Blog by Paresh Deshpande

I am always on a look out for old and collectible estate pipes, especially those related to important evolving pipe history, to be added to my personal collection and this pipe on my work table precisely meets the above criteria.

The pipe that I selected to work on next is a deeply rusticated robust sitter with smooth surface on left and right side of the shank and a unique asymmetric acrylic saddle stem. It is stamped on the left smooth panel with model code “149” over “CAMINETTO” in inverted commas and in running italics over “BUSINESS” in block capital letters. The right side of the shank bears the stampings “ASCORTI” over “RADICE” over “CUCCIAGO” over “CANTU- ITALY”. The upper surface of the asymmetric saddle stem bears the logo of MOUSTACHE that resembles a bird in flight.

I have worked and researched Caminetto pipes earlier and from what I recollect, Ascorti and Radice moved away from Castello and jointly made Caminetto pipes for a few years before separating to establish their own brands Ascorti and Radice respectively. Thus, pipes that bore the stamp of both Ascorti and Radice are early pipes and are highly collectible and fetch top dollars. For detailed information, I visited pipedia.org and have reproduced the relevant information below (https://pipedia.org/wiki/Caminetto).

I have worked and researched Caminetto pipes earlier and from what I recollect, Ascorti and Radice moved away from Castello and jointly made Caminetto pipes for a few years before separating to establish their own brands Ascorti and Radice respectively. Thus, pipes that bore the stamp of both Ascorti and Radice are early pipes and are highly collectible and fetch top dollars. For detailed information, I visited pipedia.org and have reproduced the relevant information below (https://pipedia.org/wiki/Caminetto).

Caminetto’s history started in 1959 when Guiseppe Ascorti, from Cucciago, and known to his friends as “Peppino”, was hired by Carlo Scotti to work at Castello, located in nearby Cantu. Since it’s foundation in 1947 Castello had contributed substantially to regained glory for Italian pipemaking. Talent and assiduity soon made Ascorti one of Scotti’s most notable pipemakers – a man he counted on for the future. But, Ascorti had his own far reaching plan: He wanted to work as a self-employed pipemaker! After his wife, Paola, had taken over her parent’s small greengrocery in the early 1960’s this plan became more concrete. The additional income from the shop enabled him to buy tools and machines little by little to furnish his own workshop. By the end of 1968 he was ready and left Castello. Ascorti also persuaded his co-worker, the young and highly-talented pipemaker Luigi Radice (born 1939), to join him – the two were neighbors in Cucciago. Carlo Scotti, whom is known as a perfect gentleman, is reported to have spoken unreservedly about this development.

Ascorti & Radice started to manufacture pipes on their own. One of the first who agreed to market their pipes was Gianni Davoli, proprietor of a tobacco shop in Milan. The situation was perfect–two pipemakers in search of a distributor, and a pipe merchant in search of a mainstay brand to market. Davoli – via friends and relations in the States – had made flourishing contacts with US pipe wholesalers and traders. He shipped some pipes across the pond for inspection and received excellent feedback for the very high quality of the pipes. He, shortly after, offered to be the sole distributor worldwide, and Ascorti & Radice happily accepted.

Then came the legendary evening when Ascorti, Radice and Davoli gathered around the fireplace after a hard day’s work enjoying their pipes, a glass of wine, and humorous conversation. Davoli is said to be the one who associated the pipes with the fireplace or chimney, which is “camino” in Italian. Hence “Caminetto”, the diminutive (smaller) singular version of camino, was coined as the brand’s name. Ascorti, Radice and Davoli later became famous as “I tre Camini” – the three chimneys. Maybe, they had more than one glass of wine each, but it’s not certain whether the distinctive mustache logo on the stem and the Caminetto slogan “La Pipa del Baffo” – “the pipe with the moustache” – was created the same night. In fact, Ascorti and Radice both wore impressively large moustaches, and a pharmacist in the neighborhood had been kidding them about that. (Davoli, for reasons of corporate identity, later wore a big moustache, too.)

Now, Davoli concentrated on marketing the Caminetto brand in the United States. His strategy was as simple as it was brilliant. There was a remarkable Castello hype at the time. Castello pipes were highly sought after but hard to get due to limited production. Davoli filled the gap, promoting the Caminetto to be absolutely equal to the Castello in terms of quality, while asking only half the price. And best of all: the Caminetto pipes were consignable! The Tinder Box International would be under contract with successful nationwide distribution. The brand’s success was overwhelming – far beyond any expectation, with the rusticated Business line becoming the most popular.

The boom continued strongly – especially in the US. Production increased steadily, from 3,000 to 5,000 and then 7,000 pipes being made per year, placing Caminetto at the top of US sales in their market segment. The 1974 Tinder Box catalog celebrated Gianni Davoli as “master pipe maker and designer” and “sole creator of Caminetto” without a single mention of Ascorti or Radice!

Caminetto prospered throughout the 1970’s. Everyone was hard at work, and sales continued to increase, but soon disagreements occurred among the three principles, marking the beginning of the end.

First, Luigi Radice became increasingly discontent with the factory-like production. Pipes were made by standard shape numbers, and there was no longer room for his own creative pipemaking and personal development. He was also afraid that the increased production would eventually lead to a reduction in quality. Radice started quarreling with Ascorti about the future course of Caminetto, and they were unable to find a solution. Radice, being an employed pipemaker, rather than a partner, could not assert himself. Ascorti shared Radice’s concerns about maintaining quality in the face of the higher production, but Davoli had gained almost total control by this time, and insisted on the higher production numbers.

The next controversy was regarding Roberto Ascorti. The young man had visited a school of arts and also completed his service in the army. Roberto did not want to attend a university, and instead started helping in the workshop with pipe repairs and making his first few pipes. His father wanted to hire him on as a full-time pipemaker, but Davoli refused, being afraid to lose influence to the potentially strong alliance between father and son.

The situation worsened in 1979. The foreseen quality issues occurred–there were complaints from the US. And, there is some indication that Carlo Scotti considered legal actions, asserting that Caminetto had copied some of Castello’s successful shapes too exactly. At this point Ascorti wanted to sever ties with Davoli, but Davoli was able to assert himself and maintained control.

‘I tre Camini’ disbanded in December of 1979, when Luigi Radice left, without prospects, knowing not where or how he would continue as a pipemaker. A clear indication that he had very strong feelings as to his future with Caminetto.

Ascorti vs. Davoli continued for a few more months. The Ascorti family offered to buy the brand, but they couldn’t afford it at the time. So, Guiseppe Ascorti hastily equipped a new workshop, and then he left company which was essentially his own. But the complete crew whom he had trained in the old Caminetto workshop followed him. And thus they were able to re-start making pipes within a few weeks in 1980. For three months they sold pipes under the name Sergio. Only 800 to 1,000 Sergio pipes were released. Then Giuseppe Ascorti and his son Roberto founded a new company under their own last name. – For the further history see Ascorti!

Gianni Davoli, last chimney standing, stayed behind, now owning a pipe workshop without any pipemakers. Strangely enough, the old Caminetto workshop caught fire shortly afterward and burned down to ashes.

At the end of this article, there is another link to Brothers of Briar forum where Joshoowah has written his further research of Caminetto, dating guide and shape codes. Here’s a link to the write up

https://pipedia.org/wiki/The_History_of_Caminetto_(shapes,_stamping,_articles,_etc.)

He picks up from the point where the Caminetto workshop was burned down to ashes after December 1980. He notes:-

It is at this point where details become hazy, as the brand Caminetto seems to have disappeared all but entirely from the market. Some claim Peppino continued to make pipes under the name Caminetto on into the 80s (see smokingpipes.com), but this is fairly unclear and uncertain, particularly because Divoli owned the Caminetto brand and the shop burning down between 1979-1981.

The story picks back up in late 1985 and early 1986, where Roberto Ascorti re-opens the line of Caminetto. Though the “Business” rustication changed somewhat, the original shapes and finishes have largely been left unchanged. From what I can gather, Roberto bought the name Caminetto sometime in 1985. “From who?” is the question, perhaps Divoli himself. Roberto revitalized the once great Caminetto line in memory of his father and the legacy of Caminetto in the Italian pipe industry, as well as to show his capability of producing high quality masterpieces. In saying such, Roberto has been his “flavor” on many of the Caminetto models over the years, stretching and adjusting some shapes to his own liking and style. It seems, by most accounts, he has done well in continuing the Caminetto legacy. One thing that has changed, however, are the prices of the newer lines, which sometimes reach the prices of Castello’s themselves.

That is the history of Caminetto as far as I have found in my years of appreciating the brand. It is key to note the particular brands that came out of the fall-out of the original Caminetto that now have a bit of good standing behind them:

- Luigi Radice — We all know Radice’s work. It is marvelous, fairly unique, and full of passion and heart for the art of pipe making.

- Roberto Ascorti — We, too, are familiar with Ascorti, which has produced quality pieces for a number of years, which resemble some of the later years of Caminetto (i.e. 1976-1981).

- Caminetto — This, too, is Roberto’s work but carries a different flavor to his Ascorti line, resembling some of the work of his father, Peppino, and the original Caminetto, which includes the wax-drip and new dear finish.

- Enzo Galluzzo — This is one many may not know about, particularly because the company closed in 1991. In the fallout of Ascorti, Radice, and Divoli, there was another aspiring pipe maker among them who went his own way — Enzo Galluzzo. Galluzzo invented a new line of pipes in which he branded “Capitello.” Capitello took on the character of Caminetto, including some of its shapes and finishes, but Galluzzo produced some real nice pieces for a fraction of the cost of Caminetto, Castello, and even Ascorti. One interesting fact is that Capitello’s were the only oil-cured pipes of the 80s, essentially carrying on the tradition of the oil-cured pipe of Caminetto. The company ran from 1982-1991.

Stampings and dating

First off, dating earlier Caminetto’s is nearly impossible. Nevertheless, there were three phases, some in which were much earlier, of development that occurred in the stamping process of Caminetto. Before that though, every pipe had the stamp of Caminetto in one of two ways: Caminetto in script or Caminetto within quotation marks in block letters (I do not know how it was decided which pipe got which stamp, as I have had EARLY Caminetto’s with both). The stampings:

ASCORTI

RADICE

CUCCIAGO

CANTU- ITALY

There are two other variations to the stampings, but I have not included them as they are irrelevant to the pipe that I am currently working on for the sake of brevity. Another aspect useful for dating Caminetto pipes is the style of moustache stamped on the stem. Joshoowah comments on this aspect as under:-

In addition to the above stampings, there was always the trademark mustache on the stem. The earlier models (1968/69-1974/75) had the iconic gold, sometimes white, “bird-in-flight” mustache and the later models (1975-1979/80/81) had a gold, or white, “double comma” mustache.

Pipes stamped like #1 are the most valuable Caminetto’s as they are the earliest production of the brand, as well as what some would claim the most perfect of Ascorti and Radice’s work.

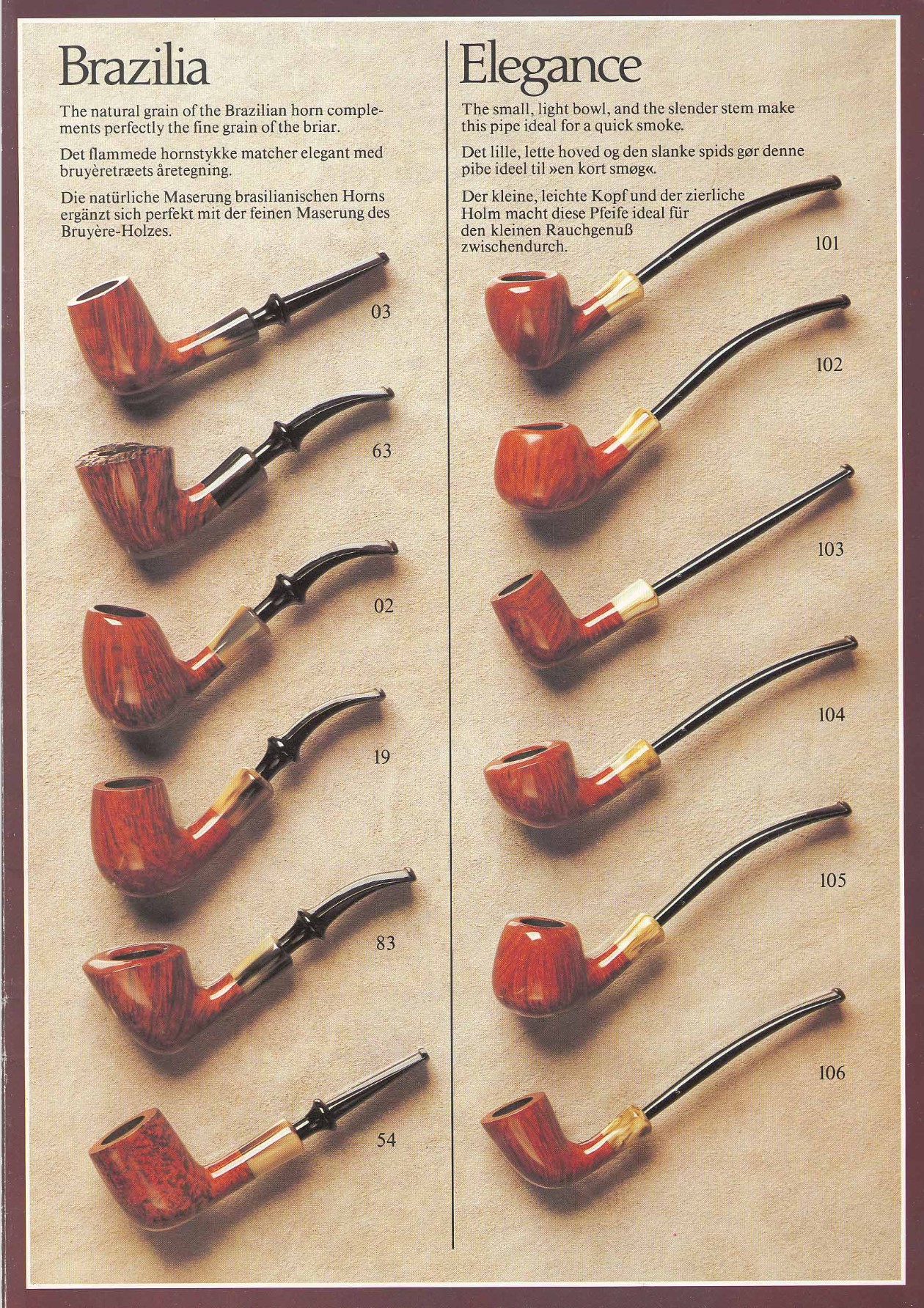

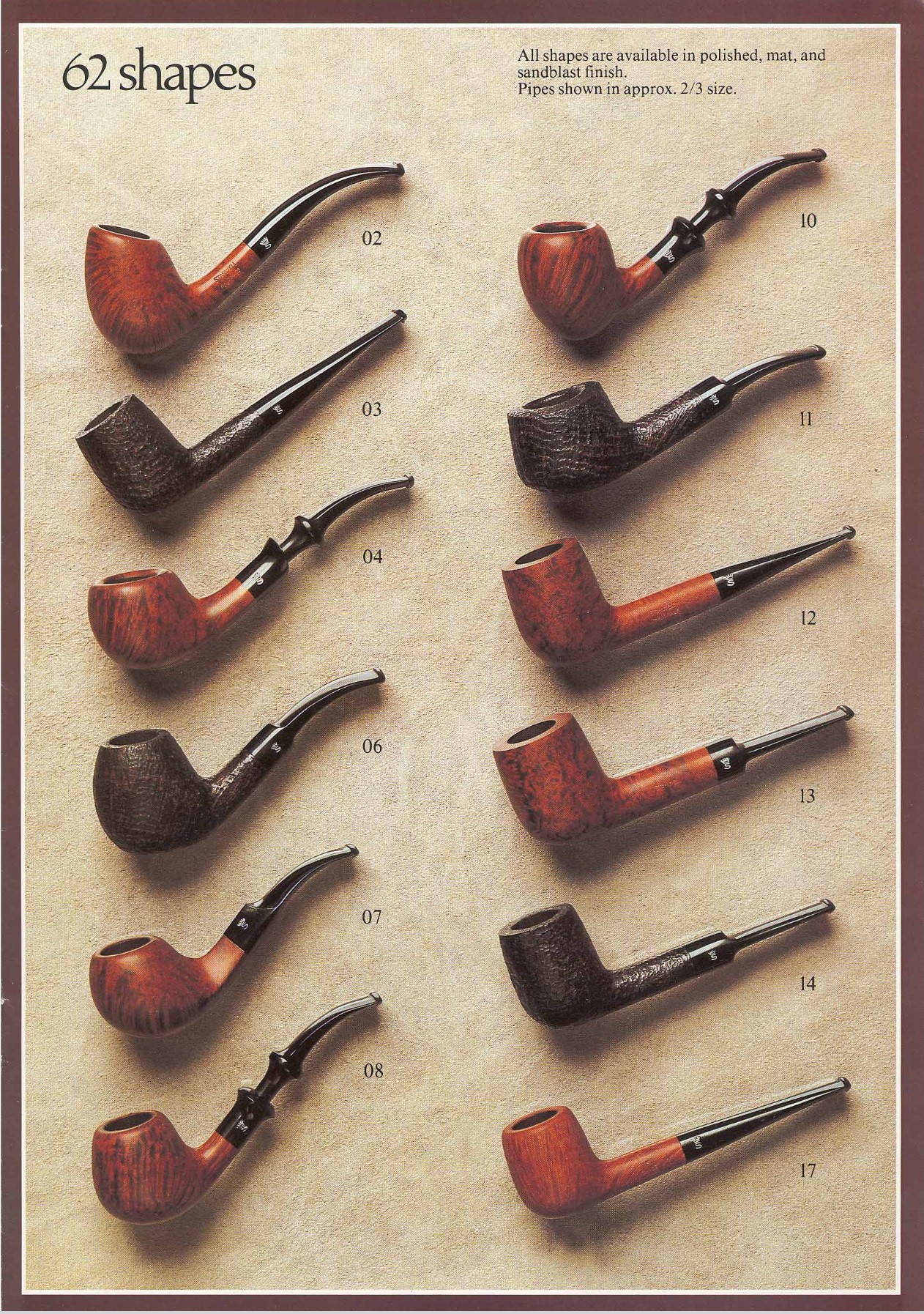

The shape code chart that has been uploaded on this page is reproduced below and the pipe that I am working on is indicated by a red arrow. Thus, from the above, it is certain that the pipe currently on my work table is an earliest production of the brand made during the period 1968 to 1975.

Thus, from the above, it is certain that the pipe currently on my work table is an earliest production of the brand made during the period 1968 to 1975.

Initial Visual Inspection

This deeply rusticated and perfectly proportioned sitter has a medium thick layer of cake in the chamber with darkening over the also rusticated rim top surface. The beautifully rusticated stummel surface is covered in dust and grime. This grime and dirt can be seen in the deep rustications and lends a dull and lifeless appearance to the pipe. The stummel sides are stained with the grime and hand oils from previous usage. The mortise is relatively clean and would be cleaned further during the refurbishing process. The grey acrylic stem with swirls of black and it’s golden bird-in-flight stem logo is also in decent condition. There is some light tooth chatter in the bite zone on either surface while the buttons are intact. Overall, the pipe is in very good condition requiring only a little TLC to get it back to its pristine condition. The following pictures will aid in your visual inspection too.

Detailed Inspection

Detailed Inspection

This pipe has a large bowl with a depth of 2 ¾ inch. The chamber has an even layer of thick hard cake. There is a heavy overflow of lava over the rim top surface. The rim top has darkened considerably. The condition of the inner walls of the chamber and the inner edge can be commented upon after the cake has been taken down to the bare briar. The ghost smells in the chamber are very strong. The deeply rusticated stummel surface has a very beautiful texture and hand feel to it. The stummel has a very natural Virgin stain and supposed to darken as it is smoked. The surface is covered in dust and grime. The fact that the rustications are dusty and filled with dirt is accentuated more due to the dark stains on the stummel sides on account of hand oils and sweat. The briar looks lifeless and bone dry and has taken on dull hues. The mortise is relatively clean with slight darkening of the mortise wall. The ghost smells are pretty strong and should reduce once the chamber and mortise is cleaned up.

The deeply rusticated stummel surface has a very beautiful texture and hand feel to it. The stummel has a very natural Virgin stain and supposed to darken as it is smoked. The surface is covered in dust and grime. The fact that the rustications are dusty and filled with dirt is accentuated more due to the dark stains on the stummel sides on account of hand oils and sweat. The briar looks lifeless and bone dry and has taken on dull hues. The mortise is relatively clean with slight darkening of the mortise wall. The ghost smells are pretty strong and should reduce once the chamber and mortise is cleaned up.

The asymmetrical saddle variegated acrylic grey stem with swirls of black beautifully compliments the stummel. There is minor tooth chatter on either surface of the stem. The moustache gold stem logo is in pristine condition. The tenon opening and the horizontal slot shows accumulated dried gunk and grime. The button edges are crisp and the slot end is undamaged.

The asymmetrical saddle variegated acrylic grey stem with swirls of black beautifully compliments the stummel. There is minor tooth chatter on either surface of the stem. The moustache gold stem logo is in pristine condition. The tenon opening and the horizontal slot shows accumulated dried gunk and grime. The button edges are crisp and the slot end is undamaged. The Process

The Process

I began the process of refurbishing this pipe by reaming the chamber with a PipNet reamer tool, using the second and third head. Using my fabricated knife; I further took the cake down to the bare briar. With a 150 grit sand paper, the walls of the chamber were rid of all the remnants of the cake, revealing smooth chamber walls. I further wiped the chamber with a cotton swab wetted with isopropyl alcohol to completely remove the residual carbon dust. The inner rim edge appears darkened all around but more so on the left side of the chamber. There are a few minor heat lines crisscrossing the chamber walls. It is my experience that such fissures are usually addressed after a salt and alcohol treatment and subsequent sanding of the chamber walls since these are indicative of very thin layer of hard cake which is moistened during alcohol treatment and easily removed thereafter by sanding.

I scraped the shank internals with a fabricated tool to remove all the crud that had accumulated along the shank walls and further cleaned it with bristled and regular pipe cleaners dipped in isopropyl alcohol.

I scraped the shank internals with a fabricated tool to remove all the crud that had accumulated along the shank walls and further cleaned it with bristled and regular pipe cleaners dipped in isopropyl alcohol. I continued the cleaning of the chamber and shank internals with a salt and alcohol bath. I use cotton balls which is an at par substitute as I have realized over the years. I draw out a wick from the cotton and along with a folded regular pipe cleaner; insert it in to the mortise and through the draught hole in to the chamber. Thereafter, I packed the chamber with cotton balls to about quarter of an inch below the rim inner edge and soaked the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having being absorbed by the cotton. I topped it up once again and set it aside overnight. By next afternoon, the cotton and alcohol had drawn out all the remaining oils and tars from the chamber and mortise, fulfilling its intended task. I removed the cotton balls and ran pipe cleaners through the mortise to clean out all the loosened tars and gunk. Using my fabricated tool, I scraped out the entire loosed gunk from the sump and further cleaned it with alcohol and q-tips. The chamber now smells clean and fresh. I set the stummel to dry out naturally.

I continued the cleaning of the chamber and shank internals with a salt and alcohol bath. I use cotton balls which is an at par substitute as I have realized over the years. I draw out a wick from the cotton and along with a folded regular pipe cleaner; insert it in to the mortise and through the draught hole in to the chamber. Thereafter, I packed the chamber with cotton balls to about quarter of an inch below the rim inner edge and soaked the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having being absorbed by the cotton. I topped it up once again and set it aside overnight. By next afternoon, the cotton and alcohol had drawn out all the remaining oils and tars from the chamber and mortise, fulfilling its intended task. I removed the cotton balls and ran pipe cleaners through the mortise to clean out all the loosened tars and gunk. Using my fabricated tool, I scraped out the entire loosed gunk from the sump and further cleaned it with alcohol and q-tips. The chamber now smells clean and fresh. I set the stummel to dry out naturally. While the chamber was soaking in the salt and alcohol bath, I worked the stem, starting with cleaning the internals of the stem using thin shank brush and anti oil dish washing soap. I scrubbed the tenon end and the horizontal slot with soap and Scotch Brite pad till clean. Once the stem internals were clean, I ran a couple of pipe cleaners through the stem airway to get rid of any remaining soap as well as to dry it out.

While the chamber was soaking in the salt and alcohol bath, I worked the stem, starting with cleaning the internals of the stem using thin shank brush and anti oil dish washing soap. I scrubbed the tenon end and the horizontal slot with soap and Scotch Brite pad till clean. Once the stem internals were clean, I ran a couple of pipe cleaners through the stem airway to get rid of any remaining soap as well as to dry it out.  Next, I move to clean the exterior of the stummel. I generously applied Murphy’s oil soap with a hard bristled tooth brush and scrubbed the stummel and rim top with the soap. I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth. I deliberately cleaned the rusticated rim top with a soft brass wired brush, Scotch Brite and soap. The stummel surface has cleaned up nicely with the robust rusticated patterns looking splendid.

Next, I move to clean the exterior of the stummel. I generously applied Murphy’s oil soap with a hard bristled tooth brush and scrubbed the stummel and rim top with the soap. I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth. I deliberately cleaned the rusticated rim top with a soft brass wired brush, Scotch Brite and soap. The stummel surface has cleaned up nicely with the robust rusticated patterns looking splendid.

I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush. I dried the mortise using paper towels and set the stummel aside to dry out naturally.

I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush. I dried the mortise using paper towels and set the stummel aside to dry out naturally. While the stummel was set aside to dry out, I worked on the stem. Using a flat head needle file, I lightly sand the inner edge of the buttons on either surface to a crisp sharpness. I further sand the entire bite zone with a folded piece of 220 grit sandpaper. This helps to even out the minor tooth chatter and also reduce the filing marks left behind by the needle file. The sanding marks will be further addressed during the sanding and polishing process.

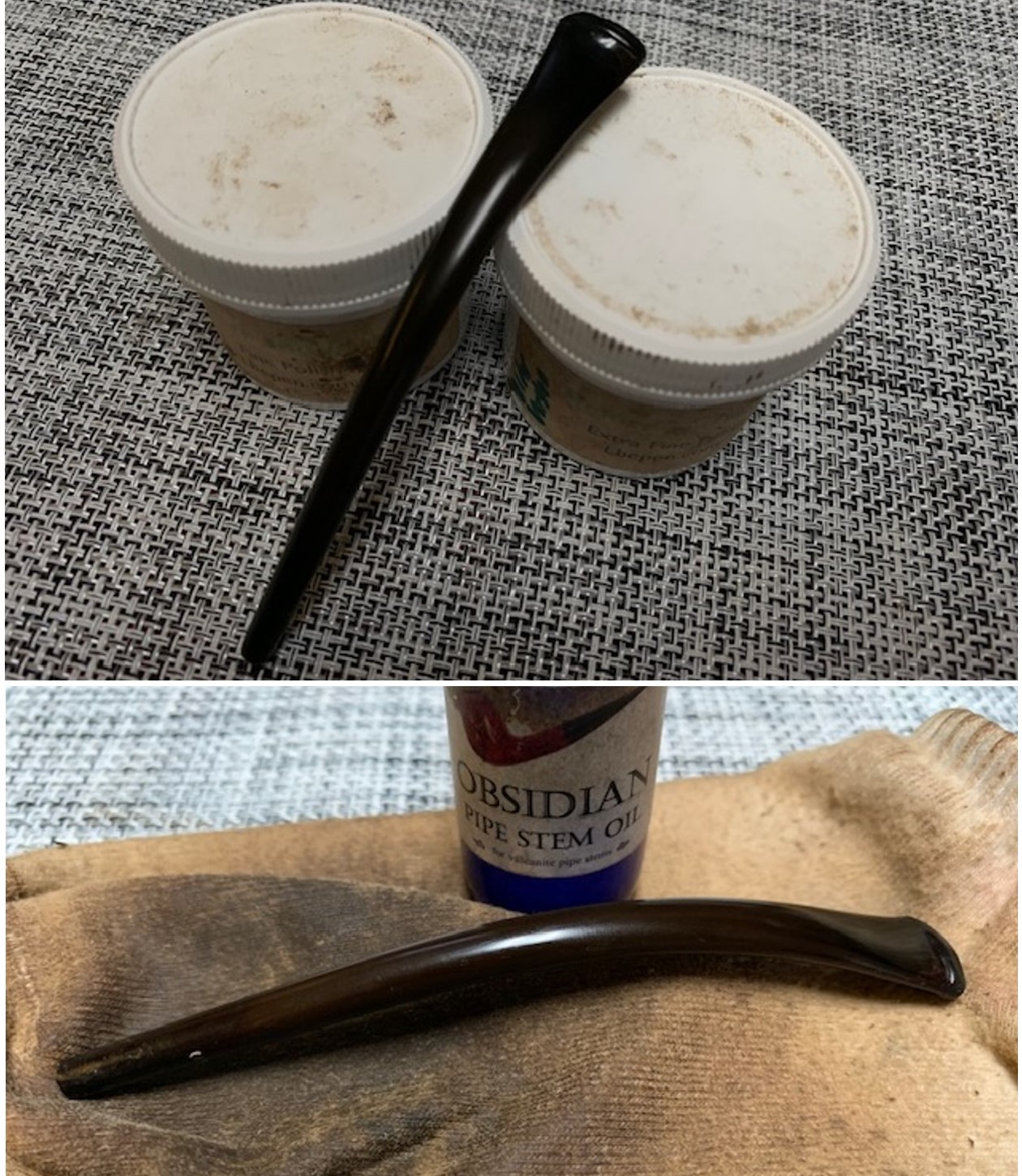

While the stummel was set aside to dry out, I worked on the stem. Using a flat head needle file, I lightly sand the inner edge of the buttons on either surface to a crisp sharpness. I further sand the entire bite zone with a folded piece of 220 grit sandpaper. This helps to even out the minor tooth chatter and also reduce the filing marks left behind by the needle file. The sanding marks will be further addressed during the sanding and polishing process. Next, I dry sanded the entire stem with 600 and 800 grit sand papers followed by wet sanding using 1000, 1500 and 2000 grit sand papers. This progressive use of higher grit sandpapers helps to, firstly, reduce the sanding marks left behind by the more abrasive ones, secondly, completely eliminate the dullness from the years of use and imparting a clean shine to the stem surface. I went through with the micromesh polishing cycle by dry sanding the surface with 3200 to 12000 grit micromesh pads. I applied a little EVO and set the stem aside for a few minutes. This stem, as the rest of the pipe, is a real beauty.

Next, I dry sanded the entire stem with 600 and 800 grit sand papers followed by wet sanding using 1000, 1500 and 2000 grit sand papers. This progressive use of higher grit sandpapers helps to, firstly, reduce the sanding marks left behind by the more abrasive ones, secondly, completely eliminate the dullness from the years of use and imparting a clean shine to the stem surface. I went through with the micromesh polishing cycle by dry sanding the surface with 3200 to 12000 grit micromesh pads. I applied a little EVO and set the stem aside for a few minutes. This stem, as the rest of the pipe, is a real beauty.

I completed the polishing regimen by polishing the surface with a cotton wheel mounted on to my hand held rotary tool and Blue diamond followed by food grade carnauba wax polish.

I completed the polishing regimen by polishing the surface with a cotton wheel mounted on to my hand held rotary tool and Blue diamond followed by food grade carnauba wax polish. By the time I was done working on the stem refurbishment, the stummel had completely dried out. I decided to address the darkened inner rim edge by creating a slight bevel using a folded piece of 220 grit sandpaper pinched between fingers and running it along the rim edge. The rim edge looks much better at this stage.

By the time I was done working on the stem refurbishment, the stummel had completely dried out. I decided to address the darkened inner rim edge by creating a slight bevel using a folded piece of 220 grit sandpaper pinched between fingers and running it along the rim edge. The rim edge looks much better at this stage. Next, I rubbed a small quantity of “Before and After Restoration Balm” into the briar with my finger tips and let it rest for a few minutes. The balm almost immediately works it’s magic and the briar now had a nice vibrant appearance with the beautiful rustication patterns on full display. I have been using this balm ever since I embarked on this journey and it is this part of restoration that I always look forward to. I further buffed it with a horse hair shoe brush. This pipe really oozes of a very high quality.

Next, I rubbed a small quantity of “Before and After Restoration Balm” into the briar with my finger tips and let it rest for a few minutes. The balm almost immediately works it’s magic and the briar now had a nice vibrant appearance with the beautiful rustication patterns on full display. I have been using this balm ever since I embarked on this journey and it is this part of restoration that I always look forward to. I further buffed it with a horse hair shoe brush. This pipe really oozes of a very high quality.

I completed this project by hand polishing the stummel with Halcyon II wax. I rubbed this polish deep into the rustications and after a couple of minutes, vigorously hand buffed the stummel with a microfiber cloth to a deep shine. This is a gorgeous looking pipe and will be an integral part of pipe history in my collection.

I completed this project by hand polishing the stummel with Halcyon II wax. I rubbed this polish deep into the rustications and after a couple of minutes, vigorously hand buffed the stummel with a microfiber cloth to a deep shine. This is a gorgeous looking pipe and will be an integral part of pipe history in my collection.

P.S.– Delving deep in to history of this pipe took me through the labyrinth of interconnectivity of Italian pipe carvers and marquees that have dominated our pipe world and given pipe smokers the world over some of their favourite smokers.

P.S.– Delving deep in to history of this pipe took me through the labyrinth of interconnectivity of Italian pipe carvers and marquees that have dominated our pipe world and given pipe smokers the world over some of their favourite smokers.

I wish to thank each one for sparing their valuable time to read through this write up and praying for the health and safety of you and your loved ones.