by Steve Laug

We picked some older pipes to work on next. The second of these is a Lorenzo larger Lovat Stack with the light sandblast and polished finish. We purchased this one on 01/22/2024 from Jordan, Minnesota, USA as part of a lot on eBay. Just one more piece of evidence that, contrary to my own opinion, there are still some good finds at good prices to be found on that site. The pipe is a tall, large Lovat that is stamped on a smooth band on the underside of the shank and reads Lorenzo [over] Ravenna followed by Studio [over] 826 followed by Italy. The pipe was well used. The finish was dirty with dust and debris in the sandblast. The bowl had a thick cake in it and some lava on the rim top and the inner edge. There was also some roughening to the inner edge of the bowl. The vulcanite saddle stem was oxidized and had some tooth marks on the surface ahead of the button. Jeff took photos of the pipe before he started his cleanup work.

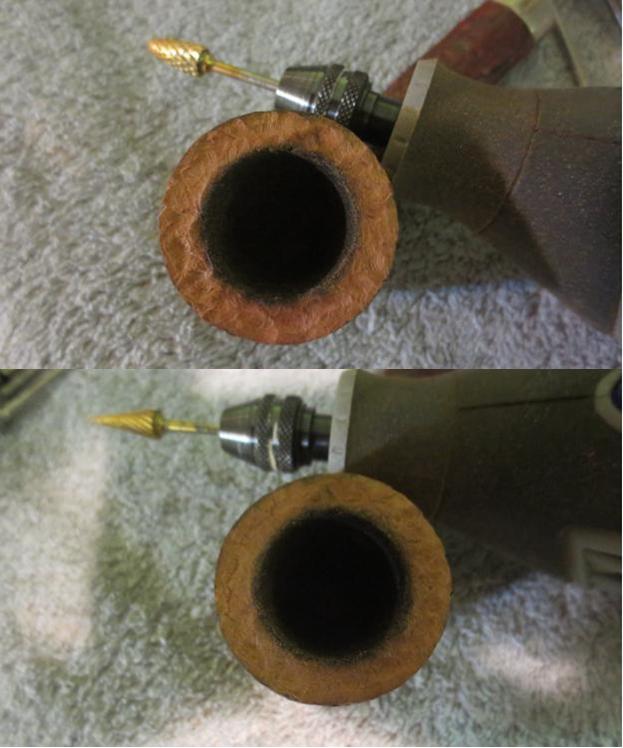

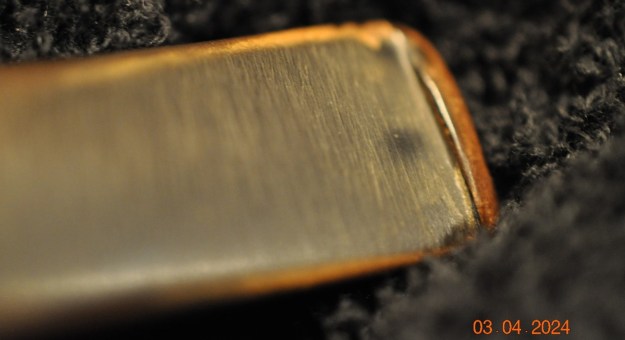

He took some closer photos of the rim top and bowl to show the condition. You can see the thick cake in the bowl and the debris on the rim top and lava on the inner edge. It is hard to know for certain but it looks like there is some roughening on the back inner edge. He also took photos of the stem to show its condition. You can see the oxidation, calcification and tooth marks.

He took some closer photos of the rim top and bowl to show the condition. You can see the thick cake in the bowl and the debris on the rim top and lava on the inner edge. It is hard to know for certain but it looks like there is some roughening on the back inner edge. He also took photos of the stem to show its condition. You can see the oxidation, calcification and tooth marks.

Jeff took some photos of the sides and heel of the bowl to show the sandblast and the condition of the finish around the bowl and shank. It is a great looking pipe.

Jeff took some photos of the sides and heel of the bowl to show the sandblast and the condition of the finish around the bowl and shank. It is a great looking pipe.

He captured the stamping on the underside of shank. It reads a noted above. It is interesting to the length of the stamping on the smooth panel. There is also the stylized cursive L on the top of the saddle stem.

He captured the stamping on the underside of shank. It reads a noted above. It is interesting to the length of the stamping on the smooth panel. There is also the stylized cursive L on the top of the saddle stem.

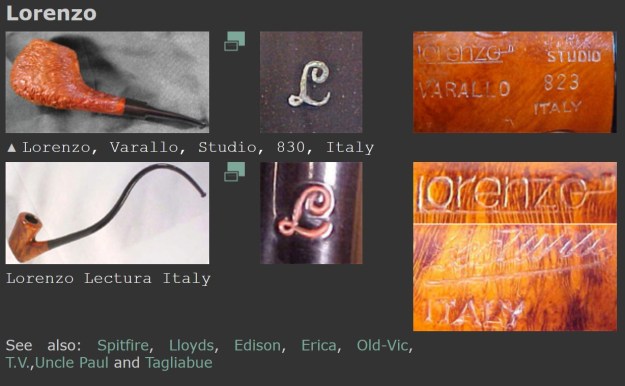

I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-l6.html) to have a look at what was there on the Lorenzo brand. I did a screen capture and included the side bar info below.

I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-l6.html) to have a look at what was there on the Lorenzo brand. I did a screen capture and included the side bar info below. Brand created in 1946. In 1969 Lorenzo Tagliabue began to manage the company and ran it until 1987. After the death of L. Tagliabue, Riccardo Aliverti bought the brands rights in 1988. His son Massimo Aliverti succeeded him as manager in 1991.

Brand created in 1946. In 1969 Lorenzo Tagliabue began to manage the company and ran it until 1987. After the death of L. Tagliabue, Riccardo Aliverti bought the brands rights in 1988. His son Massimo Aliverti succeeded him as manager in 1991.

From there I turned to Pipedia (https://pipedia.org/wiki/Lorenzo) to read the details on the brand. It is quite interesting to read about. I have actually spent time in Varese so it is fascinating to see that location noted below. I included a portion of that article below.

Following Rossi (1886 in Barasso) and Ceresa (1897 in Cassano Magnano) the third pipe manufacture in the Lombardian province of Varese was established in 1900 in the picturesque city of Gallarate by two brothers. Fratelli Lana (Lana Bros.) produced briar pipes for the Italian market under their own brand name.

In 1922 Fratelli Lana went into a close co-operation with the merchant’s family Tagliabue from Milano. Sales outside of Italy began immediately and the demand throughout Europe steadily increased. By 1939 the manufacture had grown to factory size with 120 persons employed – a considerable number for the time. The program remained unchanged for decades: cheap, unpretentious budget pipes for the mass markets. Most of them didn’t even have any stampings besides “Genuine Bruyere” or similar. A large share of the production emerged as fabrications for other firms so that an own style of the Lana pipes was hardly recognizable.

After WW II the world of the briar pipe wasn’t the same anymore and especially Italian firms suffered from the ravages. In 1946 Tagliabue took over Fratelli Lana and changed the name to Manufattura di Pipe Tagliabue. Shortly before 1950 Lorenzo Tagliabue became in charge of the company’s management. He had closely studied the first successful steps of the newly established Italian brands like Castello and Brebbia and began to design new models of his own in an unmistakable style. Simultaneously the previous segment of the cheap, cheaper, cheapest bulk pipes was left and pipes reflecting to more elevated standards were produced.

From 1969 on Lorenzo Tagliabue changed the brand’s name to Lorenzo Pipes. The reason currently quoted is another pipemaking firm named Tagliabue.

The newly issued Lorenzos mostly showed extremely strong forms in designs appealing greatly and massively. Thick, “beefy” walls of the bowls and broad and strong stems were significant for them. As contemporary ads said, these pipes were “Made for real men with strong hands”. Many had a flattened bottom to sit on the table. Next to the unusual shapes, the patina effect of the silk mat surface combined with a bold red or a bright orange staining gave the pipes their distinctive look. The most successful model was a big Oom Paul that was executed in numerous variations…

…In 1983 Lorenzo Tagliabue came to bitter grief: his little daughter, the only child, died of cancer. He lost all interest in the business and retired still in 1983, leaving no heirs who wished to continue the business. Lorenzo Pipes was licensed for and continued for a shorter period by Comoy’s of London (Cadogan / Oppenheimer Group). Then Lorenzo Pipes almost disappeared and Lorenzo Tagliabue passed away in 1987.

But this wasn’t the end. In 1988 Riccardo Aliverti and his wife Gabriella purchased all rights to the Lorenzo trademark from the Tagliabue family and production of the renown Lorenzo Pipes resumed.

The Aliverti family is involved in pipemaking since Romolo Aliverti, the father of the current owners, joined the Lana Brothers in 1920. He later reached the rank of technical director. No wonder that his son Riccardo showed an interest in pipe making. Riccardo began learning the pipemaking trade in 1954 at the age of fourteen under his father’s watchful eyes and succeeded him as technical director upon his father’s retirement in 1973.

Today the third generation of the Aliverti family is working for the company. Massimo Aliverti, Riccardo’s son, has been with the company as sales director since 1991. He works closely with his father and knows all phases of production. Massimo has established a broad customer base for Lorenzo around the world.

As far as the informations are reliable, Lorenzo’s better lines (One Star, Two Star, Three Star, Moscato, Spumante and the Grand Canadian) are made in Italy while the cheaper ones (New Era – Riesling, New Era – Poggio, Angera, Angera Satinato, Cadry, Churchwarden, Filtro, Arena, Cadore, Sport PS and Garden) are made in Albania by Tomori to benefit from the rich deposit of briar in Albania.

Armed with that information I turned to work on the pipe itself. Jeff had cleaned up the pipe and it looked very good. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs, shank brushes and pipe cleaners. He soaked the stem in Briarville’s Stem Deoxidizer and rinsed it off with warm water. I took photos of the pipe before I started my part of the restoration work.

The rim top cleaned up really well. The rim top and outer edge of the bowl look very good. The inner edge has some damage. The stem surface was rough but the oxidation was lessened and calcification was gone. Overall it looked very good with a few light tooth marks and chatter on both sides near the button.

The rim top cleaned up really well. The rim top and outer edge of the bowl look very good. The inner edge has some damage. The stem surface was rough but the oxidation was lessened and calcification was gone. Overall it looked very good with a few light tooth marks and chatter on both sides near the button. The stamping on and underside of the shank is clear and readable. It is stamped as noted above. The saddle stem is also stamped with the Lorenzo L logo on the top. I removed the stem and took a photo of the pipe to give a sense of the whole.

The stamping on and underside of the shank is clear and readable. It is stamped as noted above. The saddle stem is also stamped with the Lorenzo L logo on the top. I removed the stem and took a photo of the pipe to give a sense of the whole.

I cleaned up the inner edge of the bowl with a folded piece of 220 grit sandpaper to smooth out the damage. Once I had smoothed out the edge the bowl was ready. I worked over the sandblast rim top with a brass bristle wire brush to work out the debris. It looked better when finished.

I cleaned up the inner edge of the bowl with a folded piece of 220 grit sandpaper to smooth out the damage. Once I had smoothed out the edge the bowl was ready. I worked over the sandblast rim top with a brass bristle wire brush to work out the debris. It looked better when finished.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips and a horsehair shoe brush to get it into the depths of the sandblast. It works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and buffed with a cotton cloth to raise the shine. The sandblast took on depth and the pipe came alive.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips and a horsehair shoe brush to get it into the depths of the sandblast. It works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and buffed with a cotton cloth to raise the shine. The sandblast took on depth and the pipe came alive.

I set the bowl aside and turned my attention to the stem. The overall look of the stem was clean. I decided to touch up the L stamp on the top of the saddle portion of the stem. I used a folded pipe cleaner to work some Rub’n Buff Antique Gold into the stamp and then buffed it off with a soft cloth. It came out looking good.

I set the bowl aside and turned my attention to the stem. The overall look of the stem was clean. I decided to touch up the L stamp on the top of the saddle portion of the stem. I used a folded pipe cleaner to work some Rub’n Buff Antique Gold into the stamp and then buffed it off with a soft cloth. It came out looking good. I started polishing the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil impregnated cloth. It removes the dust and also gives the sanding pads some bite. By the final pad it was looking quite good.

I started polishing the stem with 320-3500 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil impregnated cloth. It removes the dust and also gives the sanding pads some bite. By the final pad it was looking quite good. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I rubbed it down with a final coat of Obsidian Oil and let it dry.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I rubbed it down with a final coat of Obsidian Oil and let it dry.

This Lorenzo Ravenna Studio 826 Tall Sandblast Lovat is a great looking pipe now that it has been restored. The shallow sandblast that is used around the bowl is quite beautiful and works well with both the shape and the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the wheel and followed by buffing the pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Lorenzo Ravenna Studio 826 Lovat fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 52 grams/1.87 ounces. I will be putting it on the rebornpipes store in the Italian Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. I appreciate your support and time!

This Lorenzo Ravenna Studio 826 Tall Sandblast Lovat is a great looking pipe now that it has been restored. The shallow sandblast that is used around the bowl is quite beautiful and works well with both the shape and the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the wheel and followed by buffing the pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Lorenzo Ravenna Studio 826 Lovat fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 2 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 52 grams/1.87 ounces. I will be putting it on the rebornpipes store in the Italian Pipemakers Section shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. I appreciate your support and time!