Blog by Steve Laug

The next pipe I have chosen is a smooth Briarlee Stroller Illustrious Rhodesian that was incredibly dirty. The contrast of the brown stains gave the bowl a sense of depth. Jeff and I picked it up from an auction early in 2019 in Wilkes Barre, Pennsylvania, USA. It was stamped on the left side of the shank and read Briarlee [over] Stroller. On the right side of the shank it read Illustrious [over] Imported Briar. It was in filthy with grime and grit ground into the finish of the bowl when he brought it to the table. The rim top was dirty with dust in the rustication on the cap and the beveled edge had some buildup of lava. There was a moderate cake mixed with bits of tobacco in the bowl and an overflow of lava on the beveled inner edge of the bowl. The stem was oxidized, calcified and had light tooth marks and chatter on the top and underside on and near the button. Jeff took photos of the pipe before his cleanup work. They tell the story and give a glimpse of the promise that we see in this pipe.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is moderately caked with a lava overflow on the rim top. The stem is oxidized, calcified and has tooth marks on the top and underside near the button.

Jeff took photos of the rim top and stem to show the general condition of the pipe. The bowl is moderately caked with a lava overflow on the rim top. The stem is oxidized, calcified and has tooth marks on the top and underside near the button.

Jeff took some photos of the bowl sides and heel to show carving that was around this bowl. It is a nice looking pipe.

Jeff took some photos of the bowl sides and heel to show carving that was around this bowl. It is a nice looking pipe.  Jeff took photos of the pipe with the stem unscrewed from the shank.

Jeff took photos of the pipe with the stem unscrewed from the shank.  He took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. He also took a photo of the band.

He took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. He also took a photo of the band.  I am including the information from Pipedia. It connects the Briar Lee brand to the Arlington Briar Pipes Corp brand (https://pipedia.org/wiki/American_Pipe_Brands_%26_Makers_A_-_B). I have included a bit of the pertinent history here.

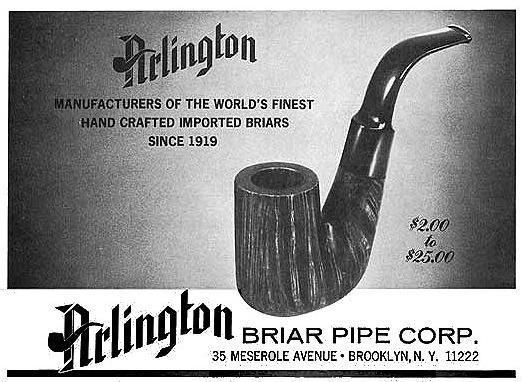

I am including the information from Pipedia. It connects the Briar Lee brand to the Arlington Briar Pipes Corp brand (https://pipedia.org/wiki/American_Pipe_Brands_%26_Makers_A_-_B). I have included a bit of the pertinent history here.

The article on Arlington Briar Pipes Corporation (https://pipedia.org/wiki/Arlington) includes a link to the Briar Lee Pipes. I have highlighted that connection in the paragraph below. It also gives a good summary of the history of the brand.

Arlington Briar Pipes Corporation was founded in 1919 in Brooklyn, New York, and produced the Arlington, Briarlee, Firethorn, Krona and Olde London brands among dozens of others, primarily acting as a subcontractor making pipes to be sold under other brand names. Among others, in the 1950’s, Arlington turned pipes for the famed Wilke Pipe Shop in New York City. The corporation was dissolved by the State of New York as inactive on December 6, 1978. Arlington Briar Pipe Corporation, located at 200 Kosciusko Street, Brooklyn, New York, registered only a single brand trademark, the Arlington brand, the trademark for which was applied for on November 13, 1962 and granted on February 25, 1964. Jack Kaye, of Arlington Briar, was also granted a patent for a combined mirror and stand in 1967.

According to José Manuel Lopes, “North American brand that belonged to Arlington Briar Pipes Corp., Brooklyn, New York, founded in 1919. In the 1940s, Ludwig Rosenberger gave the company new life, and it continued until the 70s. His son, Mel Rosenberger, has recently launched the DiMonte brand. Jack Uhle was also linked to Arlington.” Arlington, as far as known, mainly operated as a sub-contractor for other brands. The Jobey pipes are said to be made by Arlington at an unknown point of time. Arlington’s own pipes are seldom seen.  I knew that I was dealing with a pipe that was made before 1978 when the company was dissolved. Now it was time to work on the pipe.

I knew that I was dealing with a pipe that was made before 1978 when the company was dissolved. Now it was time to work on the pipe.

Jeff had done a great job cleaning up the pipe as usual. He reamed the pipe with a PipNet reamer and cut back the cake back to the bare briar. He cleaned up the walls with a Savinelli Fitsall Pipe Knife. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He worked on the rim top lava and darkening with the soap and tooth brush. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Before & After Deoxidizer. He washed it off with warm water to remove the deoxidizer. The pipe looked far better.

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top and edges look quite good. It should clean up really well. I also took close up photos of the stem to show the light tooth marks on the surface near the button.

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top and edges look quite good. It should clean up really well. I also took close up photos of the stem to show the light tooth marks on the surface near the button.  I took photos of the stamping on the sides of the shank. You can see that it is stamped as noted above. It is clear and readable.

I took photos of the stamping on the sides of the shank. You can see that it is stamped as noted above. It is clear and readable.  I took the pipe apart and took a photo of the pipe. It is a good looking pipe and has some great carvings around the bowl and shank.

I took the pipe apart and took a photo of the pipe. It is a good looking pipe and has some great carvings around the bowl and shank. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I am excited to finish this Arlington Made Briarlee Stroller Illustrious Rhodesian. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl mulitiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the grain popping through on the bowls sides and rim top. Added to that the black vulcanite stem gave the pipe a classic look that was reminiscent of Tracy Mincer’s Custom-Bilt pipes though smaller. This rusticated Briarlee Stroller Rhodesian is nice looking small pipe that feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 4 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 28grams/.99oz. It is a beautiful pipe and one that will be on the American Pipe Makers section of the rebornpipes store soon. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to finish this Arlington Made Briarlee Stroller Illustrious Rhodesian. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl mulitiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the grain popping through on the bowls sides and rim top. Added to that the black vulcanite stem gave the pipe a classic look that was reminiscent of Tracy Mincer’s Custom-Bilt pipes though smaller. This rusticated Briarlee Stroller Rhodesian is nice looking small pipe that feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 4 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 28grams/.99oz. It is a beautiful pipe and one that will be on the American Pipe Makers section of the rebornpipes store soon. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.