Blog by Robert M. Boughton

Member, International Society of Codgers

Member, North American Society of Pipe Collectors

Member, Facebook Gentlemen’s Pipe Smoking Society

https://www.facebook.com/roadrunnerpipes/

http://about.me/boughtonrobert

Photos © the Author except as noted

For Liz B. Smith: this one’s for you

It’s not the size of the dog in the fight; it’s the size of the fight in the dog.

— Samuel Langhorne Clemens (Mark Twain), 1835-1910, U.S. humorist, writer, editor and extraordinary adventurer

The word ‘American’ terminates in ‘I can,’ and ‘dough’ begins with ‘do.’

— Attributed to Alfred Carl Fuller (1885-1973), founder of the Fuller Brush Co.

INTRODUCTION

A great American rock group called The Doors summed up this blog in the most famous couplet from the 1967 song “The End.” The rest of the brilliant yet rambling lyric poetry, alas, is too morose and even sinister to cobble together a quote for the occasion, no matter how many annoying ellipsis marks might be used by, say, someone with the skill set to edit negative book reviews so they sound glowing on the dust jackets. Hence the more merry samples above, which still bely the sadness I feel at the close of my attempt to serialize various facets of the ways women enjoy the pleasures of pipes as much as do men. (Twain, I’m sure, would have despised Fuller’s aphorism and hated being associated with a salesman.) The nine months since my first installment seem more like years given the travails I’ve faced and overcome. But fret not; I won’t go there now – at least not in great detail.

I had two more conventional instruments for savoring pipe tobacco set aside for the seventh and last part of the series and was still deliberating which to use. As circumstances transpired, they were lost to the most shameful, unscrupulous and downright worthless excuse for a human I have ever encountered in a slumlord, and with whom I am still engaged, in ever-escalating legal battles. The dispute is now poised to escalate from civil to criminal for the felony property conversion perpetrated by the contemptible principal of several offenders. But I will write more about that in a future blog detailing the loss of almost every material possession I held most dear. Suffice it to say for now that the devastating event has proved to be the single most unnerving and excruciating test of my ability to come to terms in my own mind with any set of undeniable facts, to discuss the odious injustice of the whole despicable experience with family and friends and, perhaps most difficult of all, even to brooch the subject in this forum, I have ever experienced. The memories still sting and I believe will even after the full weight of the law crushes the scoundrel.

And so, after careful consideration, I decided to combine a look at salesman samples, a separate blog of which I began drafting some months ago, with the culmination of my ladies pipes series. In the span of a few years I amassed an admirable collection of these little gems of tobacciana and still have several, thanks to the fact that they were stashed in my go-bag, as I call the portable kit of rotation pipes, tobaccos, restoration tools and odds and ends. They were snug in a small box of restorations in progress or just completed when the slime ball who is now the central focus of my ever more litigious life made the premeditated decision to lock me out of my home with the purpose of converting my property to his own gain. After all, he was sued twice in the past on the same grounds and only had to pay for one of them. At any rate, in my research into female pipe enjoyers, I found a greater incidence of affinity for these tiny pipes among women compared to men, despite the frequent common ground of the two genders viewing them as impractical for loading with leaf and lighting up. I shall do my best to dispel the myth.

While I am aware of the unusual interest in salesman samples in recent contributions to this forum, all of which included good information on the peculiar items, I will give my two cents worth for those who may have missed the others six parts and, I hope, add a little more context and color. I would also like to celebrate some of the collection that was mine and those that remain.

Salesman samples were not toys – nothing like the Matchbox and Hot Wheels cars many of us collected as children. They were not knickknacks such as thimbles or figurines of people, animals, castles, super heroes and creatures from fantasy and mythology. Salesman samples came into existence as marketing tools for manufacturers of almost every mechanical and non-agricultural commodity and were most popular in the early 20th century. Few folks nowadays remember a time when cars and airplanes were not the standards of transportation, and products could not be shipped in viable ways, often overnight, to showrooms all over the country and world.

Enter the intrepid peddlers of every type of ware – baseballs, coal stoves, violins, furniture, upright carpet cleaners and, of course, tobacco pipes, to name a fraction of the goods they offered – and who had no mode of travel better than trains, and in some more remote locales, stagecoaches and even by horseback. Think about that. How could one person carry many samples of the items he sold, which were either huge or fragile, to convince prospective buyers to purchase them?

Then some merchandising brainiac came up with the idea of exact replicas that could be conveyed in valises. Giants like Sears & Roebuck were made as much by direct salesmen as mail order catalogs, to be sure. The reality of traveling salesmen is that they covered vast and perilous territories going “door-to-door,” which in those days was farm to farm, and they were often far between. For anyone who complains about road conditions now, thank your lucky stars you weren’t around back in the day. Then again, maybe a few old curmudgeons were! True, there were also small general stores to be pitched, but most folks had few chances to make the dusty, jarring journey into town. Some salesmen even had to pay in advance for their merchandise and keep the profits. Here’s the real kicker: back then, bartering was the name of the game, and with little cash on hand, the yokels and mercantile proprietors tended to trade with eggs, butter, vegetables and other what-have-you. In short, the life of the traveling salesman was rough and grungy long before the latter word was coined in the 1960s, yet today he is remembered in popular movies and cheesy novels as a fast-talking bespectacled dandy from “sumwer back east.”

Remember, all of the following genuine salesman samples are about the size indicated in the photos with a tape measure and a ruler. Now for some pipes I’d like to own.

Now for some pipes I’d like to own.

And here was my own collection of salesman samples.

And here was my own collection of salesman samples.

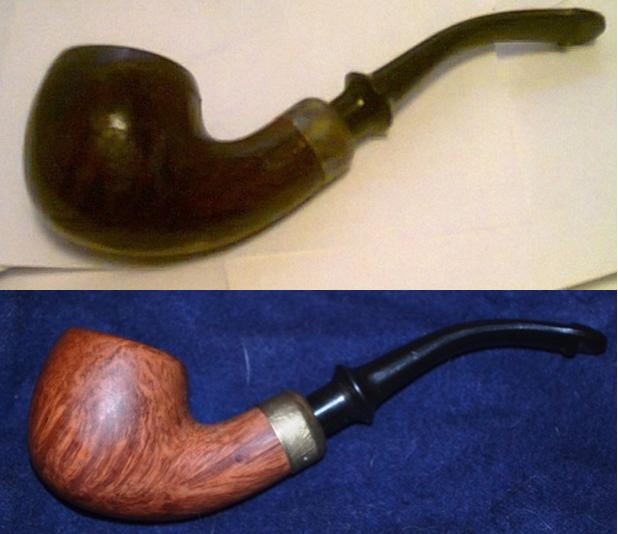

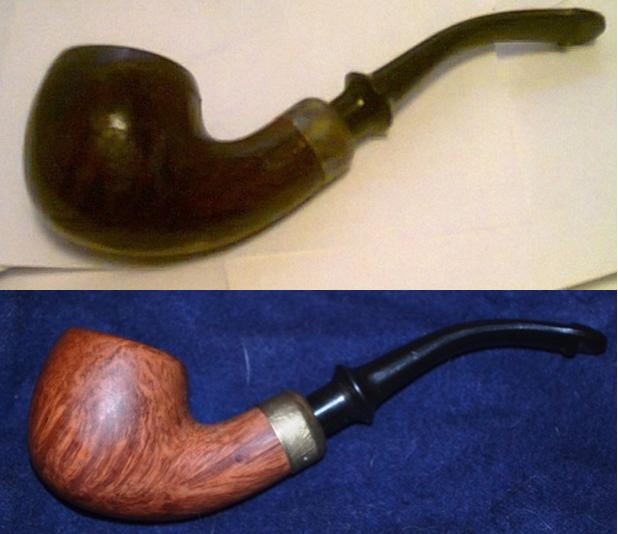

William Demuth & Co. (WDC) Bent Pot with screw-in rim guard, before and after

William Demuth & Co. (WDC) Bent Pot with screw-in rim guard, before and after

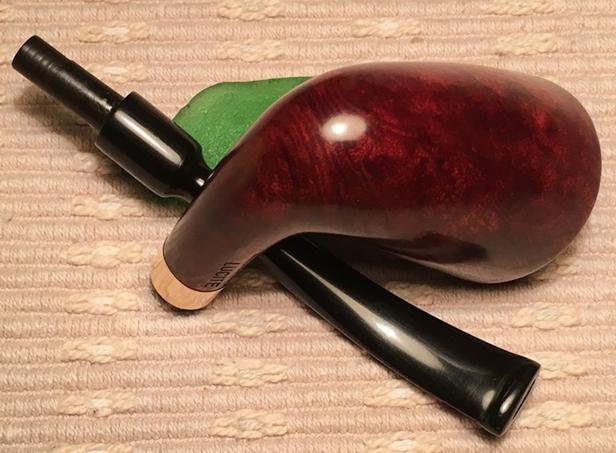

WDC Wellington Bent Apple, before and after

WDC Wellington Bent Apple, before and after

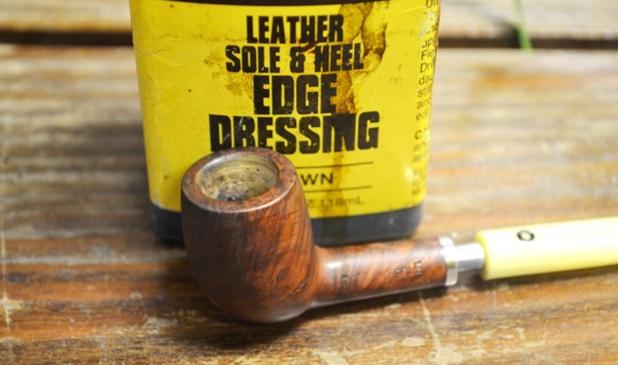

Yello-Bole Straight Billiard

Yello-Bole Straight Billiard

“Mahjong” Bent Billiard, probably made of Bakelite

“Mahjong” Bent Billiard, probably made of Bakelite

Kaywoodie Straight Apple

Kaywoodie Straight Apple

Custombilt Porcelain (filled mouthpiece – not smokable)

Custombilt Porcelain (filled mouthpiece – not smokable)

No-Name Rhodesian

No-Name Rhodesian

La Grande Bruyere Bent Apple, Czech, before and after. This was my first restore.

La Grande Bruyere Bent Apple, Czech, before and after. This was my first restore.

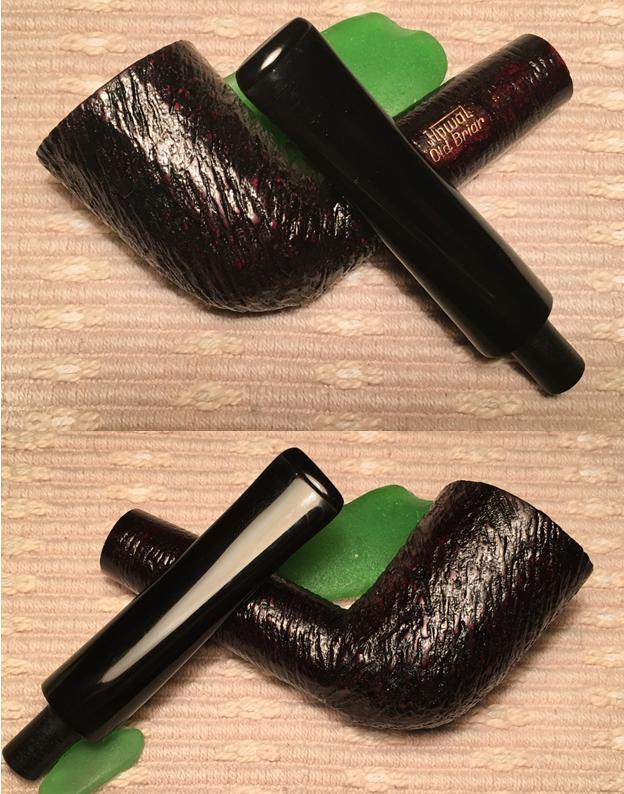

Only three of the diminutive but intricate works of craftsmanship in my promising and cherished sub-collection of these fading pieces of tobacciana and history survived theft by the slumlord: the Mahjong, which at an astounding length of 2½” with a chamber diameter of ⅜” x ¾” may indeed be the smallest functional tobacco pipe ever made, as the seller hinted; the WDC bent billiard, mere fractions larger in every respect, and last but by no means least, the Yello-Bole, at a whopping 3¾” long sporting a ⅜” x ½” chamber. To emphasize the point, their salvation was by the sole grace of my having them with me when the illegal lockout was executed.

The subject of this final Ladies Pipes blog is the restoration of the Yello-Bole, which, I’m sorry to report, was not all that difficult, beyond Plato’s maxim, “Better a little which is well done, than a great deal imperfectly.” Steve wrote a wonderful blog concerning a no-name carved apple salesman sample (3¼” long, 1″ tall with a ⅞” outer bowl diameter and a ⁷∕₁₆” inner bowl diameter). In the first photo, my favorite, he contrasts the dinky apple with a giant KBB Yello-Bole Imperial 3068C Bent Billiard (length 10″, height 2¼” and inner bowl diameter ⅞”). See https://rebornpipes.com/2016/12/26/a-tiny-salesman-pipe-what-a-contrast-to-those-giant-house-pipes/. KBB Yello-Bole Giant vs. Tiny Carved No-Name, courtesy S. Laug

KBB Yello-Bole Giant vs. Tiny Carved No-Name, courtesy S. Laug

Steve also summed up the relative natures of a standard pipe restoration and that of a salesman sample when he wrote, “It takes as much work to clean and restore a tiny pipe as it does a big one and the steps and process [are] the same regardless of size.”

And so, as I begin again to practice the wonderful disorder that is pipe acquisition, with the three salesman samples and a handful of other survivors to my name, I have a strong desire and need to share. My good friend and mentor emeritus, Chuck Richards, taught me that. Therefore, in light of the kindness and encouragement she has shown me on the Smokers Forums UK, her invaluable guidance in this series and the interest I know she has in mini pipes and salesman samples, to repeat my opening dedication with a tad more emphasis: this Yello-Bole is for you, Liz – literally.

RESTORATION

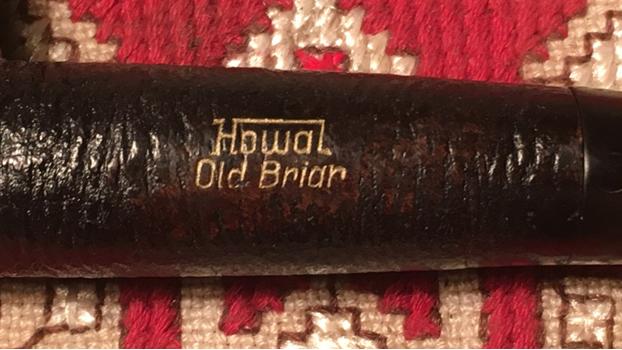

The Yello-Bole, to be honest, was a cleanup job. The most troublesome aspect of rejuvenating the delicate little working scale example of a pipe that would likely measure 5½” long was stripping the old stain and replacing it, and as a consequence removing a bad discoloration on the front. Confident an Everclear soak would not harm the nomenclature, I began with that and an OxiClean bath for the bit. Stripping the original stain did a fine job of revealing the rough edges, so to speak, of the briarwood. To be still more honest, after perhaps ten minutes of immersion in Everclear, the stummel might just as well have cried to me through the depth, as I recall even now the mental flash of eradicating that all-important if carbon-obscured facet of the chamber, being “CURED WITH REAL HONEY.”

The Yello-Bole, to be honest, was a cleanup job. The most troublesome aspect of rejuvenating the delicate little working scale example of a pipe that would likely measure 5½” long was stripping the old stain and replacing it, and as a consequence removing a bad discoloration on the front. Confident an Everclear soak would not harm the nomenclature, I began with that and an OxiClean bath for the bit. Stripping the original stain did a fine job of revealing the rough edges, so to speak, of the briarwood. To be still more honest, after perhaps ten minutes of immersion in Everclear, the stummel might just as well have cried to me through the depth, as I recall even now the mental flash of eradicating that all-important if carbon-obscured facet of the chamber, being “CURED WITH REAL HONEY.”

With a reflexive thrust of a hand toward the Tupperware bowl in which the minuscule bit of wood had sunk to the bottom like lost treasure, I plucked it out and wrapped it in a soft cotton cloth. I wiped it. I turned and scrubbed it, inside and out. I ran an end of a cleaner through the shank and bent it in half to dry the chamber walls. I did everything short of CPR. Observing the miraculous near perfection of the coat of whatever cured honey concoction the factory applied so many years earlier, I’m here to tell you, the full comprehension of the reprieve I was granted in the nick of time was acute and profound.

The bit came out of its cleaning solution some time later, a little better for the bath. I used the white end of the same cleaner as before to dispel the insignificant impurities that remained.

The bit came out of its cleaning solution some time later, a little better for the bath. I used the white end of the same cleaner as before to dispel the insignificant impurities that remained.

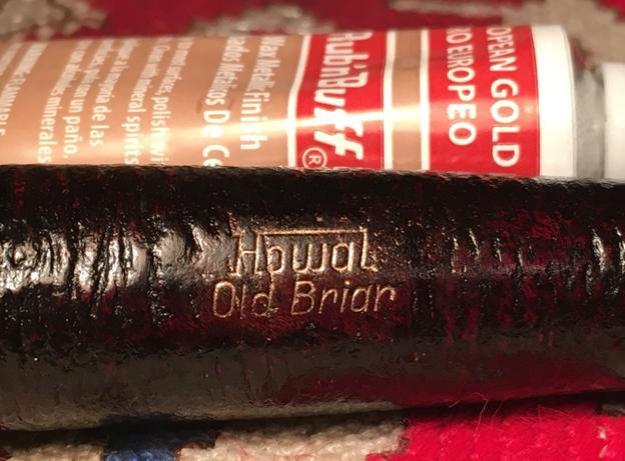

Super fine “0000” steel wool and 320-grit paper got rid of the unpleasant large light blotch on the bowl’s front and gave the whole spotted but rich wood a nice shine.

The gamut of micro mesh from 1500-12000 elicited the highest sheen the briarwood would achieve before the final electric buffing.

The gamut of micro mesh from 1500-12000 elicited the highest sheen the briarwood would achieve before the final electric buffing.

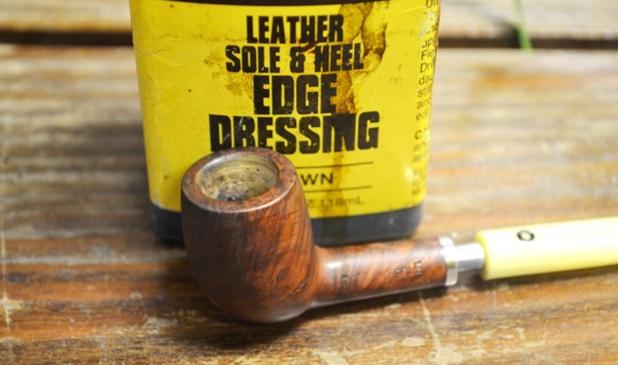

Several minutes after staining the stummel with Fiebing’s Brown leather dye and flaming out the alcohol with a Bic, I gave the surface a gentle buff with 8000 grade micro mesh.

Several minutes after staining the stummel with Fiebing’s Brown leather dye and flaming out the alcohol with a Bic, I gave the surface a gentle buff with 8000 grade micro mesh.

A retort was neither needed nor called for under the circumstances I described earlier with my nearly disastrous soaking of the stummel in Everclear. Micro meshing the bit was so simple I forgot to mention doing it until now. And so, all that remained to do was buff the wood with red and white Tripoli, White Diamond and carnauba, and the bit with white Tripoli and carnauba.

A retort was neither needed nor called for under the circumstances I described earlier with my nearly disastrous soaking of the stummel in Everclear. Micro meshing the bit was so simple I forgot to mention doing it until now. And so, all that remained to do was buff the wood with red and white Tripoli, White Diamond and carnauba, and the bit with white Tripoli and carnauba.

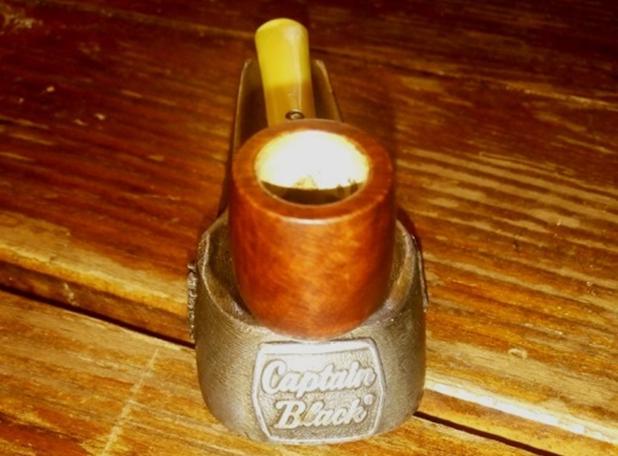

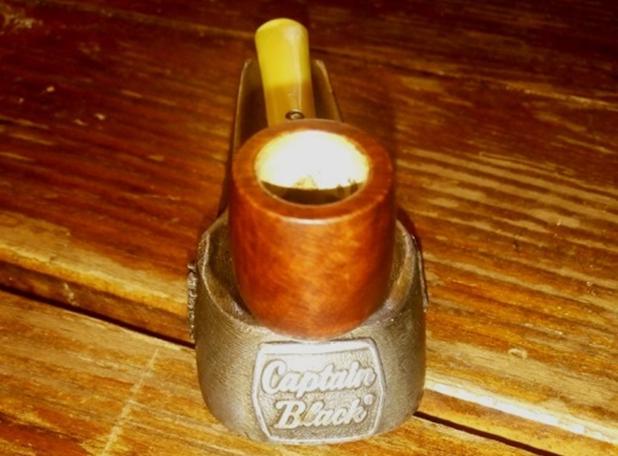

The final shot I took is some sort of weird view I found by accident with a cell phone camera toggle switch marked “NG.” So far I haven’t a clue what it stands for, but it seems to show the inner pipe. I offer it for entertainment purposes more than anything else. Maybe someone can explain it to me.

The final shot I took is some sort of weird view I found by accident with a cell phone camera toggle switch marked “NG.” So far I haven’t a clue what it stands for, but it seems to show the inner pipe. I offer it for entertainment purposes more than anything else. Maybe someone can explain it to me. CONCLUSION

CONCLUSION

My ideal for the series was, in the language of college essays, to compare and contrast the primary topic of tobacco pipes and their attraction to men and women in general through some key aspects of the pastime, and to gain potential insights into what differences in tastes and interests, if any, might exist. I knew from the beginning that my hopes were overambitious, but I have at least made some headway. Perhaps a book is in order.

At times I was disheartened by the apparent lack of interest in the topic. But comparing reactions to the first six, looking at votes, comments and likes, I see they all average out to one of my typical blogs here. My primary objective was to bring the men and women of the pipe community more together. Only time will tell.

Now I just need to get Liz’ address to send her the pipe.

SOURCES

http://www.collectorsweekly.com/advertising/salesmans-samples

http://www.amiright.com/parody/90s/deepbluesomething11.shtml WARNING: SOME OFFENSIVE LYRICS

https://rebornpipes.com/2016/10/08/a-living-tiny-kbb-yello-bole-salesmans-pipe/

https://rebornpipes.com/tag/yello-bole-pipes/

http://buckcreek.tripod.com/salesman.html

http://www.sloperama.com/majexchange/id.html

THE REST OF THE SERIES

https://rebornpipes.com/2016/05/04/spotlight-ladies-pipes-part-17-a-frasa-french-bent-billiard/

https://rebornpipes.com/2016/05/07/spotlight-ladies-pipes-part-27-a-clinton-straight-oval/

https://rebornpipes.com/2016/05/14/spotlight-ladies-pipes-part-37-a-tiny-medico-acorn/

https://rebornpipes.com/2016/05/20/spotlight-ladies-pipes-part-47-a-real-briar-bounty/

https://rebornpipes.com/2016/06/17/spotlight-ladies-pipes-part-57-a-vintage-dr-grabow-carved-duke/

https://rebornpipes.com/2016/09/26/spotlight-ladies-pipes-part-67-an-albertson-baby-bent-brandy/