent Bulldog, Diamond Taper Stem. Yep, that describes this pipe, alright. Anyway, for a more thorough view of Brigham’s history, please visit Pipedia’s article here. Meanwhile, here is a view of Brigham’s patented filter system: On with the restoration! The pipe is in good condition for its age – just particularly grungy. I was fairly impressed with the condition of the stummel. There was no notable damage, just a lot of grime – especially on the rim, where the grime was really ground in. The stem was heavily oxidized and had quite a bit of tooth chatter. There were some significant dents in the vulcanite and the button was somewhat squashed.

On with the restoration! The pipe is in good condition for its age – just particularly grungy. I was fairly impressed with the condition of the stummel. There was no notable damage, just a lot of grime – especially on the rim, where the grime was really ground in. The stem was heavily oxidized and had quite a bit of tooth chatter. There were some significant dents in the vulcanite and the button was somewhat squashed.

First things first. I used a disposable lighter and ‘painted’ the stem with its flame. The gentle heat of the flame can often cause the dents in the vulcanite of the stem to expand back into shape. In this case, there was perhaps a bit of movement – but not much. I used isopropyl alcohol on a few cotton rounds and wiped down the stem to provide an initial cleaning of filth before moving on to the next steps.

First things first. I used a disposable lighter and ‘painted’ the stem with its flame. The gentle heat of the flame can often cause the dents in the vulcanite of the stem to expand back into shape. In this case, there was perhaps a bit of movement – but not much. I used isopropyl alcohol on a few cotton rounds and wiped down the stem to provide an initial cleaning of filth before moving on to the next steps. The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean. I used a huge number of pipe cleaners and cotton swabs – more than shown in the photo. In addition, the aluminum filter chamber was so heavily choked with debris, that I used a drill bit to break down and remove all of this detritus. Amazing.

The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean. I used a huge number of pipe cleaners and cotton swabs – more than shown in the photo. In addition, the aluminum filter chamber was so heavily choked with debris, that I used a drill bit to break down and remove all of this detritus. Amazing.

The goal of the next step is the removal (or minimization) of oxidation. In this case, it was only minimization – the photos simply do not communicate how badly oxidized this stem was. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result was a hideous, ochre-coloured mess – but better off the stem than on it.

The goal of the next step is the removal (or minimization) of oxidation. In this case, it was only minimization – the photos simply do not communicate how badly oxidized this stem was. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result was a hideous, ochre-coloured mess – but better off the stem than on it. Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush. Due to the severity of the oxidation, I then repeated the scrubbing with the cream cleanser for maximum effect. It turns out that even that wasn’t good enough. I actually used red Tripoli on my buffing wheel to remove even more oxidation.

Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush. Due to the severity of the oxidation, I then repeated the scrubbing with the cream cleanser for maximum effect. It turns out that even that wasn’t good enough. I actually used red Tripoli on my buffing wheel to remove even more oxidation. As the stem was now clean and dry, I set about fixing the marks and dents in the vulcanite. This was done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on.

As the stem was now clean and dry, I set about fixing the marks and dents in the vulcanite. This was done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on. The penultimate step for the stem is sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done.

The penultimate step for the stem is sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done. As the stem was (nearly) complete, I moved on to the stummel. The first step was to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensured that all the debris was removed.

As the stem was (nearly) complete, I moved on to the stummel. The first step was to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensured that all the debris was removed. Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. With a pipe this dirty, it took quite a while and much cotton to clean. Although, it was easy compared to the stem!

Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. With a pipe this dirty, it took quite a while and much cotton to clean. Although, it was easy compared to the stem! I then decided to ‘de-ghost’ the pipe – that is to say, exorcize the remaining filth from the briar. I filled the bowl and the shank with cotton balls, then saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the remaining oils, tars and smells to leach out into the cotton.

I then decided to ‘de-ghost’ the pipe – that is to say, exorcize the remaining filth from the briar. I filled the bowl and the shank with cotton balls, then saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the remaining oils, tars and smells to leach out into the cotton. To tidy up the briar, I wiped down the outside, using a solution of a pH-neutral detergent and some distilled water, with cotton rounds. I also used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process was to scour the inside of the stummel with the same mild detergent and tube brushes. This was the culmination of a lot of hard work in getting the pipe clean.

To tidy up the briar, I wiped down the outside, using a solution of a pH-neutral detergent and some distilled water, with cotton rounds. I also used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process was to scour the inside of the stummel with the same mild detergent and tube brushes. This was the culmination of a lot of hard work in getting the pipe clean. I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth. For the final step, I took the pipe to my bench polisher and carefully buffed it with three coats of conservator’s wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth. For the final step, I took the pipe to my bench polisher and carefully buffed it with three coats of conservator’s wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

All done! This Brigham 226 Bent Squatty looks fantastic again and is ready to be enjoyed by my friend at church. It was a pleasure to work on and such a treat to see an older Brigham come back to life. The approximate dimensions of the pipe are as follows: length 5¾ in. (146 mm); height 1½ in. (38 mm); bowl diameter 1⅔ in. (42 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1¼ oz. (38 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

All done! This Brigham 226 Bent Squatty looks fantastic again and is ready to be enjoyed by my friend at church. It was a pleasure to work on and such a treat to see an older Brigham come back to life. The approximate dimensions of the pipe are as follows: length 5¾ in. (146 mm); height 1½ in. (38 mm); bowl diameter 1⅔ in. (42 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1¼ oz. (38 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.