by Kenneth Lieblich

Hiding amongst the bric-à-brac, in the bottom of a box of pipes I recently acquired, was this relatively inconspicuous pipe. This pipe is a Jandrew partially-rusticated calabash with a vulcanite shank extension. It also has a thin, military-mount, vulcanite stem. I asked Steve about the brand and he mentioned its provenance. I must say, this pipe didn’t immediately catch my attention. It seemed fine, but nothing of note. But as I worked on it, it grew on me. I thought about it more and more, and I liked it more and more.

The markings were brief – but very clear and readable. On the underside of the shank, were the words, Jandrew [over] 6 ∙ 99. This indicates that the pipe was made by J. Andrew Kovacs in (what I assume to be) June 1999. It also displays a handsome brass dot in the shank extension.

The markings were brief – but very clear and readable. On the underside of the shank, were the words, Jandrew [over] 6 ∙ 99. This indicates that the pipe was made by J. Andrew Kovacs in (what I assume to be) June 1999. It also displays a handsome brass dot in the shank extension. Little information is to be had about Jandrew pipes. Using the scant information I could trawl together from Pipedia, MBSD Pipes, BlueRoomBriars, and Smoking Pipes, I have collated the following:

Little information is to be had about Jandrew pipes. Using the scant information I could trawl together from Pipedia, MBSD Pipes, BlueRoomBriars, and Smoking Pipes, I have collated the following:

Jandrew pipes were made by J. Andrew Kovacs, an American artisan. He lived in both Jerome and Cottonwood, Arizona and is said to have later moved to Milwaukee, Wisconsin. He was part of a group of Arizona-based hobbyists that started carving pipes in the 1960s and 70s. Working through the late 20th century, Kovacs was part of the great American freehand scene and preferred acrylic stems. He favored the wild Danish Fancy style of shaping, and his work was once commonly found in pipe shops of the southwestern United States (especially in the Phoenix area). Horace DeJarnett (of DeJarnett Pipes) studied pipemaking for about year (on and off) in 2000 at Kovacs’ workshop in northern Arizona.

Let’s get working. As you can see, this pipe was in great shape already – not too much work needed. The stummel was a bit dirty inside, but not too bad. The stem was also in good condition – just a few, minor tooth marks. This must be an unusual Jandrew pipe insofar as the stem (and shank extension) is vulcanite – not the usual acrylic. On the whole, the pipe looked tired, worn, but in decent shape – kind of like me.

I used isopropyl alcohol on a few cotton rounds and wiped down the stem to provide an initial cleaning before moving on to the next steps. The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean.

I used isopropyl alcohol on a few cotton rounds and wiped down the stem to provide an initial cleaning before moving on to the next steps. The primary cleaning came next. I disinfected the inside of the stem with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. I scrubbed thoroughly to make sure the interior was very clean. The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result was a hideous, brownish mess – but better off the stem than on it.

The goal of the next step is the removal (or minimization) of oxidation. Going to my sink, I used cream cleanser, cotton rounds, and a toothbrush, and scoured the stem to remove as much surface oxidation as possible. As the photos show, the result was a hideous, brownish mess – but better off the stem than on it. Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush.

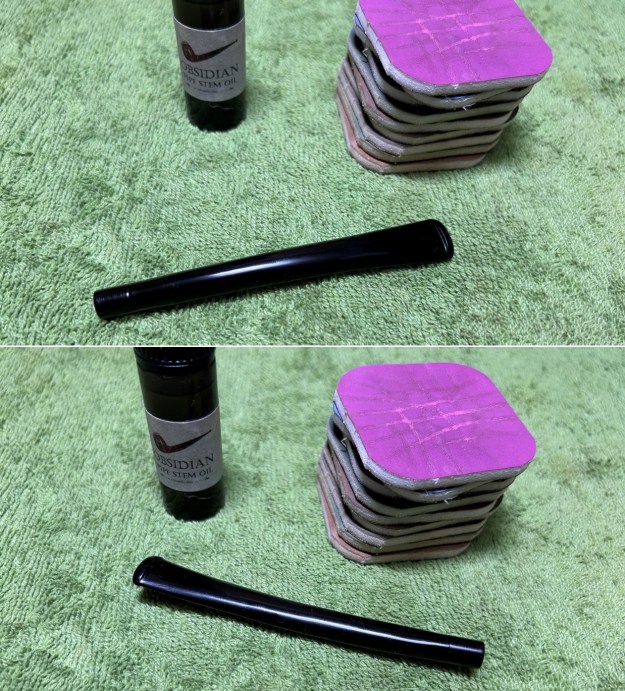

Once the stem was reasonably clean, I soaked it overnight in some Briarville Stem Oxidation Remover. This solution works to draw oxidation in the stem to the surface of the vulcanite. This is a major aid and an important step in ensuring a clean stem. The following day, I drew out the stem from its bath and scrubbed the lingering fluid with a toothbrush. As the stem was now clean and dry, I set about fixing the marks and dents in the vulcanite. This was done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on to sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done.

As the stem was now clean and dry, I set about fixing the marks and dents in the vulcanite. This was done by filling those divots with black cyanoacrylate adhesive, impregnated with carbon and rubber. I left this to cure and moved on to sanding. First, with my set of needle files, I reduced the bulk of the cyanoacrylate repairs. I removed the excess adhesive as near to the surface as possible, without cutting into the vulcanite. Following that, I used all nine of the micromesh sanding pads (1,500 through 12,000 grit) to sand out flaws, even out the vulcanite, and provide gentle polishing of the finished surface. I also applied pipe-stem oil while using the last five micromesh pads. There was a wonderful, deep black shine to the stem when I was done. As the stem was (nearly) complete, I moved on to the stummel. The first step was to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensured that all the debris was removed. Overall, it wasn’t too bad.

As the stem was (nearly) complete, I moved on to the stummel. The first step was to ream out the bowl – that is to say, remove all the cake inside the bowl. This accomplished a couple of things. First (and most obviously), it cleaned the bowl and provided a refurbished chamber for future smoking. Second, when the old cake was removed, I could inspect the interior walls of the bowl and determine if there was damage or not. I used a reamer, a pipe knife, and a piece of sandpaper taped to a wooden dowel. Collectively, these ensured that all the debris was removed. Overall, it wasn’t too bad. Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. To tidy up the briar, I wiped down the outside, using a solution of a pH-neutral detergent and distilled water, with cotton rounds. I also used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar.

Similar to the stem, I then cleaned the stummel with both pipe cleaners and cotton swabs dipped in lemon-infused 99% isopropyl alcohol. To tidy up the briar, I wiped down the outside, using a solution of a pH-neutral detergent and distilled water, with cotton rounds. I also used a toothbrush in the crevices. This did a good job of cleaning any latent dirt on the surface of the briar. The last step of the cleaning process was to scour the inside of the stummel with the same mild detergent and tube brushes. This was the culmination of a lot of hard work in getting the pipe clean.

The last step of the cleaning process was to scour the inside of the stummel with the same mild detergent and tube brushes. This was the culmination of a lot of hard work in getting the pipe clean. I used some of my micromesh pads to sand the outside of the stummel and finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth.

I used some of my micromesh pads to sand the outside of the stummel and finish it off. This sanding minimizes flaws in the briar and provides a beautiful smoothness to the wood. I rubbed some LBE Before & After Restoration Balm into the briar and let it sit for 30 minutes or so. The balm moisturizes the wood and gives a beautiful depth to the briar. I then buffed the stummel with a microfibre cloth.

For the final step, I took the pipe to my bench polisher and carefully buffed it – first with a blue diamond compound, then with three coats of conservator’s wax. This procedure makes the pipe look its best – the stummel sings and the stem glows.

For the final step, I took the pipe to my bench polisher and carefully buffed it – first with a blue diamond compound, then with three coats of conservator’s wax. This procedure makes the pipe look its best – the stummel sings and the stem glows. This Jandrew 06-99 calabash pipe is a beauty and will go into my collection (at least for now). It was a pleasure to work on. The approximate dimensions of the pipe are as follows: length 6⅜ in. (162 mm); height 1⅞ in. (48 mm); bowl diameter 1⅔ in. (42 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1½ oz. (44 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

This Jandrew 06-99 calabash pipe is a beauty and will go into my collection (at least for now). It was a pleasure to work on. The approximate dimensions of the pipe are as follows: length 6⅜ in. (162 mm); height 1⅞ in. (48 mm); bowl diameter 1⅔ in. (42 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 1½ oz. (44 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.