Blog by Steve Laug

Sometimes when you are pipe hunting there is one that just grabs you. That was the case with this interestingly shaped W.O. Larsen Sandblast. It is kind of a cross between a Rhodesian with the twin rings around the rim cap and the flow and shape of a horn. Neither Jeff nor I had seen a Larsen like this one before. We picked it up from an auction early in 2020 in Huntington Station, New York, USA. The pipe was stamped on the around the smooth end of the shank and read W.O. Larsen [over] Made in Denmark followed by Double Black followed by the shape number 66. The pipe itself was in filthy condition. The bowl was thickly caked and there was a thick lava overflow in the sandblasted rim top. The briar was very dirty with grit and grime ground into the surface. The acrylic stem was dirty had deep tooth marks on the top of the stem and chatter on the underside. There was not a logo or mark on the stem. Jeff took photos of the pipe before he did his clean up on it.

Jeff took photos of the rim top and the stem to show the condition of the pipe when we received it. You can see the cake in the bowl and the lava in the sandblast on the rim top. It is hard to know the condition of the rim edges with certainty until the pipe is clean. The stem is acrylic and has a lot of chatter and a few deep tooth marks on both sides near the button.

Jeff took photos of the rim top and the stem to show the condition of the pipe when we received it. You can see the cake in the bowl and the lava in the sandblast on the rim top. It is hard to know the condition of the rim edges with certainty until the pipe is clean. The stem is acrylic and has a lot of chatter and a few deep tooth marks on both sides near the button.

He took photos of the sides of the bowl and the heel to give an idea of the shape and the condition of the briar around the bowl. It really is a nicely shaped pipe that has charm and elegance.

He took photos of the sides of the bowl and the heel to give an idea of the shape and the condition of the briar around the bowl. It really is a nicely shaped pipe that has charm and elegance.

The next photos Jeff took show the stamping around the smooth briar on the shank end. It is clear and readable as noted above.

The next photos Jeff took show the stamping around the smooth briar on the shank end. It is clear and readable as noted above.

I refreshed my memory about the pipes coming out of Ole Larsen’s Copenhagen tobacco shop. I knew that many famous Danish Carvers started their careers carving for the shop. I turned first to the Pipephil website to get and over view of the brand (http://www.pipephil.eu/logos/en/logo-l2.html). I did a screen capture of the section on the site showing a summary of the brand and the typical stamping.

I refreshed my memory about the pipes coming out of Ole Larsen’s Copenhagen tobacco shop. I knew that many famous Danish Carvers started their careers carving for the shop. I turned first to the Pipephil website to get and over view of the brand (http://www.pipephil.eu/logos/en/logo-l2.html). I did a screen capture of the section on the site showing a summary of the brand and the typical stamping.  I then turned to Pipedia to do a bit more reading about the brand and the various lines making it up. Here is the link (https://pipedia.org/wiki/W.%C3%98._Larsen). The link took me to some pages on the finepipes.com website. Here is the link to the summary of the history of the brand. I quote it in full. I have marked the pertinent section with bold font to mark out the section on the SELECT series (https://www.finepipes.com/pipes/danish/w-o-larsen?sort=20a&page=2&zenid=562ff4b9d62f4f612d0f6ee60cab1224).

I then turned to Pipedia to do a bit more reading about the brand and the various lines making it up. Here is the link (https://pipedia.org/wiki/W.%C3%98._Larsen). The link took me to some pages on the finepipes.com website. Here is the link to the summary of the history of the brand. I quote it in full. I have marked the pertinent section with bold font to mark out the section on the SELECT series (https://www.finepipes.com/pipes/danish/w-o-larsen?sort=20a&page=2&zenid=562ff4b9d62f4f612d0f6ee60cab1224).

W.O. Larsen was one of the most famous tobacco shops in Copenhagen, with a beautiful store located on Copenhagen’s famous “Walking Street.” During the flowering of the Danish pipe in the ’60’s, they first began retailing pipes by such carvers as Sixten Ivarsson, Sven Knudsen, Poul Rasmussen, and Brakner. Urged on by his store manager Sven Bang, the owner, Ole Larsen, decided to begin making pipes in the basement of the shop. He first hired Sven Knudsen as the pipe maker, who soon passed the job to his protégé Hans “Former” Nielsen. Larsen’s fortunes rose along with the rest of the Danish pipe business, and Former was soon managing a group of carvers in the old Larsen cigar factory. Among these were Teddy Knudsen, Tonni Nielsen, Jess Chonowitch, Peter Hedegaard and others, who were responsible for the Select and Straight Grain series before they branched out on their own. After Former left to start Bentley pipes in Switzerland, his duties were taken over by Soren Refbjerg Rasmussen, while the straight grains were made by Teddy’s student Benni Jorgenson. As Ole’s health began to fail, the reins were taken over by his son Nils. Nils became convinced that the way for Larsen to prosper was by entering the low-end market, and acquired the Georg Jensen pipe factory to make an array of less expensive pipes. This turned out to be a fatal error, and Larsen was recently sold to Stanwell, who continue to produce so-called “Larsen” pipes in their huge factory. Thus ended an important part of Danish pipe history.

W.O. Larsen was one of the most famous tobacco shops in Copenhagen, with a beautiful store located on Copenhagen’s famous “Walking Street.” During the flowering of the Danish pipe in the ’60’s, they first began retailing pipes by such carvers as Sixten Ivarsson, Sven Knudsen, Poul Rasmussen, and Brakner. Urged on by his store manager Sven Bang, the owner, Ole Larsen, decided to begin making pipes in the basement of the shop. He first hired Sven Knudsen as the pipe maker, who soon passed the job to his protégé Hans “Former” Nielsen. Larsen’s fortunes rose along with the rest of the Danish pipe business, and Former was soon managing a group of carvers in the old Larsen cigar factory. Among these were Teddy Knudsen, Tonni Nielsen, Jess Chonowitch, Peter Hedegaard and others, who were responsible for the Select and Straight Grain series before they branched out on their own. After Former left to start Bentley pipes in Switzerland, his duties were taken over by Soren Refbjerg Rasmussen, while the straight grains were made by Teddy’s student Benni Jorgenson. As Ole’s health began to fail, the reins were taken over by his son Nils. Nils became convinced that the way for Larsen to prosper was by entering the low-end market, and acquired the Georg Jensen pipe factory to make an array of less expensive pipes. This turned out to be a fatal error, and Larsen was recently sold to Stanwell, who continue to produce so-called “Larsen” pipes in their huge factory. Thus ended an important part of Danish pipe history.

From all of that information I had learned that the pipe was a Danish Made pipe from the Ole Larsen workshop during the 1960s. It was made with a finish they called the Double Black. It is hard to know who actually carved the pipe when you see the list of carvers noted in the above information but it is a well shaped pipe. Now it was time to work on the pipe.

I have to say I was really looking forward to seeing what Jeff had done to this Danish Made W.O. Larsen Double Black pipe when I took it out of the box. It had shown such beauty through the grime so I was quite sure it would be stunning. He reamed the bowl with a PipNet pipe reamer and cleaned the remnants of cake back with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and oils. He cleaned the internals of the shank and stem with pipe cleaners, cotton swabs and alcohol to remove all of the tars and oils there. He scrubbed the exterior of the stem with Soft Scrub. He rinsed off the cleaner with warm water and wiped the bowl and stem down with a light coat of olive oil to rehydrate both. The pipe really was quite stunning. You can see the light burn on the front inner edge of the bowl but it does not lessen the beauty of the pipe.

I took close up photos of the stem and the rim top to show both how clean they were and what needed to be addresses with both. The bowl had some burn damage on the front inner edge. The stem looked better but the deep tooth marks and chatter were still present. I would need to remove those to bring the stem back.

I took close up photos of the stem and the rim top to show both how clean they were and what needed to be addresses with both. The bowl had some burn damage on the front inner edge. The stem looked better but the deep tooth marks and chatter were still present. I would need to remove those to bring the stem back. I removed the stem from the bowl and took a photo of the parts to give a sense of the beauty of the pipe.

I removed the stem from the bowl and took a photo of the parts to give a sense of the beauty of the pipe.  I decided to work on the damage from the burn on the inner edge of the bowl first. I used a folded piece of 220 grit sandpaper to smooth out the damage and give the edge a light bevel to blend it into the rest of the edge.

I decided to work on the damage from the burn on the inner edge of the bowl first. I used a folded piece of 220 grit sandpaper to smooth out the damage and give the edge a light bevel to blend it into the rest of the edge. I worked some Before & After Restoration Balm into the surface of the briar with my finger tips and a horse hair shoe brush to get into the crevices of the sandblast. The product is incredible and the way it brings the grain to the fore is unique. It works to clean, protect and invigorate the wood.

I worked some Before & After Restoration Balm into the surface of the briar with my finger tips and a horse hair shoe brush to get into the crevices of the sandblast. The product is incredible and the way it brings the grain to the fore is unique. It works to clean, protect and invigorate the wood.

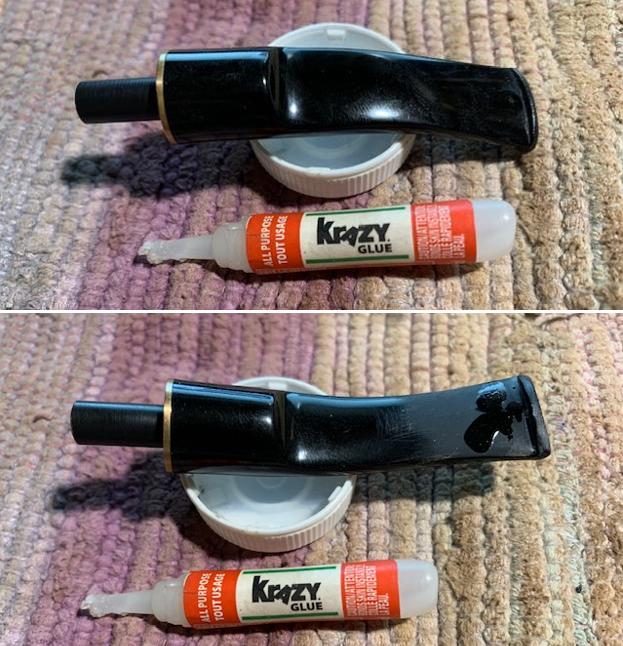

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks on the surface of both sides with clear CA glue. Once it cured I flattened the repairs with a small file. I sanded them smooth with 220 grit sandpaper to blend them into the surface of the briar. I started the polishing of the stem with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks on the surface of both sides with clear CA glue. Once it cured I flattened the repairs with a small file. I sanded them smooth with 220 grit sandpaper to blend them into the surface of the briar. I started the polishing of the stem with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – wet sanding it 1500-12000 pads. I wiped it down with Obsidian Oil after each pad to protect it and preserve it. I polished it with Before After Pipe Polish – both Fine and Extra Fine. I finished the polishing with a final coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – wet sanding it 1500-12000 pads. I wiped it down with Obsidian Oil after each pad to protect it and preserve it. I polished it with Before After Pipe Polish – both Fine and Extra Fine. I finished the polishing with a final coat of Obsidian Oil.

I am really happy with the way that this W.O. Larsen Double Black 66 Horn turned out. It really is a beautiful looking pipe with a great shape and sandblast. The acrylic saddle stem is really nice and the brass ring on the tenon end is a great feature. The blast really came alive with the buffing. The rich brown and black stains of the finish gave the pipe a sense of depth with the polishing and waxing. I put the acrylic stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished W.O. Larsen Horn really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 40 grams/1.41 oz. The pipe will be going on the rebornpipes store soon. It will be in the section on Danish Pipe Makers if you would like to add it to your collection.Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!