Blog by Steve Laug

The next pipe on the worktable is an American made pipe from the workshop of J.M. Boswell. It is a rusticated 1/4 bent apple with an amber acrylic saddle stem. The pipe came to us from eBay from a seller in Jordan, Minnesota, USA. The pipe is very dirty with a thick cake in the bowl and lava on the smooth rim top. The rim edge looks to be okay but it was hard to know what was under the lava coat on the top and edges. It is signed J.M. Boswell [over] 2006 followed by U.S.A. The finish was dusty and there was dust in the rustication and ground into the finish around the sides of the bowl. The amber acrylic saddle stem is dirty and has light tooth marks and chatter on the top and underside near the button. Jeff took some photos of the pipe before he started his cleanup work.

He took photos of the bowl and rim top to show their general condition. You can see the lava on the rim top and the thick cake in the bowl. It was hard to know the condition of the bowl edge prior to cleaning. The stem is dirty and there are light tooth marks and chatter on both sides near the button.

He took photos of the bowl and rim top to show their general condition. You can see the lava on the rim top and the thick cake in the bowl. It was hard to know the condition of the bowl edge prior to cleaning. The stem is dirty and there are light tooth marks and chatter on both sides near the button.

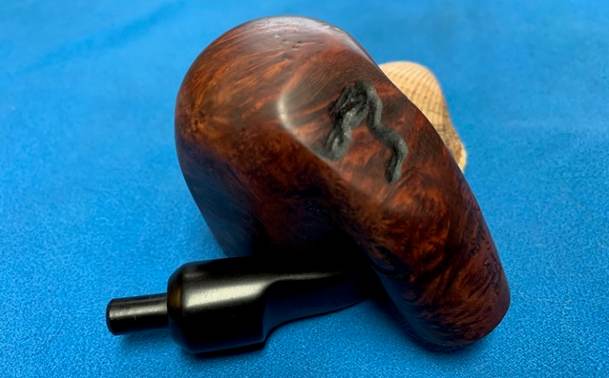

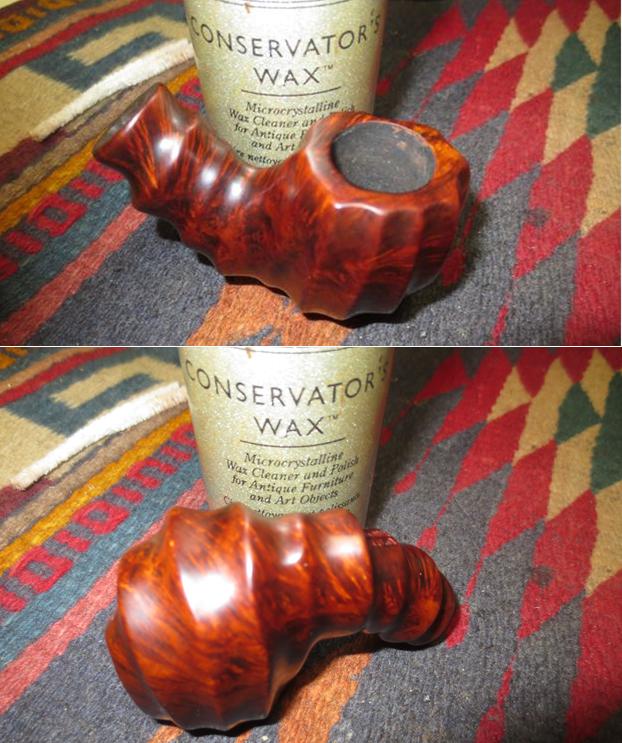

Jeff took some photos of the sides and heel of the bowl to give an idea of the rustication around the bowl and the shank. It has some great patterns around the bowl sides and bottom – a mix of random patterns with valleys and peaks. I cannot wait to see what it looks like once it is cleaned and polished.

Jeff took some photos of the sides and heel of the bowl to give an idea of the rustication around the bowl and the shank. It has some great patterns around the bowl sides and bottom – a mix of random patterns with valleys and peaks. I cannot wait to see what it looks like once it is cleaned and polished.

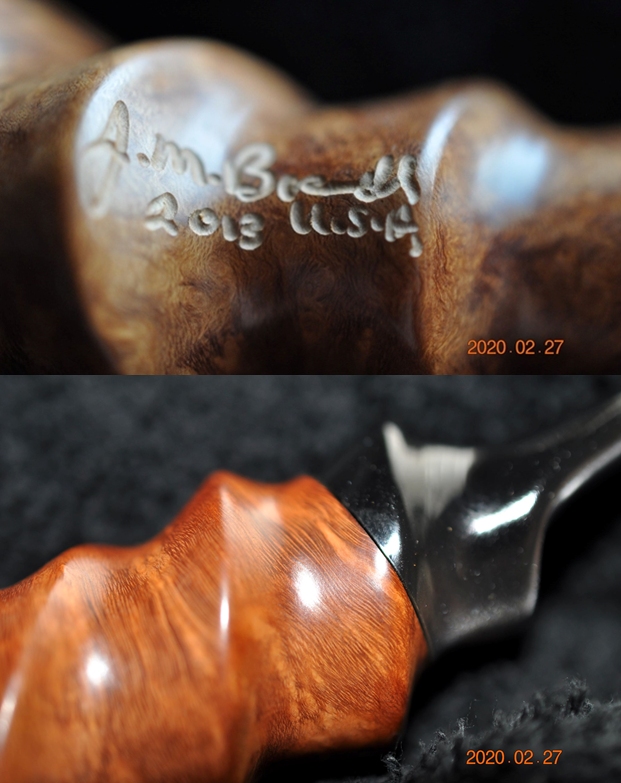

He took a photo of the stamping on the left topside of the diamond shank to capture it for me. It is clear and readable. The J.M. Boswell signature with the date it was carved and U.S.A.

He took a photo of the stamping on the left topside of the diamond shank to capture it for me. It is clear and readable. The J.M. Boswell signature with the date it was carved and U.S.A.  If you have been following the blog for any length of time you have come to know that when I am working on interesting old pipes (even sometimes those not so interesting) I like to know a bit about the background of the brand. I like to “meet” the carver to get a feel for their work and style.

If you have been following the blog for any length of time you have come to know that when I am working on interesting old pipes (even sometimes those not so interesting) I like to know a bit about the background of the brand. I like to “meet” the carver to get a feel for their work and style.

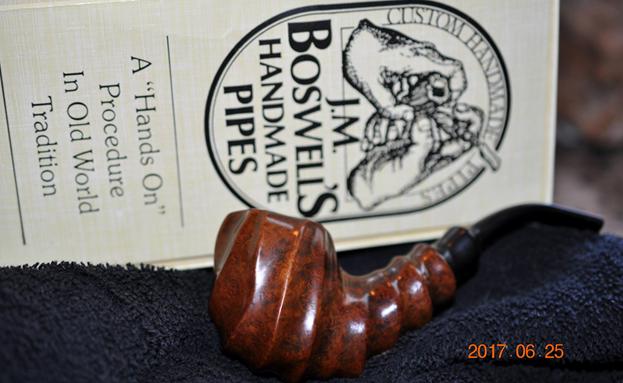

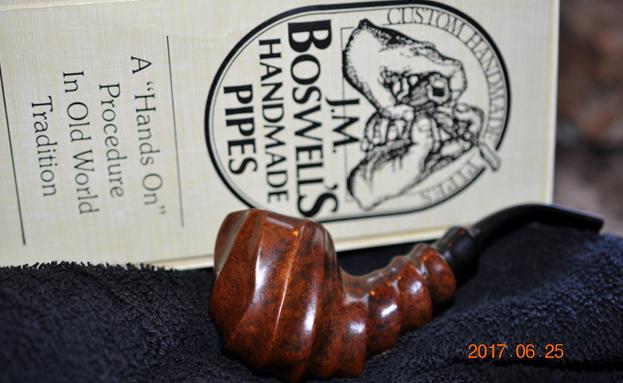

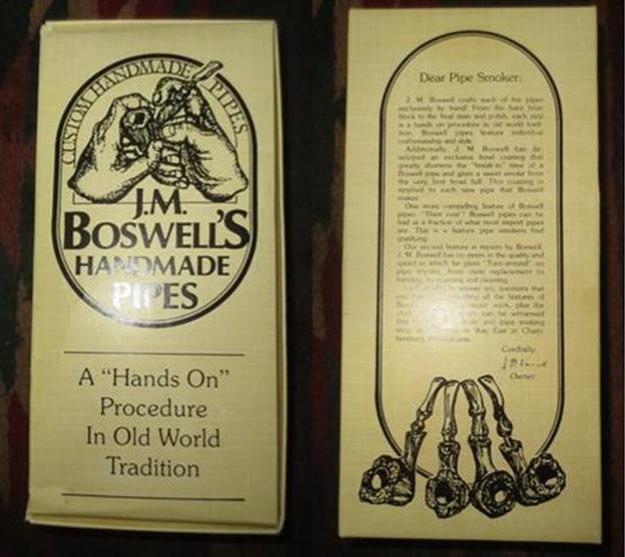

In July, 2017 I restored a Boswell Twist pipe, a 2003 and had done some research into the brand (https://rebornpipes.com/2017/07/19/refurbishing-a-boswell-2003-spiral-twist-bent-billiard/). I turned to that blog and reread the information that I had included there. I took the liberty to include the information that I included from the box that came with that pipe that below.

The backside of the box reads: Dear Pipe Smoker: J.M. Boswell crafts each of his pipes exclusively by hand! From the bare briar block to the final stain and polish, each step is a hands on procedure in old world tradition. Boswell pipes feature individual craftsmanship and style.

Additionally, J.M. Boswell has developed an exclusive bowl coating that greatly shortens the “break-in” time of a Boswell pipe and gives a sweet smoke from the very first bowl full. This coating is applied to each new pipe that Boswell makes.

One more compelling feature of Boswell pipes: “Their cost”! Boswell pipes can be had at a fraction of what most import pipes are. This is a feature pipe smokers find gratifying.

Our second feature is repairs by Boswell. J.M. Boswell has no peers in the quality and speed in which he gives “Turn-around” on pipe repairs, from stem replacement to banding, to reaming and cleaning.

I will be glad to answer any questions that you have regarding all the features of Boswell’s pipes, my repair work, plus the crafting process which can be witnessed first hand at our store and pipe making shop at 586 Lincoln Way East in Chambersburg, Pennsylvania.

Cordially J.M. Boswell, Owner.

I then turned to the Boswell Pipe and Tobacco Shop site (https://boswellpipes.com/product-category/boswell-pipes/). The description of the pipes in that section of the site parallels what I found above. I quote:

In the creation of these exquisite smoking pipes, we use the finest quality briar – “cream of the crop” is what the proprietor of the mill calls it. Boswell Pipes have their own special bowl coating for easy break-in. J.M. has used his special coating for Boswell Pipes since 1982. 100% natural coating, which will force the briar wood to absorb the moisture and heat. For the finishing touch, J.M. hand inscribes his signature into the briar. J.M. dates the year and proudly declares made in the USA “J.M. Boswell 2018 U.S.A.”.

I also found some photos of the shop online that I include as well. I It looks like it would be a great place to visit and spend time enjoying. One day I may get to do that. We shall see!  Now I had a pretty good idea of how the pipe was stamped and made. With that information I moved forward to work on the pipe itself and see what I had to do with it. Jeff had done an amazing job in removing all of the cake and the lava on the rim top. He had reamed the bowl with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He took the cake back to bare briar so we could check the walls for damage. They looked to be in good condition. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime on the bowl and rim and was able to remove the lava and dirt. He cleaned out the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol until they came out clean. He cleaned the stem with Soft Scrub to remove the grime on the exterior and cleaned out the airway with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed if off and recleaned the inside of the stem with alcohol and pipe cleaners. I took photos of the pipe before I started my part of the restoration.

Now I had a pretty good idea of how the pipe was stamped and made. With that information I moved forward to work on the pipe itself and see what I had to do with it. Jeff had done an amazing job in removing all of the cake and the lava on the rim top. He had reamed the bowl with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He took the cake back to bare briar so we could check the walls for damage. They looked to be in good condition. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime on the bowl and rim and was able to remove the lava and dirt. He cleaned out the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol until they came out clean. He cleaned the stem with Soft Scrub to remove the grime on the exterior and cleaned out the airway with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed if off and recleaned the inside of the stem with alcohol and pipe cleaners. I took photos of the pipe before I started my part of the restoration.

I took some photos of the rim top and stem. The rim top and bowl looked very good. The scratching and marks on the rim top are visible in the photo. The close up photos of the stem shows the light tooth marks and chatter on the top and underside of the stem near the button.

I took some photos of the rim top and stem. The rim top and bowl looked very good. The scratching and marks on the rim top are visible in the photo. The close up photos of the stem shows the light tooth marks and chatter on the top and underside of the stem near the button.  I took a photo of the stamping on the underside of the shank to show the condition after the cleanup. This stamping is a signature done with an engraver of some sort. I removed the stem and took a photo of the parts of the pipe.

I took a photo of the stamping on the underside of the shank to show the condition after the cleanup. This stamping is a signature done with an engraver of some sort. I removed the stem and took a photo of the parts of the pipe. I started my part of the restoration work on this pipe by addressing the damage to the front top and edge of the rim. I used a folded piece of 220 grit sandpaper to remove the damage to the bowl.

I started my part of the restoration work on this pipe by addressing the damage to the front top and edge of the rim. I used a folded piece of 220 grit sandpaper to remove the damage to the bowl. I started polishing the rim top with 320-3500 grit sanding pads. I wiped down the top after each sanding pad to remove the sanding debris. By the end it looked much better.

I started polishing the rim top with 320-3500 grit sanding pads. I wiped down the top after each sanding pad to remove the sanding debris. By the end it looked much better.

I also sanded it with the micromesh sanding pads – dry sanding with 1500-12000 grit pads. I forgot to take photos of the rim top at that point. I used a Cherry stain pen to restrain the newly sanded rim top. I looked very good with the fresh coat of stain.

I also sanded it with the micromesh sanding pads – dry sanding with 1500-12000 grit pads. I forgot to take photos of the rim top at that point. I used a Cherry stain pen to restrain the newly sanded rim top. I looked very good with the fresh coat of stain. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for about ten minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

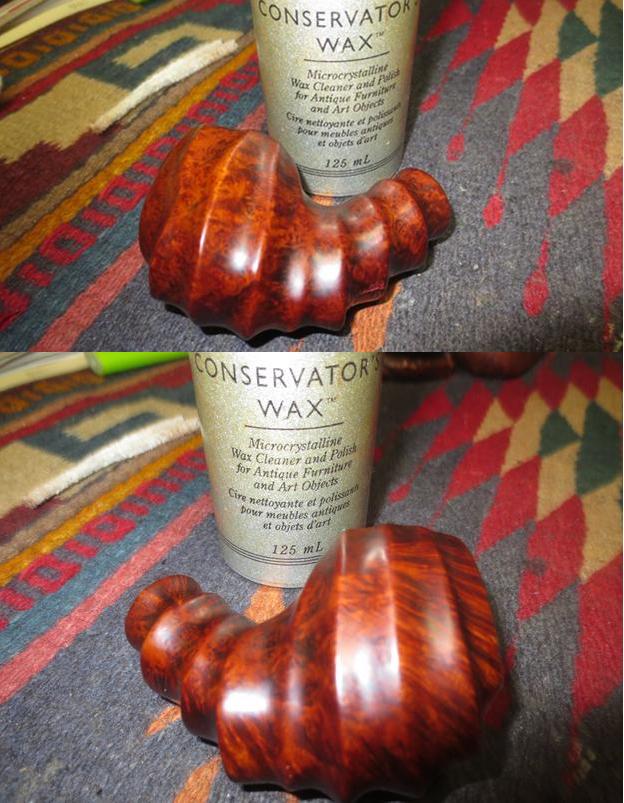

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for about ten minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and polished it with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I set the bowl aside and polished it with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

This Boswell USA 2006 1/4 Bent Apple is a nice looking pipe. The finish looks very good and rustication depths and peaks were very well done. I put the stem back on the bowl and buffed the pipe lightly with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank sides during the process. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I followed that by buffing it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is a good example of a Boswell Hand Made pipe. The flow of the finish and the way the shape follows it is very well done. Give the finished pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 3/4 inches, Outside diameter of the bowl: 1 1/2 inches, Chamber diameter: 1 inch. The weight of the pipe is 2.50 ounces/71 grams. This interesting Boswell Hand Made Rusticated Apple is a great looking pipe. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to the rebornpipes store in the American Pipemakers Section soon. If you want to add it to your collection send me an email or a message! Thanks for your time.

This Boswell USA 2006 1/4 Bent Apple is a nice looking pipe. The finish looks very good and rustication depths and peaks were very well done. I put the stem back on the bowl and buffed the pipe lightly with Blue Diamond on the buffing wheel. I carefully avoided the stamping on the shank sides during the process. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I followed that by buffing it with a clean buffing pad on the buffer. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished pipe is a good example of a Boswell Hand Made pipe. The flow of the finish and the way the shape follows it is very well done. Give the finished pipe a look in the photos below. I can only tell you that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 3/4 inches, Outside diameter of the bowl: 1 1/2 inches, Chamber diameter: 1 inch. The weight of the pipe is 2.50 ounces/71 grams. This interesting Boswell Hand Made Rusticated Apple is a great looking pipe. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be adding it to the rebornpipes store in the American Pipemakers Section soon. If you want to add it to your collection send me an email or a message! Thanks for your time.