Blog by Steve Laug

The next pipe is a really nicely grained Prince with a slender vulcanite taper stem. The classic Prince was made to hold in your hand and has a flat bottom on the bowl and shank so it can be a sitter as well. It is another light weight pipe with a taper stem and looks comfortable. We picked up this pipe off eBay on 02/10/18 from Manchester Township, New Jersey, USA. Jeff cleaned the pipe in 2018 and now I am working on it in 2022 so it has been sitting around here for over four years. The stamping is on the left side and reads Grain de Luxe and on the right side reads Algerian Bruyere. The exterior of the briar was filthy and had ground in dust and grime in the finish but the grain shone through the dirt. There was a thick cake in the bowl and a thick overflow of lava on the inner edge and rim top. It was hard to know what the edge looked like underneath the lava but the cleaning would make it very clear! The stem was oxidized, calcified and had tooth marks and chatter on both sides near the button. Jeff took photos of the pipe to give a clear picture of what we were up against with this pipe.

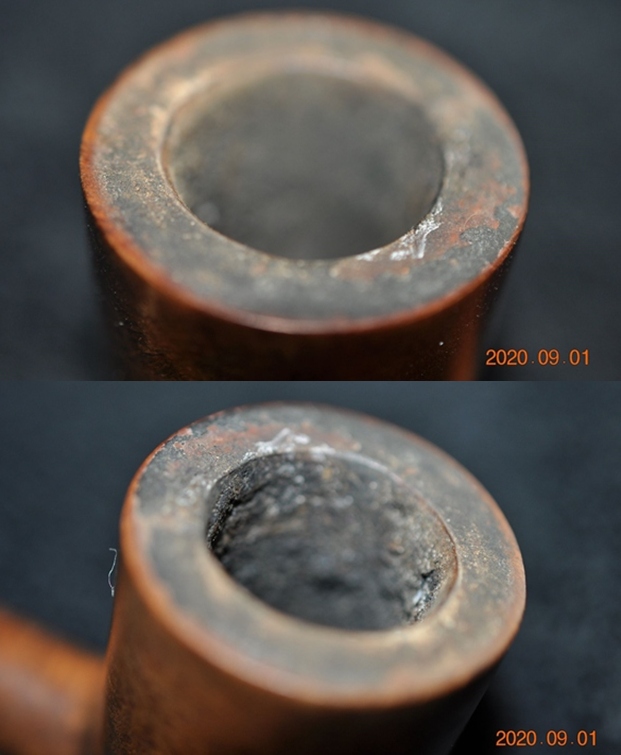

He captured the cake in the bowl and the debris and lava on the rim top and edges in the next photos. It was very clear that it was another exceptional smoker! The stem is oxidized, calcified and shows the tooth marks and chatter on both sides ahead of the button. There is an oval shaped mark on the top of the stem in the photos. It appears that there was a decal of something on the top of the stem that had long since disappeared.

He captured the cake in the bowl and the debris and lava on the rim top and edges in the next photos. It was very clear that it was another exceptional smoker! The stem is oxidized, calcified and shows the tooth marks and chatter on both sides ahead of the button. There is an oval shaped mark on the top of the stem in the photos. It appears that there was a decal of something on the top of the stem that had long since disappeared.

Jeff captured some of the beauty of the shape and the grain in the next photo. The mix of grains in the smooth portions and the rustication is quite lovely as can be seen in the photo of the heel. The second photo below shows the large flaw in the briar on the heel.

Jeff captured some of the beauty of the shape and the grain in the next photo. The mix of grains in the smooth portions and the rustication is quite lovely as can be seen in the photo of the heel. The second photo below shows the large flaw in the briar on the heel.  He took a photos of the stamping on the sides of the shank. It is clearly stamped on the right and left and reads as noted above.

He took a photos of the stamping on the sides of the shank. It is clearly stamped on the right and left and reads as noted above.  I am enjoying a nice artisan Red Ale made by Luppolo Brewing here in Vancouver as I work on this next pipe. It is really a unique short snorter. Jeff had done a great cleanup on the pipe. He reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the bowl exterior with a tooth brush and Murphy’s Oil Soap to remove the grime on the finish of the bowl and the lava from the rim top. He rinsed it under running water. One of the benefits of this scrub is that it also tends to lift some of the scratches and nicks in the surface of the briar. He dried it off with a soft cloth. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water and cleaned out the airway in the stem with alcohol, pipe cleaners and cotton swabs. I took photos of the pipe as it looked when I put it on the table.

I am enjoying a nice artisan Red Ale made by Luppolo Brewing here in Vancouver as I work on this next pipe. It is really a unique short snorter. Jeff had done a great cleanup on the pipe. He reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the bowl exterior with a tooth brush and Murphy’s Oil Soap to remove the grime on the finish of the bowl and the lava from the rim top. He rinsed it under running water. One of the benefits of this scrub is that it also tends to lift some of the scratches and nicks in the surface of the briar. He dried it off with a soft cloth. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water and cleaned out the airway in the stem with alcohol, pipe cleaners and cotton swabs. I took photos of the pipe as it looked when I put it on the table.

I took photos of the rim top and stem to show the condition. The rim top had some darkening and there was damage on the inner edge of the bowl. There were also some small nicks in the outer edge at the back of the bowl. The stem was vulcanite and there were tooth marks and chatter on both sides ahead of the button. The oval mark on the top of the stem was no longer visible.

I took photos of the rim top and stem to show the condition. The rim top had some darkening and there was damage on the inner edge of the bowl. There were also some small nicks in the outer edge at the back of the bowl. The stem was vulcanite and there were tooth marks and chatter on both sides ahead of the button. The oval mark on the top of the stem was no longer visible.  I took photos of the stamping on the left and right side of the bowl to show the stamping that was there. It was clear and readable as noted above.

I took photos of the stamping on the left and right side of the bowl to show the stamping that was there. It was clear and readable as noted above.  I removed the stem from the shank and took a photo of the pipe to give a sense of the proportions of the bowl and stem.

I removed the stem from the shank and took a photo of the pipe to give a sense of the proportions of the bowl and stem. I started my work on pipe by dealing with the roughening of the inner edge of the bowl with 220 grit sandpaper. I also smoothed out the damage and the darkening on the rim top and was able to smooth it out and remove the damage. The finished bowl top and inner edge looked much better.

I started my work on pipe by dealing with the roughening of the inner edge of the bowl with 220 grit sandpaper. I also smoothed out the damage and the darkening on the rim top and was able to smooth it out and remove the damage. The finished bowl top and inner edge looked much better.  I filled in the flaws in the bottom of the bowl and left side with clear CA glue. Once it cured I sanded the spots smooth with 220 grit sandpaper to blend it into the surface of the briar.

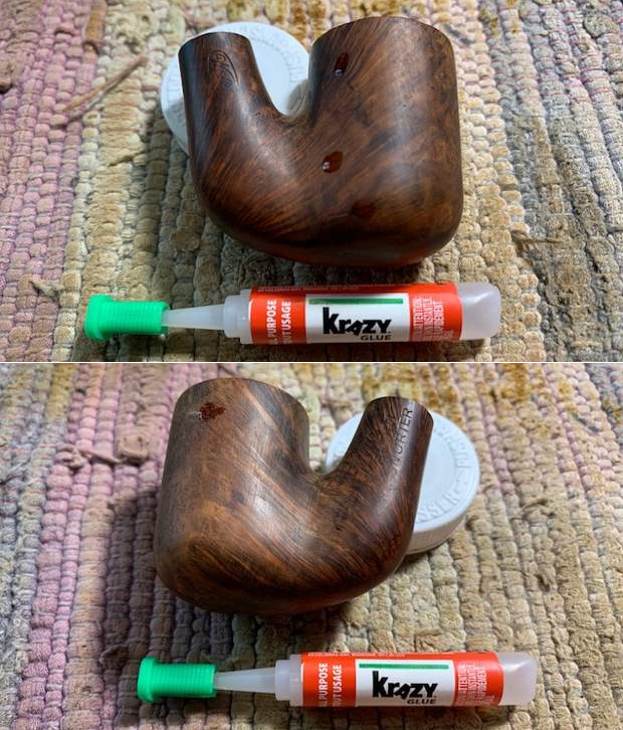

I filled in the flaws in the bottom of the bowl and left side with clear CA glue. Once it cured I sanded the spots smooth with 220 grit sandpaper to blend it into the surface of the briar.

I polished the bowl and shank with micromesh sanding pads – 1500-12000 grit pads. I wiped the bowl down between pads with a damp cloth to remove the debris.

I polished the bowl and shank with micromesh sanding pads – 1500-12000 grit pads. I wiped the bowl down between pads with a damp cloth to remove the debris.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out on the briar.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out on the briar.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a lighter and was able to lift all of them. I sanded out the remaining chatter with a folded piece of 220 grit sandpaper and then started polishing it with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a lighter and was able to lift all of them. I sanded out the remaining chatter with a folded piece of 220 grit sandpaper and then started polishing it with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I finished the polishing with Before & After Polishes – both Fine and Extra Fine. I gave it a final rub down with Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I finished the polishing with Before & After Polishes – both Fine and Extra Fine. I gave it a final rub down with Obsidian Oil and set it aside to dry.

I checked the fit of the stem in the shank and found that it was a bit loose. I checked out the shank end and found some small cracks – multiple hairline fissures on the shank end but none worked their way up the shank. I went through my bands and found one that was the right size for the shank. I pressed it on to the shank end by pressing it against the place mat that I worked on. It tightened up the fit of the stem in the shank and added a nice touch to the pipe.

I checked the fit of the stem in the shank and found that it was a bit loose. I checked out the shank end and found some small cracks – multiple hairline fissures on the shank end but none worked their way up the shank. I went through my bands and found one that was the right size for the shank. I pressed it on to the shank end by pressing it against the place mat that I worked on. It tightened up the fit of the stem in the shank and added a nice touch to the pipe.

I took photos of the pipe with the stem on the shank end. The look works well with the wood and the vulcanite. It was a great final touch with this restoration.

I took photos of the pipe with the stem on the shank end. The look works well with the wood and the vulcanite. It was a great final touch with this restoration.  This Grain de Luxe Algerian Bruyere Prince with a polished brass band and a vulcanite taper stem has beautiful grain around the bowl and shank. The rich browns and blacks of the contrasting stain makes the grain come alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Grain de Luxe Prince really is unique looking and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.13 oz./32 grams. This pipe will soon be on the American Pipe Makers Section of the rebornpipes store if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Grain de Luxe Algerian Bruyere Prince with a polished brass band and a vulcanite taper stem has beautiful grain around the bowl and shank. The rich browns and blacks of the contrasting stain makes the grain come alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Grain de Luxe Prince really is unique looking and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.13 oz./32 grams. This pipe will soon be on the American Pipe Makers Section of the rebornpipes store if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!