Blog by Steve Laug

I wanted a bit of a breather so I went through my box of pipes for repair and picked this multi-finish Jobey Asti Classic Bent Billiard to clean up. The stamping on the left side reads Jobey Asti Classic and on the right side France and the shape number 470. At first glance it looked like it would be a simple restore and clean. The bowl looked decent in the box and the stem was okay as well. When I got back to the table and did a closer examination I was surprised by what I saw. The bowl rim was in bad shape with the outer edge knocked and damaged. There were dent and score marks in the top of the rim. The lava had flown over the top and it looked as if someone had thrown a coat of Urethane on top of the bowl, grime and all. I looked at the exterior and found that even the grooves in the rusticated bottom of the bowl were thickly coated with the plastic stuff. The stem looked good at first but as I examined it I found that it had been cut off and the button recut and a slot fashioned that was not clean or even. The surface of the stem on the top and bottom next to the button was heavily built up with what appeared to be black epoxy and it was bubbled and full of pin prick like holes. It also was not bent correctly to the shape of the bowl. Truly it would need a lot more work than originally thought. (As an aside don’t use Urethane on bowls it is a bear to clean off and if you have to at least clean them before you dip them in that awful plastic stuff.)

I took the pipe apart and unscrewed the Jobey Link from the bowl and took a picture of the parts. I wanted to see how dirty the internals were and if the Link would come out easily. For those of you who don’t know the Link system one of the nice perks is that the end of the tenon that sits in the stem are slotted so you can insert a slot or blade screwdriver to loosen and remove the Link. It is a great piece of forethought on the part of the designer.

I took the pipe apart and unscrewed the Jobey Link from the bowl and took a picture of the parts. I wanted to see how dirty the internals were and if the Link would come out easily. For those of you who don’t know the Link system one of the nice perks is that the end of the tenon that sits in the stem are slotted so you can insert a slot or blade screwdriver to loosen and remove the Link. It is a great piece of forethought on the part of the designer. Because of the coat of Urethane over the lava I needed to top the bowl to remove the grime and also to clean up the outer edges of the bowl. I topped it with 220 grit sandpaper on my topping board.

Because of the coat of Urethane over the lava I needed to top the bowl to remove the grime and also to clean up the outer edges of the bowl. I topped it with 220 grit sandpaper on my topping board. I sanded the finish on the smooth portion of the bowl with a medium grit sanding block and then wiped the bowl down with acetone to try to break the plastic finish. I was partially successful in removing it but more work would need to be done.

I sanded the finish on the smooth portion of the bowl with a medium grit sanding block and then wiped the bowl down with acetone to try to break the plastic finish. I was partially successful in removing it but more work would need to be done. I reamed the bowl with the PipNet reamer and also with the Savinelli Pipe Knife to remove the remnants of cake that still were deep in the bowl. I reamed it back to bare briar so that the new owner could build a cake of their own choosing. You can also see the top and outer edge of the rim in these photos that show it after the topping of the bowl.

I reamed the bowl with the PipNet reamer and also with the Savinelli Pipe Knife to remove the remnants of cake that still were deep in the bowl. I reamed it back to bare briar so that the new owner could build a cake of their own choosing. You can also see the top and outer edge of the rim in these photos that show it after the topping of the bowl. In the next photo you can see the film of the plastic stuff still on the bowl with the scratches from the sanding block visible. I decided to let it soak in the alcohol bath for a day and a half to see if the finish would break down some more now that it had been broken through with the sanding blocks.

In the next photo you can see the film of the plastic stuff still on the bowl with the scratches from the sanding block visible. I decided to let it soak in the alcohol bath for a day and a half to see if the finish would break down some more now that it had been broken through with the sanding blocks. When I took it out of the bath the finish was pretty smooth. The plastic stuff was gone. I sanded the bowl and shank with micromesh sanding pads to remove some of the scratching and was careful around the stamping on the sides of the shank. I washed the bowl down with some acetone on cotton pads and then stained it with a dark brown aniline stain. I flamed it and repeated the process to make sure I got and even coverage.

When I took it out of the bath the finish was pretty smooth. The plastic stuff was gone. I sanded the bowl and shank with micromesh sanding pads to remove some of the scratching and was careful around the stamping on the sides of the shank. I washed the bowl down with some acetone on cotton pads and then stained it with a dark brown aniline stain. I flamed it and repeated the process to make sure I got and even coverage. While the bowl dried I turned to work on the stem. I heated it with the heat gun to soften the Lucite enough that I could bend it to the proper angle. It did not take too much to get the angle correct but the heat caused the epoxy patch to bubble. The perk of that was that the airhole pin prick marks disappeared.

While the bowl dried I turned to work on the stem. I heated it with the heat gun to soften the Lucite enough that I could bend it to the proper angle. It did not take too much to get the angle correct but the heat caused the epoxy patch to bubble. The perk of that was that the airhole pin prick marks disappeared. I wiped the bowl down with alcohol on cotton pads to remove some of the dark stain and bring the grain to the forefront.

I wiped the bowl down with alcohol on cotton pads to remove some of the dark stain and bring the grain to the forefront. I cleaned out the interior of the stem with cotton swabs, pipe cleaners and alcohol. I cleaned out the area where the Jobey Link sat in the stem and the airway to ensure good fit and draw.

I cleaned out the interior of the stem with cotton swabs, pipe cleaners and alcohol. I cleaned out the area where the Jobey Link sat in the stem and the airway to ensure good fit and draw. Now it was time to work on repairing the stem repairs! The next photos show what the patches looked like when I started. They stood out clearly and the heat of the gun made them raise and bubble. To me they looked like overkill in terms of a repair. It was almost if the person who did the patch was trying to build up the thickness of the stem at the button to give it strength. It would take some work to make it blend in. I sanded the surface of the stem with 220 grit sandpaper to smooth things out and try to match the stem surface. Of course I forgot to take photos of the process but the ones shown below with the micromesh sanding pads will show the change. The third photo below shows the slot in the button. I worked on it with needle files to clean it up and shape it and again forgot to take photos of the process.

Now it was time to work on repairing the stem repairs! The next photos show what the patches looked like when I started. They stood out clearly and the heat of the gun made them raise and bubble. To me they looked like overkill in terms of a repair. It was almost if the person who did the patch was trying to build up the thickness of the stem at the button to give it strength. It would take some work to make it blend in. I sanded the surface of the stem with 220 grit sandpaper to smooth things out and try to match the stem surface. Of course I forgot to take photos of the process but the ones shown below with the micromesh sanding pads will show the change. The third photo below shows the slot in the button. I worked on it with needle files to clean it up and shape it and again forgot to take photos of the process. I rubbed the bowl down with some Conservator’s Wax so that when I cleaned out the shank and Jobey Link System with would not damage the finish that I had done. (I know I should have done this before staining but this one irritated me and I forgot to do so.) I cleaned the link and then put a little Vaseline on the threads and turned it into the mortise. I adjusted it with the screwdriver to set it into the shank.

I rubbed the bowl down with some Conservator’s Wax so that when I cleaned out the shank and Jobey Link System with would not damage the finish that I had done. (I know I should have done this before staining but this one irritated me and I forgot to do so.) I cleaned the link and then put a little Vaseline on the threads and turned it into the mortise. I adjusted it with the screwdriver to set it into the shank.

I buffed the bowl lightly with Blue Diamond on the wheel and gave it a light coat of olive oil. I took the following photos to show what the pipe looked like at this point in the process. You can also see the state of the stem in these photos. Overall the pipe is looking pretty good at this point. It is far better than I expected when I started. The contrast of the dark stain on the rustication and the lighter stain on the smooth briar makes this pipe look quite “classic” matching its name.

I buffed the bowl lightly with Blue Diamond on the wheel and gave it a light coat of olive oil. I took the following photos to show what the pipe looked like at this point in the process. You can also see the state of the stem in these photos. Overall the pipe is looking pretty good at this point. It is far better than I expected when I started. The contrast of the dark stain on the rustication and the lighter stain on the smooth briar makes this pipe look quite “classic” matching its name.

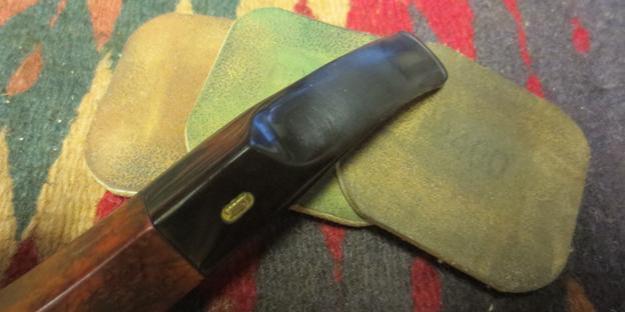

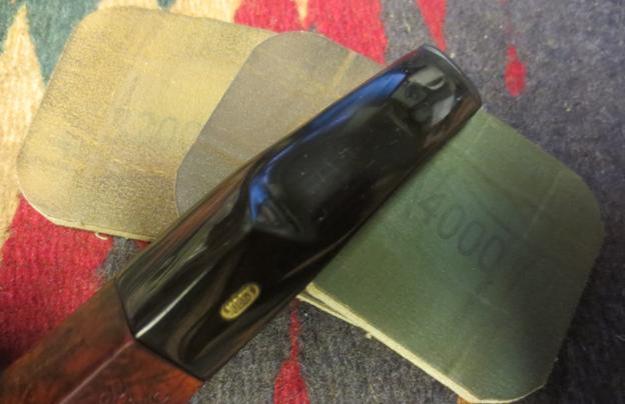

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded with 3200-4000 grit pads. I finished sanding with 6000-12000 grit pads.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded with 3200-4000 grit pads. I finished sanding with 6000-12000 grit pads.

I buffed the bowl and stem with Blue Diamond. I avoided the rusticated portion so as not to get polishing compound in the crevices and pits of bottom half of the bowl. I waxed the bowl and the stem with multiple coats of carnauba. The finished pipe is shown in the photos below. The grain is quite beautiful and the contrast between the smooth and the rusticated portions gives a unique look to the pipe. Thanks for looking.

I buffed the bowl and stem with Blue Diamond. I avoided the rusticated portion so as not to get polishing compound in the crevices and pits of bottom half of the bowl. I waxed the bowl and the stem with multiple coats of carnauba. The finished pipe is shown in the photos below. The grain is quite beautiful and the contrast between the smooth and the rusticated portions gives a unique look to the pipe. Thanks for looking.