Blog by Steve Laug

To me there is something almost electric about handling and working on a pipe designed and carved by Preben Holm. I can’t describe adequately the feeling I have when I turn the bowl and stem over in my hands even before I start working on one of these his pipes. All I know is that there is an energy and fluidity that flows through the pipe because of the way he carved and shaped the briar. He is a master of chasing the grain in the briar. Every time I get a chance to work on one I am excited about the possibility. So, a few weeks ago when I got an email from a reader of the blog about his Ben Wade, Preben Holm pipe it was with no hesitation that I accepted working on it. I have included that email below along with a photo I asked him to send me to see the pipe.

I wondering if you can find me a replacement pipe stem for my Ben Wade pipe. Dropped my pipe and broke it. — Tom This Ben Wade Golden Matt was no exception to my experience with Ben Wade pipes. Tom sent it to me and today it arrived. I was excited to be able to work on it. This one has incredible grain around the bowl sides and shank. The bowl had a very thick cake on the walls. The plateau on the rim top is filled with tars and lava but it is a large top. The shank end also has a plateau finish. It is very unique pipe. The combination of dark and medium stains highlights grain that runs like flames across both sides of the bowl culminating at the flat heel of the bowl. The rim top is plateau and it looks quite unique – with the valleys and hills in the top and also something that looked like it had been wire brush. The variegated copper, brown and gold acrylic stem is beautiful and the turning of acrylic give it an amazing look. The tenon is broken off and fortunately the piece has been pulled from the shank. It is a smooth break which makes things easier. There were tooth marks on the top and underside of the stem ahead of the button. I took photos of the pipe to try and capture what it looked like before I started working on it. It really is a beauty in spite of the grime in the finish.

This Ben Wade Golden Matt was no exception to my experience with Ben Wade pipes. Tom sent it to me and today it arrived. I was excited to be able to work on it. This one has incredible grain around the bowl sides and shank. The bowl had a very thick cake on the walls. The plateau on the rim top is filled with tars and lava but it is a large top. The shank end also has a plateau finish. It is very unique pipe. The combination of dark and medium stains highlights grain that runs like flames across both sides of the bowl culminating at the flat heel of the bowl. The rim top is plateau and it looks quite unique – with the valleys and hills in the top and also something that looked like it had been wire brush. The variegated copper, brown and gold acrylic stem is beautiful and the turning of acrylic give it an amazing look. The tenon is broken off and fortunately the piece has been pulled from the shank. It is a smooth break which makes things easier. There were tooth marks on the top and underside of the stem ahead of the button. I took photos of the pipe to try and capture what it looked like before I started working on it. It really is a beauty in spite of the grime in the finish.

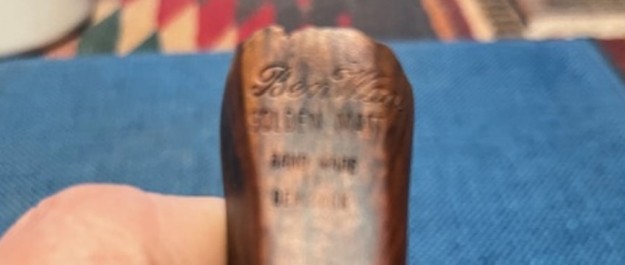

I took some time to really examine the condition of the pipe. I made some notes of what I saw. It is clear to me that this is one of Tom’s favourite pipes as you can see from the thick cake in the bowl and the lava on the rim top. It is hard to know the condition of the inner edge of the bowl due to the lava on the edges. The outside of the bowl and plateau portions are dirty and dusty but the grain pops through. The fancy acrylic turned stem still had a faint BW Cross and Crown logo on the top just past the fancy turnings. The stem as a whole was dirty and dusty with tooth marks and chatter on the both sides ahead of the button. I took a photo of the stamping on the underside of the shank to capture all of the stamping. It was clear and read Ben Wade in script at the top [over] Golden Matt [over] Hand Made [over] in [over] Denmark. Though the photo is a bit blurry the stamping is much clearer in person.

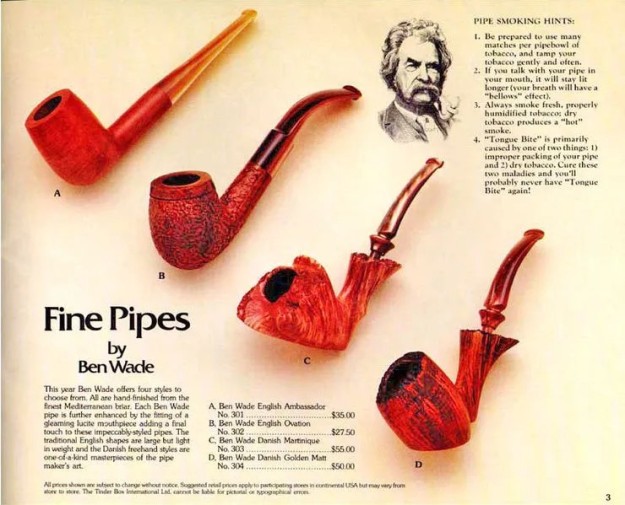

I took some time to really examine the condition of the pipe. I made some notes of what I saw. It is clear to me that this is one of Tom’s favourite pipes as you can see from the thick cake in the bowl and the lava on the rim top. It is hard to know the condition of the inner edge of the bowl due to the lava on the edges. The outside of the bowl and plateau portions are dirty and dusty but the grain pops through. The fancy acrylic turned stem still had a faint BW Cross and Crown logo on the top just past the fancy turnings. The stem as a whole was dirty and dusty with tooth marks and chatter on the both sides ahead of the button. I took a photo of the stamping on the underside of the shank to capture all of the stamping. It was clear and read Ben Wade in script at the top [over] Golden Matt [over] Hand Made [over] in [over] Denmark. Though the photo is a bit blurry the stamping is much clearer in person. I wanted to get a sense of the background of the pipe. I always enjoy the background as a part of my work on a pipe. I am including the history that I included in a previous blog. It includes the idea that the Preben Holm pipes were marketed under the Ben Wade label in the US and imported through Lane Ltd. I turned to Pipedia and read the listing on the brand to refresh my memory and flesh out the knowledge of the brand (https://pipedia.org/wiki/Ben_Wade). I have included a photo from that site that was taken from a Tinderbox advertisement. The pipe labelled D in the advertisement is a Ben Wade Golden Matt Freehand.

I wanted to get a sense of the background of the pipe. I always enjoy the background as a part of my work on a pipe. I am including the history that I included in a previous blog. It includes the idea that the Preben Holm pipes were marketed under the Ben Wade label in the US and imported through Lane Ltd. I turned to Pipedia and read the listing on the brand to refresh my memory and flesh out the knowledge of the brand (https://pipedia.org/wiki/Ben_Wade). I have included a photo from that site that was taken from a Tinderbox advertisement. The pipe labelled D in the advertisement is a Ben Wade Golden Matt Freehand.

I quote the portion of the article that summarizes the history of the brand.

Young Copenhagen master pipemaker Preben Holm had made a meteoric career heading a pipe manufacture employing 45 people at the age of 22! But around the turn of 1970/71 he was in major financial difficulties. His US distributor, Snug Harbour Ltd. in New York City, left him in the lurch. Holm had three unpaid invoices on his desk and another large shipment was ready for the USA, when Snug Harbour’s manager told him on the phone that there was no money at all on the account to pay him.

So, the Dane went to New York for an almost desperate search for a new distribution partner. He made contacts with Lane Ltd. and met Herman G. Lane in February 1971. Lane Ltd. had no interest in Holm’s serial pipes produced at that time but so much the more in the hand-carved freehands because the hype for Danish freehands and fancies in the States was still on its way to the climax then. The meeting resulted in an agreement to start a cooperation. Lane insisted to improve the quality considerably and in return he assured to be able to sell essentially larger quantities.

Holm went back home to work on new samples with all-new designs and altered finishes for Lane. Both, Lane and Holm, agreed that it would be unwise to sell the pipes under Preben Holm’s name as long as Snug Harbour had a considerable stock of Preben Holm pipes and might sell them pipes at very low prices just to bring in some money.

So, on Mr. Lane’s proposal it was determined to use the name Ben Wade belonging to Lane Ltd. Lane spent considerable amounts of money for advertising the new brand in the big magazines– the centerpiece being whole-page ads showing a very exclusive Seven Day’s Set.

The cooperation with Lane Ltd. proved to be an eminent business success for both partners. Within a very short time Ben Wade Handmade Denmark sold in much larger quantities and at higher prices than they had ever dreamed of. And the hype these freehands and fancy pipes caused went on unbroken long after Herman G. Lane deceased. Preben Holm – obviously much more brilliant in pipe making than in pipe business – was in major troubles again in 1986 and had to sack most of his staff. The Ben Wade production was significantly lowered but continued until his untimely death in June of 1989.

Up to now Preben Holm made Ben Wade pipes are cult and highly sought for on the estate markets.

This pipe was another Preben Holm made Freehand distributed in the US by Lane Ltd under the name Ben Wade. The freehand rage occurred in the late 70s and the pipes were made until Preben’s death in 1989. My guess would be that this pipe was made sometime during that time period and potentially in the late 70s.

Armed with that information I moved forward to work on the pipe itself and see what I had to do with it. I reamed the pipe with a PipNet pipe reamer using the second and the third cutting head to take the cake back to bare briar. I cleaned up the remnants of the cake with a Savinelli Fitsall Pipe Knife. I finished the bowl internals by sanding the bowl walls with 220 grit sandpaper wrapped around a piece of dowel. The bowl walls looked very good with no checking or cracking to the walls.

I worked over the rim top with a brass bristle wire brush to knock off the loose debris on the rim top. I worked it over to clean out the grooves and valleys of both the plateau top and the wire marks across the surface of the rim. It really is a beautiful pipe and a unique looking rim top finish. It cleaned up quite well.

I worked over the rim top with a brass bristle wire brush to knock off the loose debris on the rim top. I worked it over to clean out the grooves and valleys of both the plateau top and the wire marks across the surface of the rim. It really is a beautiful pipe and a unique looking rim top finish. It cleaned up quite well. With the internals of the bowl cleaned I worked on the airway in the shank, mortise and the stem. I cleaned it with pipe cleaners – both regular and bristle, cotton swabs and 99% isopropyl alcohol. I was able to remove a lot of the debris and oils in the pipe. It smells much better.

With the internals of the bowl cleaned I worked on the airway in the shank, mortise and the stem. I cleaned it with pipe cleaners – both regular and bristle, cotton swabs and 99% isopropyl alcohol. I was able to remove a lot of the debris and oils in the pipe. It smells much better.  Now that the reaming and scrubbing of the interior was finished, I moved on to the exterior of the pipe. I scrubbed the plateau rim top and shank end along with the smooth bowl with undiluted Murphy’s Oil Soap and a tooth brush. The grime and oils just rinsed off under the warm water that I ran over the finish. I dried it off with a soft cloth and I was please with how clean it was and how the grain stood out.

Now that the reaming and scrubbing of the interior was finished, I moved on to the exterior of the pipe. I scrubbed the plateau rim top and shank end along with the smooth bowl with undiluted Murphy’s Oil Soap and a tooth brush. The grime and oils just rinsed off under the warm water that I ran over the finish. I dried it off with a soft cloth and I was please with how clean it was and how the grain stood out.

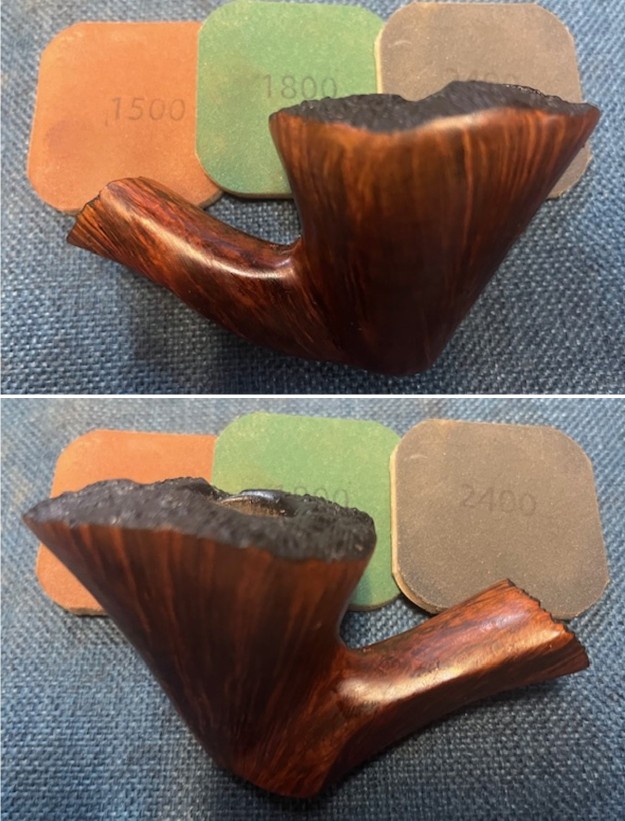

I sanded the briar with 320-3500 grit sanding pads. I wiped the briar down after each sanding pad with a damp cloth to remove the debris that was left behind. By the time I finished the last pad the briar was very smooth and clean to the touch.

I sanded the briar with 320-3500 grit sanding pads. I wiped the briar down after each sanding pad with a damp cloth to remove the debris that was left behind. By the time I finished the last pad the briar was very smooth and clean to the touch.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad. The bowl began to really shine with the polishing.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad. The bowl began to really shine with the polishing.

I worked some Before & After Restoration Balm into the finish of the smooth briar with my finger tips. I worked it into the plateau on the rim top and shank end with a horse hair shoebrush. The product works well to clean, enliven and protect the briar and really brings it back to life. I have been using it for quite a few years now and really like the way it makes the briar come alive and makes the grain pop.

I worked some Before & After Restoration Balm into the finish of the smooth briar with my finger tips. I worked it into the plateau on the rim top and shank end with a horse hair shoebrush. The product works well to clean, enliven and protect the briar and really brings it back to life. I have been using it for quite a few years now and really like the way it makes the briar come alive and makes the grain pop.

The bowl is finished and really looks amazing. All that remains is that I have to polish it on the buffer. I set it aside and turned my attention to the broken tenon. I went through my collection of tenons and found a couple that would work. The difference was in the diameter of the portion of the tenon that went into the stem.

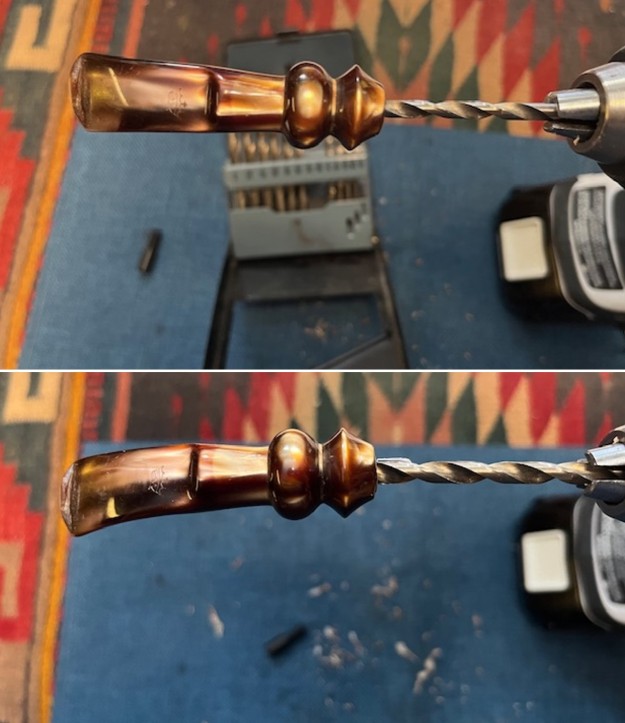

The bowl is finished and really looks amazing. All that remains is that I have to polish it on the buffer. I set it aside and turned my attention to the broken tenon. I went through my collection of tenons and found a couple that would work. The difference was in the diameter of the portion of the tenon that went into the stem. I chose the top one in the photo above as the tenon insertion point was smaller in diameter and would fit better in the stem. I used a Dremel and sanding drum and 220 grit sandpaper and a topping board to flatten the broken end on the snapped tenon. I wanted a flat surface to be able to drill the airway for the new tenon.

I chose the top one in the photo above as the tenon insertion point was smaller in diameter and would fit better in the stem. I used a Dremel and sanding drum and 220 grit sandpaper and a topping board to flatten the broken end on the snapped tenon. I wanted a flat surface to be able to drill the airway for the new tenon. Once it was flattened I used progressively larger drill bits to open the airway. By the third drill bit the opening was perfect for the diameter of the tenon insert end.

Once it was flattened I used progressively larger drill bits to open the airway. By the third drill bit the opening was perfect for the diameter of the tenon insert end.

I smoothed out the junction of the tenon and the stem using a flat file and the transition was very smooth. I flattened the threads of the insert end with the file at the same to make the fit snug. I knew that once I glue it in place it would be secure and strong.

I smoothed out the junction of the tenon and the stem using a flat file and the transition was very smooth. I flattened the threads of the insert end with the file at the same to make the fit snug. I knew that once I glue it in place it would be secure and strong. I painted the end of the threaded portion of the tenon with rubberized black CA glue. I inserted a pipe cleaner in the stem and threaded the new tenon onto the pipe cleaner. Once everything was aligned I pressed the tenon in place in the stem end. It aligned perfectly with the pipe cleaner as a guide.

I painted the end of the threaded portion of the tenon with rubberized black CA glue. I inserted a pipe cleaner in the stem and threaded the new tenon onto the pipe cleaner. Once everything was aligned I pressed the tenon in place in the stem end. It aligned perfectly with the pipe cleaner as a guide. Once the glue had set and the tenon was firmly in place I sanded it with 220 grit sandpaper to achieve a snug fit in the shank.

Once the glue had set and the tenon was firmly in place I sanded it with 220 grit sandpaper to achieve a snug fit in the shank. I touched up the Cross & Crown stamp on the top of the stem with Rub’n Buff Antique Gold and buffed it off with a cotton pad. It was faint but it was readable. I sanded the tooth marks and chatter on both sides with the 220 grit sandpaper to smooth out the marks and minimise them. It looked better.

I touched up the Cross & Crown stamp on the top of the stem with Rub’n Buff Antique Gold and buffed it off with a cotton pad. It was faint but it was readable. I sanded the tooth marks and chatter on both sides with the 220 grit sandpaper to smooth out the marks and minimise them. It looked better. I polished the stem with micromesh sanding pads. I used 1500-12000 grit sanding pads. I wiped it down with a damp cloth to remove the sanding debris on the surface of the stem. I polished the new tenon at the same time and both took on a rich shine and looked better. I finished by polishing the stem and tenon with Before & After Pipe Stem Polish and gave it a final wipe with Obsidian Oil.

I polished the stem with micromesh sanding pads. I used 1500-12000 grit sanding pads. I wiped it down with a damp cloth to remove the sanding debris on the surface of the stem. I polished the new tenon at the same time and both took on a rich shine and looked better. I finished by polishing the stem and tenon with Before & After Pipe Stem Polish and gave it a final wipe with Obsidian Oil.

This is a beautiful Hand Made Preben Holm made Ben Wade Golden Matt Freehand with a fancy, turned, variegated acrylic stem. It has a great look and feel. The shape fits well in the hand with the curve of the bowl and shank junction a perfect fit for the thumb around the bowl when held. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the plateau on the rim top and shank end multiple coats of Conservator’s Wax. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine andwith a microfiber cloth to deepen the shine. The rich combination of browns and black in the smooth finishes and the black plateau areas took on life with the buffing. The rich colour of the briar works well with the polished stem. I like the grain and finished look of this Preben Holm Ben Wade Golden Matt Freehand. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 2 wide x 2 ¼ inches long, Chamber diameter: 7/8 of an inch. The weight of the pipe is 74 grams/2.61 ounces. This Danish Freehand is a real beauty. Thanks for walking through the restoration with me as I worked over another beautiful pipe. It will be heading back to Tom shortly and he will once again have his favourite pipe to enjoy. Thanks for your time.

This is a beautiful Hand Made Preben Holm made Ben Wade Golden Matt Freehand with a fancy, turned, variegated acrylic stem. It has a great look and feel. The shape fits well in the hand with the curve of the bowl and shank junction a perfect fit for the thumb around the bowl when held. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the plateau on the rim top and shank end multiple coats of Conservator’s Wax. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine andwith a microfiber cloth to deepen the shine. The rich combination of browns and black in the smooth finishes and the black plateau areas took on life with the buffing. The rich colour of the briar works well with the polished stem. I like the grain and finished look of this Preben Holm Ben Wade Golden Matt Freehand. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 2 wide x 2 ¼ inches long, Chamber diameter: 7/8 of an inch. The weight of the pipe is 74 grams/2.61 ounces. This Danish Freehand is a real beauty. Thanks for walking through the restoration with me as I worked over another beautiful pipe. It will be heading back to Tom shortly and he will once again have his favourite pipe to enjoy. Thanks for your time.