by Steve Laug

In the latest box of pipes I received from Jeff were two Malaga Pipes to work on. The first of those on the table was an interesting Malaga I would call a large decorative straight Egg (https://rebornpipes.com/2024/09/15/what-an-interesting-malaga-hand-made-egg-to-convert-to-an-egg/). The second one is a bent egg with rustication patterns around the bowl and shank. We purchased both on 06/23/24 off eBay from a seller in Farmington Hills, Michigan, USA. The grain on the smooth portions of this pipe is also quite nice. There was a rusticated leaf shape on the left side of the bowl curving from the top edge of the bowl down and over the underside of the bowl. There was also a rustication pattern on the right side of the shank end and on the underside. It is another pattern of rustication that I have never seen before on the Malaga pipes that I have worked on. It was obviously another favourite of the previous pipeman. It is stamped on the left side of the shank and read “MALAGA” [over] Custom Carved. The finish was dirty and worn. There were tars and oils ground into the surface of the briar. The bowl had a thick cake that flowed over the top of the rim top. The top, inner and outer edge has heavy damage on the right side of the bowl. There was lava flowing over the edges down the first 1/4 inch of the bowl. It was hard to clearly assess the damage to the inner edge. The condition of the rim edge and top would become clear in the cleaning process. The vulcanite taper stem was vulcanite. It was oxidized, calcified and there was chatter and tooth marks on the top and the underside of the stem ahead of the button. Jeff took photos of the pipes before he started his clean up work.

Jeff took photos of the rim and bowl to show the cake and lava on the rim top and edges. The inner edge of the rim showed thick cake coming up to the top and flowing over the edge. The damage to the rim top is also very visible in the photo. The pipe was a dirty one but still a beauty. The vulcanite taper stem had tooth marks and chatter on the top and underside of the stem ahead of the button.

Jeff took photos of the rim and bowl to show the cake and lava on the rim top and edges. The inner edge of the rim showed thick cake coming up to the top and flowing over the edge. The damage to the rim top is also very visible in the photo. The pipe was a dirty one but still a beauty. The vulcanite taper stem had tooth marks and chatter on the top and underside of the stem ahead of the button.

The photos of the sides and heel of the bowl hint at the damage around the bowl sides from the rim top downward. The briar is quite nice all around the pipe. The oil curing/finish makes the grain really stand out on the bowl and shank.

The photos of the sides and heel of the bowl hint at the damage around the bowl sides from the rim top downward. The briar is quite nice all around the pipe. The oil curing/finish makes the grain really stand out on the bowl and shank.

Jeff took a photo of the stamping on the left side of the shank. It read “MALAGA” [over]Custom Carved as noted above. The stamping was clear and readable.

Jeff took a photo of the stamping on the left side of the shank. It read “MALAGA” [over]Custom Carved as noted above. The stamping was clear and readable.  For those of you who are unfamiliar with the brand, I am also including the link to a blog that I wrote that gives some of the history of the Malaga brand and the Malaga Pipe Shop in Royal Oak, Michigan in the USA. Here is the link – https://rebornpipes.com/2013/02/09/george-khoubesser-and-malaga-pipes/. That blog also includes links to a catalogue and the history of the pipemaker George Khoubesser. If you are interested to learn more then I invite you to follow the link to get a feel for the brand and the pipemaker.

For those of you who are unfamiliar with the brand, I am also including the link to a blog that I wrote that gives some of the history of the Malaga brand and the Malaga Pipe Shop in Royal Oak, Michigan in the USA. Here is the link – https://rebornpipes.com/2013/02/09/george-khoubesser-and-malaga-pipes/. That blog also includes links to a catalogue and the history of the pipemaker George Khoubesser. If you are interested to learn more then I invite you to follow the link to get a feel for the brand and the pipemaker.

I am also am including a link to some printed material on the Malaga brand that came to me from the daughter of George Koch (we purchased George’s pipes from his daughter) to help identify the particular stamping on the pipe. The link takes you to the entire collection of materials that were sent to me (https://rebornpipes.com/2019/02/27/malaga-pipes-catalogue-of-pipes-and-tobaccos/).

Jeff had cleaned up the pipe using his usual procedure. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime from around the bowl sides. It looked better but the rim top and outer edge was darkened and burned. He cleaned out the inside of the shank and the airway with alcohol, cotton swabs and pipe cleaners. The stem looked much better and the light tooth marks on both sides were still visible and would need a little work. I took photos of the pipe once I received it.

I took a photo of the rim top and the stem to show their condition. Jeff was able to clean up the cake and the lava overflow that was shown in the rim and bowl photos above. The rim top was another major mess. It was chipped and burned and was quite charred and soft. It was going to take some work and some topping to remove the damaged portion of the rim top. There was some darkening around the bowl edges and top. The right side of the rim is quite thin and the bowl is out of round. The stem looked better, though there were tooth marks and chatter on both sides ahead of the button.

I took a photo of the rim top and the stem to show their condition. Jeff was able to clean up the cake and the lava overflow that was shown in the rim and bowl photos above. The rim top was another major mess. It was chipped and burned and was quite charred and soft. It was going to take some work and some topping to remove the damaged portion of the rim top. There was some darkening around the bowl edges and top. The right side of the rim is quite thin and the bowl is out of round. The stem looked better, though there were tooth marks and chatter on both sides ahead of the button. I took a photo of the stamping on the shank to show that the clean up had not damaged it at all. It looked good. I removed the stem from the shank and took a photo of the parts to give a sense of what the pipe looks like.

I took a photo of the stamping on the shank to show that the clean up had not damaged it at all. It looked good. I removed the stem from the shank and took a photo of the parts to give a sense of what the pipe looks like. I started my work on the pipe by addressing the mess of the burned/charred rim top and edges. The briar was actually almost charcoal like and soft. The softness was not as deep as the previous one but the thin right side needed to be topped to added thickness. I topped it with a Dremel and sanding drum and then cleaned it up on a topping board with 220 grit sandpaper. The rim top was finally solid at this point as was the inner edge of the bowl.

I started my work on the pipe by addressing the mess of the burned/charred rim top and edges. The briar was actually almost charcoal like and soft. The softness was not as deep as the previous one but the thin right side needed to be topped to added thickness. I topped it with a Dremel and sanding drum and then cleaned it up on a topping board with 220 grit sandpaper. The rim top was finally solid at this point as was the inner edge of the bowl.  I worked on the inner edge of the rim with a wooden sphere and a piece of 220 grit sandpaper. It took some work to smooth out the edge and bring it back to round. It is significantly shorter in height but the soft wood is gone and the rim top is solid. I worked over the rim edge and top with a 320 grit sanding pad to smooth out the bevel. I was liking the way it turned out.

I worked on the inner edge of the rim with a wooden sphere and a piece of 220 grit sandpaper. It took some work to smooth out the edge and bring it back to round. It is significantly shorter in height but the soft wood is gone and the rim top is solid. I worked over the rim edge and top with a 320 grit sanding pad to smooth out the bevel. I was liking the way it turned out. I smoothed out the bevel of the rim top with a folded piece of 220 grit sandpaper and a 320 gir sanding pad. I stained the rim top with a Cherry stain pen to match the colour of the rest of the bowl. It is looking quite good at this point.

I smoothed out the bevel of the rim top with a folded piece of 220 grit sandpaper and a 320 gir sanding pad. I stained the rim top with a Cherry stain pen to match the colour of the rest of the bowl. It is looking quite good at this point.  I wiped the bowl down with a damp cloth and sanded the smooth portions of the bowl with 320-3500 grit sanding pads. The finish began to have a rich shine. I was able to blend the repairs on the rim top into the surrounding briar and the bowl looked very good.

I wiped the bowl down with a damp cloth and sanded the smooth portions of the bowl with 320-3500 grit sanding pads. The finish began to have a rich shine. I was able to blend the repairs on the rim top into the surrounding briar and the bowl looked very good.

I polished the bowl sides and the smooth rim top with micromesh sanding pads. I dry sanded it with 1500-12000 grit micromesh pads (I forgot to take photos of the sanding with the micromesh pads). I wiped it down after each pad. It really began to be beautiful.

I polished the bowl sides and the smooth rim top with micromesh sanding pads. I dry sanded it with 1500-12000 grit micromesh pads (I forgot to take photos of the sanding with the micromesh pads). I wiped it down after each pad. It really began to be beautiful.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I worked it into the twin rings in the bowl cap with a shoe brush to get deep in the grooves. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I worked it into the twin rings in the bowl cap with a shoe brush to get deep in the grooves. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

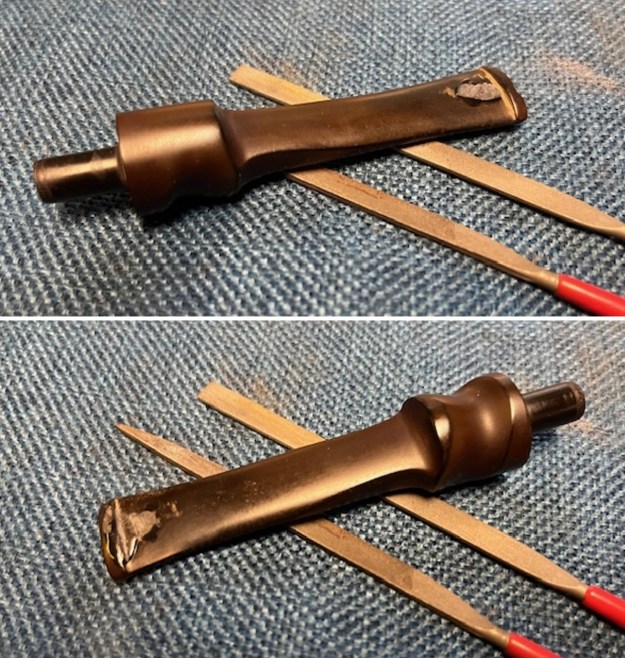

I set the bowl aside and turned my attention to the stem. I heated the stem with a lighter to soften the vulcanite. Once it was flexible I bent it to the proper angle. It looked much better.

I set the bowl aside and turned my attention to the stem. I heated the stem with a lighter to soften the vulcanite. Once it was flexible I bent it to the proper angle. It looked much better. I “painted” the tooth marks with the flame of a lighter to lift them. I was able to lift them significantly. There were several deeper ones that I filled with clear CA glue. Once the glue hardened I flattened them with a small file. I sanded them with 220 grit sandpaper to blend them further into the surface of the stem.

I “painted” the tooth marks with the flame of a lighter to lift them. I was able to lift them significantly. There were several deeper ones that I filled with clear CA glue. Once the glue hardened I flattened them with a small file. I sanded them with 220 grit sandpaper to blend them further into the surface of the stem.

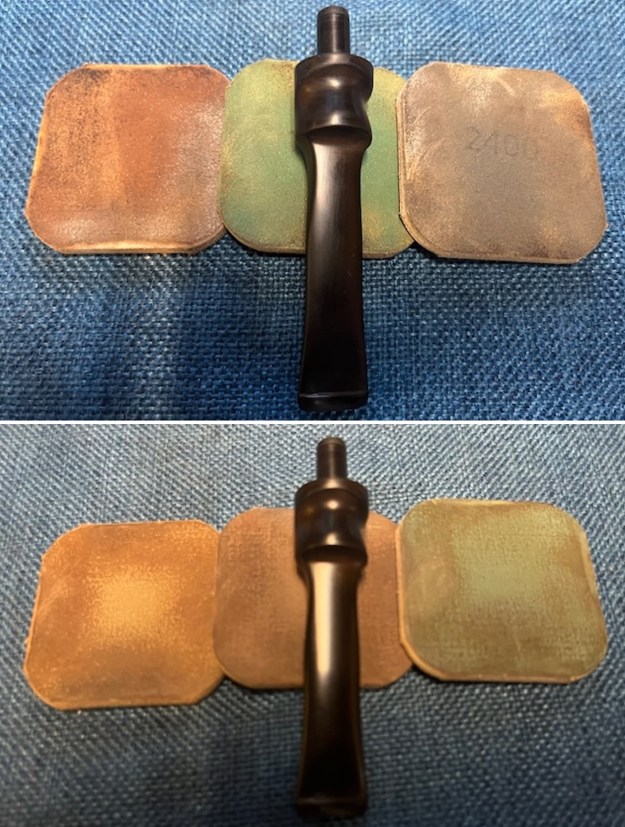

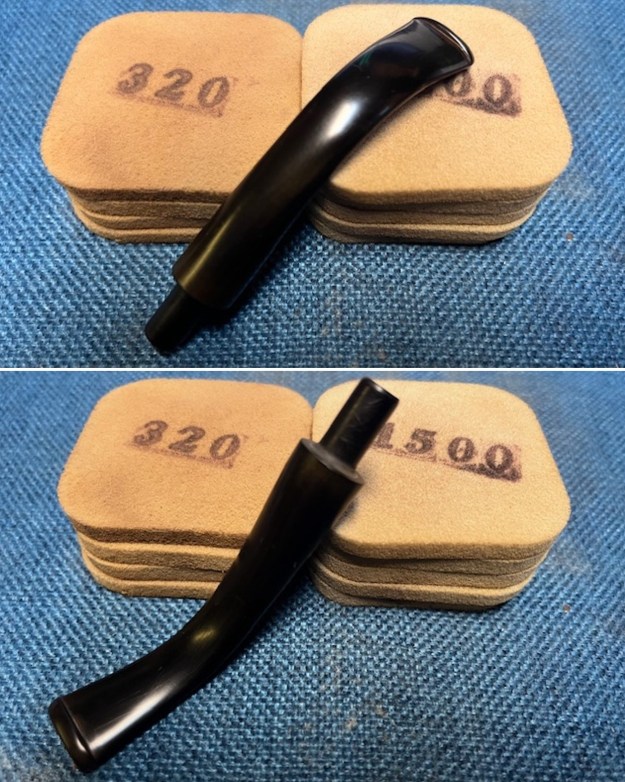

I sanded the stem with the 2 inch square 320-3500 grit sanding pads. I wiped down the stem after each sanding pad. I was able to remove the tooth marks and chatter on both sides with the pads. The stem looked very good.

I sanded the stem with the 2 inch square 320-3500 grit sanding pads. I wiped down the stem after each sanding pad. I was able to remove the tooth marks and chatter on both sides with the pads. The stem looked very good. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I did a final hand polish of the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I did a final hand polish of the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I put the stem back on the reshaped bowl of this “MALAGA” Custom Carved Bent Egg and took it to the buffer. I buffed the bowl and stem with Blue Diamond to polish the briar and the vulcanite. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. I am amazed at how well it turned out. The finished pipe is shown in the photos below. This is beautiful smooth finished “MALAGA” Custom Carved Bent Egg and the vulcanite taper stem combine to give the pipe a great look. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.87 ounces/53 grams. This is another pipe that I will be putting on the rebornpipes online store in the American Pipe Makers and Pipemaking Companies Section shortly, if you are interested in adding it to your collection. Thanks for walking through the restoration with me on this beauty! As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.

I put the stem back on the reshaped bowl of this “MALAGA” Custom Carved Bent Egg and took it to the buffer. I buffed the bowl and stem with Blue Diamond to polish the briar and the vulcanite. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. I am amazed at how well it turned out. The finished pipe is shown in the photos below. This is beautiful smooth finished “MALAGA” Custom Carved Bent Egg and the vulcanite taper stem combine to give the pipe a great look. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.87 ounces/53 grams. This is another pipe that I will be putting on the rebornpipes online store in the American Pipe Makers and Pipemaking Companies Section shortly, if you are interested in adding it to your collection. Thanks for walking through the restoration with me on this beauty! As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.