by Kenneth Lieblich

Say hello to this beautiful Savinelli Nonpareil 9614 bent billiard! It came to me in a lot of pipes I bought some time ago and it seemed right to bring this one back to life. At first, it seemed like a relatively straightforward restoration, but – wow – this pipe ended up taking an awful lot of work. You can now buy this pipe for your collection and enjoy the fruits of my labours.

This pipe promises to be a great smoker, I figure. Let’s look at the markings. The left side of the shank reads Savinelli [over] Nonpareil. Despite Savinelli being an Italian company, the word nonpareil is French and means “without equal” – literally, “not the same”. On the left side of the shank is the lovely Savinelli crown, next to which are the marks 9614 [over] Italy. Naturally, the number refers to the shape. Finally, there are two brass dots on the left side of the stem – very nice touch.

This pipe promises to be a great smoker, I figure. Let’s look at the markings. The left side of the shank reads Savinelli [over] Nonpareil. Despite Savinelli being an Italian company, the word nonpareil is French and means “without equal” – literally, “not the same”. On the left side of the shank is the lovely Savinelli crown, next to which are the marks 9614 [over] Italy. Naturally, the number refers to the shape. Finally, there are two brass dots on the left side of the stem – very nice touch.

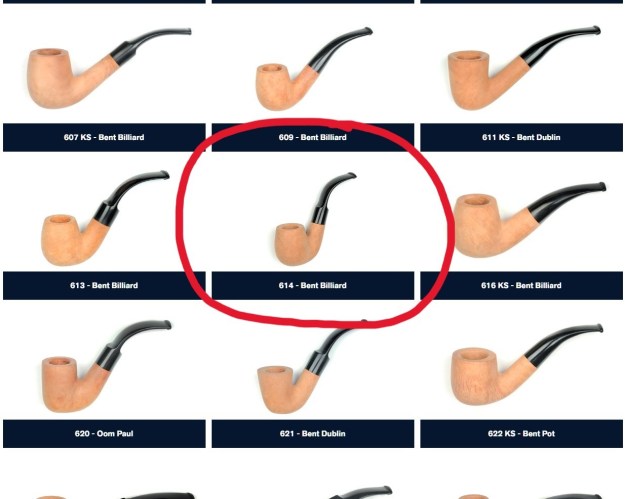

Savinelli is one of the most recognized names in pipe smoking and they have a long and storied history. You can read about them from their own website or from Pipedia’s article about them. However, I was particularly interested in learning more about the Nonpareil line. Sadly, Pipedia had nothing on this subject. I checked with Pipephil and they did have a bit of information, which I display below. I learned from Pipephil that old Savinellis used to have four-digit shape numbers, newer ones three. The exceptions to this rule, however, are the Nonpareil and Dry System lines.

Savinelli is one of the most recognized names in pipe smoking and they have a long and storied history. You can read about them from their own website or from Pipedia’s article about them. However, I was particularly interested in learning more about the Nonpareil line. Sadly, Pipedia had nothing on this subject. I checked with Pipephil and they did have a bit of information, which I display below. I learned from Pipephil that old Savinellis used to have four-digit shape numbers, newer ones three. The exceptions to this rule, however, are the Nonpareil and Dry System lines.

The stem on this pipe definitely shows signs of use. There were some tooth marks – dents and scratches – and plenty of calcification. Of course, there was also some oxidation, but I didn’t realize just how much until much later. The stummel was tired and drab. There were indications of lava on the rim and plenty of cake in the bowl. Also, the briar had a few little scratches from the years of love of its previous owner. Nothing to worry about – or so I thought. More on that later.

The stem on this pipe definitely shows signs of use. There were some tooth marks – dents and scratches – and plenty of calcification. Of course, there was also some oxidation, but I didn’t realize just how much until much later. The stummel was tired and drab. There were indications of lava on the rim and plenty of cake in the bowl. Also, the briar had a few little scratches from the years of love of its previous owner. Nothing to worry about – or so I thought. More on that later.

Well, the usual cleaning procedures were in order for this pipe. I started on the stem by wiping it down with some Murphy’s on a cotton round. Then, I cleaned out the insides of the stem with pipe cleaners and lemon-oil isopropyl alcohol.

Well, the usual cleaning procedures were in order for this pipe. I started on the stem by wiping it down with some Murphy’s on a cotton round. Then, I cleaned out the insides of the stem with pipe cleaners and lemon-oil isopropyl alcohol.

At this point, I took a BIC lighter and ‘painted’ the stem with its flame in order to lift the tooth marks. This was moderately successful in raising the dents. Once that was done, the stem went for an overnight soak in the Before & After Hard Rubber Deoxidizer. After soaking, I cleaned off the de-oxidizing fluid with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and I used SoftScrub to work it off. I was surprised at how poorly this worked (as compared with other restorations), so I actually sent it for another soak in the deox fluid and repeated the same cleaning procedures afterwards.

At this point, I took a BIC lighter and ‘painted’ the stem with its flame in order to lift the tooth marks. This was moderately successful in raising the dents. Once that was done, the stem went for an overnight soak in the Before & After Hard Rubber Deoxidizer. After soaking, I cleaned off the de-oxidizing fluid with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and I used SoftScrub to work it off. I was surprised at how poorly this worked (as compared with other restorations), so I actually sent it for another soak in the deox fluid and repeated the same cleaning procedures afterwards.

Once I got the stem looking vaguely deoxidized (and before I moved on to the Micromesh pads), I built up the tooth damage on the stem with black cyanoacrylate adhesive and let it fully cure. I used my miniature files to take down the majority of the dried glue. I then sanded it down with 400-grit sandpaper to meld seamlessly into the stem.

Once I got the stem looking vaguely deoxidized (and before I moved on to the Micromesh pads), I built up the tooth damage on the stem with black cyanoacrylate adhesive and let it fully cure. I used my miniature files to take down the majority of the dried glue. I then sanded it down with 400-grit sandpaper to meld seamlessly into the stem.

I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. But WAIT! I never made it through all nine pads because I could see that the oxidation was so stubborn, I would need to put in some extra work first. Recently, Steve kindly introduced me to a new type of sanding pad – more aggressive grit for more aggressive jobs. I’m going to refer to them as the ‘grey pads’ since that’s their colour. I used the grey pads to really attack the oxidation on the stem and they worked very well. I don’t have photos of this, but I’m pleased with the results. There are some small wounds remaining on the stem, but they are not an issue at all. Once done with the greys, I went back again to the Micromesh pads. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. This also really made the brass dots pop! Putting the stem aside, I moved on to the stummel.

I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. But WAIT! I never made it through all nine pads because I could see that the oxidation was so stubborn, I would need to put in some extra work first. Recently, Steve kindly introduced me to a new type of sanding pad – more aggressive grit for more aggressive jobs. I’m going to refer to them as the ‘grey pads’ since that’s their colour. I used the grey pads to really attack the oxidation on the stem and they worked very well. I don’t have photos of this, but I’m pleased with the results. There are some small wounds remaining on the stem, but they are not an issue at all. Once done with the greys, I went back again to the Micromesh pads. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. This also really made the brass dots pop! Putting the stem aside, I moved on to the stummel.

I used the PipNet Reamer (and some sandpaper taped to a wooden dowel) to take the bowl down to bare briar, as I wanted to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was a lot of nastiness inside this stummel and – boy-oh-boy – it took a lot of cotton to get this thing clean!

I used the PipNet Reamer (and some sandpaper taped to a wooden dowel) to take the bowl down to bare briar, as I wanted to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was a lot of nastiness inside this stummel and – boy-oh-boy – it took a lot of cotton to get this thing clean!

I took a close look at the rim. In order to save as much of the rim as possible, I used a piece of machine metal to very delicately scrape away as much lava as I could. I do this before automatically jumping to my topping board. This worked well and the topping board was not needed.

I took a close look at the rim. In order to save as much of the rim as possible, I used a piece of machine metal to very delicately scrape away as much lava as I could. I do this before automatically jumping to my topping board. This worked well and the topping board was not needed. A de-ghosting session seemed like a good idea. This de-ghosting consisted of thrusting cotton balls in the bowl and the shank, and saturating them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the oils, tars and smells to leech out into the cotton. Finally, a relatively clean and fresh-smelling bowl emerged. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. What a difference that made! I also cleaned the insides with some Castile soap and tube brushes.

A de-ghosting session seemed like a good idea. This de-ghosting consisted of thrusting cotton balls in the bowl and the shank, and saturating them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the oils, tars and smells to leech out into the cotton. Finally, a relatively clean and fresh-smelling bowl emerged. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. What a difference that made! I also cleaned the insides with some Castile soap and tube brushes. I examined the scratches and bumps in the briar. I dug out my iron and a damp cloth to try to raise them. The hot and moist steam can often cause the wood to swell slightly and return to shape. This worked quite well, but alas, I forgot to take pictures. After this, I used all nine Micromesh pads (1,500 through 12,000 grit) to remove the scratches in the wood and make everything smooth. Prior to that, however, I applied some clear hockey tape to the shank extension – it was already lovely and smooth, and I didn’t want to scratch it. This tape is fantastic because it is incredibly resistant to sanding yet comes off with no residue whatsoever.

I examined the scratches and bumps in the briar. I dug out my iron and a damp cloth to try to raise them. The hot and moist steam can often cause the wood to swell slightly and return to shape. This worked quite well, but alas, I forgot to take pictures. After this, I used all nine Micromesh pads (1,500 through 12,000 grit) to remove the scratches in the wood and make everything smooth. Prior to that, however, I applied some clear hockey tape to the shank extension – it was already lovely and smooth, and I didn’t want to scratch it. This tape is fantastic because it is incredibly resistant to sanding yet comes off with no residue whatsoever.

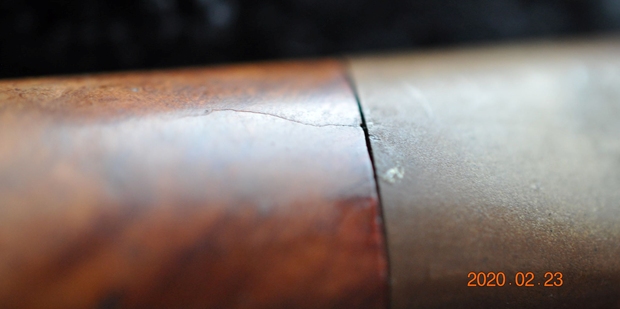

I applied some Before & After Restoration Balm and began to admire my work when my eyes saw something that was uncovered in my restoration: a thin craze line in the valley between the stummel and the shank. It was certainly not visible before, so the cleaning and sanding had revealed it. Even though the line was incredibly thin and seemingly shallow, I needed to address it. My first step was to ensure that the line would not continue to creep after I had repaired it. To that end, I took a micro-drill bit, inserted it in my Dremel, and very carefully drilled a hole in both ends of the line. That done, I carefully applied a tiny bead of cyanoacrylate adhesive to the tiny hole and the tiny line. Finally, I let it cure. This was a great success – I was really pleased with how the repair looked.

I applied some Before & After Restoration Balm and began to admire my work when my eyes saw something that was uncovered in my restoration: a thin craze line in the valley between the stummel and the shank. It was certainly not visible before, so the cleaning and sanding had revealed it. Even though the line was incredibly thin and seemingly shallow, I needed to address it. My first step was to ensure that the line would not continue to creep after I had repaired it. To that end, I took a micro-drill bit, inserted it in my Dremel, and very carefully drilled a hole in both ends of the line. That done, I carefully applied a tiny bead of cyanoacrylate adhesive to the tiny hole and the tiny line. Finally, I let it cure. This was a great success – I was really pleased with how the repair looked.

I had to sand this area again, of course, so I applied my hockey tape all over the place (see photo) and went to work with some sandpaper and Micromesh pads. I then rubbed in some more Before & After Restoration Balm and finally saw the beauty of my work.

I had to sand this area again, of course, so I applied my hockey tape all over the place (see photo) and went to work with some sandpaper and Micromesh pads. I then rubbed in some more Before & After Restoration Balm and finally saw the beauty of my work. Off to the bench polisher I went. I applied some White Diamond and a few coats of carnauba wax and they added the finishing touch. This Savinelli Nonpareil 9614 bent billiard was in need of a reminder of its beauty and Italian heritage. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the “Italy” pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the Savinelli Nonpareil 9614 bent billiard are as follows: length 4¾ in. (121 mm); height 5⅛ in. (130 mm); bowl diameter 1⅝ in. (40 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅞ oz. (55 g). I hope you enjoyed reading the story of this restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

Off to the bench polisher I went. I applied some White Diamond and a few coats of carnauba wax and they added the finishing touch. This Savinelli Nonpareil 9614 bent billiard was in need of a reminder of its beauty and Italian heritage. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the “Italy” pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the Savinelli Nonpareil 9614 bent billiard are as follows: length 4¾ in. (121 mm); height 5⅛ in. (130 mm); bowl diameter 1⅝ in. (40 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅞ oz. (55 g). I hope you enjoyed reading the story of this restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.