Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.meboughtonrobert

Photos © the Author

“There is nothing like being left alone again, to walk peacefully with oneself in the woods. To boil one’s coffee and fill one’s pipe and to think idly and slowly as one does it.”

― Knut Hamsun (1859-1952), Pulitzer Prize winning Norwegian author

INTRODUCTION

When, a few years back, I became serious about collecting pipes, it was for the most part all about anything made by Peterson’s and Savinelli in particular and meerschaums in general, with an emphasis on the latter. While these pipes formed the basis for what has become a rather large, P.A.D.-fueled assemblage, I have, since those earliest days, branched out, so to speak, into many other fine brands.

Some of the brands of which I have various models greater than one include Barling, Butz-Choquin, Comoy’s, Dunhill, GBD, Karl Erik, Kaywoodie, V. Rimkus, Ropp, Stanwell and Don Warren, which do not include the large selection of individuals such as a Cavicchi 4C Silver Band Freehand, Burgundy Falcon, Charatan Make Deluxe Prince and Stefano FX Bean Pot. In short, I have become, as time passes, more attuned to the endless variety of great pipes out there, not to mention a few of more dubious origin such as a “The Pipe” (which nevertheless, in my opinion, no true collection should lack at least one sample) and a recent, still to be restored but excellent example of the odd but unique Doodler.

To use a term I recently coined in a previous blog, I am an omnitobacarius-phile, or lover of all things tobacco-related, at least as far as smoking pipes are concerned.

And, of course, there is my growing assortment of Ben Wade pipes, the latest addition to which this blog concerns.

Here are my other BW pipes, in order: a Town and Country Bent Dublin London Made with a 14K gold “Barling” band (don’t ask me how), Cheltenham Straight Billiard, Selected Grain Short Apple, London Made Dublin, Blue Diamond and Tall Canted Poker. There is also a BW that was once a Tall Straight Billiard but, due to extreme abuse by some unknown villain, suffered a large and fatal crack from the top of the bowl about halfway down, requiring a radical change in shape to a squat pot, as I call it. The result of that surgery is now a very special shop pipe.

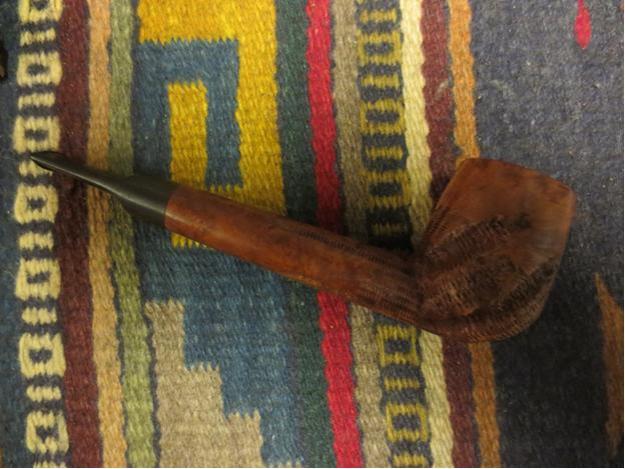

What, you might well ask, do all of these pipes have in contrast to the one of which I will describe the light refurbish in this blog? They were all made in England, where BW is best known for its production, although it has also made pipes in France and Denmark. The uncommon country of origin, the unusual wood and the beauty of the freehand itself wangled my mind around the idea that I truly needed this fine specimen. Of course, I was also very strongly attracted to the Danish golden walnut freehand.

What, you might well ask, do all of these pipes have in contrast to the one of which I will describe the light refurbish in this blog? They were all made in England, where BW is best known for its production, although it has also made pipes in France and Denmark. The uncommon country of origin, the unusual wood and the beauty of the freehand itself wangled my mind around the idea that I truly needed this fine specimen. Of course, I was also very strongly attracted to the Danish golden walnut freehand.

Of an incidental reason for my appreciation of this pipe, I came to suspect, during the research phase, that the beauty was crafted by the late great pipe maker, Preben Holm, who sometimes made his services available to BW. One reason is the inclusion of “Hand Made” in the nomenclature of another golden walnut freehand that Hr Holm just happened to make for BW, while a briar plateau freehand the master carver created for BW bore only the stamp “Made in Denmark.” For the rest of my reasoning, see http://www.pipephil.eu/ logos/en/logo-benwade.html to start, and click on the link to Preben Holm for more examples of his distinctive work and style.

THE GROOMING

Honestly, this was one of the few almost ready to enjoy pipes I have ever bought online. The only completely restored, cleaned and sanitized pipe I purchased by this medium was a Ropp Deluxe Cherrywood #901. I sold it for less than my cost to a prospective basic cleaning customer in Scottsdale, Arizona whose #815 of the same brand and general look was delivered to another Post Office Box holder who seems to have the deficient morals needed to abscond with it. What can I say? It seemed to be the right business thing to do, and the buyer of the 901 wrote that its condition upon arrival was “fantastic” and promised to send me future estate pipes he finds for cleaning. He will not, however, be sending them via USPS. And yo! To the deadbeat out there who stole the 815, if you’re reading this, feel free to let me do the cleaning it likely still needs, and I’ll give you the deal you deserve.

But returning to my subject, had our excellent host, Steve, not wanted to see what became of the pipe he explained was made from a piece of plateau walnut, so simple was the “refurbishing” process that I never would have bothered with a blog on it. Still, given that the Danish freehand did need slight chamber work, re-staining of the plateau rim and shank opening, minor scratch removal, retorting and stem shining, I could not help giving the pipe attention I have to rank even below refurbishing: what I call here a grooming, much as an unruly lad sometimes needs his face wiped, hair combed and shirt tucked in.

Making the dulled black stain of the plateau rim and shank opening the first order of business, I decided to remove the stain with a localized soak in Everclear.

Making the dulled black stain of the plateau rim and shank opening the first order of business, I decided to remove the stain with a localized soak in Everclear. I had hoped that removing the old plateau stain would reveal a rim suitable for buffing in its natural state and color, but such was not the case. And so I re-stained it.

I had hoped that removing the old plateau stain would reveal a rim suitable for buffing in its natural state and color, but such was not the case. And so I re-stained it.

A small but clear rectangular pattern of black pits near the upper right area of the right side of the bowl annoyed me.

A small but clear rectangular pattern of black pits near the upper right area of the right side of the bowl annoyed me. Trying 1500 micromesh, I was able to lessen the downgrade the presence of the pits to dots, but 800 was needed to get rid of them altogether. A quick buff with superfine steel wool returned the natural golden glow of the walnut.

Trying 1500 micromesh, I was able to lessen the downgrade the presence of the pits to dots, but 800 was needed to get rid of them altogether. A quick buff with superfine steel wool returned the natural golden glow of the walnut.

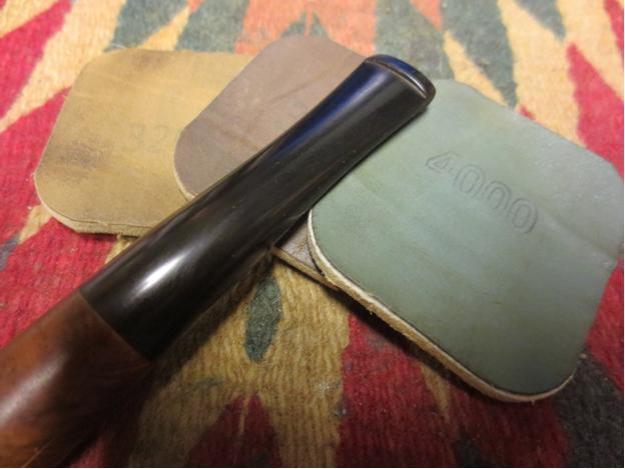

There were other small defects on the bowl too small even to show up in photos, but my eye saw them, and that was what mattered. I gave the entire bowl a going over with micromesh from 2400 through 4000 and found the walnut as smooth and fresh as could be.

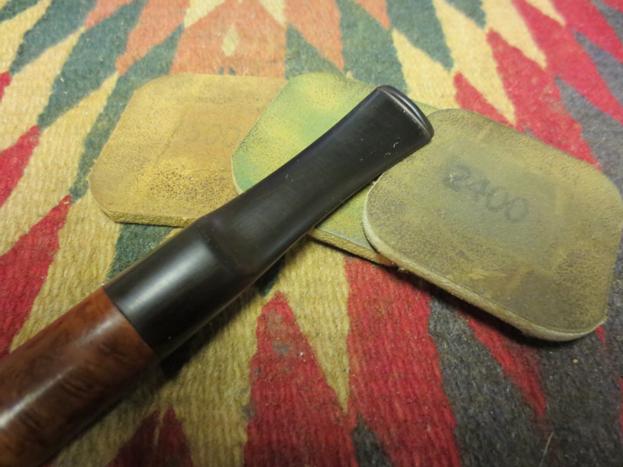

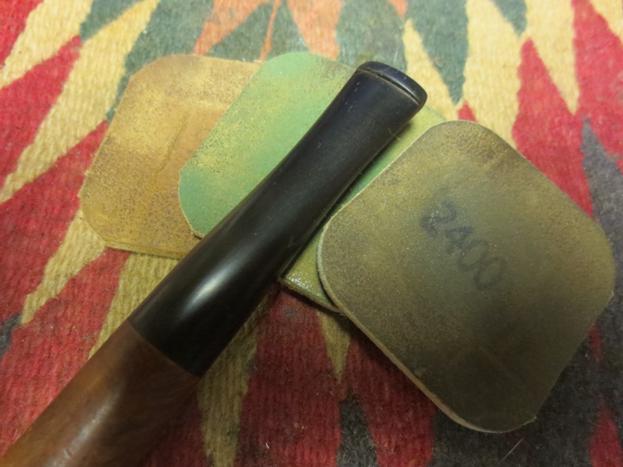

Last of all, I attacked the stem. Although I like the look of the freehand style stem, in particular this one with two rounded bulges, for lack of a better term at the moment, near the shank opening, they are always more of a bother to sand away discoloration. I always have to do the process in stages, sanding the entire stem with 200-grit paper, wiping it down with a soft cloth, then focusing on the harder areas, sometimes three or even four times until the color is uniform. Then I apply the micromesh, starting with 1500 and progressing upward to 4000.

Ready for the final buffing, I used red and white Tripoli followed by White Diamond on the stem and those waxes plus a final coat of carnauba on the bowl and shank, including the black plateau spaces. I worried – as I perhaps too often do – that the resulting shininess of the plateaus was a bit much, but that’s my nature.

CONCLUSION

CONCLUSION

So there it is. After writing this up, I realize there was more work than I remembered, but then this pipe presented itself to me in such glory that I never considered the task as anything more than that.

I kept this one, as you might have surmised. I have come to have a genuine respect and weakness for the wonderful variety of pipes made by Ben Wade and their consistent quality of engineering, grace and high-grade pleasure of smoking.

ADDITIONAL PHOTOS AND INFORMATION

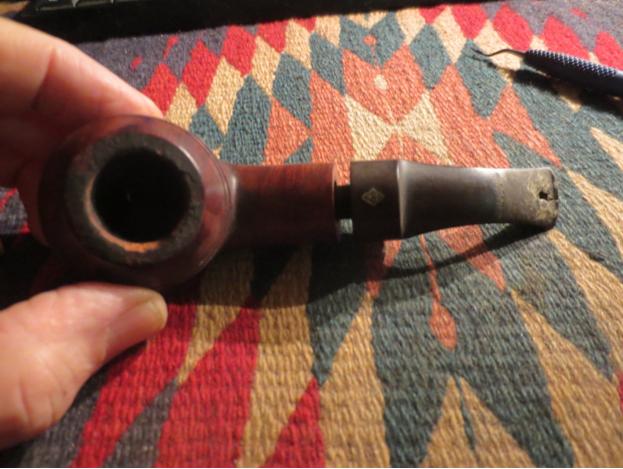

I made a comment on the blog thanking Steve for the great history he emailed me and the confirmation of the Preben Holm connection. I was troubled by not seeing the stem etching the pipephil.eu photos showed and then noticed on the pictures of the stem in my blog that the etch was still there! After filling in with a marker, I was able to make out the mark better. Here are the new before and after photos (the after shot, obviously, being before cleaning up the stem again):