Blog by Steve Laug

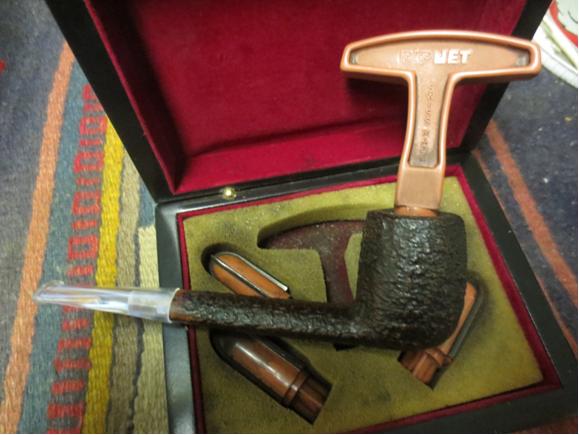

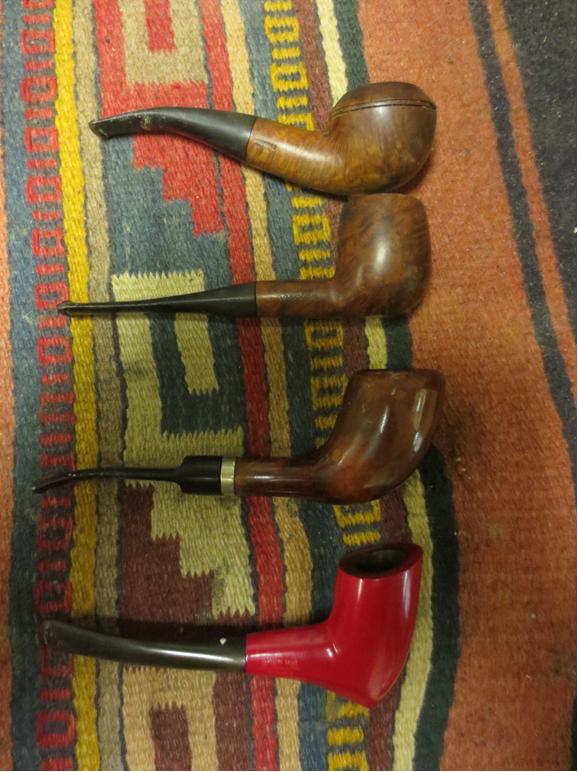

Another pipe from the treasure trove my brother Jeff sent me was an early Kirsten. The metal barrel is stamped Kirsten in script on the left side of the barrel and on the underside it is stamped Pats. & Pats. Pend. – A. When I received it the bowl would unscrew from the barrel and it had no metal cap on the bottom. It was a wooden bowl without the cap which along with the stamping pointed to an early Kirsten. The stem and rod were stuck in the barrel and the adjustable valve on the front of the barrel was frozen solid. The valve had evidently been frozen for some time as someone had used pliers on it to try to remove it. They had left behind the tooth marks of the pliers on the aluminum valve cover. Because of the vulcanite lip on the stem that sat against the barrel that there would not be a rubber grommet between the stem and the barrel. The bowl had a thick, rock hard cake and the bottom of the bowl was not visible to see what the condition of the screw head was like. I have no idea how the pipe man ever drew air through this pipe as the bottom of the bowl was solid. The finish on the bowl was dull and lifeless with no grain visible through the grime. The top of the rim was covered with over flow from the cake in the bowl. It was a large bowl initially so once the cake was gone it would be an inch in diameter. I looked up information to see if I could find a cut away drawing of the Kirsten and found this one and a bit of history and information on the concept of the Kirsten pipe. The following is from the Kirsten website https://www.kirstenpipe.com/page_pipestyles.shtml and https://www.kirstenpipe.com/page ourstory.shtml

I looked up information to see if I could find a cut away drawing of the Kirsten and found this one and a bit of history and information on the concept of the Kirsten pipe. The following is from the Kirsten website https://www.kirstenpipe.com/page_pipestyles.shtml and https://www.kirstenpipe.com/page ourstory.shtml “It is by no means merely puffery to say that Professor Frederick K. Kirsten was a genuine American original. He first sailed to this country in 1902, as a cabin boy from Hamburg, Germany. After successfully rounding the Horn and eluding the shanghai gangs of the West Coast, he navigated the educational system at the University of Washington to become a Professor of Aeronautical Engineering. Here, his inventive spirit took wing. He created the world-famous Kirsten Wind Tunnel, Air-washing equipment for factories, an air-cooled Utopian Bed, and, most notably, a revolutionary propeller which enables boats to stop and turn on a dime. Today, in the same waters where he jumped ship almost 100 years ago, ocean-going vessels are landed by sturdy tugs driven by Kirsten cycloidal propellers, piloted by equally sturdy captains smoking cool Kirsten pipes.”

“It is by no means merely puffery to say that Professor Frederick K. Kirsten was a genuine American original. He first sailed to this country in 1902, as a cabin boy from Hamburg, Germany. After successfully rounding the Horn and eluding the shanghai gangs of the West Coast, he navigated the educational system at the University of Washington to become a Professor of Aeronautical Engineering. Here, his inventive spirit took wing. He created the world-famous Kirsten Wind Tunnel, Air-washing equipment for factories, an air-cooled Utopian Bed, and, most notably, a revolutionary propeller which enables boats to stop and turn on a dime. Today, in the same waters where he jumped ship almost 100 years ago, ocean-going vessels are landed by sturdy tugs driven by Kirsten cycloidal propellers, piloted by equally sturdy captains smoking cool Kirsten pipes.”

“Rightly called the coolest pipe in the world, this latter innovation came about when a doctor advised Professor Kirsten to switch from cigarettes. He quickly dreamed up a way to trap the moisture, tars and tongue-biting acids which attack the users of briar pipes. After 50 years and counting, Kirsten pipes are still produced by the Kirsten family, faithfully following the basic designs of this father of invention.”

“Professor Kirsten revolutionized pipesmoking by creating the Radiator stem. When tobacco, which is 30% to 60% moisture, is lit in the bowl, it creates steam. As the smoke is drawn through the stem, the steam is cooled and condenses into a liquid. This bitter-tasting liquid is trapped in the stem, along with tars, nicotine and tongue-biting acids.”

“Only clean, cool, moisture-free smoke passes through the intake tube to the mouthpiece. To remove the trapped liquid, you simply remove the valve. You can clean a KIRSTEN in seconds by pushing a tissue through the bore of the stem, exactly as you would clean a gun barrel.”

The cleaning in seconds must not have been something that the previous owner of this pipe ever read or understood. I decided to work on the bowl first as it was the only part of the pipe that I could remove at that point in the process. I took the photo below to give an idea of the thickness of the cake and the minimal size of the air hole at the bottom of the bowl. You can see that it is virtually clogged and the airflow would be very restricted. The lack of a cap on the bottom of the bowl can be seen in the next three photos. The first two photos show the state of the finish. In the second one you can see the grain peeking through the grime on the finish. In the third photo you can see the stamping on the bottom of the bowl. It reads Kirsten Pats Appl For.

The lack of a cap on the bottom of the bowl can be seen in the next three photos. The first two photos show the state of the finish. In the second one you can see the grain peeking through the grime on the finish. In the third photo you can see the stamping on the bottom of the bowl. It reads Kirsten Pats Appl For.

I put the barrel and stem in an alcohol bath to soak overnight to try to loosen the frozen stem and rod.

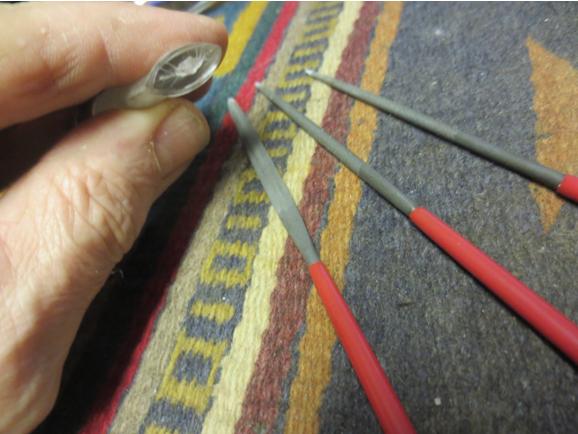

I put the barrel and stem in an alcohol bath to soak overnight to try to loosen the frozen stem and rod. I reamed the bowl with the largest cutting head on the PipNet reamer and took the cake back to bare briar. I used a pen knife to work on the bottom of the bowl and was finally able to see the characteristic Kirsten screw. I sanded the inside of the bowl with 220 grit sandpaper and used an ice pick to remove the screw. From the underside of the bowl I inserted the ice pick into the drilled centre of the screw and tapped it gently and the screw came free from the bowl.

I reamed the bowl with the largest cutting head on the PipNet reamer and took the cake back to bare briar. I used a pen knife to work on the bottom of the bowl and was finally able to see the characteristic Kirsten screw. I sanded the inside of the bowl with 220 grit sandpaper and used an ice pick to remove the screw. From the underside of the bowl I inserted the ice pick into the drilled centre of the screw and tapped it gently and the screw came free from the bowl.

I lightly topped the rim on a topping board to remove the damage and the build up on that surface.

I lightly topped the rim on a topping board to remove the damage and the build up on that surface.

I scrubbed down the exterior of the bowl and rim with acetone on cotton pads to remove the grime and the remaining finish. I was quite pleasantly surprised by the grain that was revealed in the process.

I scrubbed down the exterior of the bowl and rim with acetone on cotton pads to remove the grime and the remaining finish. I was quite pleasantly surprised by the grain that was revealed in the process.

I cleaned the inside and the outside of the screw with a tooth brush and alcohol until it shone.

I cleaned the inside and the outside of the screw with a tooth brush and alcohol until it shone.

I sanded the bowl with a medium and a fine grit sanding block to clean up the scratches and smooth out the finish on the sides and top of the bowl.

I sanded the bowl with a medium and a fine grit sanding block to clean up the scratches and smooth out the finish on the sides and top of the bowl. I wet sanded the bowl with micromesh sanding pads from 1500-2400 grit and dry sanded with 3200-12000 grit pads.

I wet sanded the bowl with micromesh sanding pads from 1500-2400 grit and dry sanded with 3200-12000 grit pads.

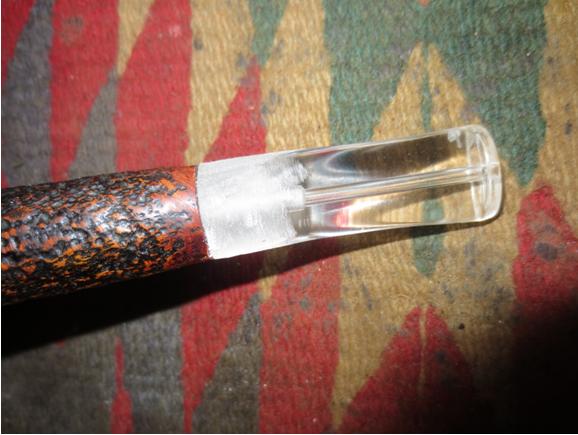

I took the barrel out of the bath and put it in a cup of boiling water. I dipped both ends into the boiling water hoping to break one of the frozen ends loose. I was able to remove the stem and the rod assembly after the alcohol bath and the boiling water dip. The stem and the rod were quite brown with the shellac of old tobacco juices. Of course dipping the stem in the boiling water caused the oxidation on the stem to come to the surface.

I took the barrel out of the bath and put it in a cup of boiling water. I dipped both ends into the boiling water hoping to break one of the frozen ends loose. I was able to remove the stem and the rod assembly after the alcohol bath and the boiling water dip. The stem and the rod were quite brown with the shellac of old tobacco juices. Of course dipping the stem in the boiling water caused the oxidation on the stem to come to the surface.

I scrubbed the rod assembly with 0000 steel wool and alcohol to remove the shellac coat that had built up and polish it. There was some corrosion that came to light at the middle of the rod. I would need to work on that once I had cleaned up the stem.

I scrubbed the rod assembly with 0000 steel wool and alcohol to remove the shellac coat that had built up and polish it. There was some corrosion that came to light at the middle of the rod. I would need to work on that once I had cleaned up the stem. I sanded the stem and rod with 220 grit sandpaper and then with a medium and fine grit sanding sponge to remove the scratches.

I sanded the stem and rod with 220 grit sandpaper and then with a medium and fine grit sanding sponge to remove the scratches.

I worked on the stem and rod with micromesh sanding pads – wet sanding with 1500-2400 grit pads and then rubbing down the stem with Obsidian Oil. The micromesh pads removed the last of the corrosion on the rod and polished it. I dry sanded with 3200-4000 grit pads and gave the stem another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I failed to take photos of the final steps in the micromesh process but it is the typical procedure and each successive grit of pads gave more of a polish to the vulcanite.

I worked on the stem and rod with micromesh sanding pads – wet sanding with 1500-2400 grit pads and then rubbing down the stem with Obsidian Oil. The micromesh pads removed the last of the corrosion on the rod and polished it. I dry sanded with 3200-4000 grit pads and gave the stem another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I failed to take photos of the final steps in the micromesh process but it is the typical procedure and each successive grit of pads gave more of a polish to the vulcanite. I cleaned out the stem and tenon with alcohol and pipe cleaners inserted from both ends. I was able to clean out all of the oils and tars and the cleaners came out clean.

I cleaned out the stem and tenon with alcohol and pipe cleaners inserted from both ends. I was able to clean out all of the oils and tars and the cleaners came out clean. Now the bowl and the stem unit were cleaned, polished and ready to go once I was able to remove the valve from the end of the barrel. This was proving a very difficult task. I had put the barrel in the freezer overnight hoping to loosen the valve – no luck. I had boiled it multiple times – no luck. I had given it several alcohol baths – no luck. I let it sit with penetrating oil in the barrel to try to loosen the valve end. I tried to drive it out with a round end file and a small hammer. Nothing worked. I posted that on rebornpipes and got a response from Old Man in the Cave suggesting that I heat it with a heat gun.

Now the bowl and the stem unit were cleaned, polished and ready to go once I was able to remove the valve from the end of the barrel. This was proving a very difficult task. I had put the barrel in the freezer overnight hoping to loosen the valve – no luck. I had boiled it multiple times – no luck. I had given it several alcohol baths – no luck. I let it sit with penetrating oil in the barrel to try to loosen the valve end. I tried to drive it out with a round end file and a small hammer. Nothing worked. I posted that on rebornpipes and got a response from Old Man in the Cave suggesting that I heat it with a heat gun.

I geared up for the process. He had suggested setting the barrel in a wood vise which is a tool I don’t have yet. I chose instead to hold the barrel with some insulated leather gloves over the heat gun. I heated the barrel with gun until it was hot. Then I used a pair of pliers that had cotton pads on the jaws and gave it a light twist and the valve came free. I don’t know if the heat from the gun finally did what I should have done in the first place or if the combination of methods finally came together and it worked. It does not matter as the valve finally came free. I now know why the later models of Kirsten pipes came with a rubber o-ring around the valve and the stem so that it provided something between the two metal pieces and the barrel. Somehow the combination of tobacco juice and saliva left to sit becomes shellac or lacquer that is almost impossible to break free. Thanks to Old Man in the Cave the valve is free and I could finally clean out the barrel and put the pipe back together. The next photos show the condition of the valve once I was able to remove it from the barrel. You can see the tapered angle of the top portion of the valve (on the right below the cap). The lacquer or shellac that bound the valve in the barrel is also very evident. I am guessing that there would have been much more if it had not been sitting in alcohol and been heated so much. But even that little band held the valve tightly in place.

I scrubbed the valve and the inside of the barrel with 0000 steel wool. I ran the steel wool through the barrel to clean out the build up inside and then used a wooden dowel to push alcohol soak cotton pads through the barrel to clean it until it shone. I cleaned out the inside of the valve with alcohol and cotton swabs. I was able to get everything shining again. It took some work to remove some of the tooth marks that were on the valve end from previous owners who had attempted to turn it but I was able to sand them smooth with micromesh sanding pads. They are still present but not as obvious.

I scrubbed the valve and the inside of the barrel with 0000 steel wool. I ran the steel wool through the barrel to clean out the build up inside and then used a wooden dowel to push alcohol soak cotton pads through the barrel to clean it until it shone. I cleaned out the inside of the valve with alcohol and cotton swabs. I was able to get everything shining again. It took some work to remove some of the tooth marks that were on the valve end from previous owners who had attempted to turn it but I was able to sand them smooth with micromesh sanding pads. They are still present but not as obvious.

Once all the parts were clean and polished I greased the valve and the end of the stem and rod unit with Vaseline so that it would slide into the barrel with less resistance. I know that it will not stop the buildup of tars but it will at least slow it down. The next photos show the disassembled pipe and then the pipe put back together. The valve turned easily and I aligned the hole in the valve with the hole in the top of the barrel where the bowl screwed in place. The airflow was clear and unrestricted.

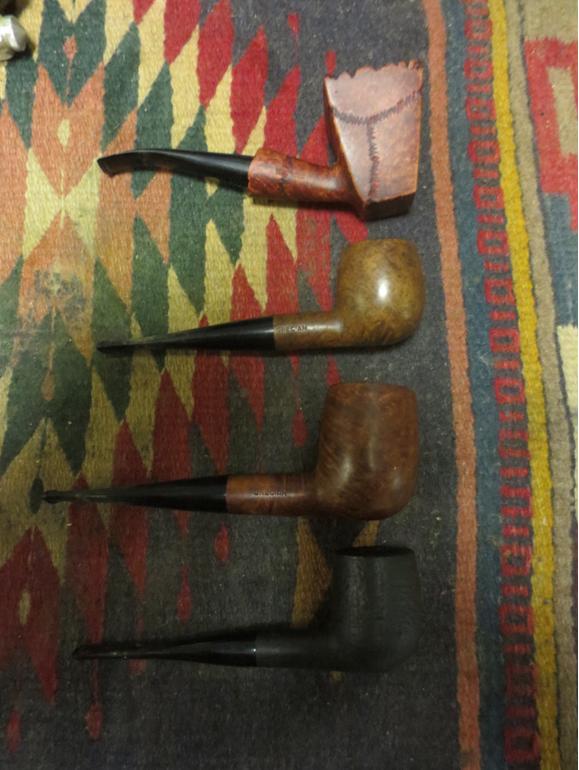

I hand buffed the barrel with Meguiar’s Scratch X2.0 to remove the scratches and give it a shine. I rubbed on some Conservators Wax and then hand buffed the barrel with a shoe brush. I buffed the briar bowl with Blue Diamond on the wheel and then gave it multiple coats of carnauba wax and buffed it with a clean flannel buff. Once I had finished I screwed the bowl in place and buffed it a microfibre cloth. The finished pipe is shown in the photos below.

I hand buffed the barrel with Meguiar’s Scratch X2.0 to remove the scratches and give it a shine. I rubbed on some Conservators Wax and then hand buffed the barrel with a shoe brush. I buffed the briar bowl with Blue Diamond on the wheel and then gave it multiple coats of carnauba wax and buffed it with a clean flannel buff. Once I had finished I screwed the bowl in place and buffed it a microfibre cloth. The finished pipe is shown in the photos below.

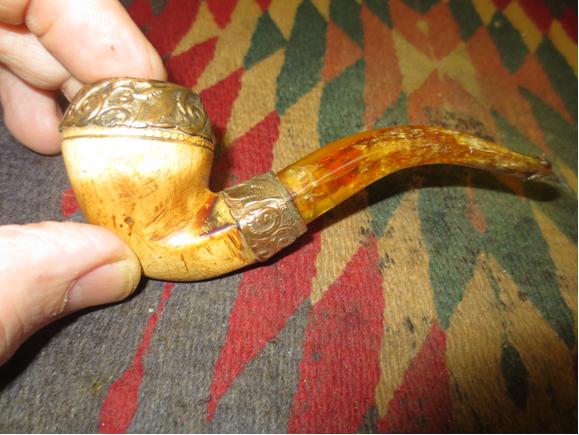

I took the pipe apart so that I could take the next two pictures to show the cleaned and polished parts. Everything is once again in working order. It was clear looking at all of the parts that I was dealing with a Generation 1 Kirsten. These were made between the years 1936-1958. The wooden bowl on this generation connects directly to the metal barrel and there is no metal cup spacer. It is a pretty flush fit that goes flat against the barrel. On the underside of the metal barrel it is stamped with one or more of the following “Pat. Appl. For” (1936-38) and “Pats. & Pats. Pending” (1938-1958) over “Made in USA” – S” (or applicable size – S, M, L). There are no O-rings on the bit or metal shank insert.

I took the pipe apart so that I could take the next two pictures to show the cleaned and polished parts. Everything is once again in working order. It was clear looking at all of the parts that I was dealing with a Generation 1 Kirsten. These were made between the years 1936-1958. The wooden bowl on this generation connects directly to the metal barrel and there is no metal cup spacer. It is a pretty flush fit that goes flat against the barrel. On the underside of the metal barrel it is stamped with one or more of the following “Pat. Appl. For” (1936-38) and “Pats. & Pats. Pending” (1938-1958) over “Made in USA” – S” (or applicable size – S, M, L). There are no O-rings on the bit or metal shank insert.

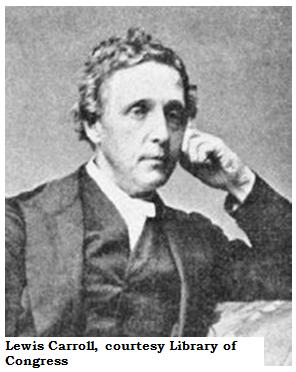

The origination of tobacco in the Americas and Australia is not as common knowledge as, say, that Columbus didn’t actually discover America, but then, there are stranger facts associated with the leafy plant’s history. Certain forms of tobacco were – and likely still are – used in the spiritual practices of various native populations to produce reactions that, by newer and more close-minded cultures, are called hallucinogenic. While there is no evidence to support the idea, and I am not suggesting a serious connection, Lewis Carroll (as the brilliant author will always be remembered) could have been under the influence of tobacco hallucinogens when he wrote the above masterpiece and its sequel.

The origination of tobacco in the Americas and Australia is not as common knowledge as, say, that Columbus didn’t actually discover America, but then, there are stranger facts associated with the leafy plant’s history. Certain forms of tobacco were – and likely still are – used in the spiritual practices of various native populations to produce reactions that, by newer and more close-minded cultures, are called hallucinogenic. While there is no evidence to support the idea, and I am not suggesting a serious connection, Lewis Carroll (as the brilliant author will always be remembered) could have been under the influence of tobacco hallucinogens when he wrote the above masterpiece and its sequel. Consider this. Without Carroll, we would not have fantastic, imaginative and endearing verbs, adjectives and nouns such as galumph as well as chortle, frabjous, mimsy, vorpal, snark and, last but not least, jabberwocky. The colloquial term snarky, for irritable or short-tempered, was adapted by Edith Nesbit, in her 1906 novel “Railway Children,” from the name of a variety of disconcerting creatures introduced to the world in Carroll’s poem, “The Hunting of the Snark.” As a hopeful point of interest, my spellchecker recognized chortle, galumph and jabberwocky, so accepted in the English lexicon they have grown. And as I added the rest to my Word dictionary, should I ever have occasion to use them again, they will appear without the annoying red, squiggly underlines. What’s more, thanks to the periodic transmission of these additions to Microsoft, where they will undergo due consideration by vorpal, slithy folk whose job it is to determine their worthiness, perhaps someday the perspiration-coated toilers over such heady decisions will make it possible for Carroll’s now-real words never to trouble other users of the magical expressions.

Consider this. Without Carroll, we would not have fantastic, imaginative and endearing verbs, adjectives and nouns such as galumph as well as chortle, frabjous, mimsy, vorpal, snark and, last but not least, jabberwocky. The colloquial term snarky, for irritable or short-tempered, was adapted by Edith Nesbit, in her 1906 novel “Railway Children,” from the name of a variety of disconcerting creatures introduced to the world in Carroll’s poem, “The Hunting of the Snark.” As a hopeful point of interest, my spellchecker recognized chortle, galumph and jabberwocky, so accepted in the English lexicon they have grown. And as I added the rest to my Word dictionary, should I ever have occasion to use them again, they will appear without the annoying red, squiggly underlines. What’s more, thanks to the periodic transmission of these additions to Microsoft, where they will undergo due consideration by vorpal, slithy folk whose job it is to determine their worthiness, perhaps someday the perspiration-coated toilers over such heady decisions will make it possible for Carroll’s now-real words never to trouble other users of the magical expressions.