Blog by Steve Laug

Last week I was in Idaho to spend time with my 87-year-old father who needed to have the aorta valve on his heart replaced. His surgery was on Tuesday and went exceptionally well. On Thursday morning my brother Jeff and I visited him in the hospital and then drove to a neighbouring city to do some pipe hunting. There is something about the thrill of a pipe hunt that is hard to beat in terms of the adventure of the hunt and the thrill of the finds. It is something that we both enjoy doing and it is great to be able to do it together. In preparation for our hunt that day we had done a bit of research on our destination city. We had visited a few shops in the town where my brother lived and picked up a magazine of antique shops. He had hunted pipes in the neighbouring community so we knew there were a few shops.

But in our digging we found that there were 13 antique shops in that city and that many of them may well have pipes. So we drove the fifty miles to get there with expectation but we had no idea what we would run into when we arrived. The first shop we went to had several pipes that I picked through. I purchased a bent billiard Peterson K-Pipe with a fish tail stem that was in decent shape for $10 and the shop keeper gave me a GBD Lovat with a severely cracked bowl. He sent it along to see if I could do anything with it and only wanted photos of the process.

The second shop we went to had no pipes but did have a wealth of information for us on the antique shop scene in the city. She recommended two shops owned by a husband and wife team that was only a couple of blocks away. We walked to the shops and enjoyed a great visit with the wife and the staff of the two shops. They went through their stock in the back room and were able to find four pipes that I picked up – a Dr. Grabow bent bulldog for $8, an Ehrlich Canadian with a monogram on the shank $8, a Ben Wade Freehand $6 without a stem and a Peterson System pipe bowl without the stem for $3. I had happened to put a stem in my bag when I flew to Idaho for another pipe my brother had and it fit perfectly. So far I had spent a whopping $35 and had six pipes to show for it. I was pretty pumped and we had only covered four shops at this point.

We put our bounty in the back seat of the car and drove to the next shop. The owner had sold out everything in her pipe section but a couple of beat up corn cobs. I asked if she had any other pipes in the back. She thought for a moment and then opened a bag under the counter and took out a nice flat bottom rusticated Jobey Stromboli Bent sitter. I don’t remember the shape number as it is still packed away. That one was $10. She recommended another shop to us so we drove to the next shop. It was a small hole in the wall shop – an old single story house that had been converted into and antique shop.

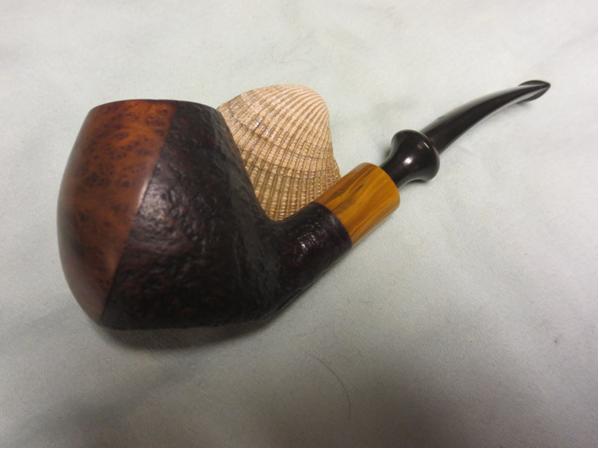

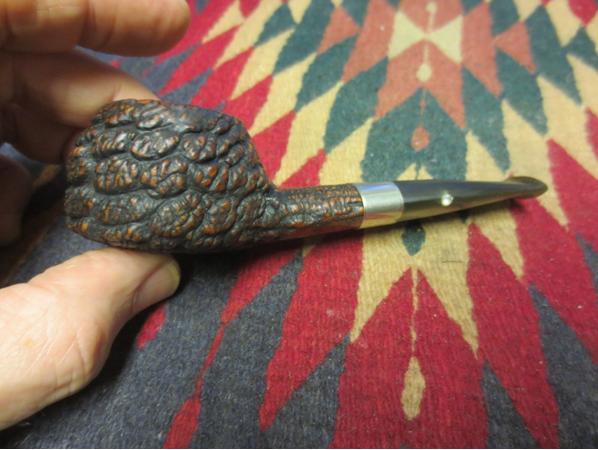

When we got there the owner was outside painting the building. She said that her 84-year-old mom was running the shop and she would show us the pipes that they had. We looked around for a while and she pointed out their stock. I picked up a Peterson Dublin Castle that was barely smoked for $42 and a Scandia Bent acorn with a twin bore stem for $6. I also picked up a nice leather pipe pouch for $10. My brother picked up a beautiful Servi Basket Weave carved block meerschaum for $49. It was barely smoked. By far this was the shop where we spent the most – a total of $107. We had 10 pipes and a new pipe pouch for a total of $152 at this point in the process.

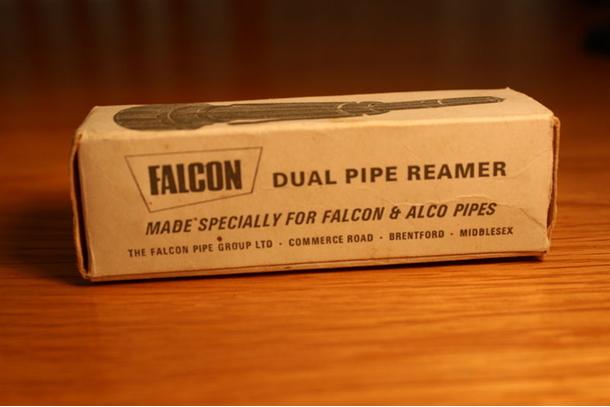

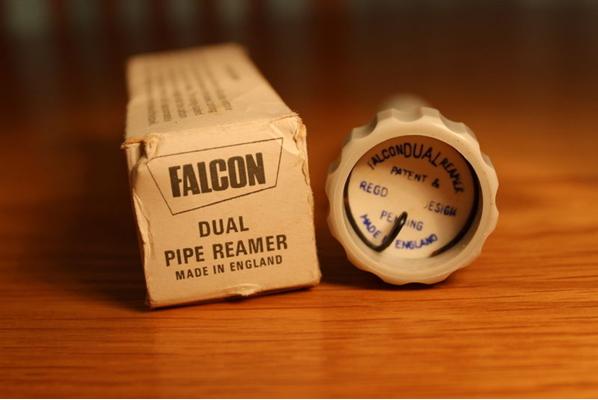

In the course of our conversation with the mother of the shop owner it turned out that her husband had owned a pipe shop and that these pipes were some of his stock. I asked if he had more and if he would be willing to have a couple of visitors. She called him and let me talk with him about what I was looking for. It turned out he was willing to meet us at his house if we were serious about buying estate pipes. He had many that he was motivated to sell. We left the shop and drove to his house. He met us at the door smoking some Lanes 1Q in a Stanwell. He took us into the kitchen to show us what he had for sale. He had a rack of 36 pipes and a small rack of about 6 and at least 6 unsmoked and four smoked Gourd Calabash pipes. There was also an assortment of other loose pipes on the counter to look at. On the floor was a large ice chest filled with bulk tobacco that he was also selling.

As I looked over the pipes I felt like we had hit the jackpot with this lot. I spent a lot of time talking with him as I went through the pipes he had displayed for sale. I mentally catalogued the ones on the rack. There were 7 Savinellis, 6 Petersons (2 shape 999 one of my favourites), 2 Bjarne pipes, 2 Nordings, 1 Dunhill Shell, 4 Italian Corsena pipes, a Castleford, two older horn stemmed pipes, a Tracy Mincer author, a Jobey Asti,a Dutch made ceramic double walled Dublin, a Stanwell 63 and a Lane billiard. I looked through the others and as I picked them up he would get a sentimental look on his face and remove those from sale. There were a lot of pipes for sale in that lot. He kept repeating that he was a motivated seller. While I was fiddling at choosing a bunch to take with me, Jeff asked him what he wanted for the lot. He stalled a bit but finely gave us a price for the rack and the pipes that were on it. We dickered a bit and he threw in a Gourd Calabash for my brother. We made a deal and added 35 more pipes to the days finds along with a solid oak three tiered 36 pipe rack. I also picked up a tin of GLP’s Blackpoint and a sealed package of Esoterics’ Peacehaven (a pleasant mix of 6 Virginia tobaccos).

We loaded our bounty in the car and bid the old pipeman farewell. He hinted at the fact that he had many more pipes that he would be selling in the near future so I am sure we will one day go back for another visit. We had a bit of lunch and made our way back to the hospital. All in all it was one of those amazing days. We came home with 35 pipes (several that were unsmoked), a pipe pouch and an oak pipe rack. My brother has been hunting pipes for a while now and we both knew that this was a rare find that we had stumbled upon – we got to cherry pick a pipeman’s estate and bring home some of his old pipes. It was a mixed lot but there were more than enough really nice pipes in it to make it a worthwhile purchase. Besides that we got to meet a nice older pipeman who was thrilled that his pipes were going to someone who obviously loved pipes as much as he did.

Oh, I almost forgot. When he had his shop I used to stop by there on the way to visit my mom and dad. I stopped and bought pipe tobacco and cleaning supplies from him over the years. When we walked in his front door he remembered me and I remembered him. That was the icing on the cake for me. He had closed his shop several years before and I had lost touch with him. It was a very good day pipe hunting.

When we got back to my brother’s house I set up the pipes and took the following photos of the haul. You can see the amazing pipes that we found. The first photo shows the rack and the finds in their entirety. The next photos I tried to get some closer pictures. The first one below shows rows 1 and 2 of the rack. The second one shows rows 2 and 3. The third photo shows the pipes on the table in front of the rack. I put the Peterson stem I had brought along in the Peterson bowl I found. See if you can identify the pipes in the rack and on the table. What do you think of the results of our hunt? I am still pretty pumped by the find and had to share it with folks who understand what it feels like to make this kind of find. Thanks for looking.

The next photos I tried to get some closer pictures. The first one below shows rows 1 and 2 of the rack. The second one shows rows 2 and 3. The third photo shows the pipes on the table in front of the rack. I put the Peterson stem I had brought along in the Peterson bowl I found. See if you can identify the pipes in the rack and on the table. What do you think of the results of our hunt? I am still pretty pumped by the find and had to share it with folks who understand what it feels like to make this kind of find. Thanks for looking.