Blog by Steve Laug

This is a continuation of the work that began with an email from Anthony, a reader of rebornpipes asking if I would be willing to help him clean up his Dad’s pipes. He wrote; “I have a few pipes (8 or so) that haven’t been smoked in 15 years. They were my dad’s. I would like to get someone to restore them”. We chatted back and forth via email and the long and short of the story is that I have eight of his Dad’s pipes in my shop now to work on. The photo below shows the mixture of pipes that he sent me. There are some interesting shapes and most are very dirty and have very little if any of the original finish left on the briar. All have an overflow of carbon on the rim top and all have damaged stems and buttons. Anthony remembers his Dad smoking them throughout the years he was growing up so they went from regular use to being boxed and stored. They will need a lot of TLC to bring life back to them but it should be fun to give it a go. I went through the pipes and assessed their condition and contacted him and got the go ahead to proceed on the lot. I have completed the restoration of three of the pipes. I put red X’s through the pipes in the above photo to show the ones that I have completed. The next pipe I chose to work on was the full bent briar with a stem that turned over the bowl to make it a pocket pipe – it is the second pipe down on the right hand column in the above photo. I have circled it in red. It is an interestingly shaped full bent pipe with the shank and the bowl being side by side with no gap between them. The only stamping on the pipe is on the underside of the shank at the stem/shank junction and reads ITALY. The bowl was very dirty and the finish was worn to the point that it was lifeless looking. Once again, not only did it have a thick cake in the bowl and some darkening and lava overflowing onto the rim top it also appeared that Anthony’s Dad had laid the pipe aside mid smoke. The bowl was about 1/3 full of partially burned tobacco that had hardened and dried with age. The bent, vulcanite stem was the least chewed of the collection and had some tooth chatter and light marks on both sides around the button. It was also oxidized and would need to be cleaned. I took photos of the pipe to show its overall condition when it arrived at my work table.

I have completed the restoration of three of the pipes. I put red X’s through the pipes in the above photo to show the ones that I have completed. The next pipe I chose to work on was the full bent briar with a stem that turned over the bowl to make it a pocket pipe – it is the second pipe down on the right hand column in the above photo. I have circled it in red. It is an interestingly shaped full bent pipe with the shank and the bowl being side by side with no gap between them. The only stamping on the pipe is on the underside of the shank at the stem/shank junction and reads ITALY. The bowl was very dirty and the finish was worn to the point that it was lifeless looking. Once again, not only did it have a thick cake in the bowl and some darkening and lava overflowing onto the rim top it also appeared that Anthony’s Dad had laid the pipe aside mid smoke. The bowl was about 1/3 full of partially burned tobacco that had hardened and dried with age. The bent, vulcanite stem was the least chewed of the collection and had some tooth chatter and light marks on both sides around the button. It was also oxidized and would need to be cleaned. I took photos of the pipe to show its overall condition when it arrived at my work table.

I turned the stem over the bowl to show how it was used as a pocket pipe and took a photo. The stem turned gave the pipe a better profile and it could easily be stuffed in a coat or vest pocket for use and reuse.

I turned the stem over the bowl to show how it was used as a pocket pipe and took a photo. The stem turned gave the pipe a better profile and it could easily be stuffed in a coat or vest pocket for use and reuse. I took some close up photos of the bowl, rim top and the stem to show what I was going to be dealing with on this pipe. The rim top was dirty and lava covered but the inner edge appeared to be in decent condition. The stem was lightly oxidized and it had the least chewing damage of any of these pipes. There were light marks and tooth chatter on both sides of the stem and button.

I took some close up photos of the bowl, rim top and the stem to show what I was going to be dealing with on this pipe. The rim top was dirty and lava covered but the inner edge appeared to be in decent condition. The stem was lightly oxidized and it had the least chewing damage of any of these pipes. There were light marks and tooth chatter on both sides of the stem and button. I took photos of the bowl from various angles to try to capture the condition of the pipe for you. The briar appears to have some interesting grain around the sides. There is one fill in the bottom of the bowl that is chipped and damaged.

I took photos of the bowl from various angles to try to capture the condition of the pipe for you. The briar appears to have some interesting grain around the sides. There is one fill in the bottom of the bowl that is chipped and damaged.

I shared the tribute that I asked Anthony to write about his Dad and his pipe smoking in the last blog post and will share it again now. I always find that it gives me a sense of the previous pipeman when I work on a pipe from an estate. Anthony sent me a great tribute. Here it is in his words:

I shared the tribute that I asked Anthony to write about his Dad and his pipe smoking in the last blog post and will share it again now. I always find that it gives me a sense of the previous pipeman when I work on a pipe from an estate. Anthony sent me a great tribute. Here it is in his words:

When my dad died 6 years ago, my mom asked if I wanted my dad’s old pipes. He was a long time pipe smoker, ever since I was a kid I can remember him sitting on the couch smoking his pipe inside. He worked at IBM and used to smoke his pipe in his office before they changed the laws in California. So you can imagine he had quite the collection over the years.

I took his pipes and put them in storage for a few years, I myself recently quit smoking cigarettes and decided to take up pipe smoking as it was easier on the wallet. I asked in /r/pipetobacco if anyone could recommend a pipe restoration service and someone told me about rebornpipes.com. I was hesitant but after looking at the blog I knew it would be a good place to send my dad’s pipes.

My dad loved smoking his pipes, sitting out by the pool in the sun taking a nap or in the garage wood working. The house was my mom’s area and the garage was my dad’s area. I spent hours sitting out in the garage as a kid watching the niners or a’s and giants on tv while doing woodworking projects. I hope to do the same with my kids these days.

I’m not sure if my dad smoked other tobacco but I remember Captain Black was the kind he smoked regularly. He had tins of it in the garage, full and empty and would turn the old tin jars into storage for odds and ends, like screws or washers or miscellaneous stuff.

I remember when I played little league my dad would sit in the stands and smoke his pipes. One of my teammates asked “What is that smell?” and I ashamedly said “Oh that’s my dad’s pipe…I’ll go tell him to put it out” and my teammate said “No man, it smells good!”. It’s funny how the little conversations over the years you remember.

Another time when I was in 3rd grade or so we learned how smoking was bad for you (this was back in the 80s). I remember I asked my teacher if smoking a pipe was bad for you too….and she hesitated and said “Not as bad as cigarettes, since you don’t inhale it”. After that I was no longer worried about my dad smoking.

Knowing my mom I have no idea how my dad pulled this off but he managed to smoke his pipe in the house. I guess she liked the smell of it. Recently when I was waiting for my girls to get out of school I was sitting on a side street smoking my pipe and someone walked by and thanked me for bringing the pipe back. He said his dad used to smoke a pipe and he loved the smell. As did mine. The only difference is my daughters complain constantly about the smell of my car, but that is mostly because I smoke cigars too.

Anyway, grab some fine tobacco, light up a bowl and sit back and relax. I don’t have a pool like my dad did but you can catch me working on my laptop sitting in my driveway smoking a nice pipe, especially one of these restored pipes from reborn pipes….I can’t wait to smoke them.

Today after publishing the blog on the twisted freehand pipe I received an email from Anthony. He copied me an email that he had received from his Mom after she read the blog. It gives more insight into his Dad so he gave me permission to post it here.

Dear Anthony,I really enjoyed your email attachment about Steve Laug’s restoration of your dad’s pipes (“#1 and #3”)! Your father would be so thrilled to see this master craftsman bringing back to life his old favorites — especially as he so loved wood-working himself — and to know that you treasure them. (I wonder if the one I “rescued” from his workshop and now display in plastic case — the meerschaum lion’s head — is ruined. After vacuuming and blowing out all the dust and rat-turds, I soaked it in vinegar till white again. It looks good, anyway!)

I also loved reading your comments about Dad’s enjoyment of them. I don’t think he was ever addicted to tobacco; he just enjoyed it casually (and mostly chewing on them!).

I remember when he acquired the large, twisted one (“#3”) at a pipe shop called “Andre’s,” around 1969 or ’70. It was a unique shop, originally in Los Gatos or Campbell (I think) which later moved — maybe to The Alameda area in San Jose. I’m not sure if Andre made any that he sold, but as a woodworker Dad was fascinated by this one especially. He also bought his favorite tobacco blends there. (Maybe there’s something on the Internet about Andre’s, if he became more well known.)

While expecting our first child in early April 1971, I went down there to get Dad a surprise gift pipe for his April 25 birthday and picked out a plump, short one labeled “The Little Chub.” Not knowing in those days whether Baby would be a boy or girl, I wrapped it with a card saying it was “To My New Daddy from your Little Chub.” Lo and behold, Baby arrived on Dad’s very own birthday, when I tucked the pipe into my suitcase for the hospital and presented it to him there (along with The Little Chub herself — his best birthday gift ever)! I don’t see it among these photos, so I guess it got chewed down worse than the others!

Re. your notes on changes over the years in smoking habits and rules:I think it was IBM that banned smoking at work before state or local governments did. Also, as tobacco was made stronger (and more addictive), odors grew stronger and more permeating, and its terrible health effects became more obvious, more bystanders were impacted and objected.

As for my allowing pipes in the house in “the old days,” I had grown up with both parents heavy smokers, when that was common practice. (I didn’t take it up myself, as I couldn’t afford it — in the break room at work in my teens, machines sold candy bars for a nickel, but a pack of cigarettes cost 35 cents! And I liked chocolate better anyway.) But a man with a pipe was more attractive (especially if he dressed well), it seemed a sophisticated image, and the smoke smelled better. Many of my professors at Berkeley had pipes on their desks! But after we had kids and knew smoke was a hazard for them, we didn’t want them near it inside. And of course, we watched both my parents suffer terribly (Daddy’s heart attacks and emphysema, and Mom’s lung cancer) from near-lifelong smoking.

Anyway, these are beautiful, vintage, collectors’ items when restored and they’d look great in a closed case on the wall!

Love,Mom

Thanks Anthony, that gives me a sense of who your Dad was and how he used and enjoyed his pipes. I was ready to turn my attention to this third pipe. On this pipe I decided to work with the stem as it seemed a pretty straightforward cleanup (unlike the others). I cleaned out the inside with pipe cleaners and alcohol and worked on the funneled end of the tenon with a cotton swab and alcohol. It was quite dirty but it did not take too long to change that.  I used some 000 steel wool to clean off the light oxidation and then sanded the tooth chatter and marks out with 220 grit sandpaper.

I used some 000 steel wool to clean off the light oxidation and then sanded the tooth chatter and marks out with 220 grit sandpaper.  I wiped down the bowl with acetone on a cotton pad to remove the grime and remnants of the finish on the bowl. I scrubbed the rim top but that would take a bit more work to clean it off.

I wiped down the bowl with acetone on a cotton pad to remove the grime and remnants of the finish on the bowl. I scrubbed the rim top but that would take a bit more work to clean it off.

I cleaned up the fill on the bottom of the bowl and refilled it with super glue. I did not pick it out as it was merely pitted and not loose. The super glue would take care of the damage.

I cleaned up the fill on the bottom of the bowl and refilled it with super glue. I did not pick it out as it was merely pitted and not loose. The super glue would take care of the damage. With the exterior of the bowl cleaned and repaired it was time to address the rim top. I used a folded piece of 220 grit sandpaper to clean off the lava and remove the damage that was present on the surface. I worked over the surface of the shank end as well and cleaned off the grime there. There was still some darkening on the briar but it was clean.

With the exterior of the bowl cleaned and repaired it was time to address the rim top. I used a folded piece of 220 grit sandpaper to clean off the lava and remove the damage that was present on the surface. I worked over the surface of the shank end as well and cleaned off the grime there. There was still some darkening on the briar but it was clean. Now it was time to ream the bowl. I used a PipNet pipe reamer and took the cake back to bare briar. The pipe had been sitting for so long I wanted to do a maximum cleanup and also check out the walls of the bowl for damage. I cleaned up the bowl with a Savninelli Fitsall pipe knife and then sanded it with 220 grit sandpaper wrapped around a dowel.

Now it was time to ream the bowl. I used a PipNet pipe reamer and took the cake back to bare briar. The pipe had been sitting for so long I wanted to do a maximum cleanup and also check out the walls of the bowl for damage. I cleaned up the bowl with a Savninelli Fitsall pipe knife and then sanded it with 220 grit sandpaper wrapped around a dowel.  I cleaned out the sump in the shank and mortise and the airway into the bowl with pipe cleaners, cotton swabs and alcohol.

I cleaned out the sump in the shank and mortise and the airway into the bowl with pipe cleaners, cotton swabs and alcohol. I repaired some deep gouges on the right side of the bowl with clear super glue. When it was dry I sanded it smooth with 220 grit sandpaper to blend it into the surface of the bowl.

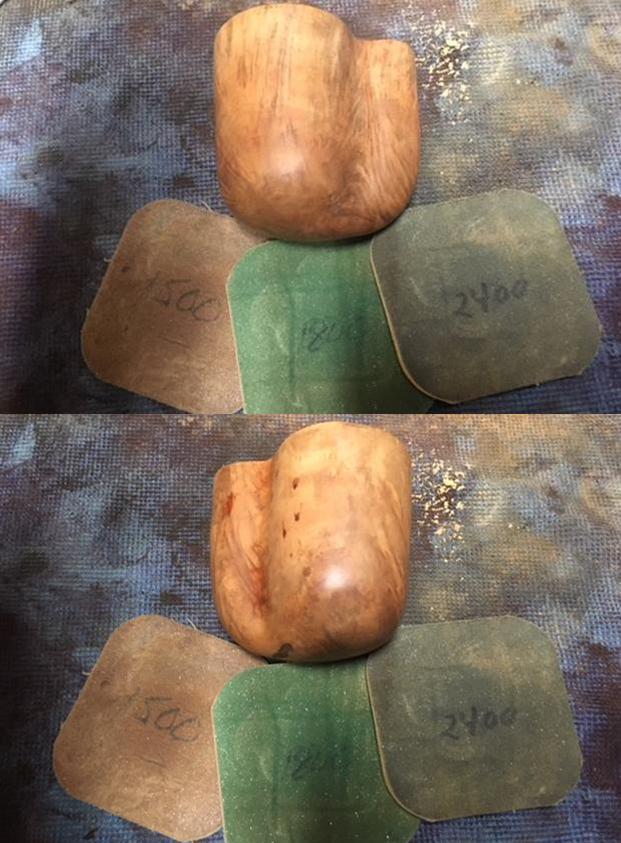

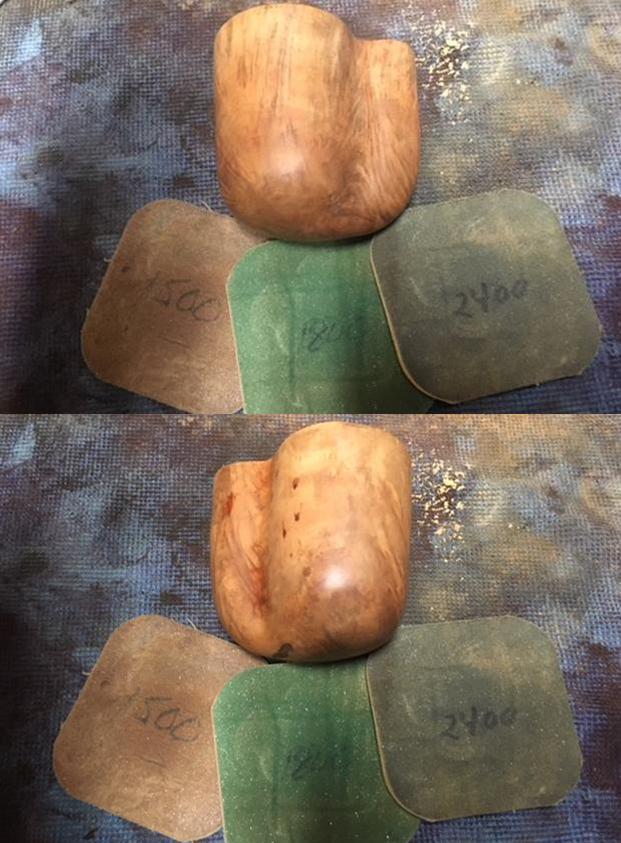

I repaired some deep gouges on the right side of the bowl with clear super glue. When it was dry I sanded it smooth with 220 grit sandpaper to blend it into the surface of the bowl. I began the polishing of the briar with a medium and a fine grit combination sanding sponge. I polished out the scratches and the repairs until the surface began to shine. I followed that by polishing it further with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the debris from the previous pad. Once I had finished I wiped it down with an alcohol dampened pad and let it dry.

I began the polishing of the briar with a medium and a fine grit combination sanding sponge. I polished out the scratches and the repairs until the surface began to shine. I followed that by polishing it further with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the debris from the previous pad. Once I had finished I wiped it down with an alcohol dampened pad and let it dry.

I rubbed Before & After Pipe Balm into the surface of the wood with my finger tips and worked it into the grain. The product did its magic and enlivened, cleaned and gave the wood a rich glow. It cleaned up the repaired areas so I could see where I needed to work in the stain to blend it into the briar. The photos show what it looked like at this point.

I rubbed Before & After Pipe Balm into the surface of the wood with my finger tips and worked it into the grain. The product did its magic and enlivened, cleaned and gave the wood a rich glow. It cleaned up the repaired areas so I could see where I needed to work in the stain to blend it into the briar. The photos show what it looked like at this point.

I buffed the bowl on the buffing wheel with Blue Diamond to further polish it. The photos below show the condition of the bowl at this point. It is almost ready to restain.

I buffed the bowl on the buffing wheel with Blue Diamond to further polish it. The photos below show the condition of the bowl at this point. It is almost ready to restain.

With the bowl cleaned, it was time to restain the pipe. I chose to use a Fiebing’s Dark Brown stain to give some life back to the pipe. It is dark enough that I figured it would hide the repairs a bit and blend the fill in on the bottom of the bowl. I heated the briar and then applied the stain with a dauber. I flamed the stain to set it in the grain and repeated the process until I was happy with the coverage.

With the bowl cleaned, it was time to restain the pipe. I chose to use a Fiebing’s Dark Brown stain to give some life back to the pipe. It is dark enough that I figured it would hide the repairs a bit and blend the fill in on the bottom of the bowl. I heated the briar and then applied the stain with a dauber. I flamed the stain to set it in the grain and repeated the process until I was happy with the coverage.

I set the bowl aside to let the stain cure overnight and called it a day. I took pictures of it once I had buffed it with Blue Diamond to remove the topcoat of crust. It needed some more work in my opinion.

I set the bowl aside to let the stain cure overnight and called it a day. I took pictures of it once I had buffed it with Blue Diamond to remove the topcoat of crust. It needed some more work in my opinion.

The stain was a bit too opaque for me as I wanted the interesting grain to stand out. I would need to sacrifice some of the coverage on the files to get the grain to stand out. I decided to go for it and wiped the bowl down with alcohol on a cotton pad to make the stain a bit more transparent.

The stain was a bit too opaque for me as I wanted the interesting grain to stand out. I would need to sacrifice some of the coverage on the files to get the grain to stand out. I decided to go for it and wiped the bowl down with alcohol on a cotton pad to make the stain a bit more transparent.

I set the bowl aside and polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit micromesh sanding pads and wiped it down with Obsidian Oil after each pad. I dry sanded it with 3200-12000 grit micromesh pads and again wiped it down after each pad with oil. I gave it a final coat of oil after the final pad and set it aside to dry.

I set the bowl aside and polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit micromesh sanding pads and wiped it down with Obsidian Oil after each pad. I dry sanded it with 3200-12000 grit micromesh pads and again wiped it down after each pad with oil. I gave it a final coat of oil after the final pad and set it aside to dry.

There were still some stubborn spots of oxidation in hard to sand spots so I polished the stem with Before & After Pipe Polish – Fine and Extra Fine polishes and I am happier with the end result.

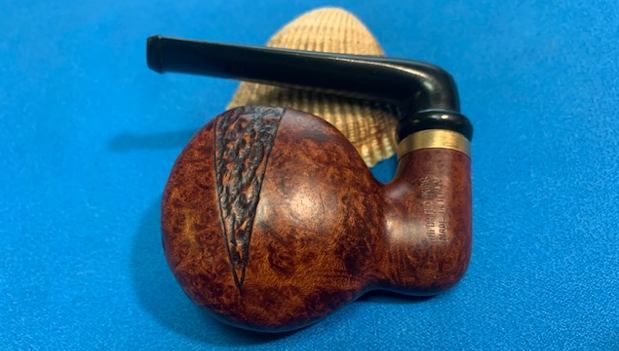

There were still some stubborn spots of oxidation in hard to sand spots so I polished the stem with Before & After Pipe Polish – Fine and Extra Fine polishes and I am happier with the end result. I polished the pipe with Blue Diamond to polish out the remaining small scratches. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. This is fourth of eight pipes that I am restoring from Anthony’s Dad’s collection. I am looking forward to hearing what Anthony thinks once he sees the finished pipe on the blog. Once I have the remaining four pipes finished I will pack them up and send them back to him. It will give him opportunity to carrying on the trust from his Dad. The dimensions are Length: 3 1/2 inches, Height: 2 1/8 inches, Outside diameter of the bowl: 1 5/8 inches, Chamber diameter: 7/8 inches. Thanks for walking through the restoration with me as I worked over this pipe from Anthony’s Dad’s collection. Four more will soon follow in the days ahead. Keep an eye out for them because there are still some unique pipes in the lot.

I polished the pipe with Blue Diamond to polish out the remaining small scratches. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The finished pipe is shown in the photos below. This is fourth of eight pipes that I am restoring from Anthony’s Dad’s collection. I am looking forward to hearing what Anthony thinks once he sees the finished pipe on the blog. Once I have the remaining four pipes finished I will pack them up and send them back to him. It will give him opportunity to carrying on the trust from his Dad. The dimensions are Length: 3 1/2 inches, Height: 2 1/8 inches, Outside diameter of the bowl: 1 5/8 inches, Chamber diameter: 7/8 inches. Thanks for walking through the restoration with me as I worked over this pipe from Anthony’s Dad’s collection. Four more will soon follow in the days ahead. Keep an eye out for them because there are still some unique pipes in the lot.

A short description would be that it is an Italian made lightly smoked Folding Pocket Pipe with a hard rubber stem. It is stamped on the left side of the shank and reads Imported Briar [over] Made in Italy. I would guess that the pipe was made by Savinelli as I have seen several very similar pipes shaped like this one made by them. The rim top was dirty and the inner edge had some lava. The exterior of the bowl was dirty and dusty and band was oxidized. Grain stood out in the smooth portions around the bowl sides and bottom and the interesting rustication wedges worked well. There was tooth chatter on both sides of the stem ahead of the button but nothing deep. I took some photos of this interesting Pocket Pipe extended and folded to show the condition when we received it. It was dusty, dirty and had some grime worked into the surface of the briar from being shuffled around a lot since it was made.

A short description would be that it is an Italian made lightly smoked Folding Pocket Pipe with a hard rubber stem. It is stamped on the left side of the shank and reads Imported Briar [over] Made in Italy. I would guess that the pipe was made by Savinelli as I have seen several very similar pipes shaped like this one made by them. The rim top was dirty and the inner edge had some lava. The exterior of the bowl was dirty and dusty and band was oxidized. Grain stood out in the smooth portions around the bowl sides and bottom and the interesting rustication wedges worked well. There was tooth chatter on both sides of the stem ahead of the button but nothing deep. I took some photos of this interesting Pocket Pipe extended and folded to show the condition when we received it. It was dusty, dirty and had some grime worked into the surface of the briar from being shuffled around a lot since it was made.

I took close up photos of the bowl and rim top and the stem to show their condition. You can see the thin cake on the bowl sides and the thin lava on the rim top. The stem looks good with light chatter and tooth marks on both sides.

I took close up photos of the bowl and rim top and the stem to show their condition. You can see the thin cake on the bowl sides and the thin lava on the rim top. The stem looks good with light chatter and tooth marks on both sides.  I took a photo of the stamping on the left side of the shank. You can see that it is somewhat faint but still readable.

I took a photo of the stamping on the left side of the shank. You can see that it is somewhat faint but still readable. I removed the stem from the shank and took a photo of the parts to give a sense of the beautiful proportions of this nice little pipe. It is going to take a little work but I think it will be quite stunning once it is restored.

I removed the stem from the shank and took a photo of the parts to give a sense of the beautiful proportions of this nice little pipe. It is going to take a little work but I think it will be quite stunning once it is restored. I reamed the bowl with a Savinelli Fitsall Pipe Knife to deal with the oval shape of the chamber. I scraped out the thin and uneven cake until the walls were clear. They looked very good. There was no heat damage or checking present.

I reamed the bowl with a Savinelli Fitsall Pipe Knife to deal with the oval shape of the chamber. I scraped out the thin and uneven cake until the walls were clear. They looked very good. There was no heat damage or checking present.  I cleaned out the mortise and the airway in the shank and stem with pipe cleaners, cotton swabs and isopropyl alcohol. The stem was an interesting challenge due to the right angle bend but it is now clean.

I cleaned out the mortise and the airway in the shank and stem with pipe cleaners, cotton swabs and isopropyl alcohol. The stem was an interesting challenge due to the right angle bend but it is now clean. I scrubbed off the shiny varnish coat on the bowl and shank with alcohol and a cotton pad. It came off quite easily and the grain really stood out. It is a nice piece of briar.

I scrubbed off the shiny varnish coat on the bowl and shank with alcohol and a cotton pad. It came off quite easily and the grain really stood out. It is a nice piece of briar.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad to check and make sure there was progress. By the end the there was a rich shine to the bowl.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad to check and make sure there was progress. By the end the there was a rich shine to the bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine. The Balm did its magic and my colours worked well.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine. The Balm did its magic and my colours worked well.

I set the bowl aside and addressed the tooth chatter in the hard rubber stem. I sanded it out with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper.

I set the bowl aside and addressed the tooth chatter in the hard rubber stem. I sanded it out with 220 grit sandpaper and started the polishing with 400 grit wet dry sandpaper. I polished out the scratches in the surface of the stem with micromesh sanding pads – 1500-12000 grit pads. I was able to remove the tooth chatter on both sides. I wiped it down with Obsidian Oil after each pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil and set it aside to cure.

I polished out the scratches in the surface of the stem with micromesh sanding pads – 1500-12000 grit pads. I was able to remove the tooth chatter on both sides. I wiped it down with Obsidian Oil after each pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil and set it aside to cure.

This interesting Italian Made Folding Pocket Pipe was fun to work on. I love the final touches that make it sing. I put the bowl and stem back together to have a look at the whole with the newly fit band on the shank. I carefully buffed the bowl and stem with Blue Diamond on the wheel. I gave it several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished shank band and the black, hard rubber stem. This richly finished Pocket Pipe is light weight and it is clean and ready load up with a favourite tobacco. Have a look at it in the photos below. When extended its measurements are Length: 4 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 inch x 1 ¼ inches, Diameter of the chamber: ½ inch x 1 inch. The folded measurements are Length: 3 inches, Height: 2 ¼ inches, Diameter of the outside and the chamber remain the same. The weight of the pipe is 33 grams/1.13 oz. I will be putting it on the rebornpipes store in the Italian Pipe Makers section if you wish to add it to your collection. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.

This interesting Italian Made Folding Pocket Pipe was fun to work on. I love the final touches that make it sing. I put the bowl and stem back together to have a look at the whole with the newly fit band on the shank. I carefully buffed the bowl and stem with Blue Diamond on the wheel. I gave it several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished shank band and the black, hard rubber stem. This richly finished Pocket Pipe is light weight and it is clean and ready load up with a favourite tobacco. Have a look at it in the photos below. When extended its measurements are Length: 4 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 inch x 1 ¼ inches, Diameter of the chamber: ½ inch x 1 inch. The folded measurements are Length: 3 inches, Height: 2 ¼ inches, Diameter of the outside and the chamber remain the same. The weight of the pipe is 33 grams/1.13 oz. I will be putting it on the rebornpipes store in the Italian Pipe Makers section if you wish to add it to your collection. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.