Blog by Aaron Henson – 2/20/16

I have found that writing up my pipe restorations is handicapped by my in-ability to remember to take pictures as I am working. On this Pipes by Lee Rhodesian I did a little better job at taking pictures. Although this was a simple restoration I thought I would take the opportunity to share my experience.

I have found that writing up my pipe restorations is handicapped by my in-ability to remember to take pictures as I am working. On this Pipes by Lee Rhodesian I did a little better job at taking pictures. Although this was a simple restoration I thought I would take the opportunity to share my experience.

I found this 3-star Lee with two other pipes (a Mastercraft and a Grabow) in a lot at a local antique shop. I wanted to know more about the Lee brand but I found there is not much out there. But here is what I found:

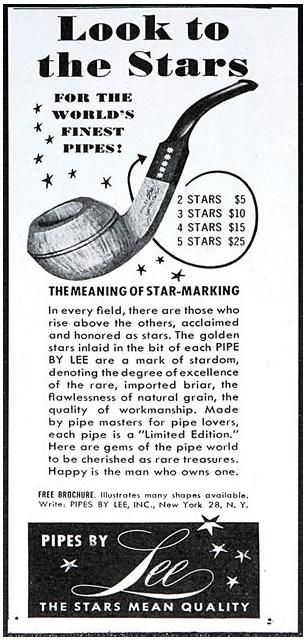

The Pipes by Lee brand was distributed by Stewart-Allen Co, Inc., NY. The pipes were graded by stars: 1 to 5 stars (5 being the high end). Early pipes have seven pointed stars; the middle run have five pointed stars and later pipes are stamped with colored gold stars. (the preceding content from the “Pipes: Logos & Markings” website and the 1947 Ad, courtesy Doug Valitchka).

This pipe has three 7-point gold/brass stars set in a line in the top of the stem. I could not find the dates of the different runs/eras mention above but based on the ad I would have to guess my pipe dates to the late 1940’s to 1950’s.

The Pipe

The outside of the pipe was in very good condition. The briar was clean and the stem was moderately oxidized. The stamps on the shank were very clear: left side read ‘Pipe by Lee’ over ‘Limited Edition’. The right side of the shank is stamped ‘An Authentic’ over ‘Imported Briar’.

The stem was slightly over-clocked and the previous owner had placed a couple of sheets of paper between the stem and shank to act as a spacer. There was one divot in the bottom stem near the button but otherwise was free from tooth chatter.

The stem was slightly over-clocked and the previous owner had placed a couple of sheets of paper between the stem and shank to act as a spacer. There was one divot in the bottom stem near the button but otherwise was free from tooth chatter.

The internals were a different story; the chamber had a healthy cake buildup and good amount of tar on the rim. The shank was full of tar and the stinger was coated in dried tar. The internals of the stem itself were not as bad as the shank and I will attribute this to the removable filter/stinger.  I began the restoration by cleaning the rim. I moistened a little powdered Oxyclean and placed it on a damp green-pad. I laid the pad on a flat surface and worked the bowl much like I was topping it. I don’t have a picture of the result but this worked very well.

I began the restoration by cleaning the rim. I moistened a little powdered Oxyclean and placed it on a damp green-pad. I laid the pad on a flat surface and worked the bowl much like I was topping it. I don’t have a picture of the result but this worked very well.

The cake was very hard and resisted my attempts with the reamer so set the bowl to soak in alcohol overnight. I also set the stem to soak in an Oxyclean bath using a pipe cleaner to hold the stinger out of the solution. With the cake nice and soft, I reamed the bowl back to bare wood with little difficulty. An inspection of the inside of the chamber showed that the briar to be sound and without burnouts or cracks. The airway was clear and located precisely at the bottom center of the chamber. The alcohol soak also removed much of the stain and revealed three small pink fills that would have to be addressed.

With the cake nice and soft, I reamed the bowl back to bare wood with little difficulty. An inspection of the inside of the chamber showed that the briar to be sound and without burnouts or cracks. The airway was clear and located precisely at the bottom center of the chamber. The alcohol soak also removed much of the stain and revealed three small pink fills that would have to be addressed. I finished up the internals by cleaning the shank with cotton swabs and pipe cleaners until they came out as clean as they went in.

I finished up the internals by cleaning the shank with cotton swabs and pipe cleaners until they came out as clean as they went in.

I neglected the pictures during this next part but in summary I used a dental pick to remove fills and packed the voids with briar dust. A dab of clear CA (cyanoacrylate) glue set the dust in place. After drying, the fills were sanded smooth. I also sanded the entire bowl (except around the stamps) with 1500-3200 micromesh pads.

Returning to the stem, I removed the aluminum ‘filter’ and cleaned it and the threads with 0000 steel wool and alcohol. Then I tried to raise the divot out of the stem with flame from a lighter. I didn’t expect to completely eliminate the divot but wanted to reduce it as much as possible before filling it. The fill was made with black CA glue and charcoal powder then sanded smooth when cured.

I polished the stem by wet sanding with 1500-4000 micromesh pads, rubbing down with mineral oil after each group of the three pads. A plastic washer was placed between the stem and the stummel at this stage to prevent damaging the wood and to keep from rounding the shoulder of the stem.

At this point I set up the alcohol retort. It took three test tubes until the alcohol was clean; note that I left the filter off during the retort. I won’t describe the retort process because that can be found in other posts but I do want to comment on one point. I have found that heating the alcohol often time lead to an explosive boiling – not a very controlled process. The smooth surface of the test tube and purity of the alcohol does not provide a surface for bubble to form on. However, if I add a small foreign object to the bottom of the tube the boil is much more controlled. I small piece of cake or charred candle wick gives the bubbles a place to form and eliminate the possibility of super-heating the alcohol.

At this point I set up the alcohol retort. It took three test tubes until the alcohol was clean; note that I left the filter off during the retort. I won’t describe the retort process because that can be found in other posts but I do want to comment on one point. I have found that heating the alcohol often time lead to an explosive boiling – not a very controlled process. The smooth surface of the test tube and purity of the alcohol does not provide a surface for bubble to form on. However, if I add a small foreign object to the bottom of the tube the boil is much more controlled. I small piece of cake or charred candle wick gives the bubbles a place to form and eliminate the possibility of super-heating the alcohol. Now that the pipe was cleaned and sanitized I finished the stummel by applying two coats of Feibing’s light brown aniline stain. I flamed the stain to set it and then wiped off the excess with a cotton pad and alcohol. While reassembling the pipe I heated the threaded tenon and re-align the stem. Then I coated the entire pipe with mineral oil and set it aside to soak in before applying three coats of carnauba wax.

Now that the pipe was cleaned and sanitized I finished the stummel by applying two coats of Feibing’s light brown aniline stain. I flamed the stain to set it and then wiped off the excess with a cotton pad and alcohol. While reassembling the pipe I heated the threaded tenon and re-align the stem. Then I coated the entire pipe with mineral oil and set it aside to soak in before applying three coats of carnauba wax.