Blog by Steve Laug

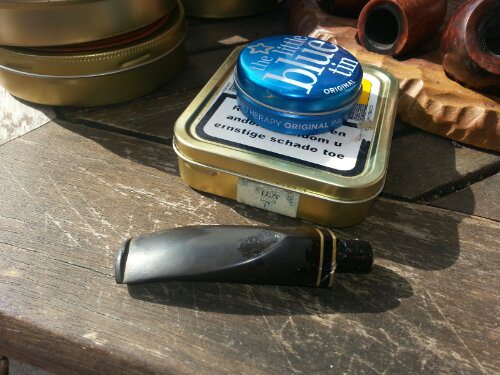

Not too long ago I laid out the various stingers I have removed from the pipes that have passed over my refurbishing work table. I don’t know why I have kept them all, but I have. Most of them came from pipes that are no longer in my collection. I was reminded of this photo that I had taken in the past because of a stinger I removed from a Comoy’s the Guildhall pipe. The shapes and sizes of stingers and the size the mortise in the pipe to accommodate them is as varied as the inventors who came up with the “brilliant” idea in the first place. Fundamentally it is designed to act as a condenser to draw out and trap the moisture in the smoke of the tobacco. The burning tobacco in the bowl creates moisture as it burns. As it is drawn into the mortise it either naturally condenses on the walls of the briar or metal shank by simple cooling or its condensation is enhanced by the introduction of the metal apparatus that is commonly known as a stinger.

The basic concept is that the stinger provides multiple surfaces on which the moisture is condensed and collected. Theoretically, the smoker is to clean the stinger after each smoke and thus remove the debris of the condensation before the next smoke. Doing this would provide a clean surface for each smoke. The built in stingers that are a part of the screw in tenon were made to encourage taking the pipe apart while it was warm and the cleanup would be relatively simple. However, judging from the many pipes I have cleaned over the years this theoretical assumption of cleaning the apparatus between smokes never happened – or at best rarely happened. The juices and moisture from the heated smoke hardened into a dark tarry substance that often welded the stinger and tenon into the mortise until the time I decided to take it apart and clean it at my table. The sheer amount of “gunk” in the shank of pipes with stingers versus those that do not have stingers seems to prove the effectiveness of the stinger. It truly seems to work in condensing the moisture from the smoke. Though that should be no surprise – the introduction of a metal tube or apparatus into the path of hot/cooling smoke drawn through the shank can only attract moisture.

All that being said I question the validity of the supposed effectiveness of the apparatus. It seems to me that the introduction of the metal stinger into the shank, no matter what unique or strange design, in fact exacerbates the problem of moisture rather than reduces it. I have smoked many pipes without a stinger and had very few issues with moisture gurgling in the shank. And those that do can be tweaked to not gurgle at all. I have also smoked pipes with the stinger in place and struggled with gurgles and moisture in the stem and shank. I still recall an old pipeman on skid row where I worked showing me how to put my thumb over the bowl and flick the pipe to get rid of the moisture. It was not a pretty sight but it was very effective. Once I removed the stinger from the tenon I found that the same pipe would smoke dry. That led me to conclude that the stinger, while certainly working to attract moisture, may actually create more moisture. In its design the stinger was also believed to calm down hot smoking tobacco and remove tongue bite. This claim assumes that the tongue bite is caused by the moisture in the smoke. While this may be true in part, I believe it is also the effect of heat on the tongue generated by too energetic a puffing cadence. The hard puffing on burning tobacco in the bowl heats up the briar so why would it not also affect the tongue? I have found that when I slow the cadence I slow the likelihood of tongue bite. So in my opinion, the stinger’s effectiveness in alleviating tongue bite may be exaggerated. Or maybe it is just the constricted draught on the pipe that makes the likelihood of tongue bite reduced, for in my experience it seems that no matter how hard you puff on the pipes with stingers the draught is the same – constricted.

In looking at the many stingers I have collected over the years I have noted both similarities and some very distinctive differences. I only took photos of the ones that are removable and to be honest over the past months I have added at least another dozen variations on the theme. The pieces pictured below can be grouped into four categories – tubes, blades, round balls, twists/spirals. When I removed them from the pipes they all were equally dirty and tarred. All of them had a brown lacquer like substance under the tar that was almost permanently bonded to the aluminum of the apparatus regardless of the shape. In the next section of this article I will give a description of the shape, structure and function of each stinger within the particular group to understand the concept behind their design.

Tubes: The first group I have collectively called Tubes. The basic design is clear from the designation – they are all open tubes. The four pictured below are all different lengths. Some of the tubes extended into the bowl of the pipe. The top left tube and the bottom right tube are a Dunhill Inner Tubes and they have an angled end that fit up against the opening in the bottom of the bowl. They are both different diameters based upon the size of the bowl and the size of the drilling in the shank. The first is from a Group 4 sized pipe and the second from a Group 2 sized pipe. The second tube down on the left side came from a no name pipe and sat in the airway pressed against the opening in the bottom of the bowl. It fit flush against the opening in the bottom of the bowl and also flush against the opening in the tenon. It thus was intended to provide a clean and direct airway into the stem. The interior of the tubes acted to cool the smoke on its way to the mouth. The first tube on the right has a hole on top of the tube where it extended into the bottom of the bowl. It thus provided a 90 degree angle for the smoke to travel from the bowl bottom into the airway. The tube extended into the tenon of the stem about a ½ inch. Once again the concept was to provide a clean airway that would not collect the moisture in the shank of the pipe and provide a cool smoke. The problem with this apparatus is that it was easily plugged by small pieces of tobacco that entered the rather large hole in the tube at the bottom of the bowl.

Blades: The second group I have called Blades because of a prominent bladelike feature included in their design. From the left of the photo, the fourth, fifth, sixth and eleventh stingers all have a variety of blades on the end of the stinger. The first three have a form like a shovel. The end is turned up like a scoop to collect moisture on the topside and the underside of the blade. Behind the blade on these three were three different ridges. The third ridge was slotted for the flow of the air to enter the stem. The fourth blade is extended and the same diameter from the front of the blade to the edge that rests against the tenon. There is a slight twist cut into the blade about 2/3 of the way down the blade that is intended to “spin” the smoke around the blade before it enters the slot at the top back edge of the blade. This “spinning” was intended to remove moisture. The fifth blade is tubular in shape. There is a portion that is scooped out of the tube with an airhole in the end of the scooped out portion. The flat surface of the tube collects moisture and also the blade does. The shape of the blade directs the air across a broad surface and into the airway of the stem.

Round balls: The third group I have called Balls because of the round ball on the end of each of them. From the left side of the photo – the first, second, seventh, tenth and twelfth as well as the first and third in the centre of the photo all are variations on the ball theme. The first, second (half ball), and seventh all remind me of trailer hitches. The ball is quite large in proportion to the stinger. The ball sometimes has holes drilled into it surface (like the Kaywoodie Stinger) and sometimes does not. Behind the ball is a flat ridge that is slightly smaller than the second ridge that rests against the tenon. There is a slot in this ridge that is aligned with a slot in the second ridge that through which the air/smoke is drawn. The interior and exterior surface of the ball collects moisture on the drilled balls and the exterior surface collects it on the undrilled ones. I find that the undrilled balls are significantly larger than the drilled ones, thus providing more surface area for condensation. The eleventh, twelfth, and the first and third in the centre all are all balls resting on top of cones with a slight ridge to no ridge below the cone. The cone is slotted to direct air/smoke into the stem. The cone/ball combination again increases the area of condensation for the smoke.

Twists/Spirals: The fourth group I have called Twists or Spirals to summarize the shape of each of them. From the left side of the photo below – numbers 8 and 9 and the second one in the centre have been grouped together in this category. These stingers are actually very unique. The 8th one is a spiral around a centre rod. The end of the spiral is flattened like a small blade, similar to a spear tip. The smoke follows the twist up to the point it enters the stem and the moisture is almost spun out of the smoke in the process. The ninth one is a more smooth and scooped spiral or twist. The tip is a flat, round disk. The smoke is dissipated around the disk and then travels down the spiral to the slot in the bottom where it joins the tenon. Again the spiral serves to spin the moisture from the smoke. The second stinger in the middle is really not a spiral in the same sense as the other two. It is two cones separated by two tire shaped rings. The moisture is given many surfaces to condense on before it moves through the slot at the end where the stinger sits against the tenon.

The diversity of the shapes and styles of stingers that have been created seems to be endless. Each new estate pipe I purchase that has a stinger, has one that is a variation on the ones above. Those pictured are representative of the creative energy that has been invested into making a cooler, drier, cleaner smoke for the pipeman. In my humble opinion, all of them achieve the same end. All of them collect moisture and may very well increase the moisture collected from the smoke. In the long run do they achieve what they were purposed to achieve? I leave that answer up to you. But to me they are appendages that are better removed from the shank and tenon. I have found that their removal holds the key to a drier and cooler smoke.