by Steve Laug

This great looking Ben Wade Freehand came to us from a seller in Downey, California USA on 08/12/2025. It is another one that links the old English Company with Preben Holm in Denmark – the master freehand maker. The particular model is the epitome of a Danish Freehand coming from Preben Holm’s workshop for the American market. It is stamped Ben Wade [over] Intermezzo [over] B [over] Hand Made [over] in [over] Denmark. The bowl of the pipe is a beautiful straight grain piece of briar. The rim top and shank end are plateau. The plateau rim top and inner edge of the bowl is dusty, dirty and has some light lava overflowing onto it. The bowl has a moderate cake. The red coloured finish is very dirty with oils and grime ground into the finish. The beauty is in no way compromised by the grime. The acrylic Cumberland stem is stamped with a Ben Wade Crown BW logo on the top. It has light tooth marks and chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his clean up work to capture the condition of the pipe when we acquired it.

He took close up photos of the bowl and rim top from different angles to show the condition of both the smooth and plateau finish. It is truly a uniquely carved rim top maximizing the plateau and the smooth parts flowing up from the bowl sides. You can see the lava and build up on the rim top and the lava flowing on the inner edge of the bowl onto the plateau. The bowl has a moderate cake lining the walls and overflowing into lava. He took photos of the top and underside of the stem to show the condition on both.

He took close up photos of the bowl and rim top from different angles to show the condition of both the smooth and plateau finish. It is truly a uniquely carved rim top maximizing the plateau and the smooth parts flowing up from the bowl sides. You can see the lava and build up on the rim top and the lava flowing on the inner edge of the bowl onto the plateau. The bowl has a moderate cake lining the walls and overflowing into lava. He took photos of the top and underside of the stem to show the condition on both.

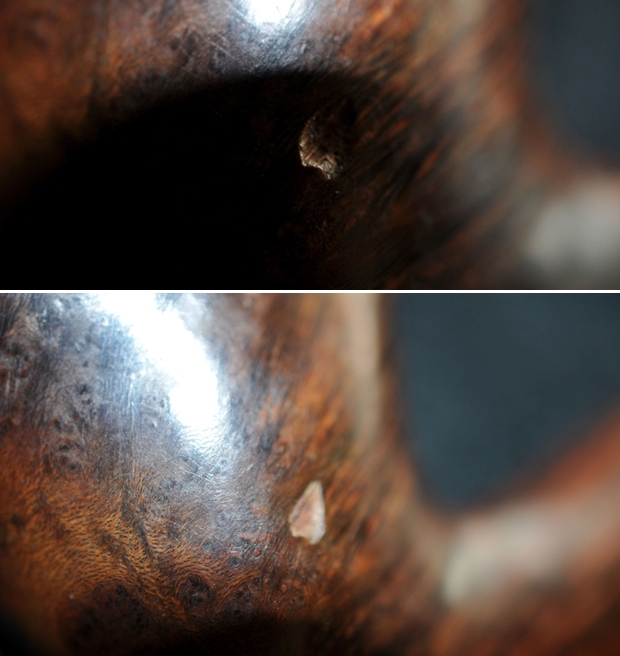

He took photos of the sides and heel of the bowl to show the lay of the grain around the pipe. It is a beautiful piece of briar. The top of the bowl and shank end are craggy and rugged looking. Unique! The grain is very beautiful.

He took photos of the sides and heel of the bowl to show the lay of the grain around the pipe. It is a beautiful piece of briar. The top of the bowl and shank end are craggy and rugged looking. Unique! The grain is very beautiful.

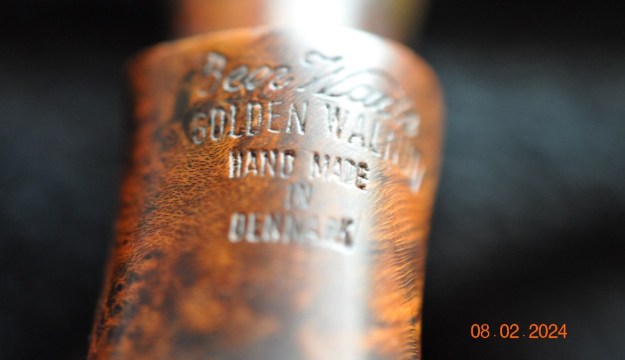

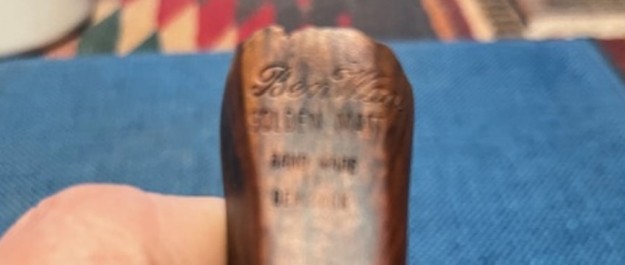

Jeff took a photo of the stamping on the underside of the shank. It was faint in spots but still clear and read as noted above.

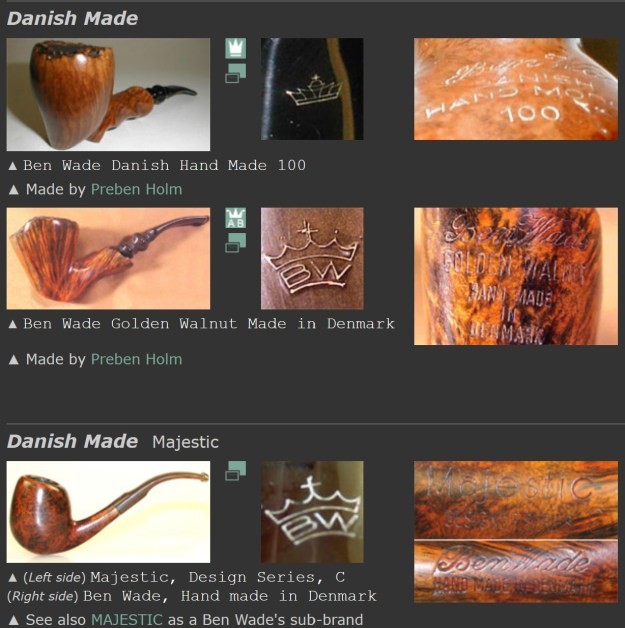

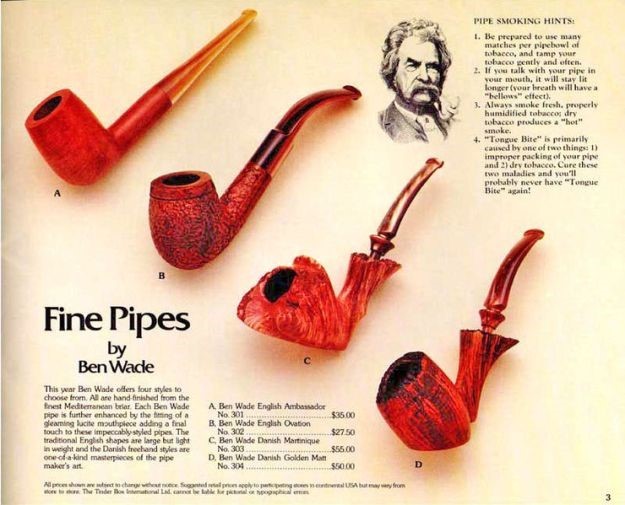

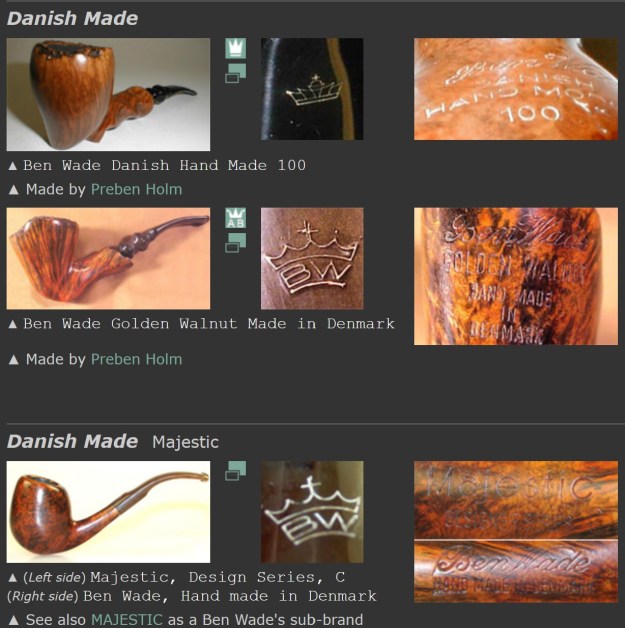

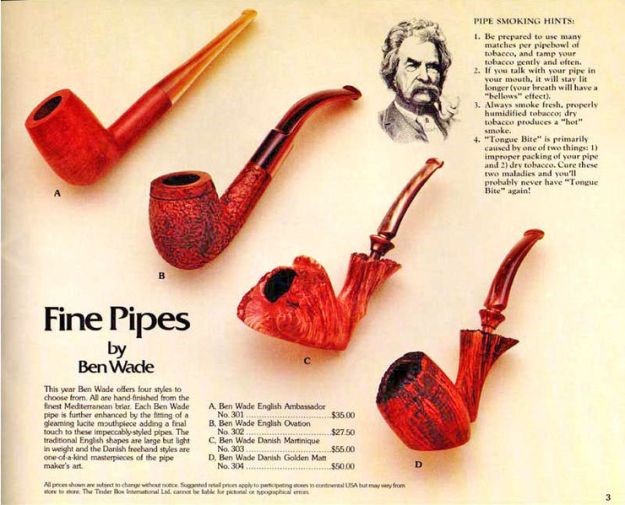

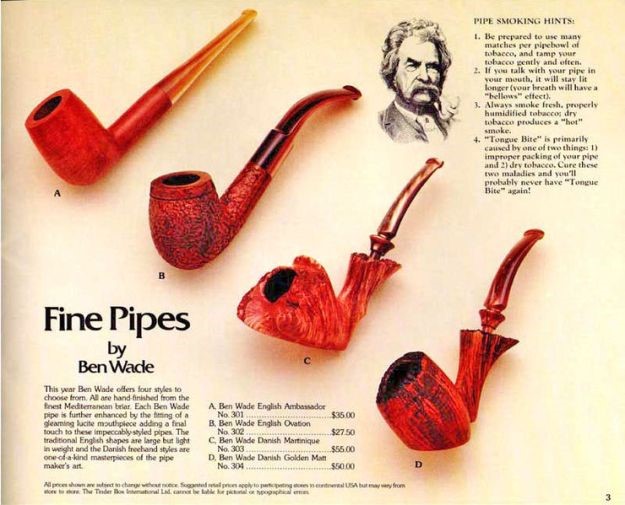

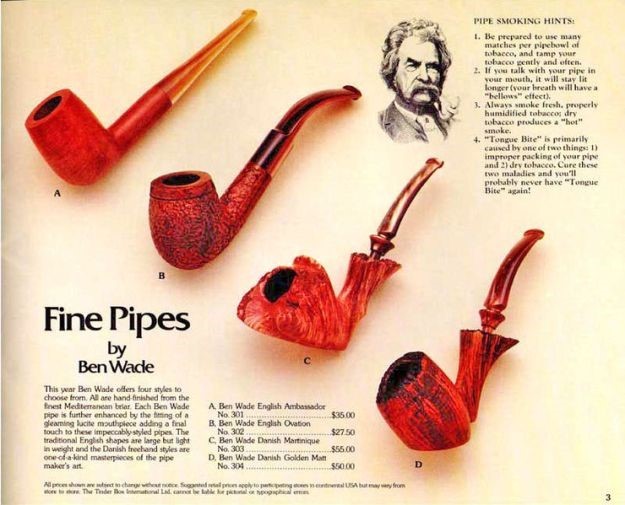

Jeff took a photo of the stamping on the underside of the shank. It was faint in spots but still clear and read as noted above. I am including the background history that I included on the previous blog. It includes the idea that the Preben Holm pipes were marketed under the Ben Wade label in the US and imported through Lane Ltd. I turned to Pipedia and read the listing on the brand to refresh my memory and flesh out the knowledge of the brand (https://pipedia.org/wiki/Ben_Wade). I have included a photo from that site that was taken from a Tinderbox advertisement.

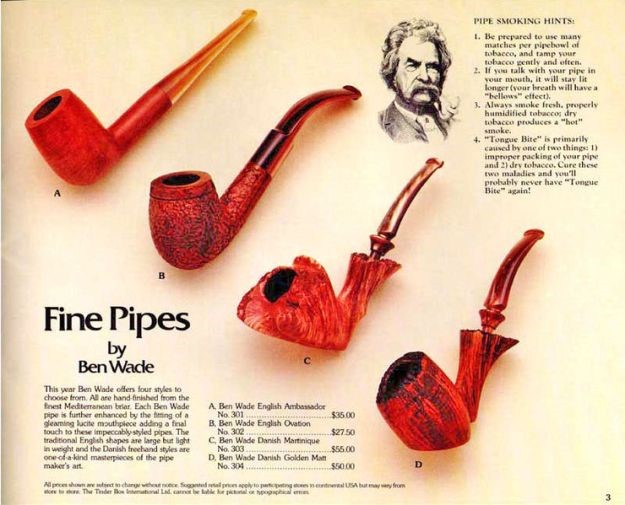

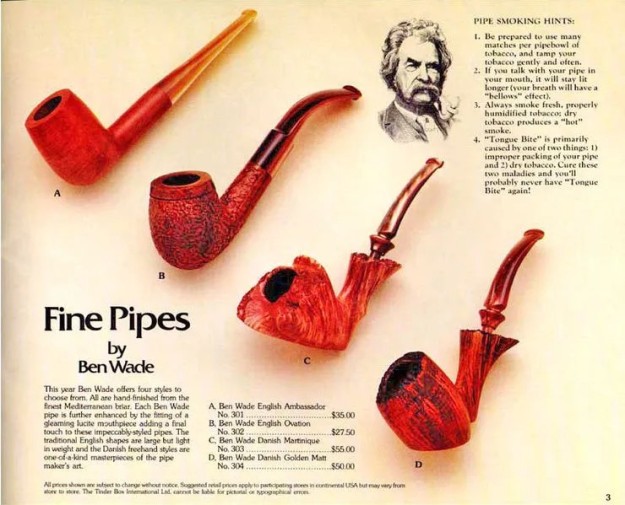

I am including the background history that I included on the previous blog. It includes the idea that the Preben Holm pipes were marketed under the Ben Wade label in the US and imported through Lane Ltd. I turned to Pipedia and read the listing on the brand to refresh my memory and flesh out the knowledge of the brand (https://pipedia.org/wiki/Ben_Wade). I have included a photo from that site that was taken from a Tinderbox advertisement.  Ben Wade Ad in a Tinder Box catalog, courtesy Doug Valitchka

Ben Wade Ad in a Tinder Box catalog, courtesy Doug Valitchka

I quote the portion of the article that summarizes the history of the brand.

Young Copenhagen master pipemaker Preben Holm had made a meteoric career heading a pipe manufacture employing 45 people at the age of 22! But around the turn of 1970/71 he was in major financial difficulties. His US distributor, Snug Harbour Ltd. in New York City, left him in the lurch. Holm had three unpaid invoices on his desk and another large shipment was ready for the USA, when Snug Harbour’s manager told him on the phone that there was no money at all on the account to pay him.

So the Dane went to New York for an almost desperate search for a new distribution partner. He made contacts with Lane Ltd. and met Herman G. Lane in February 1971. Lane Ltd. had no interest in Holm’s serial pipes produced at that time but so much the more in the hand-carved freehands because the hype for Danish freehands and fancies in the States was still on its way to the climax then. The meeting resulted in an agreement to start a cooperation. Lane insisted to improve the quality considerably and in return he assured to be able to sell essentially larger quantities.

Holm went back home to work on new samples with all-new designs and altered finishes for Lane. Both, Lane and Holm, agreed that it would be unwise to sell the pipes under Preben Holm’s name as long as Snug Harbour had a considerable stock of Preben Holm pipes and might sell them pipes at very low prices just to bring in some money.

So on Mr. Lane’s proposal it was determined to use the name Ben Wade belonging to Lane Ltd. Lane spent considerable amounts of money for advertising the new brand in the big magazines– the centerpiece being whole-page ads showing a very exclusive Seven Day’s Set.

The cooperation with Lane Ltd. proved to be an eminent business success for both partners. Within a very short time Ben Wade Handmade Denmark sold in much larger quantities and at higher prices than they had ever dreamed of. And the hype these freehands and fancy pipes caused went on unbroken long after Herman G. Lane deceased. Preben Holm – obviously much more brilliant in pipe making than in pipe business – was in major troubles again in 1986 and had to sack most of his staff. The Ben Wade production was significantly lowered but continued until his untimely death in June of 1989.

Up to now Preben Holm made Ben Wade pipes are cult and highly sought for on the estate markets.

With that information my initial thoughts were confirmed. This pipe was another Preben Holm made Freehand Sitter distributed in the US by Lane Ltd under the name Ben Wade. The freehand rage occurred in the late 70s and the pipes were made until Preben’s death in 1989. My guess would be that this pipe was made sometime during that time period and potentially in the late 70s.

Jeff had thoroughly cleaned up the pipe. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs, pipe cleaners and shank brushes. He scrubbed the exterior of the stem with Soft Scrub to remove the grime and calcification. He soaked the stem in Before & After Deoxidizer and rinsed it with warm water.

I took some photos of the rim top, shank end and stem to show the condition of them both when it arrived. It looked good. The stem had some light tooth marks and chatter ahead of the button and on the button surface on both sides.

I took some photos of the rim top, shank end and stem to show the condition of them both when it arrived. It looked good. The stem had some light tooth marks and chatter ahead of the button and on the button surface on both sides. I took a photo of the stamping on the underside of the shank. It was clear and readable. It read as noted above. I took the stem off the shank and took a photo of the pipe parts in perspective.

I took a photo of the stamping on the underside of the shank. It was clear and readable. It read as noted above. I took the stem off the shank and took a photo of the pipe parts in perspective. I started my work on the pipe by sanding the bowl and shank with 320-3500 grit sanding pads. I wiped it down after each sanding pad to remove the debris from sanding. I carefully avoided the stamping on the shank. It began to look very good as I finished.

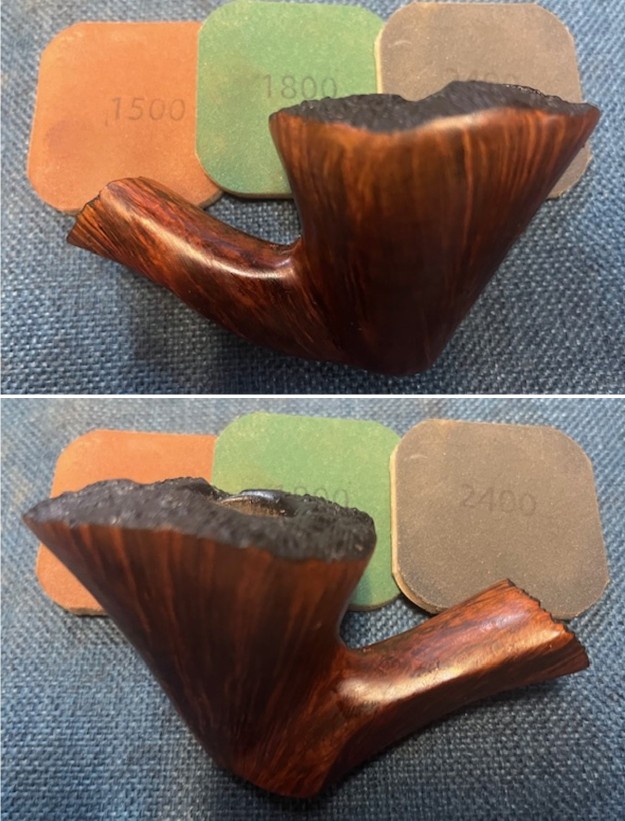

I started my work on the pipe by sanding the bowl and shank with 320-3500 grit sanding pads. I wiped it down after each sanding pad to remove the debris from sanding. I carefully avoided the stamping on the shank. It began to look very good as I finished.

I polished the bowl with and shank with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The bowl is starting to look very good.

I polished the bowl with and shank with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The bowl is starting to look very good.

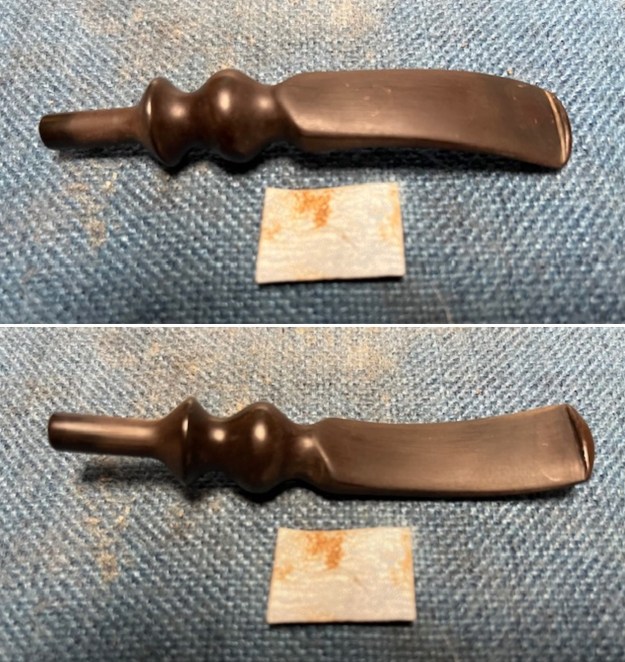

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and into the plateau rim top with a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and into the plateau rim top with a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

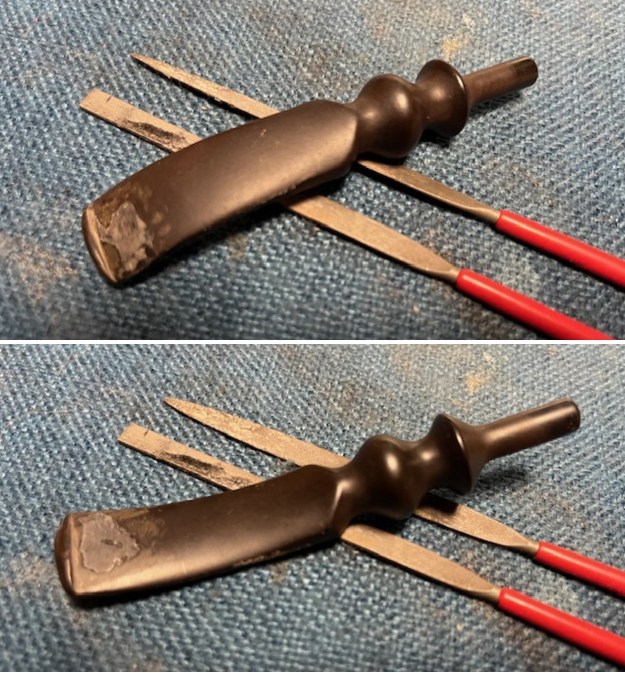

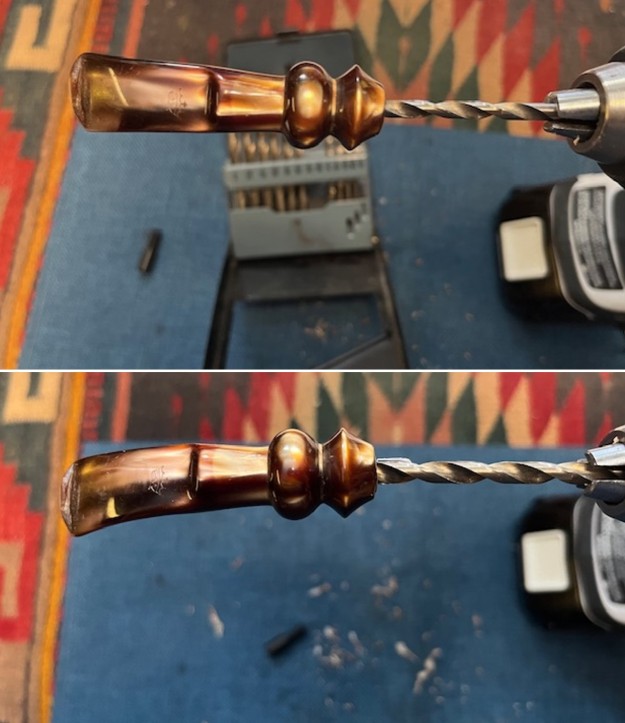

I set the bowl aside and sanded the stem with sanding pads – dry sanding with 320-3500 grit sanding pads. After each pad I wiped the stem down with Obsidian Oil on a cloth. It is looking much better.

I set the bowl aside and sanded the stem with sanding pads – dry sanding with 320-3500 grit sanding pads. After each pad I wiped the stem down with Obsidian Oil on a cloth. It is looking much better. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I wiped it down with Obsidian Oil to protect the stem and slow down the oxidation.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I wiped it down with Obsidian Oil to protect the stem and slow down the oxidation.

This is a beautiful Preben Holm made Ben Wade Intermezzo Freehand Sitter with a fancy, turned, Cumberland acrylic stem. It has a great look and feel. The shape fits well in the hand with the curve of the bowl and shank junction a perfect fit for the thumb around the bowl when held. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the plateau on the rim top and shank end multiple coats of Conservator’s Wax. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich combination of reds, browns and black in the smooth finishes and the plateau areas took on life with the buffing. The rich colour of the briar works well with the polished Cumberland acrylic stem. I like the grain and finished look of this Preben Holm Ben Wade Intermezzo Freehand. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 2 wide x 2 inches long, Chamber diameter: 1 inch. The weight of the pipe is 80 grams/2.82 ounces. This pipe will be going on the Danish Pipe Makers Section of the rebornpipes store if you are interested in adding it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. This was a fun estate to bring back to life.

This is a beautiful Preben Holm made Ben Wade Intermezzo Freehand Sitter with a fancy, turned, Cumberland acrylic stem. It has a great look and feel. The shape fits well in the hand with the curve of the bowl and shank junction a perfect fit for the thumb around the bowl when held. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the plateau on the rim top and shank end multiple coats of Conservator’s Wax. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rich combination of reds, browns and black in the smooth finishes and the plateau areas took on life with the buffing. The rich colour of the briar works well with the polished Cumberland acrylic stem. I like the grain and finished look of this Preben Holm Ben Wade Intermezzo Freehand. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 2 wide x 2 inches long, Chamber diameter: 1 inch. The weight of the pipe is 80 grams/2.82 ounces. This pipe will be going on the Danish Pipe Makers Section of the rebornpipes store if you are interested in adding it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. This was a fun estate to bring back to life.