Blog by Steve Laug

After working on the pair of Turkish Meerschaum pipes I wrote about earlier I decided to keep working on meers (https://rebornpipes.com/2019/07/21/cleaning-up-a-pair-of-no-name-turkish-made-meerschaums/). The next thing on the table was a cased set of meerschaums that included a straight billiard, a bent billiard a cigar holder and a broken cigarette holder. All were smooth meerschaum with red Bakelite or Redmanol stems. All had bone tenons directly screwed into threaded mortises in the meerschaum. There was no stamping on the pipes and holders or the stems. The box itself was covered in what looked like alligator skin with brass hinges and clasps. On the inside the case was lined in an off white preformed velveteen fabric. There was a corner ribbon across the left side of the lid that read Aristocrat. The straight billiard had been smoked pretty heavily and there was a cake in the bowl and the rim top had a thick lava coat. The exterior of the bowl was dirty. The stem had tooth marks and chatter on both sides near the button. The second pipe – the bent billiard was unsmoked but dirty with dust and debris of time. The cigar holder had been lightly smoked and there were tooth marks and chatter on in near the button. The cigarette holder was broken and two parts and the stem remained. There was a missing piece from the front of the holder. It was unused and broken. I took photos of the case and the pipes and holders before I started my work on it.

I took photos of each of the pieces in the collection. The first set of photos shows the smoked straight billiard.

I took photos of each of the pieces in the collection. The first set of photos shows the smoked straight billiard.

The second set of photos shows the unsmoked bent billiard.

The second set of photos shows the unsmoked bent billiard.

The third set shows the cigar holder.

The third set shows the cigar holder.  The fourth set shows the broken cigarette holder. All four of the pieces were dirty, some more than others but all needing work.

The fourth set shows the broken cigarette holder. All four of the pieces were dirty, some more than others but all needing work. From what I could find on Pipephil’s site I found a listing for Aristocrat linking it to John Redman Ltd. in England (http://www.pipephil.eu/logos/en/logo-a7.html). The site says that it was an export brand from the company. In looking at the various stampings in the photos below I found that the Aristocrat stamping on the ribbon on the case above matches the second and third photo below.

From what I could find on Pipephil’s site I found a listing for Aristocrat linking it to John Redman Ltd. in England (http://www.pipephil.eu/logos/en/logo-a7.html). The site says that it was an export brand from the company. In looking at the various stampings in the photos below I found that the Aristocrat stamping on the ribbon on the case above matches the second and third photo below. The photo below was a link on the site that took me to a photo of the John Redman LTD. and British Empire Pipe Com on Westland Place, Hackney, London, England. I think it is a nice historical touch to be able to include the photo.

The photo below was a link on the site that took me to a photo of the John Redman LTD. and British Empire Pipe Com on Westland Place, Hackney, London, England. I think it is a nice historical touch to be able to include the photo. I turned to Pipedia (https://pipedia.org/wiki/John_Redman_Ltd./British_Empire_Pipe_Co.) to see if I could learn a bit more about the company. I quote the full article below:

I turned to Pipedia (https://pipedia.org/wiki/John_Redman_Ltd./British_Empire_Pipe_Co.) to see if I could learn a bit more about the company. I quote the full article below:

John Redman Ltd. and British Empire Pipe Co. Other lines include Aristocrat, Buckingham, Buckingham Palace, Canberra, Captain Fortune, Dr John, Golden Square, Redonian, Richmond (not Sasieni), Twin Bore.

From these two sources it appears to me that this set of meerschaum pipes and holders was made for export by John Redman Ltd. I am not sure of the date as neither source gave clues to that information.

Given the information that I have in hand, I decided to start the restoration work on the straight meerschaum billiard. Only this pipe and the cigar holder had been smoked in the set so I figured why not start with the most smoked pipe – the most smoked billiard.

I took close up photos of the bowl and rim top as well as both sides of the Bakelite stem to show the condition that the pipe was in when I started. The bowl had a thin cake from top to bottom. There was a thick coat of lava on the surface of the rim – heavier toward the back than the front but all around. The stem was clean but had tooth chatter and light tooth marks on the top and underside ahead of the button.

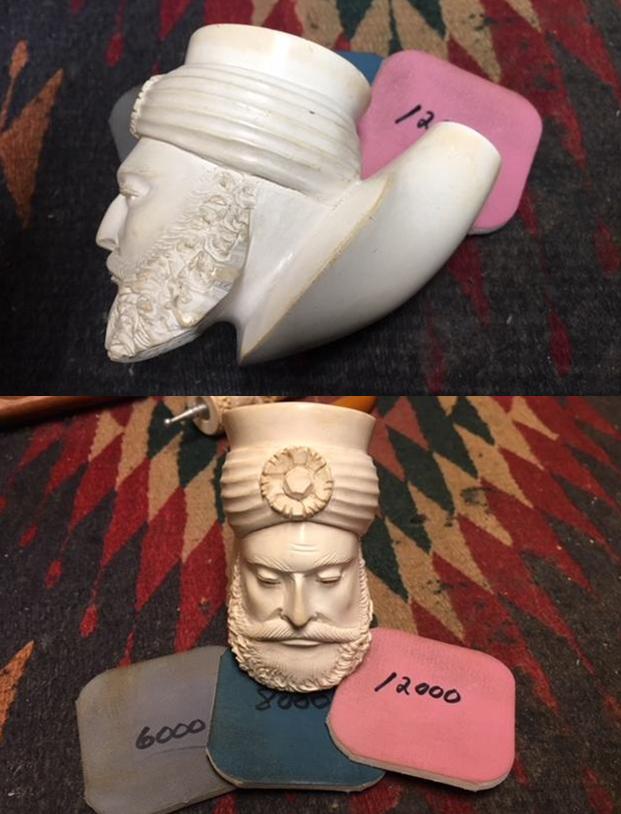

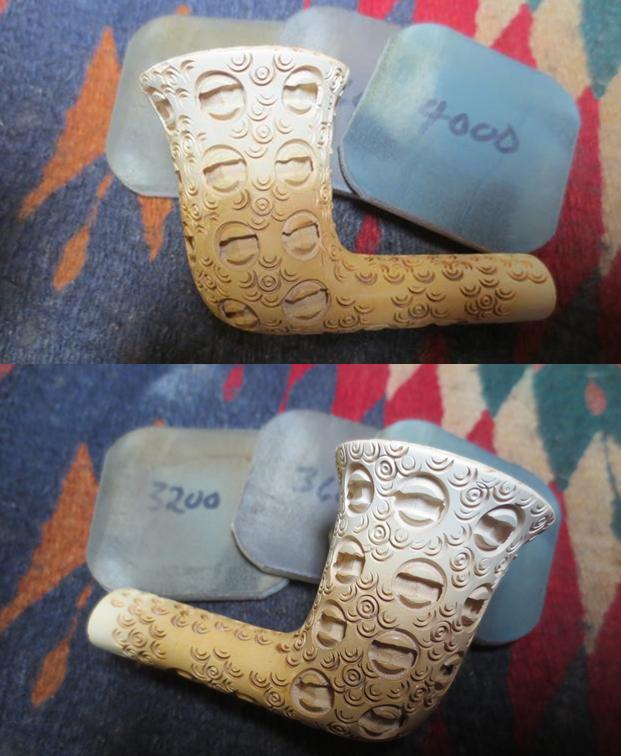

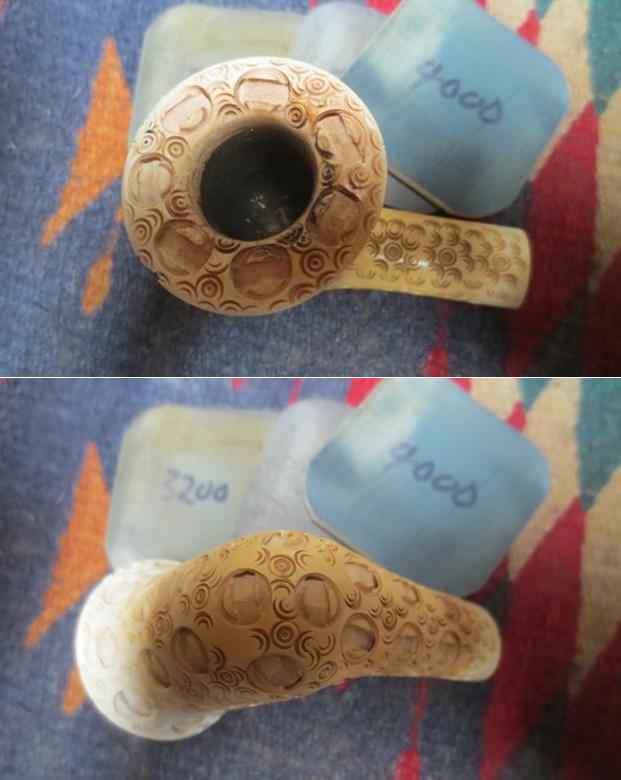

I took close up photos of the bowl and rim top as well as both sides of the Bakelite stem to show the condition that the pipe was in when I started. The bowl had a thin cake from top to bottom. There was a thick coat of lava on the surface of the rim – heavier toward the back than the front but all around. The stem was clean but had tooth chatter and light tooth marks on the top and underside ahead of the button. I used a 1500 grit micromesh sanding pad to start the rim top cleanup and sanded the outside of the bowl to start the cleanup process.

I used a 1500 grit micromesh sanding pad to start the rim top cleanup and sanded the outside of the bowl to start the cleanup process. I reamed out the cake in the bowl with a Savinelli Fitsall Pipe Knife. I took the cake back to bare meerschaum. I sanded the walls of the bowl with a piece of dowel wrapped with 220 grit sandpaper until they were smooth.

I reamed out the cake in the bowl with a Savinelli Fitsall Pipe Knife. I took the cake back to bare meerschaum. I sanded the walls of the bowl with a piece of dowel wrapped with 220 grit sandpaper until they were smooth. I decided to continue experimenting with a new product from Mark Hoover of Before & After Products. This one is a product he labels briar cleaner and it has the capacity of absorbing grime and dirt from the surface of briar. I decided to try it out this pair of meerschaum pipes. I rubbed the bowl down with some of his Briar Cleaner to see how it would work in this setting. In speaking to Mark he noted that the product is completely safe to use. The main product is even FDA approved edible. I rubbed it onto the bowl and rim top with my finger tips and worked it into the grime and grit on the bowl. I let it sit on the pipe for about 5 minutes before I rubbed it off with a microfibre cloth. I rinsed it under warm running water to remove the residue. I was pleasantly surprised by how clean the surface on the bowl looked when I was finished.

I decided to continue experimenting with a new product from Mark Hoover of Before & After Products. This one is a product he labels briar cleaner and it has the capacity of absorbing grime and dirt from the surface of briar. I decided to try it out this pair of meerschaum pipes. I rubbed the bowl down with some of his Briar Cleaner to see how it would work in this setting. In speaking to Mark he noted that the product is completely safe to use. The main product is even FDA approved edible. I rubbed it onto the bowl and rim top with my finger tips and worked it into the grime and grit on the bowl. I let it sit on the pipe for about 5 minutes before I rubbed it off with a microfibre cloth. I rinsed it under warm running water to remove the residue. I was pleasantly surprised by how clean the surface on the bowl looked when I was finished.

Since the cleaner had worked so well I decided to try out the Restoration Balm on the meerschaum as well. I rubbed the bowl down with Before & After Restoration Balm. I worked it into the meerschaum and let it sit for a short time. I buffed it off with a microfibre cloth to bring it some life. Once again I was very surprised at how well it worked. I sent Mark Hoover a note about this experiment. He was pretty amazed at the results and said he had not thought of using it for meerschaum but was not surprised as it was made to absorb grit and grime from the surface of a pipe.

Since the cleaner had worked so well I decided to try out the Restoration Balm on the meerschaum as well. I rubbed the bowl down with Before & After Restoration Balm. I worked it into the meerschaum and let it sit for a short time. I buffed it off with a microfibre cloth to bring it some life. Once again I was very surprised at how well it worked. I sent Mark Hoover a note about this experiment. He was pretty amazed at the results and said he had not thought of using it for meerschaum but was not surprised as it was made to absorb grit and grime from the surface of a pipe.

I cleaned out the internals of the airway in the shank and the stem as well as the mortise and the entrance of the airway into the bottom of the bowl. I used alcohol, cotton swabs and pipe cleaners to remove the grime. It was surprisingly clean for a pipe that was as heavily smoked as this one was.

I cleaned out the internals of the airway in the shank and the stem as well as the mortise and the entrance of the airway into the bottom of the bowl. I used alcohol, cotton swabs and pipe cleaners to remove the grime. It was surprisingly clean for a pipe that was as heavily smoked as this one was.  I set the bowl aside and worked on the stem. I sanded the tooth chatter and marks on both sides of the stem with a folded piece of 220 grit sandpaper and polished out the scratches from the sandpaper with a folded piece of 400 grit wet dry sandpaper. I wiped the stem down with Obsidian Oil and set it aside to dry out.

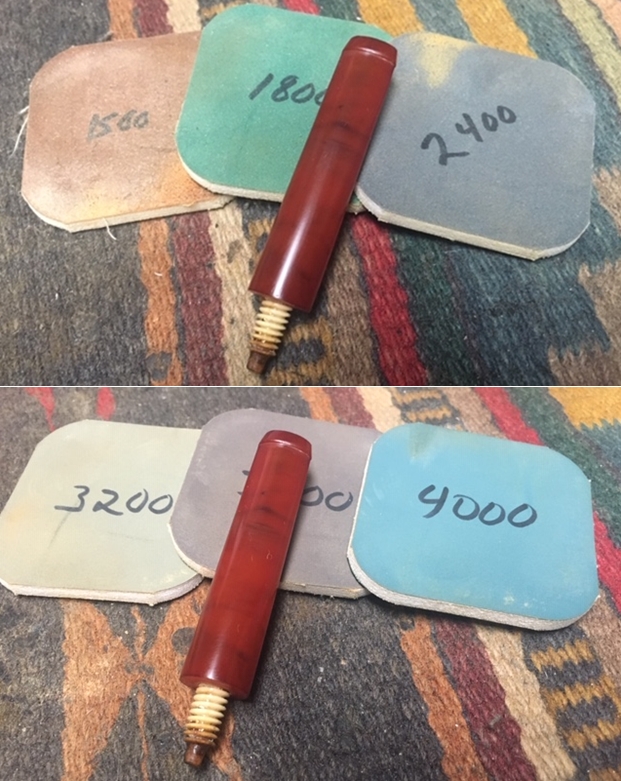

I set the bowl aside and worked on the stem. I sanded the tooth chatter and marks on both sides of the stem with a folded piece of 220 grit sandpaper and polished out the scratches from the sandpaper with a folded piece of 400 grit wet dry sandpaper. I wiped the stem down with Obsidian Oil and set it aside to dry out. I wet sanded the stem with 1500 -12000 grit micromesh pads to polish it. I wiped it down with Obsidian Oil on a cloth after each sanding pad. After the 12000 grit pad I wiped the stem down a final time with Obsidian Oil and set it aside to dry.

I wet sanded the stem with 1500 -12000 grit micromesh pads to polish it. I wiped it down with Obsidian Oil on a cloth after each sanding pad. After the 12000 grit pad I wiped the stem down a final time with Obsidian Oil and set it aside to dry.

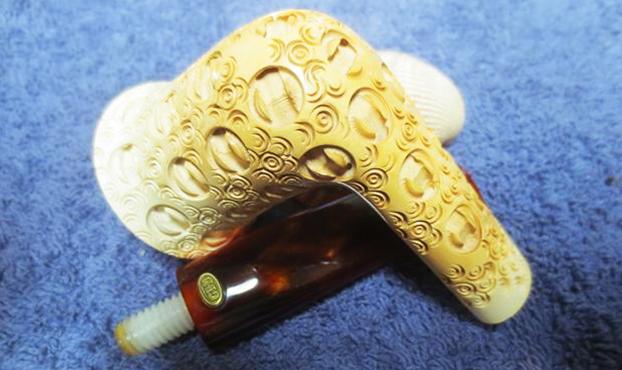

I put the bowl and stem back together. I polished the pipe with Blue Diamond to remove the remaining minute scratches in the briar and the Bakelite. I gave the bowl and stem several coats of Conservator’s Wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The contrast of the beautiful clean meerschaum with light colouring of age and the polished red Bakelite/Redmanol stem looked amazing. This older, beautiful, well made John Redman Ltd. Meerschaum straight billiard with a Redmanol stem will only get better with age. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 1/4 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: 7/8 of an inch. This is the first pipe from the Aristocrat pipe set in the photos at the beginning of this blog. The restoration of the remaining pieces in the set – the other pipe, the cigar holder and cigarette holder will be shown in future blogs. Thanks for walking through the restoration with me. Cheers.

I put the bowl and stem back together. I polished the pipe with Blue Diamond to remove the remaining minute scratches in the briar and the Bakelite. I gave the bowl and stem several coats of Conservator’s Wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The contrast of the beautiful clean meerschaum with light colouring of age and the polished red Bakelite/Redmanol stem looked amazing. This older, beautiful, well made John Redman Ltd. Meerschaum straight billiard with a Redmanol stem will only get better with age. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 1/4 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: 7/8 of an inch. This is the first pipe from the Aristocrat pipe set in the photos at the beginning of this blog. The restoration of the remaining pieces in the set – the other pipe, the cigar holder and cigarette holder will be shown in future blogs. Thanks for walking through the restoration with me. Cheers.