Blog by Steve Laug

When I saw this old pipe in the rack at the antique mall I wanted it because of its uniqueness. The price was also good – $9.95. I figured at that price it was like buying a corn cob pipe and certainly would function in the same capacity for me. This one had a nylon base and stem with a briar bowl that screwed into the base. Dr. Grabow bowls fit this pipe base perfectly but Falcon bowls do not fit. The only stamping on the pipe is on the bottom of the base where it reads Nylon. In researching this pipe on the net I was unable to find any pertinent information. When I posted it on Pipe Smoker Unlimited Forums I got a suggestion and a link to the Smoking Metals site. Low and behold the link took me to the exact pipe base as the one I had found. Here is the link: http://www.smokingmetal.co.uk/pipe.php?page=60 The pipe pictured has a far better bowl than the one that I found. What I found interesting was the information that was on the site regarding this pipe. I am copying it verbatim:

“No makers name, simply the word ‘NYLON’ on the base of the stem under the bowl. The briar bowl is Viking style, accepting all Dr Grabow Viking and Koolsmoke bowls. The bit can be varying colours and not always vulcanite so often severely damaged. The stems can be silvered or in gilt, or even painted, but it is not known if this is how they left the manufacturer. Among names sold under is Forecaster Superline. US Patent# 179,373 Inventor Berenson would seem to apply.”

This pipe was in good shape. The stem is attached and not removable. It had some tooth chatter but no tooth marks or bites. It was made of nylon and not vulcanite even though it is black. The base itself is an opalescent white colour and showed tobacco stains in the base and the shank. The bowl was unfinished and showed tooling marks from the turning on the lathe. There was a slight uneven ridge on one side where the top of the bowl curved upward. There were rough spots all around the bowl and the finish was unsanded. The wood is not briar and seems more like the maple or hickory bowls that come from Missouri Meerschaum. The inside of the bowl has a slight uneven carbon build up in the top of the bowl and dried and hardened pieces of dottle stuck to the sides in the bottom half of the bowl. The reservoir in the base also had a buildup of tars and shreds of tobacco stuck to the base. The first photo below was taken the day I found the pipe. Photos two through five show the bowl when I began working on it at my work table.

I unscrewed the bowl from the base and set it aside while I worked on the base to begin with. I cleaned out the stained reservoir with cotton swabs dipped in Everclear and used bristle and fluffy pipe cleaners on the inside of the stem and the shank. The dried tobacco shreds were stuck to the base so it took some scrubbing to remove the dried materials. The next three photos give an idea of the state of the reservoir and the slight tooth chatter on the stem. The fourth photo shows the cleaned but stained base of nylon.

Once the base was clean and the tars and buildup removed I worked on the finish of the bowl. I sanded it with 220 grit sandpaper to remove the marks from the lathe and the rough spots. I wanted to remove as much of the marking on the bowl as possible without changing the shape. As I sanded it I was impressed by the grain on the particular piece. I sanded the stem at the same time with the 220 grit sandpaper to remove the tooth chatter. Interestingly the nylon stem sanded out greyish white. The sanding dust was light grey in colour.

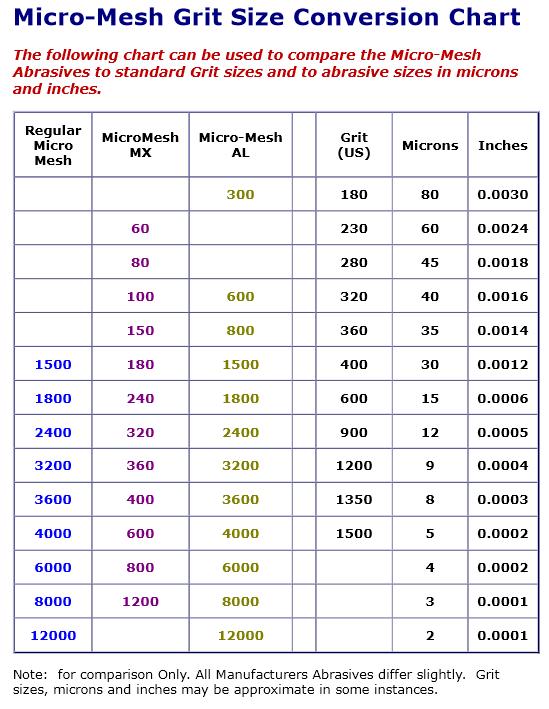

The next step in the sanding process was to use a medium grit sanding sponge and also with a fine grit sanding block to remove the marks and scratches left behind by the 220 grit sandpaper on both the bowl and the stem. I followed that by wet sanding the bowl and the stem with 1500, 1800 and 2400 grit micromesh sanding pads.

I then dry sanded with the remaining grits of micromesh sanding pads from 3200-12,000 grit. I used the micromesh pads on both the bowl and the stem. I did not include pictures of all of the sanding process but chose the one below as representative.

When I had finished sanding the stem and the bowl I buffed them lightly with White Diamond and then gave both a coat of carnauba wax. I chose for this bowl to not stain it but leave it natural as I like the look of the grain in the wood. The photos below show the finished pipe. Any ideas on what the wood might be?