Blog by Steve Laug

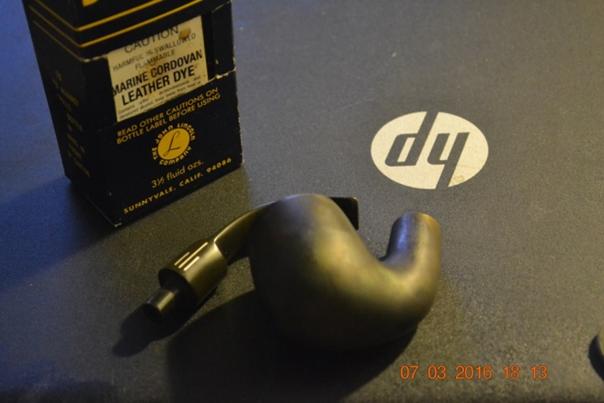

This pipe is stamped Tom Howard on the left side of the shank and Imported Briar on the right side. A friend of mine emailed me and asked if I would clean it up for him and bring it back to life. He said the stem tasted awful. He said he had tried to clean it up a bit but was not happy with the results. He dropped it by the house before he left on a short trip. Here is what it looked like when it arrived.

There was a pretty thick cake in the bowl and the rim had overflow on the top. The grooves and worm trails were pretty much filled in with grime. The stem was badly oxidized and there were some deep scratches in the surface. There was tooth chatter on the top and bottom of the stem near the button.

There was a pretty thick cake in the bowl and the rim had overflow on the top. The grooves and worm trails were pretty much filled in with grime. The stem was badly oxidized and there were some deep scratches in the surface. There was tooth chatter on the top and bottom of the stem near the button.

I reamed the bowl in stages. I began with a Savinelli Pipe Knife to take back the inner edge of the bowl.

I reamed the bowl in stages. I began with a Savinelli Pipe Knife to take back the inner edge of the bowl. I used a brass bristle wire brush to clean off the top of the rim and get rid of the buildup.

I used a brass bristle wire brush to clean off the top of the rim and get rid of the buildup. I scrubbed the bowl with a tooth brush and Murphy’s Oil Soap to remove the buildup of tars and oils that darkened the bowl and shank. It did not take too much to get the briar clean. I rinsed the bowl with running water and dried it off with a towel. The cleaned exterior is shown in the photos below.

I scrubbed the bowl with a tooth brush and Murphy’s Oil Soap to remove the buildup of tars and oils that darkened the bowl and shank. It did not take too much to get the briar clean. I rinsed the bowl with running water and dried it off with a towel. The cleaned exterior is shown in the photos below.

I did the second stage of reaming the bowl with a PipNet Reamer and took the cake back to bare briar. I cleaned up that reaming with the Pipe Knife again.

I did the second stage of reaming the bowl with a PipNet Reamer and took the cake back to bare briar. I cleaned up that reaming with the Pipe Knife again. I used the dental spatula to scrape out the mortise and then scrubbed it with pipe cleaners, cotton swabs and alcohol until it was clean.

I used the dental spatula to scrape out the mortise and then scrubbed it with pipe cleaners, cotton swabs and alcohol until it was clean. I decided to scrub the surface some more with a cotton pad and acetone. I was able to remove more of the finish on the bowl and lighten it even more.

I decided to scrub the surface some more with a cotton pad and acetone. I was able to remove more of the finish on the bowl and lighten it even more.

I used a folded piece of 220 grit sandpaper to clean up the inner edge of the rim and smooth out some of the damage that was there.

I used a folded piece of 220 grit sandpaper to clean up the inner edge of the rim and smooth out some of the damage that was there. I cleaned out the inside of the stem with pipe cleaners and alcohol.

I cleaned out the inside of the stem with pipe cleaners and alcohol. I sanded the stem with 220 grit sandpaper to remove the oxidation that was on the surface of the saddle, the groove where the saddle joined the bowl and the area around the button.

I sanded the stem with 220 grit sandpaper to remove the oxidation that was on the surface of the saddle, the groove where the saddle joined the bowl and the area around the button. Before continuing on the stem I stuffed a cotton ball in the bowl of the pipe and also the bowl of a second one I was working on and filled it with alcohol. The alcohol pulled the tars and residue from the bowl and shank into cotton ball.

Before continuing on the stem I stuffed a cotton ball in the bowl of the pipe and also the bowl of a second one I was working on and filled it with alcohol. The alcohol pulled the tars and residue from the bowl and shank into cotton ball. I let it sit in the bowl for several hours while I worked on the stem. You can see the oils and tars that are being drawn into the cotton ball in the next photo.

I let it sit in the bowl for several hours while I worked on the stem. You can see the oils and tars that are being drawn into the cotton ball in the next photo. The underside of the stem near the button had one deep tooth mark in the surface that I was unable to sand out. I cleaned it up and then filled it with some black super glue. Once the glue had dried I sanded the patch back to blend it into the surface of the stem.

The underside of the stem near the button had one deep tooth mark in the surface that I was unable to sand out. I cleaned it up and then filled it with some black super glue. Once the glue had dried I sanded the patch back to blend it into the surface of the stem. I wet sanded the stem with 1500-2400 grit micromesh sanding pads. I sanded and polished the stem. I rubbed it down with Obsidian Oil. I dry sanded it with 3200-4000 grit pads and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I set it aside to dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads. I sanded and polished the stem. I rubbed it down with Obsidian Oil. I dry sanded it with 3200-4000 grit pads and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it a final coat of Obsidian Oil. I set it aside to dry.

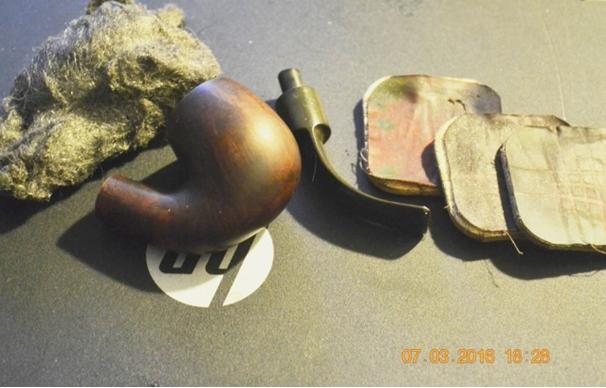

I stained the bowl with some medium walnut Danish Oil and then buffed it with Blue Diamond on the wheel. I gave the bowl several coats of Conservator’s Wax and the stem several coats of carnauba wax. I buffed the pipe with a clean buffing pad and then hand buffed it with a microfibre cloth. The pipe is clean, the smell and bad taste are gone and to me the pipe looks better than when I started the process. The bowl smelled clean. The pipe is ready to go back to its owner once I get the second pipe finished. Thanks for looking. Theo if you see this – your first pipe is ready for you when you return.

I stained the bowl with some medium walnut Danish Oil and then buffed it with Blue Diamond on the wheel. I gave the bowl several coats of Conservator’s Wax and the stem several coats of carnauba wax. I buffed the pipe with a clean buffing pad and then hand buffed it with a microfibre cloth. The pipe is clean, the smell and bad taste are gone and to me the pipe looks better than when I started the process. The bowl smelled clean. The pipe is ready to go back to its owner once I get the second pipe finished. Thanks for looking. Theo if you see this – your first pipe is ready for you when you return.