Blog by Steve Laug

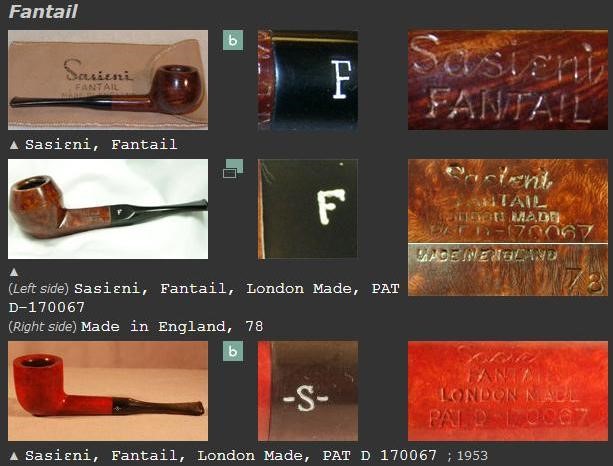

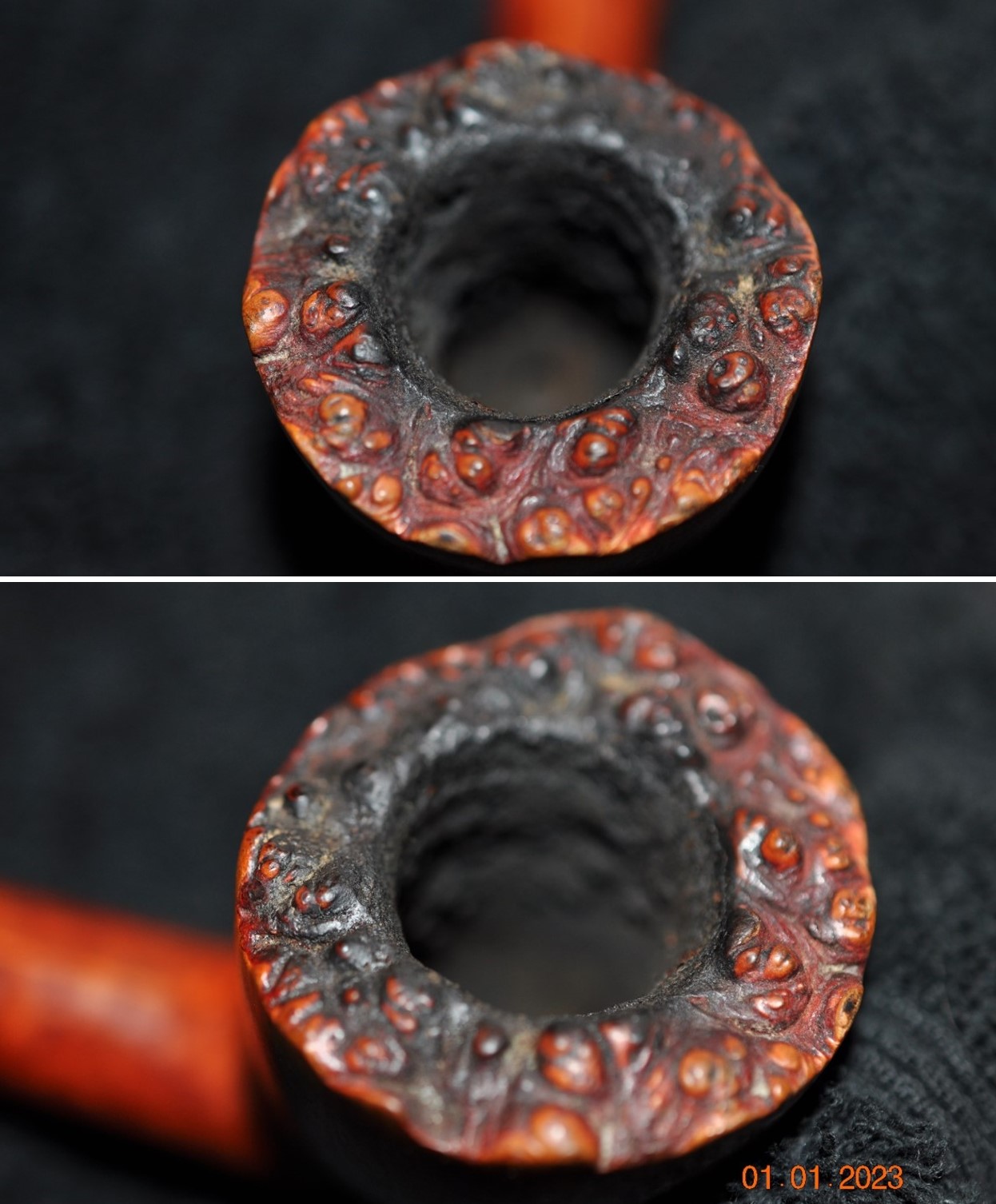

The next pipe on the work table is an interesting pipe in many ways – shape, style and stamping. We purchased it on 11/14/2022 from our connection in Copenhagen, Denmark. It is a shape that is hard to define – a cross between a Billiard and a poke. The bottom of the shank and heel of the bowl is flattened and the pipe stands leaning to the right side. This makes it quite unique. The stamping is clear and readable. On the left side it reads RATOS [over] Standard. That is followed by a stamping that runs at an angle toward the stem and reads Old Briar. On the right side it is stamped N7 which I assume is a shape number. The bowl had a thick cake and lava overflow on the inner edge of the rim. It was hard to estimate the condition of the edges with the cake and lava coat but I was hoping it had been protected from damage. The outer edge appeared to be in good condition. The finish was dull and dirty but had some nice grain under the grime and the finish appeared to be in good condition. A lot would be revealed once Jeff had worked his magic on it. The 9mm filter stem was dirty, lightly oxidized, calcified and had tooth chatter and tooth marks near the button on both sides. There was a faint RATOS stamp on the left side of the taper stem. Jeff took photos of the pipe before he started his cleanup work. Jeff took some close up photos of the rim top and the inner edge of the bowl to give an idea of the condition the pipe when he received it. I am sure glad that this was another one that he worked on. The bowl has a very thick cake and the rim top and a lava overflow around the entire top. The stem was lightly oxidized and had tooth marks and chatter on both sides.

Jeff took some close up photos of the rim top and the inner edge of the bowl to give an idea of the condition the pipe when he received it. I am sure glad that this was another one that he worked on. The bowl has a very thick cake and the rim top and a lava overflow around the entire top. The stem was lightly oxidized and had tooth marks and chatter on both sides.

Jeff took photos of the sides of the bowl and heel to show the finish around pipe. You can see the grime and the oils in the finish that are ground into the bowl. You can also see the great looking grain around the bowl.

Jeff took photos of the sides of the bowl and heel to show the finish around pipe. You can see the grime and the oils in the finish that are ground into the bowl. You can also see the great looking grain around the bowl.

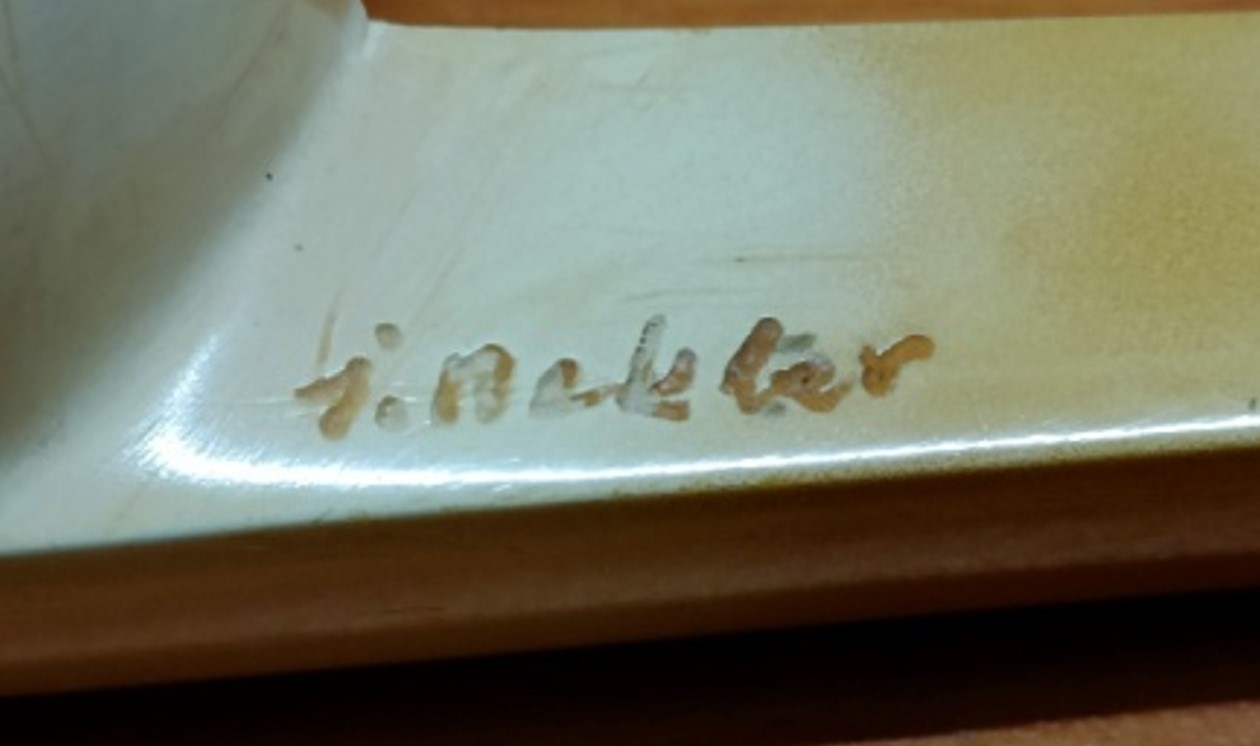

The next series of photos capture the stamping. The stamping is clear and readable as noted above.

The next series of photos capture the stamping. The stamping is clear and readable as noted above.

I turned to Pipedia and looked up the Ratos brand (https://pipedia.org/wiki/Ratos). I quote from the article below to show the information that was available on this brand.

I turned to Pipedia and looked up the Ratos brand (https://pipedia.org/wiki/Ratos). I quote from the article below to show the information that was available on this brand.

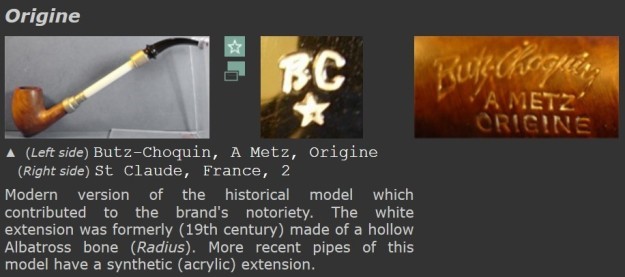

Ratos is a Swedish classic that has been on the Swedish market for more than 40 years. Pipe smokers know Ratos as an affordable quality pipe in many different shapes. Quality are all equally high, only genuine ‘Old’ briarroot may be used. Some of the pipes have meerschaum lined bowls. In 2009, all Ratos pipes are fitted with filters.

Some of these pipes are distributed by the Borkum Riff tobacco brand at pipe smoking contests.

In 2009, Ratos pipes are manufactured in France, in the oldest factory still operating.

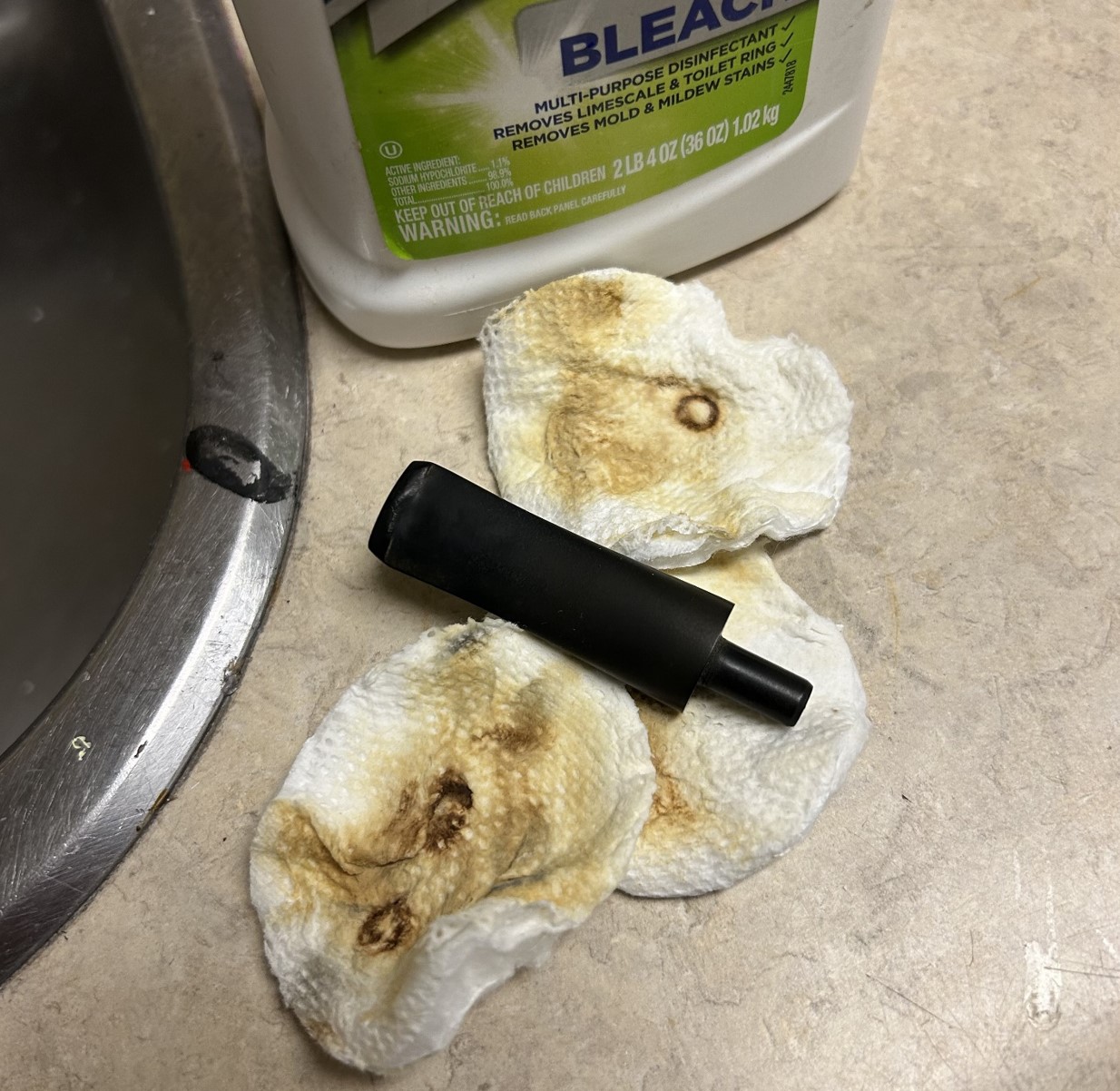

Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I received it.

I took close up photos of both the rim top and the stem. Jeff had been able to get the grime and lava off the rim top and it looked much better. There was some darkening on the rim top and edges. The stem looked very clean. The tooth marks and chatter were minimal and should be easy to remove.

I took close up photos of both the rim top and the stem. Jeff had been able to get the grime and lava off the rim top and it looked much better. There was some darkening on the rim top and edges. The stem looked very clean. The tooth marks and chatter were minimal and should be easy to remove.  I took photos of the stamping on the shank sides to show that they are very clear and readable.

I took photos of the stamping on the shank sides to show that they are very clear and readable.

I started my work on the pipe by addressing the remaining darkening on the rim top and the inner edge of the bowl. I sanded the bevelled edge with a folded piece of 220 grit sandpaper. I worked over the rim top at the same time and smooth out and remove the darkening. It looked much better.

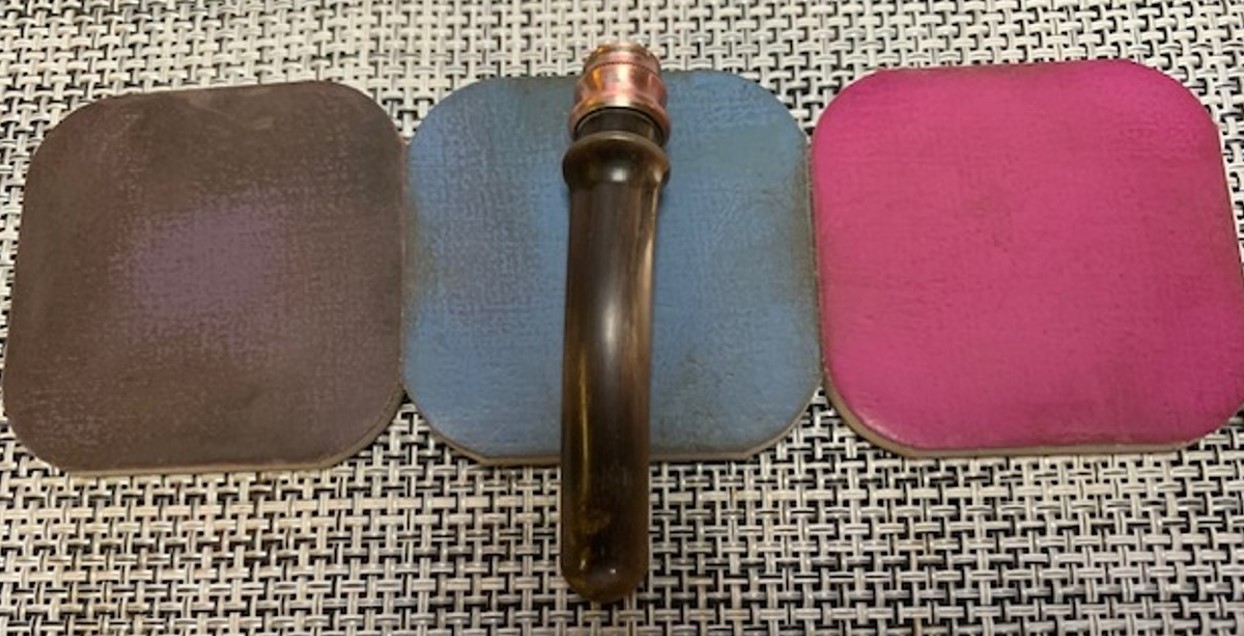

I started my work on the pipe by addressing the remaining darkening on the rim top and the inner edge of the bowl. I sanded the bevelled edge with a folded piece of 220 grit sandpaper. I worked over the rim top at the same time and smooth out and remove the darkening. It looked much better. Now it was time to do my work on the pipe. I polished the bowl and rim top with micromesh sanding pads using 1500-12000 grit sanding pads and wiping it down after each sanding pad with a damp cloth to remove the sanding dust and debris.

Now it was time to do my work on the pipe. I polished the bowl and rim top with micromesh sanding pads using 1500-12000 grit sanding pads and wiping it down after each sanding pad with a damp cloth to remove the sanding dust and debris.

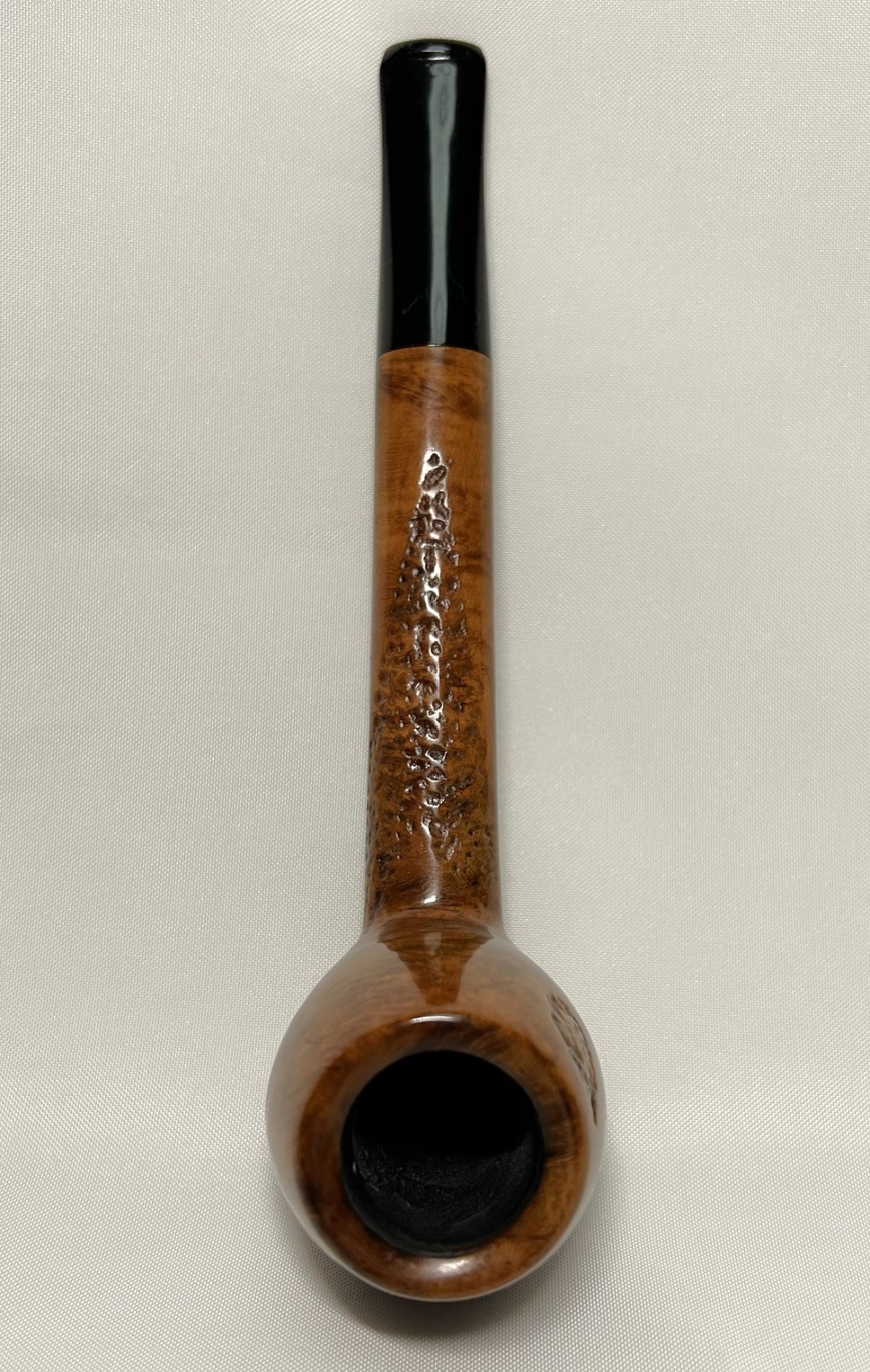

I worked some Before & After Restoration Balm into the finish of the bowl and shank with my fingers. I want the product to go deep into the finish because it works to clean, enliven and protect the briar. Once I was confident that it was deeply worked into the finish I wiped it off and buffed it with a soft cloth to polish it. The pipe really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. The grain really stands out on the pipe in the photos below.

I worked some Before & After Restoration Balm into the finish of the bowl and shank with my fingers. I want the product to go deep into the finish because it works to clean, enliven and protect the briar. Once I was confident that it was deeply worked into the finish I wiped it off and buffed it with a soft cloth to polish it. The pipe really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. The grain really stands out on the pipe in the photos below.

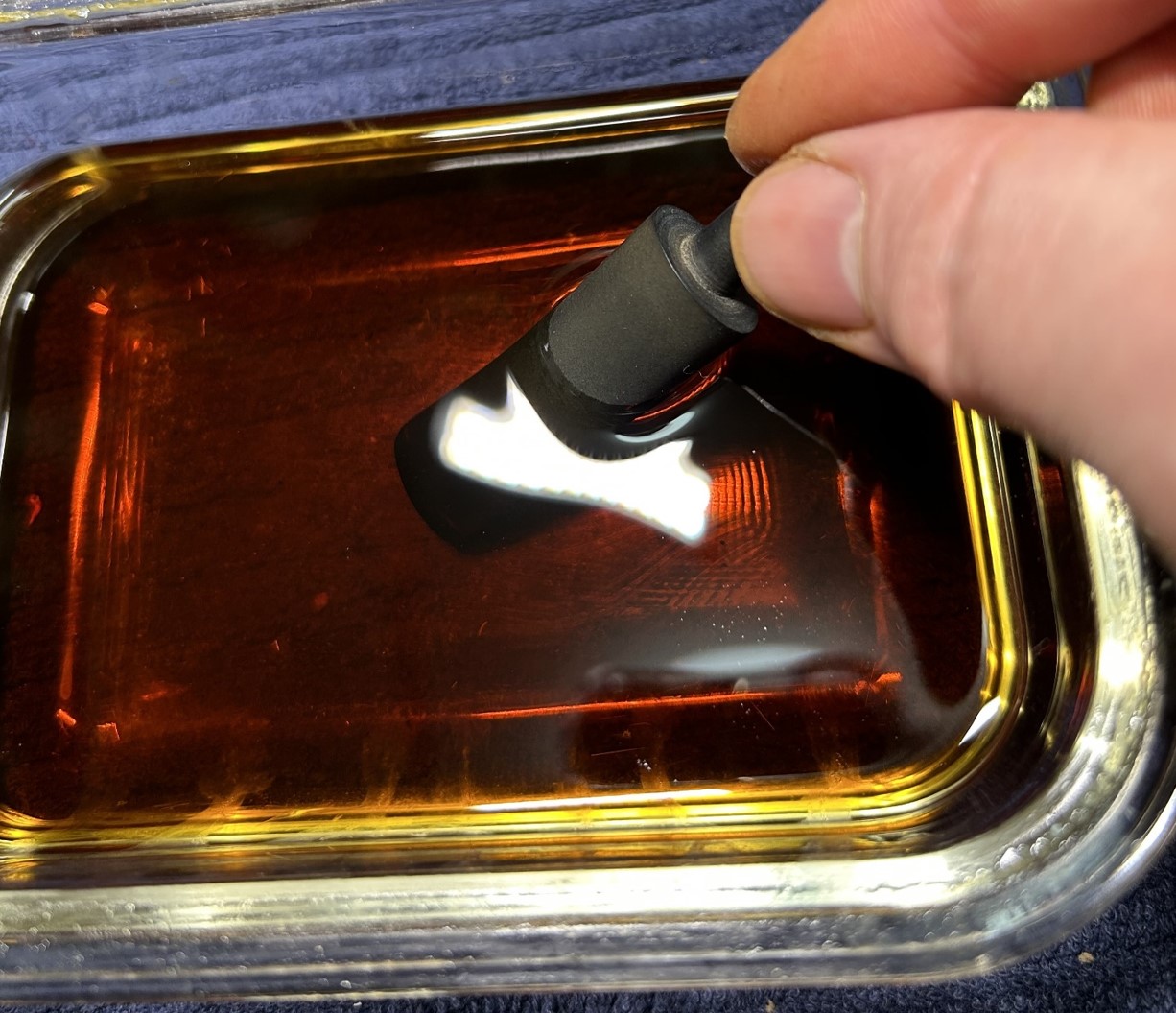

I set the bowl aside and turned to work on the stem. I polished the vulcanite stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I set the bowl aside and turned to work on the stem. I polished the vulcanite stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I polished it with Before & After Pipe Polish – both the Fine and Extra Fine polishes. I gave it a final coat of oil and set it aside to dry.

I polished it with Before & After Pipe Polish – both the Fine and Extra Fine polishes. I gave it a final coat of oil and set it aside to dry.  This RATOS Standard Old Briar N7 Sitter Billiard was another fun pipe to work on and I really was looking forward to seeing it come back together again. With the grime and debris gone from the finish and the rim top the birdseye grain is beautiful. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank during the process. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The rich finish on the bowl looks really good with the black vulcanite stem. It is very well done. Give the finished RATOS N7 Standard Old Briar a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 42grams/1.48oz. This is truly a great looking Ratos Sitter Billiard. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to the rebornpipes store in the Pipes From Various Makers Section. If you want to add it to your collection send me an email or a message! Thanks for your time.

This RATOS Standard Old Briar N7 Sitter Billiard was another fun pipe to work on and I really was looking forward to seeing it come back together again. With the grime and debris gone from the finish and the rim top the birdseye grain is beautiful. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank during the process. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The rich finish on the bowl looks really good with the black vulcanite stem. It is very well done. Give the finished RATOS N7 Standard Old Briar a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 42grams/1.48oz. This is truly a great looking Ratos Sitter Billiard. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to the rebornpipes store in the Pipes From Various Makers Section. If you want to add it to your collection send me an email or a message! Thanks for your time.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.